Patents

Literature

33results about How to "Physical properties are not affected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

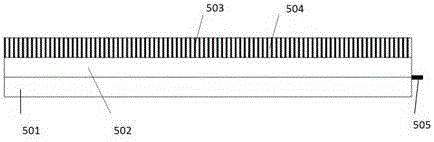

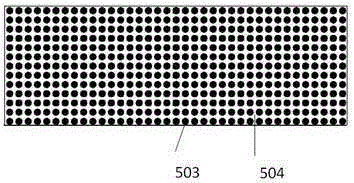

Optical thin film with high covering power and high luminance and display device comprising optical thin film

ActiveCN102759761APhysical properties are not affectedIncrease coverageSynthetic resin layered productsCoatingsHigh luminanceLight source

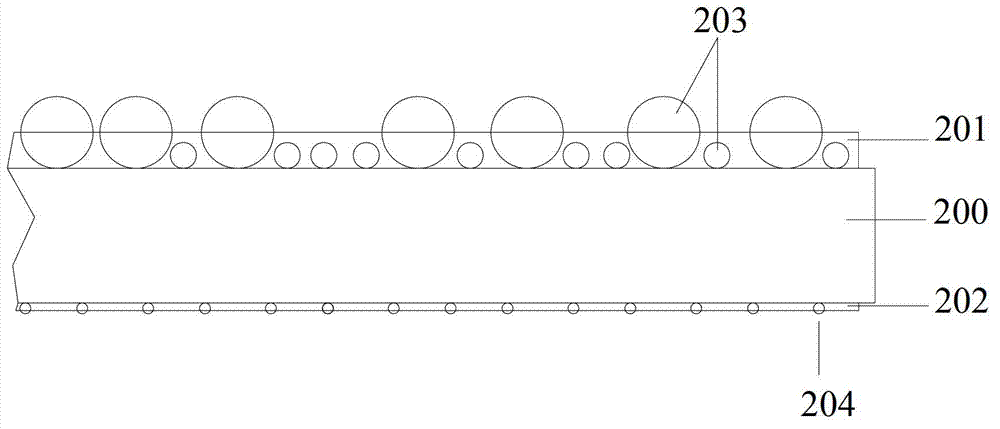

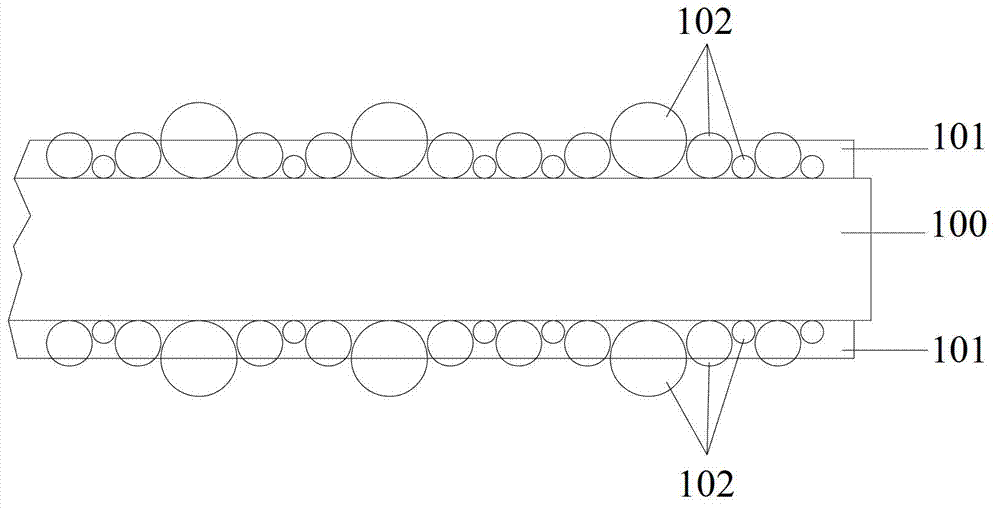

The invention discloses an optical thin film with high covering power and a high luminance and a display device comprising the optical thin film. The optical thin film comprises a transparent substrate, wherein two surfaces of the transparent substrate both are provided with diffusing coatings, the two diffusing coatings contain same ingredients, each diffusing coating comprises a diffusing glue layer embedded with diffusion particles, the diffusion particles comprise organic diffusion particles and inorganic diffusion particles, the organic diffusion particles consist of large organic diffusion particles and small organic diffusion particles, the range of particle sizes of the large organic diffusion particles is 10-50 microns, the range of particle sizes of the small organic diffusion particles is 1-10 microns, the range of particle sizes of the inorganic diffusion particles is 0.1-10 microns, and the thickness of the solidified diffusing coating is 1 / 5-4 / 5 of the particle size of the large organic diffusion particles. The optical thin film disclosed by the invention can be used for optimizing the utilization rate of a light source and strengthening the light condensation capability so as to not only have higher luminance and a balance atomizing effect, but also have excellent covering property.

Owner:NINGBO EXCITON TECH

Honed embossed adhesive tape basilemma and production method thereof

A honed embossed adhesive tape basilemma is made of pure polyolefin resin, the roughness of the front face Ra value is 20-60 mu inch, the roughness of the back face Ra value is 60-200 mu inch, the production method thereof comprises steps of melting and extruding, embossing and finishing. The honed embossed adhesive tape basilemma prepared by the invention has special honed effect, even surface roughness, even thickness stability, good longitudinal and transverse tear resistance, good anti-blocking effect and excellent gluing effect. The method of the invention does not change the inner structure of the basilemma material, thus not influencing the physical performance of the basilemma material, and being applicable to production of honed embossed adhesive tape basilemma and production of honed basilemma for other special uses.

Owner:湖北慧狮塑业股份有限公司

Cold bending electrical protective casing and manufacturing method thereof

ActiveCN102702644AImprove gelationImprove rigidityElectrical apparatusThermal statePolyvinyl chloride

The invention relates to a PVC (Polyvinyl Chloride) tube, in particular to a manufacturing method of a cold bending electrical protective casing. The cold bending electrical protective casing is prepared from the following components by weight: 75 kg of PVC resin, 3.8 kg of composite stabilizer, 0.5 kg of stearic acid, 0.5 kg of chlorinated polyethylene, 3 kg of titanium dioxide, 0.6 kg of paraffin, 30 kg of light calcium carbonate and 1 kg of 401 auxiliary agent. The formula of the cold bending electrical protective casing is not influenced by seasonal temperature. The 401 processing modification auxiliary agent is added after adjustment, so that plasticizing, toughening and weathering resistance of the PVC product are promoted by a low-temperature modification toughing agent. By adding 401 into the PVC product, the PVC gelling and plasticizing effects can be promoted. Through plasticizing process operation, the PVC multiple particle structure is damaged, the release of primary particles of the PVC is promoted, a PVC extrusion processing process is formed, the plasticizing is quick, the viscosity is increased, and the thermal state strength is improved.

Owner:安徽玉发塑业有限公司

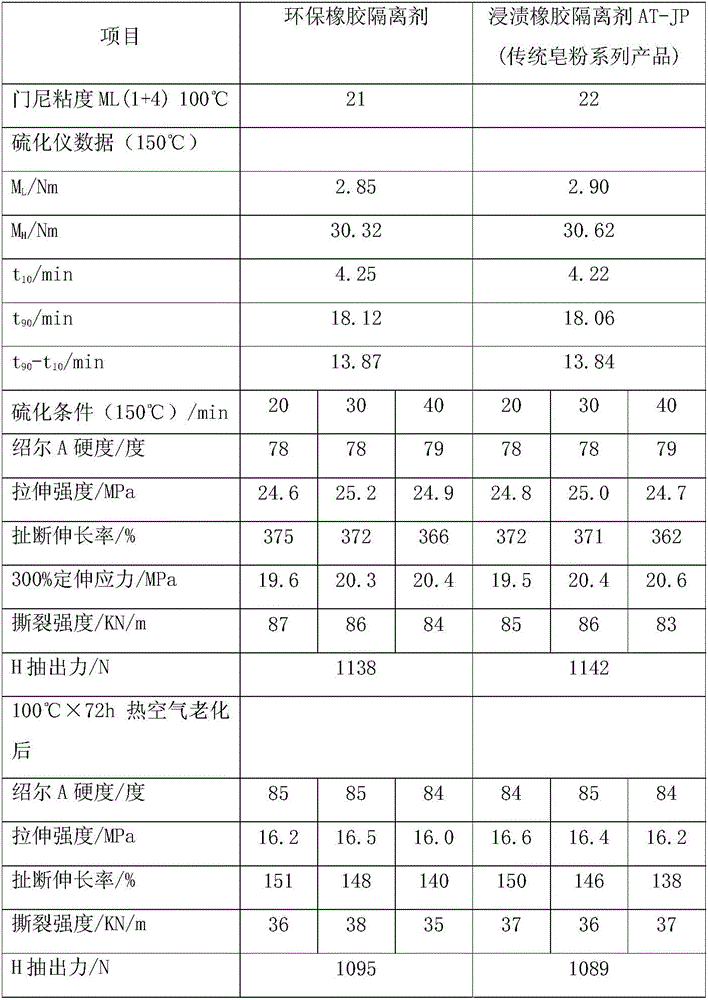

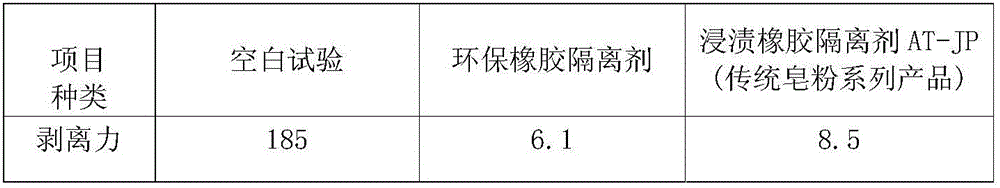

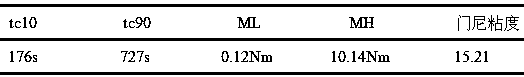

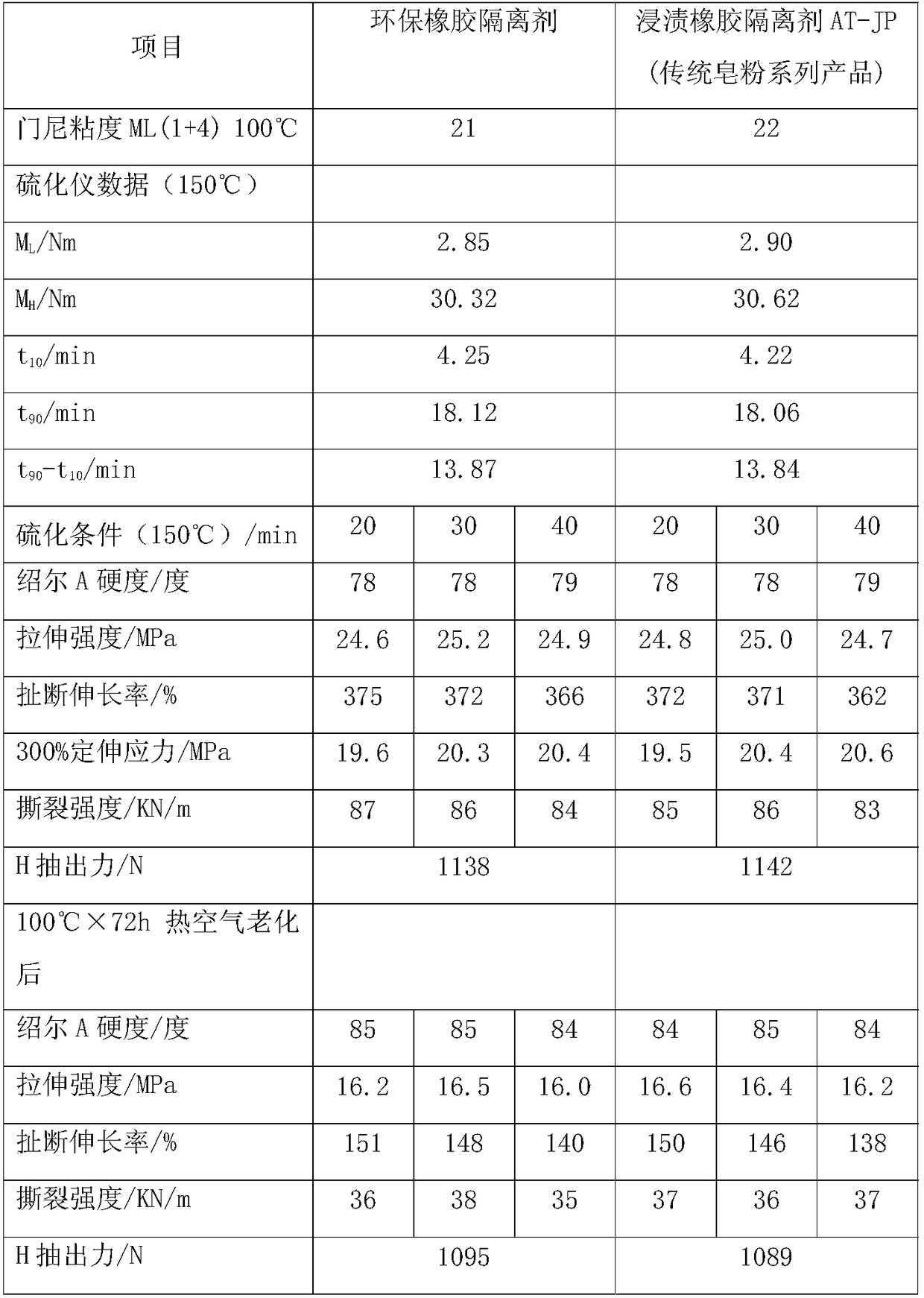

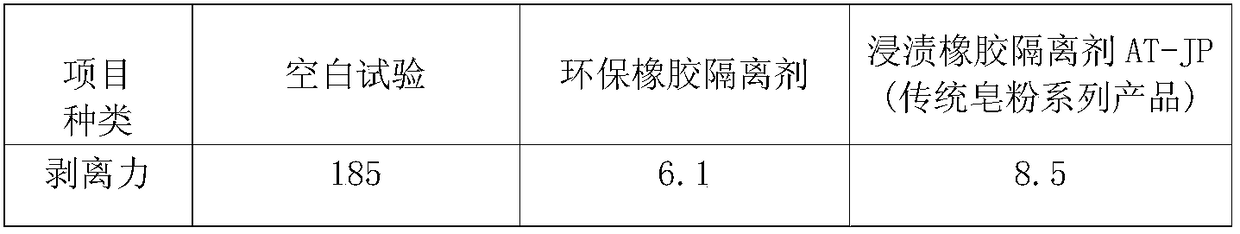

Environment-friendly rubber isolation agent

The invention discloses an environment-friendly rubber isolation agent. The isolation agent comprises the following components in parts by weight: 24-36 parts of polyoxyethylene sorbitan monooleate, 2-4 parts of waterborne polyamide wax, 30-38 parts of calcium stearate, 18-30 parts of hydrated silicon dioxide, 8-14 parts of potassium stearate, 2-5 parts of silicone oil defoaming agents and 2-6 parts of sodium carboxymethylcellulose. The isolation agent is excellent in compatibility, long in actual effect and low in addition amount, and is green and environmentally friendly; the preparation process of the environment-friendly rubber isolation agent is simple and feasible; the cost is low.

Owner:JIANGSU KAOU CHEM

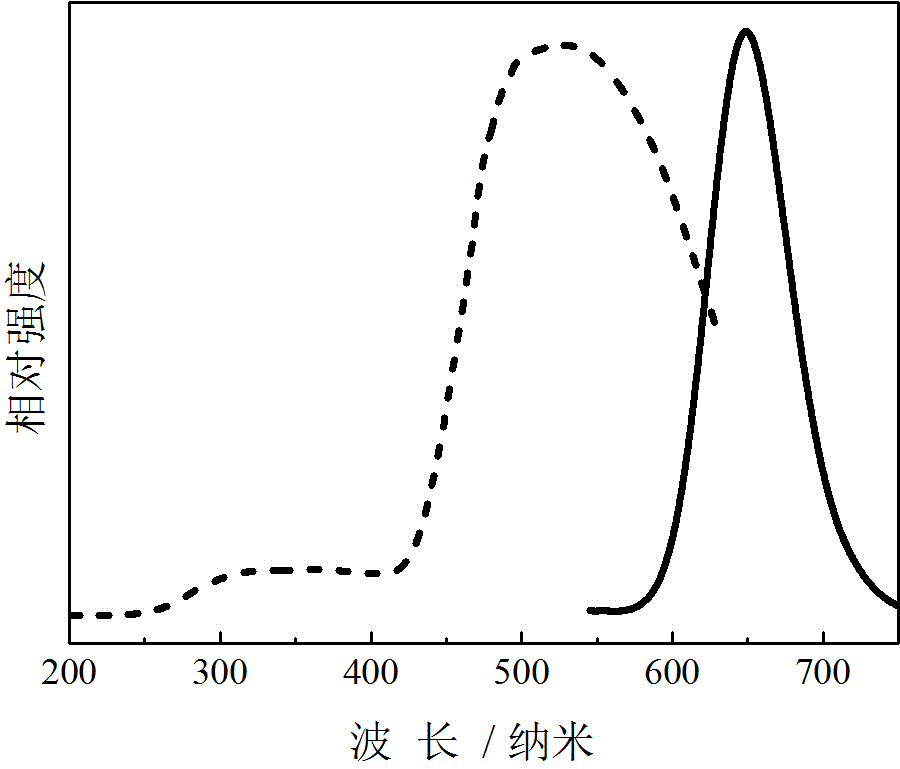

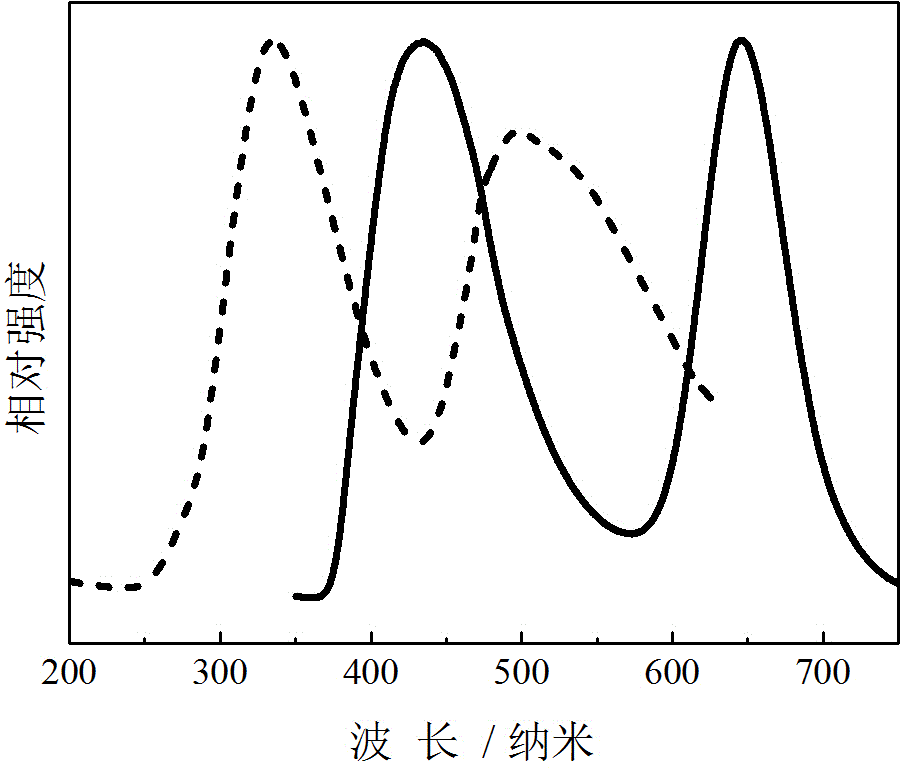

Solar spectrum conversion resin and preparation and application methods thereof

InactiveCN104617170AWith light energy conversion performanceEasy to preparePhotovoltaic energy generationLuminescent compositionsStearic acidSolar cell

The invention provides a solar spectrum conversion resin and preparation and application methods of the solar spectrum inversion resin. The solar spectrum inversion resin is characterized in that a light conversion agent subjected to surface modification is mixed with solid PVB resin and molten; the melt is casted and extruded through an extruder to prepare a light conversion PVB resin film; or the light conversion agent is directly dispersed into liquid light curing glass resin to obtain light curing conversion glass resin, wherein the light conversion agent is one or two of a green-to-red light conversion agent, a red and blue double light conversion agent, a purple-to-blue light conversion agent and a purple-to-red light conversion agent; the particle size ranges from 0.01 to 5.0 microns; 0.05 to 5.0% by mass of light conversion agent is added to the resin; a surface modifier is prepared from one or two of methylsilicone oil, KH-570 and stearic acid, and 4 to 40% by mass of the surface modifier is added; the two light conversion resins can be used for preparing light conversion laminated glass which has all-day light conversion function and can absorb near ultraviolet or / and green light and emit blue light and / or red light; the light conversion laminated glass can be applied to a glass greenhouse to increase the photosynthesis of the crops as well as promoting the growth of plants; a purple / green-to-red light conversion PVC resin film can be applied to solar cell packaging, and therefore, the photovoltaic efficiency of a solar cell can be increased.

Owner:HUNAN NORMAL UNIVERSITY +1

Paste water-based isolation agent, preparation method and application method thereof

The invention discloses a paste water-based isolation agent, a preparation method and an application method thereof thereof. The paste water-based isolation agent comprises the following components by mass: 3-5 parts of an inorganic powder additive, 0.1-1.0 part of an anionic surfactant, 0.5-5.5 parts of a nonionic surfactant, 5-10 parts of a thixotropic agent, 0.2-2.0 parts of a thickener, 0.1-0.5 part of a defoaming agent, and 60-100 parts of deionized water. The preparation method consists of: mixing water with the surfactants, conducting stirring dissolving, adding the inorganic powder additive, and adding the defoaming agent dropwise, adding the thixotropic agent and thickener in batches, stirring the materials fully, and performing grinding to a homogeneous phase, thus obtaining the isolation agent. And the application method includes: during use, preparing the isolation agent into a water solution according to a mass ratio of 1:3-15, adding the water solution into a water cooling groove of a rubber slice to realize isolation agent coating at the same time of water cooling, and then carrying out rod hanging drying and stacking. The paste water-based isolation agent provided by the invention has the advantages of easy water dissolution, no toxicity, no smell, simple process and low cost, and almost has no effect on the subsequent processing performance of rubber.

Owner:江苏益路昇新材料有限公司

High-hardness high-transparency high-flowability PC (polycarbonate) alloy and preparation method thereof

The invention belongs to the technical field of high molecular alloy materials, and particularly relates to a high-hardness high-transparency high-flowability PC (polycarbonate) alloy and a preparation method thereof. The PC alloy comprises the following components in parts by weight: 80-95 parts of PC resin, 10-20 parts of PS (poly styrene), 6-10 parts of transparent toughener, 1-5 parts of SMA (styrene maleic anhydride) random copolymer, 0.06-0.1 part of transparent PC halogen-free flame retardant, 0.2-2 parts of main antioxidant, 0.2-2 parts of auxiliary antioxidant and 0.2-1 part of silane coupling agent. Alternatively, the PC alloy comprises the following components in parts by weight: 80-95 parts of PC resin, 6-10 parts of transparent toughener, 10-20 parts of SMA random copolymer, 0.06-0.1 part of transparent PC halogen-free flame retardant, 0.2-2 parts of main antioxidant, 0.2-2 parts of auxiliary antioxidant and 0.2-1 part of silane coupling agent. According to the invention, the PC alloy material is prepared through a melt blending method, the preparation method is convenient, the technological operation is easy to realize, the cost is low, and the period is short; and the surface hardness and flowability of the alloy are simultaneously improved under the condition of keeping high transparency, so that the alloy has excellent physical and chemical properties on the whole. Thus, the invention is suitable for popularization.

Owner:DALIANG PLASTIC2 SHUNDE FOSHAN

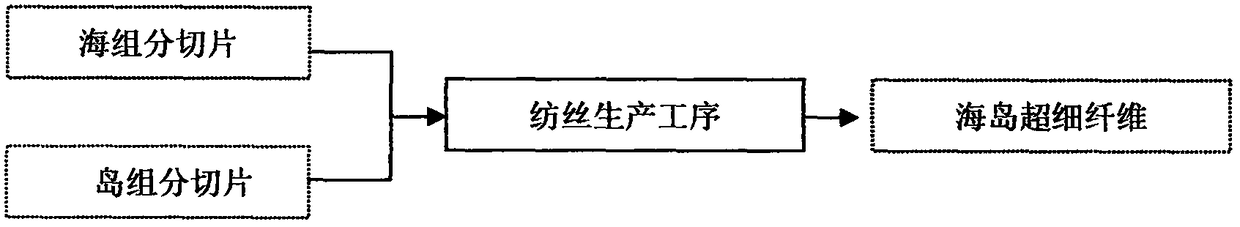

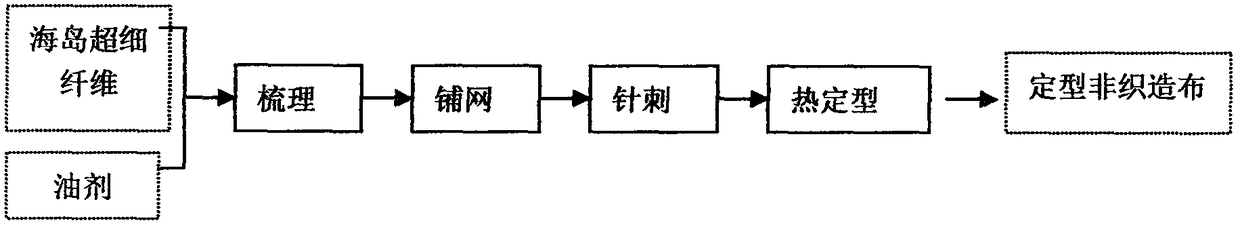

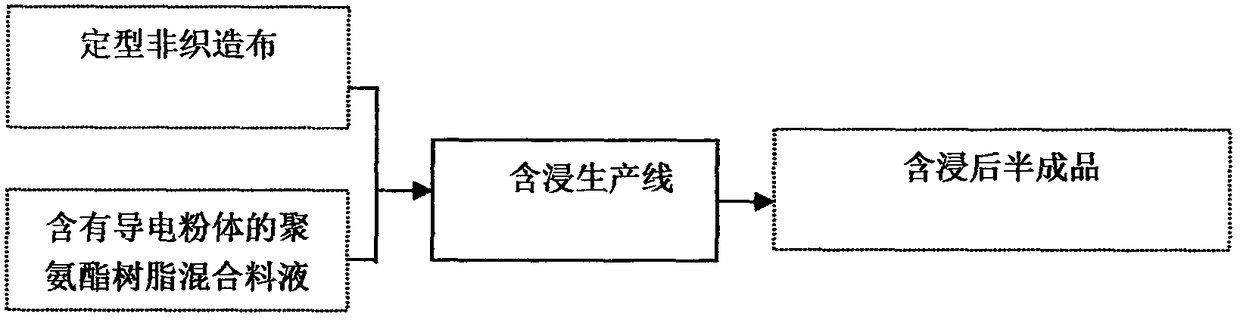

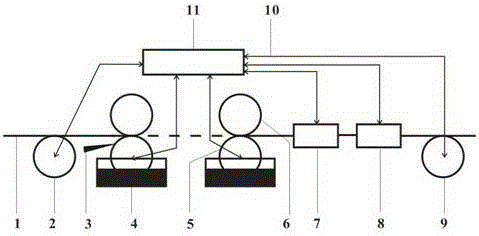

Production method of superfine fiber synthetic leather with antistatic and electrically conductive properties

PendingCN108708174AEasy to operateGood flexibilityNon-woven fabricsElectrically conductiveConductive polymer

The invention relates to the technical field of superfine fiber synthetic leather, and especially relates to a production method for a superfine fiber synthetic leather with antistatic and electrically conductive properties. By directly adding electrically conductive powder to superfine fiber wet impregnated slurry, the prepared superfine fiber product has the permanent electrically conductive property, the operation method is simple, adding the electrically conductive powder has no effects on the physical properties of the superfine fiber suede, and the inherent physical properties such as flexibility and tearing of the original superfine fiber synthetic leather can be maintained.

Owner:ANAN CHINA

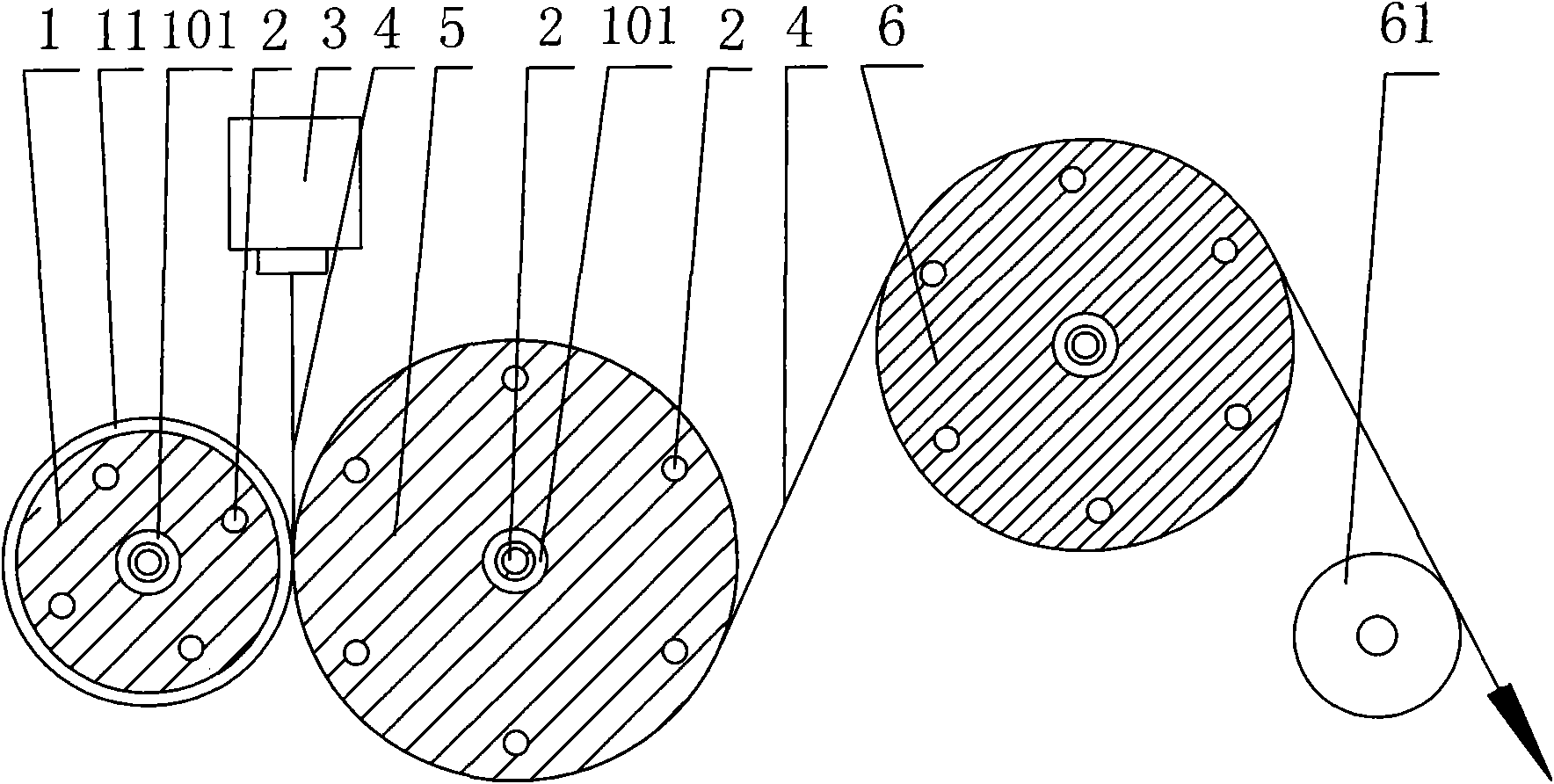

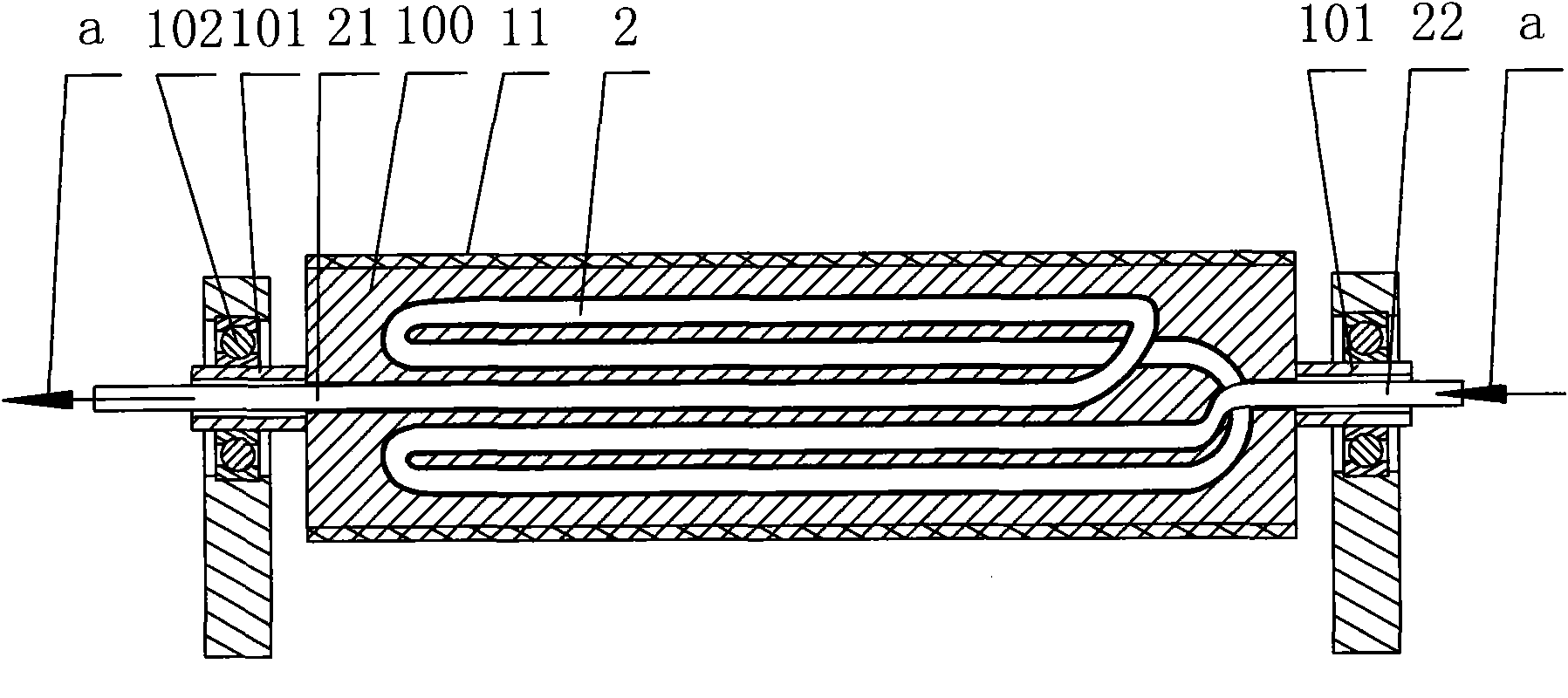

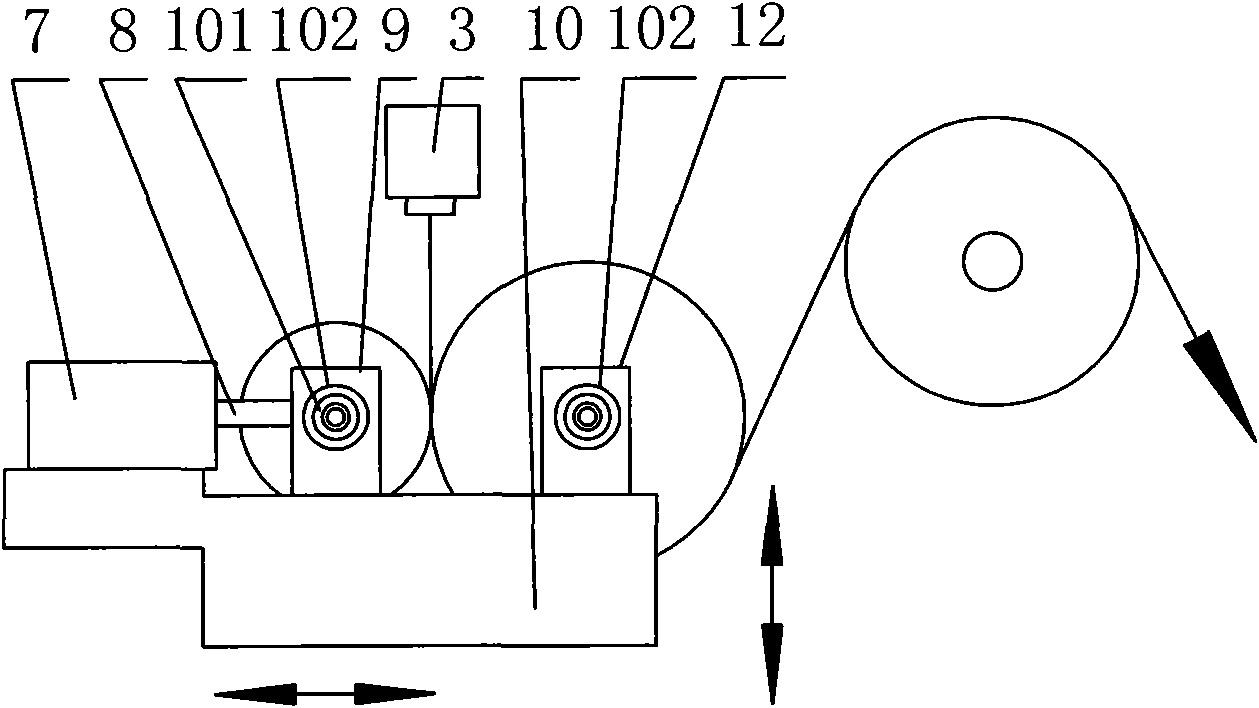

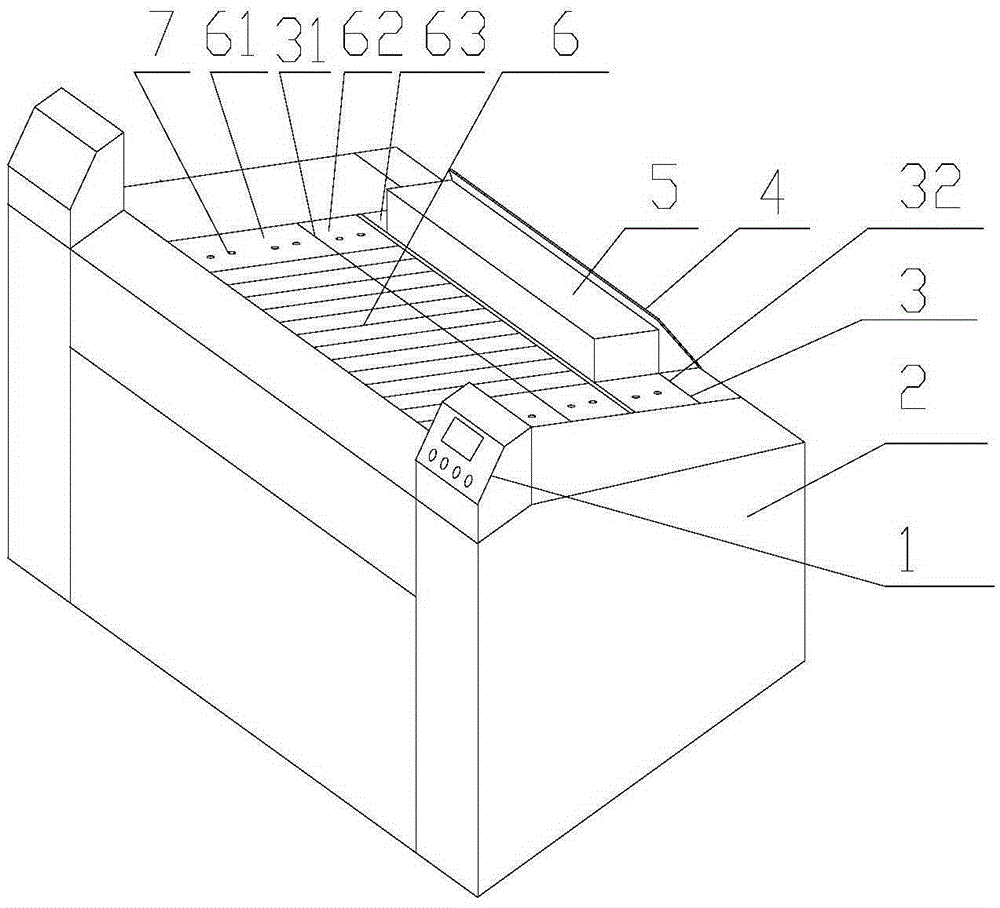

Intelligent electronic intaglio-printing-roll printing system and plate making method

ActiveCN105252883AEliminate plate making processSave plate making materialsRotary intaglio printing pressForme preparationCeramicElectricity

The invention discloses an intelligent electronic intaglio-printing-roll printing system and a plate making method. The system comprises a printing stock, a conveying and winding device, an ink scraping device, an ink tank, an intaglio printing roll, an impression cylinder, a locating and aligning device, a curing device, a winding device, a connection line and an upper computer. According to the intelligent electronic intaglio-printing-roll printing system, according to the graphic information of an original manuscript, piezoelectric ceramics in all ink cells are controlled in real time through the upper computer to be deformed, so that corresponding patterns are formed on the intaglio printing roll, and the plate making step is omitted; the ink cells of the intaglio printing roll can be changed in real time, electronic printing products with different circuit patterns or different breadths are printed, and multi-printing is achieved through one roll; and multiple plate making processes are omitted, plate making materials are saved, and environment-friendly printing is achieved.

Owner:HUBEI ZHONGXIN JINGHUA COLOR PRINTING

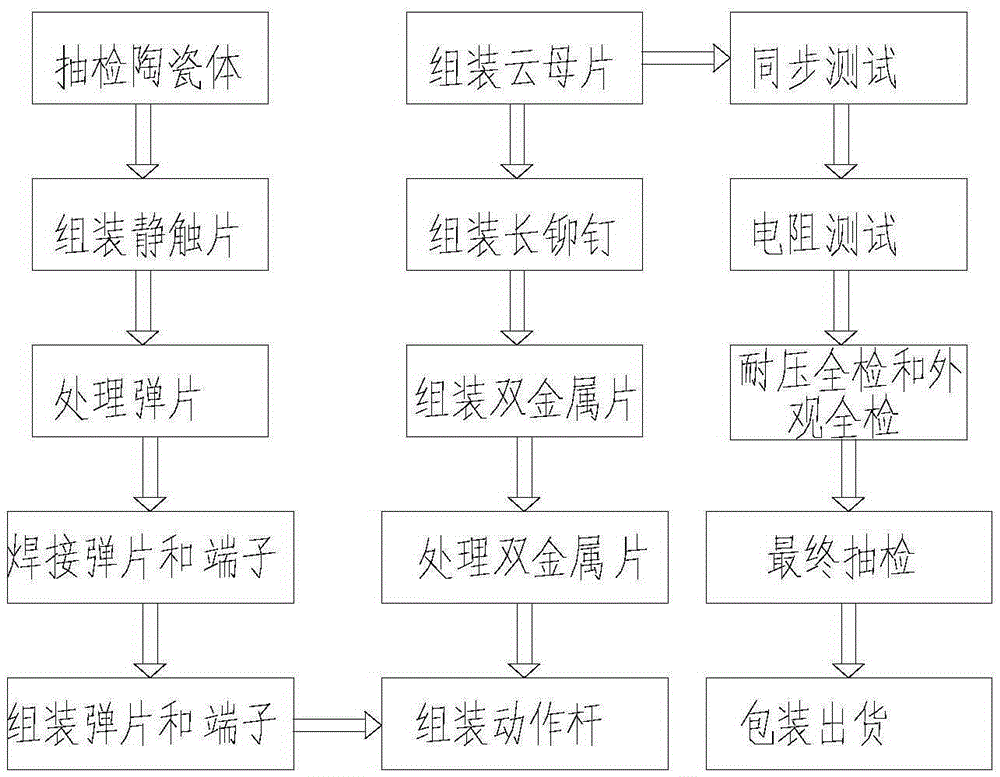

Production technology of high temperature resistant temperature controller

ActiveCN105355484AImprove securityIncrease heat treatment processElectric switchesActuatorHot Temperature

The invention discloses a production technology of a high temperature resistant temperature controller. The production technology comprises the following steps: (a) casual inspection of a ceramic shell; (b) assembling of a static contact; (c) cooled placement; (d) welding of a spring plate and a terminal; (e) assembling of the spring plate and the terminal; (f) assembling of an actuator rod; (g) treatment of bimetallic strips; (h) assembling of the bimetallic strips; (i) assembling of long rivets; (j) assembling of amica sheet; (k) synchronous testing; (i) resistance testing; (m) pressure resistance full-inspection and appearance full-inspection; (n) final casual inspection; and (o) packaging and shipment. A heat treatment technology for the spring plate and the bimetallic strips is added to the production process of the temperature controller, so that the physical properties of the spring plate and the bimetallic strips are not affected in a high-temperature environment within 600 DEG C; and the safety performance of the temperature controller is greatly improved.

Owner:海盐久拓温控有限公司

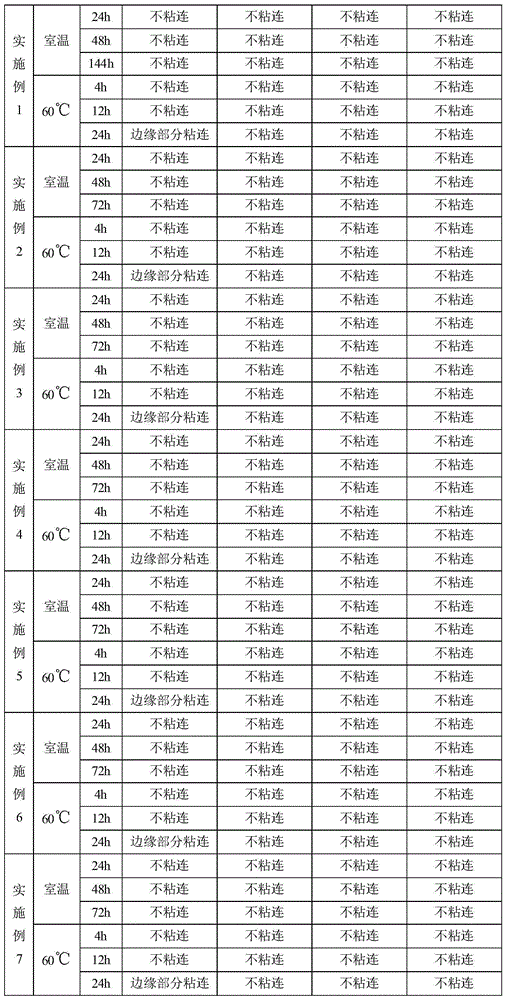

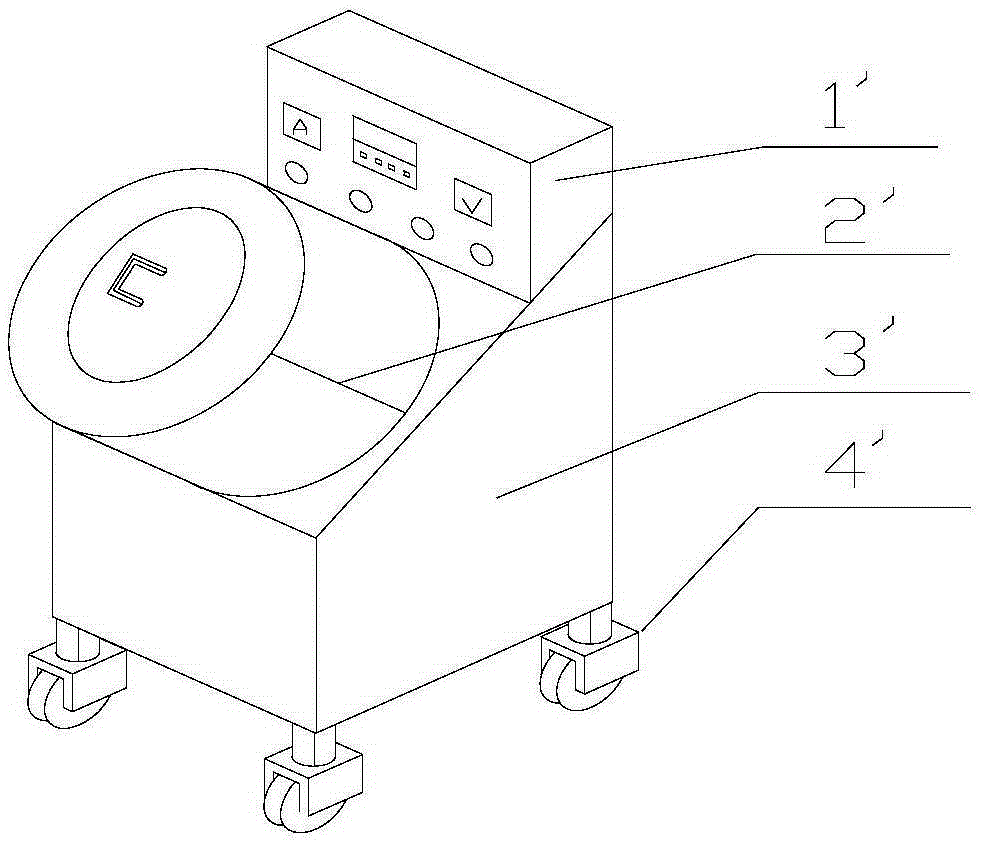

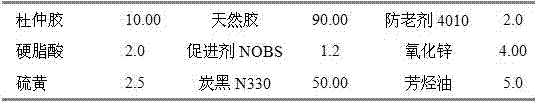

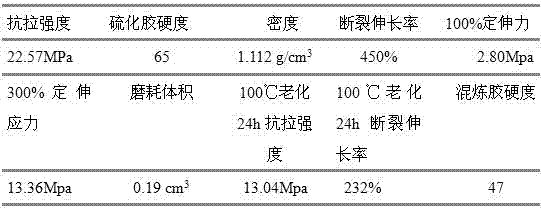

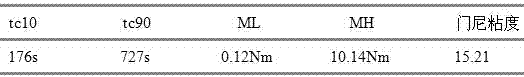

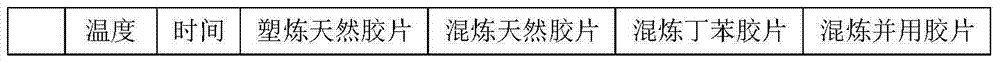

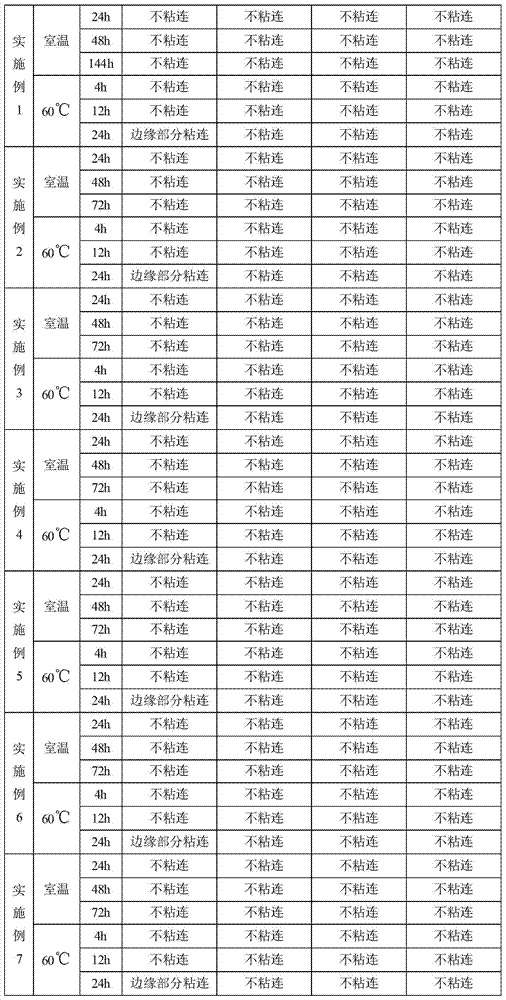

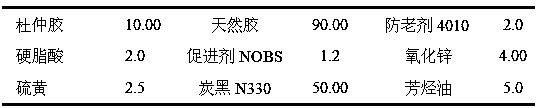

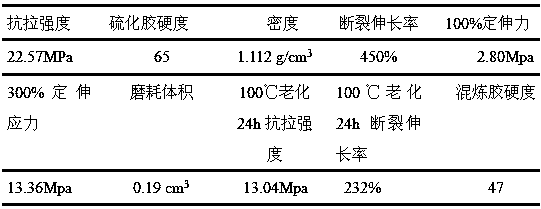

Preparation method of gutta-percha combined rubber compound for normal-temperature forming and processing

ActiveCN107415074AExcellent formabilityPhysical properties are not affectedGutta-perchaPolymer science

The invention discloses a preparation method of a gutta-percha combined rubber compound for normal-temperature forming and processing and relates to a rubber forming and processing method. Rubber is put in an internal mixer, a screw extruder or an open mill for plastifying, then stored natural rubber is mixed with 20-60 parts of carbon black, 30-80 parts of white carbon black and 2-10 parts of plasticizer in the equipment mentioned above, and rubber master batch is obtained and stored for 2-24 hours; gutta-percha is put in the internal mixer, the screw extruder or the open mill for plastifying, other accessory ingredients are added, gutta-percha rubber compound is obtained; and the gutta-percha rubber compound which is not stored and the rubber master batch are simultaneously added into the internal mixer or the open mill for uniform mixing (operation is performed at the low temperature between 25 DEG C and 35 DEG C), and then discharging is performed. By means of the preparation method of the gutta-percha combined rubber compound for normal-temperature forming and processing, the hardness of the gutta-percha and rubber compound combined with the gutta-percha is effectively lowered, the plasticity of the gutta-percha combined rubber compound is improved, the effect that the plasticity of a normal rubber compound is achieved is ensured, a series of operations such as rolling, extrusion and forming can be facilitated under the normal conditions, and the practical application value is good.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

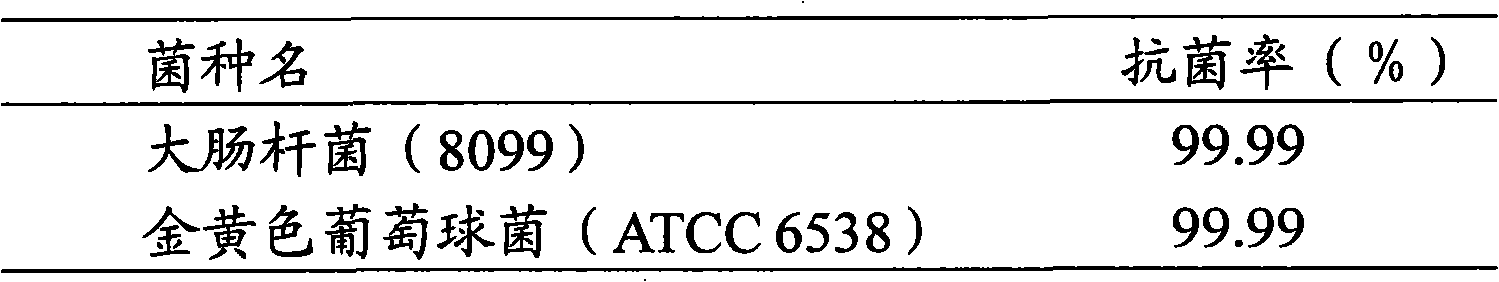

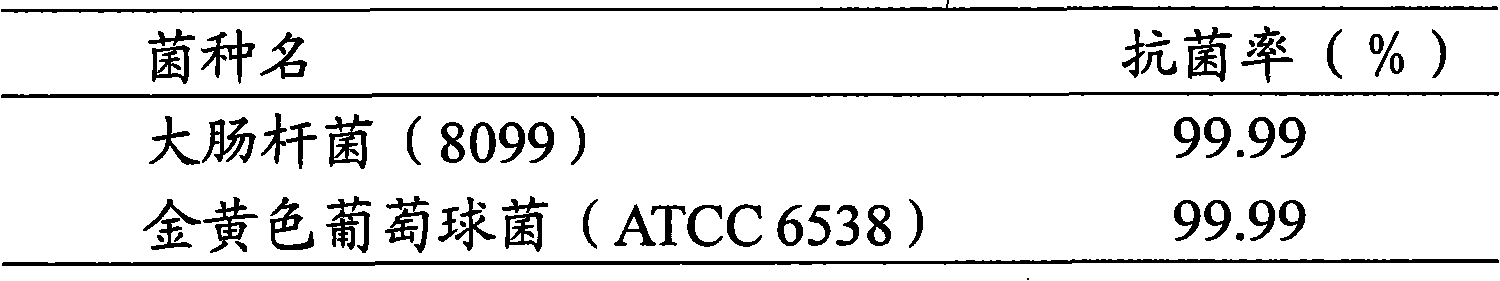

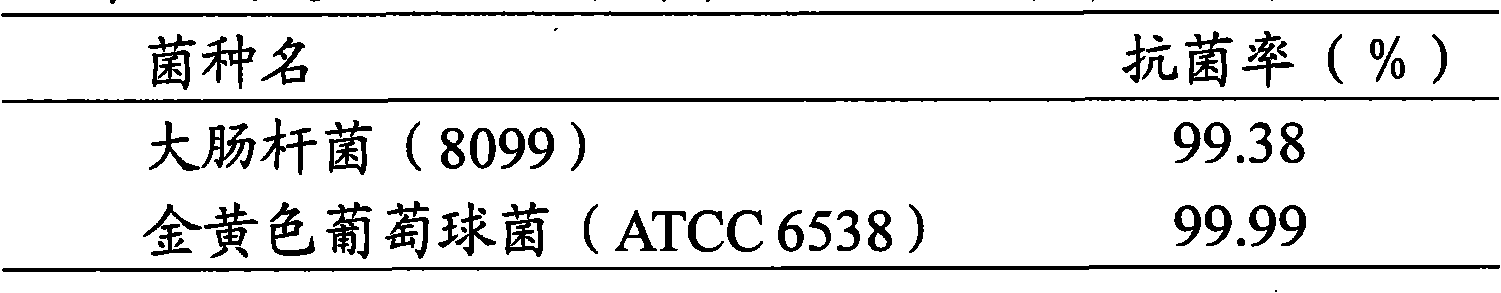

Biologic antibiosis protective material and preparation method thereof

The invention discloses a biologic antibiosis protective material which is highly safe and applies to protective products such as biologic protective mask, biologic protective clothes and the like, and a preparation method thereof. The biologic antibiosis protective material is characterized by comprising at least one biologic antimicrobial agent and polyethylene terephthalate which are boned together by a covalence; wherein the biologic antimicrobial agent is Epsilon-polylysine, polymyxin sulfate, nisin or natamycin. According to the invention, the PET first undergoes surface modification, proper group-carboxyl can be introduced out, and then the carboxyl is activated and then caused to react with an N rear end of the antimicrobial agent, therefore, a covalence bonding method can be adopted for fixing the antimicrobial agent on the PET surface, and the antimicrobial agent can be bonded on the protective material for a long time after the fixation. The biologic antibiosis protective material does not affect the physical properties of the protective material PET, has high sterilizing rate and mostly achieves over 99 percent of sterilizing rate.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

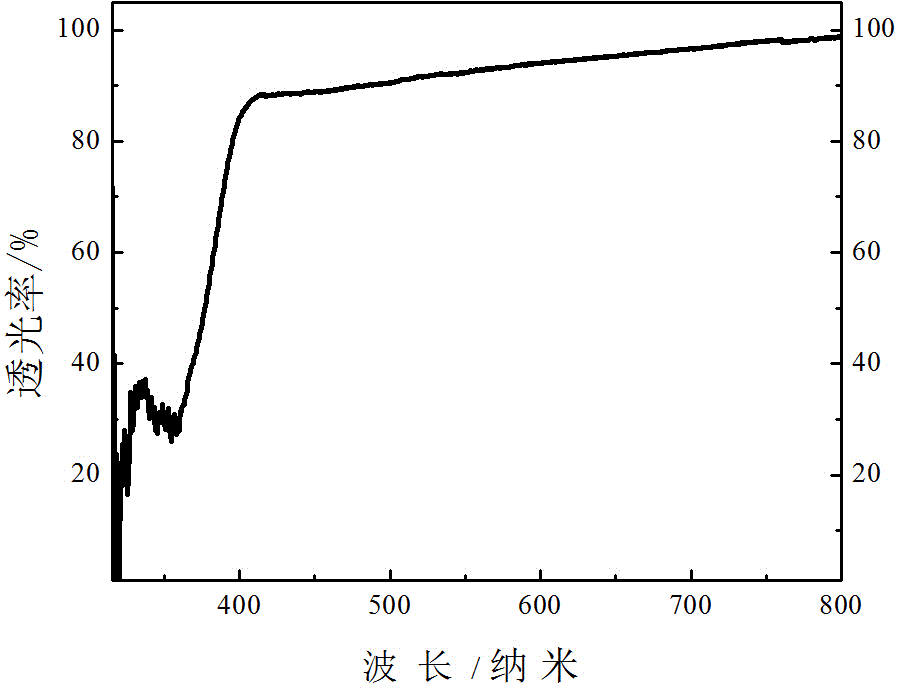

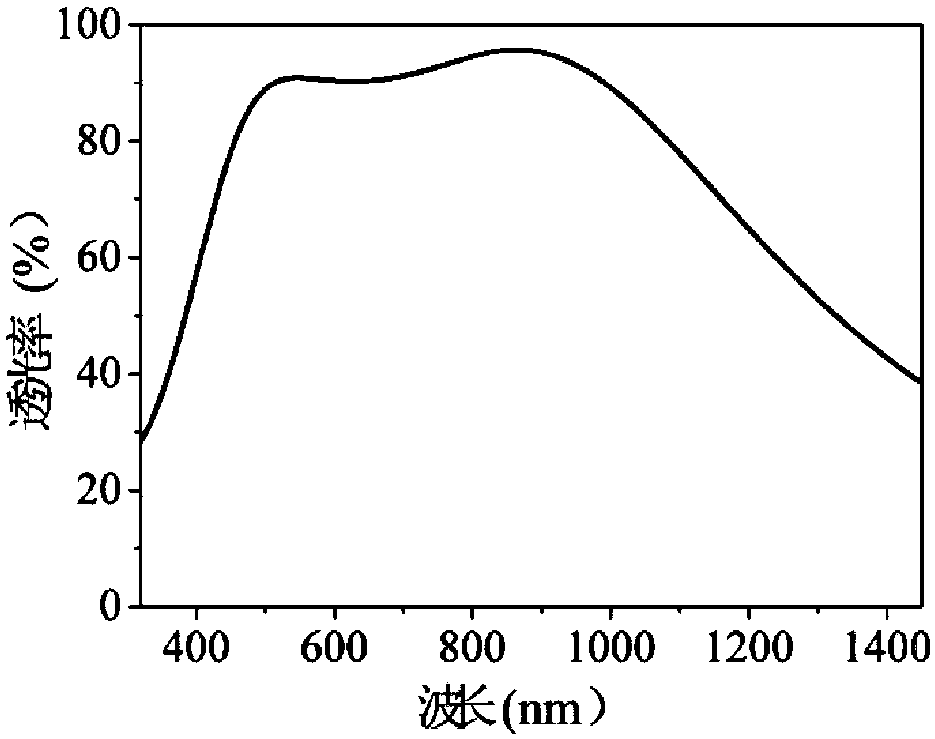

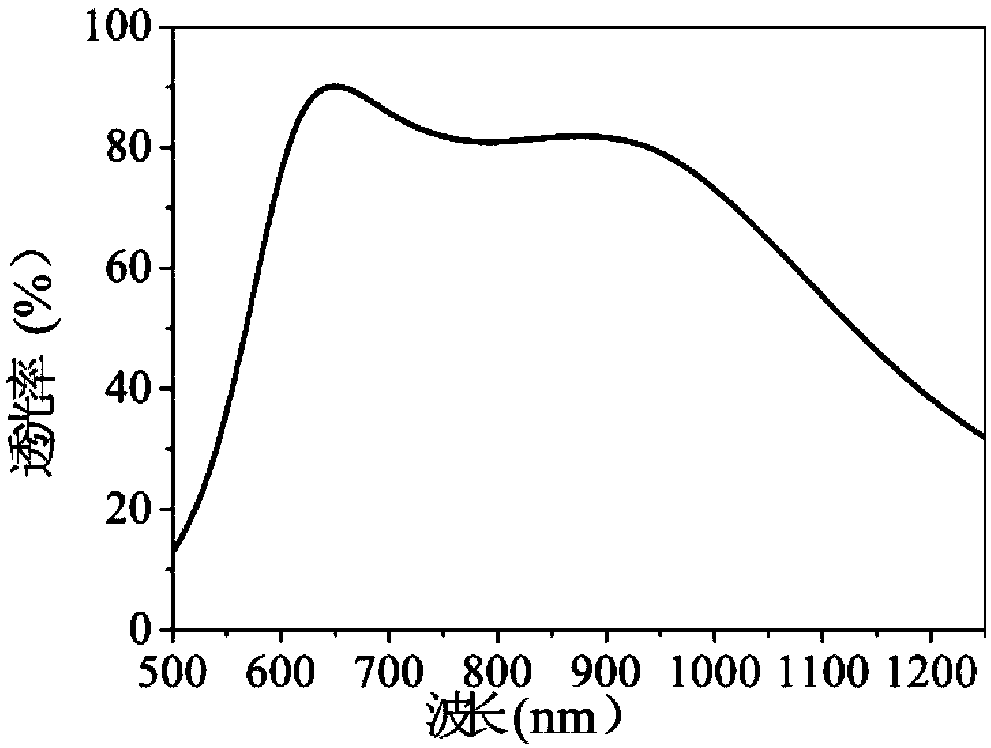

Transparent electrode and manufacturing method thereof

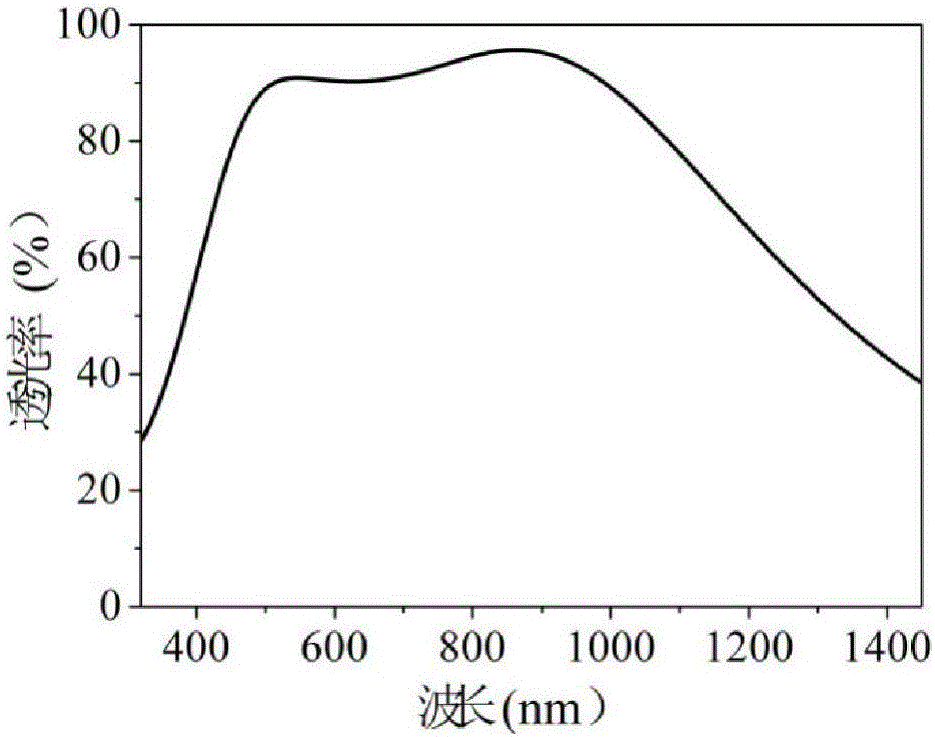

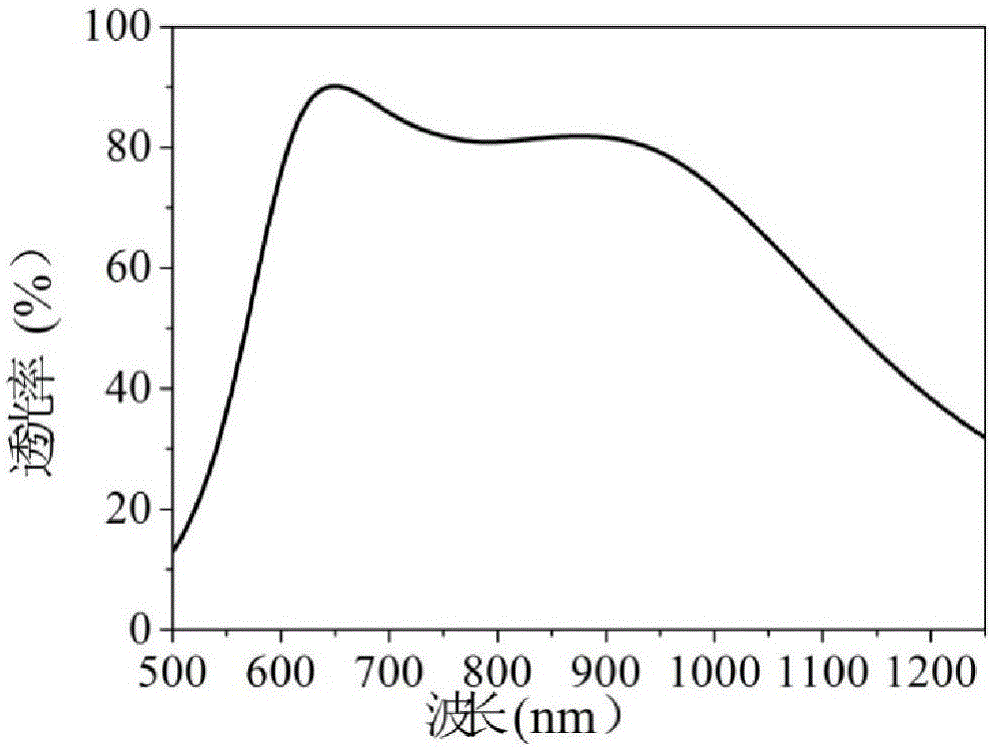

InactiveCN106847942AGood electrical conductivityStrong bending and flexibilityFinal product manufactureSemiconductor devicesFrequency bandBroadband

The invention provides a transparent electrode and a manufacturing method thereof. The transparent electrode comprises a transparent substrate, a first high-dielectric film layer, a metal film layer and a second high-dielectric film layer, wherein the first high-dielectric film layer , the metal film layer and the second high-dielectric film layer are sequentially arranged on the transparent substrate. The metal film layer is a continuous metal film layer. The dielectric constant of each high-dielectric film is greater than or equal to 6.25. Design and preparation of high-conductivity and high-transparency transparent electrode materials are achieved by utilizing magnetic resonance characteristics of a high-dielectric material. The transparent electrode utilizes the magnetic resonance characteristics of the high-dielectric material and the coupling input and output effect of the high-dielectric material and incident light. A composite structure of the high-dielectric film layers and the continuous metal film layer can provide broadband and transparent light, a spectral range covers light ranging from visible light to infrared light, and a photoelectric application range of the transparent electrode in different frequency bands is greatly widened. In addition, the transparent electrode has stronger bending property and flexibility and is easily integrated with external structure units such as other active layers or photoelectric control modules or flexible substrates.

Owner:JIANGXI NORMAL UNIVERSITY

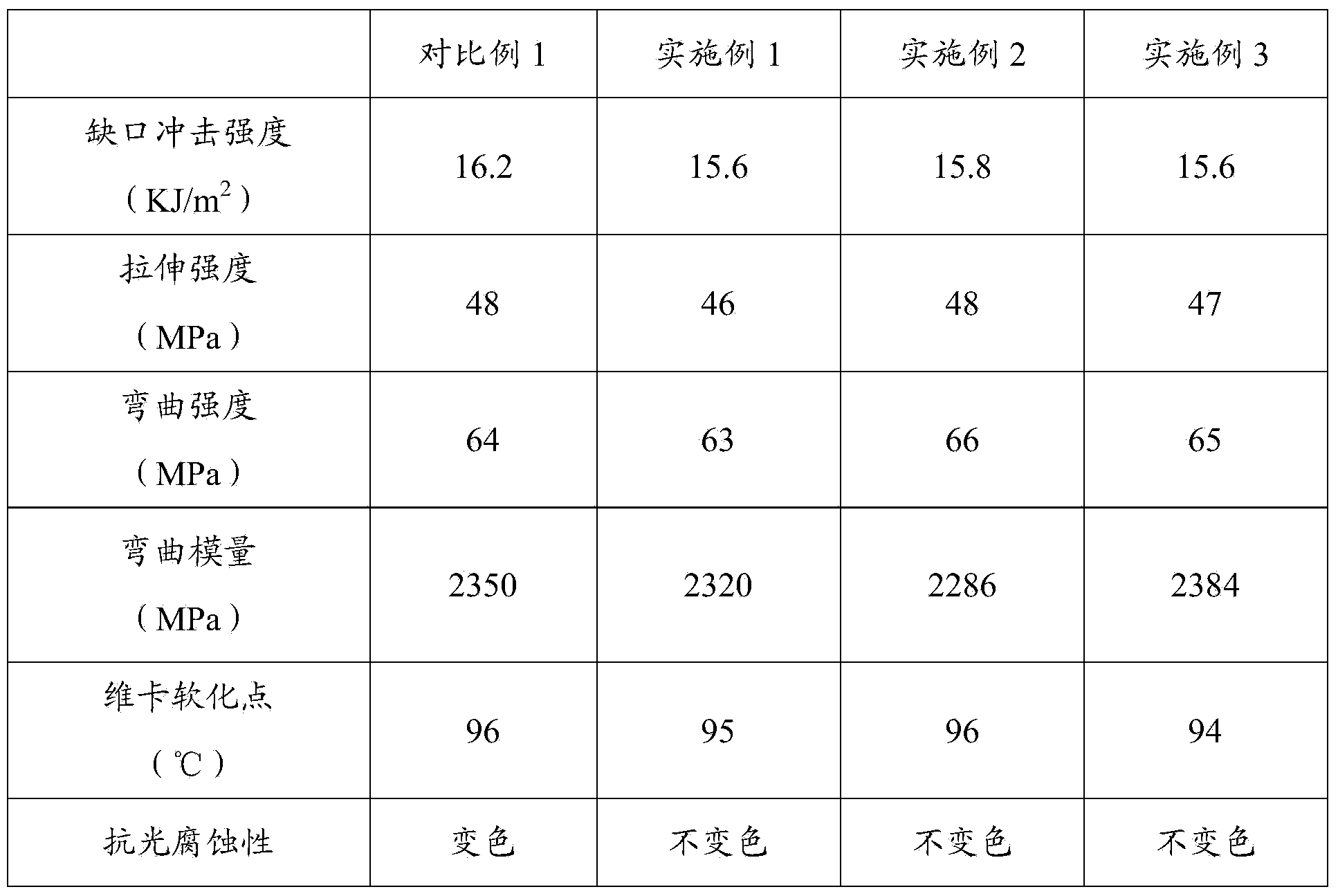

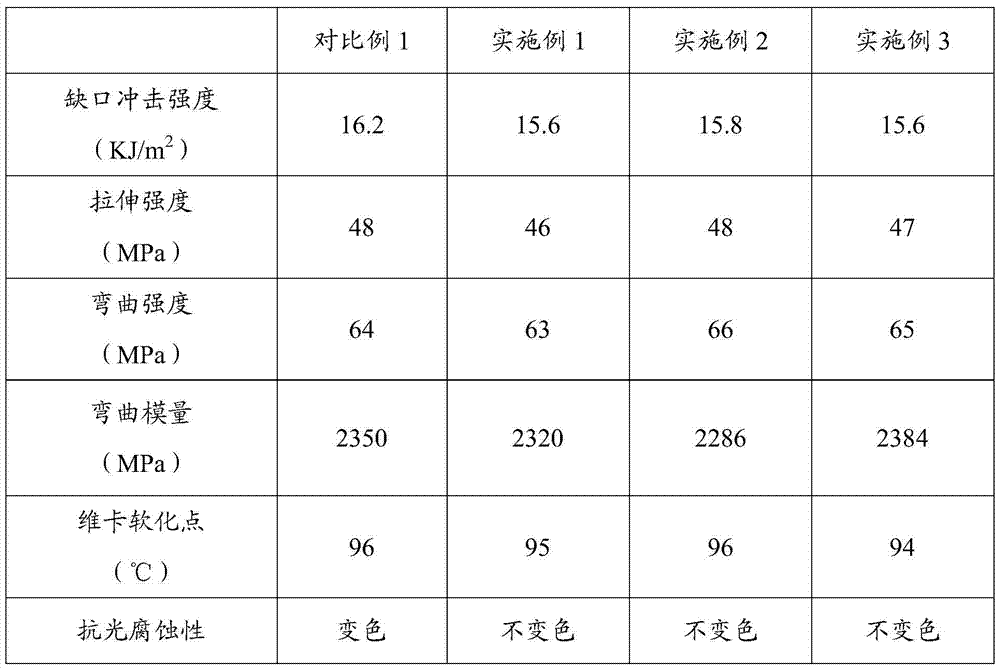

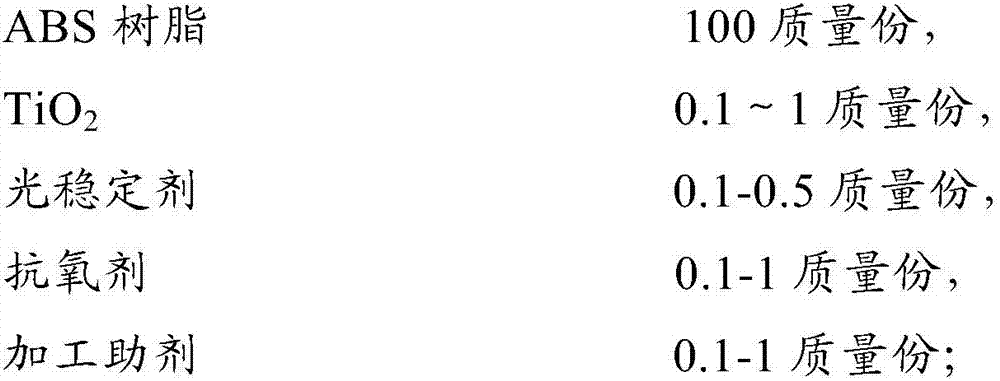

Light corrosion resistant ABS (acrylonitrile-butadiene-styrene) composition, light-passing plate and air conditioner

The invention provides a light corrosion resistant ABS (acrylonitrile-butadiene-styrene) composition, a light-passing plate and an air conditioner. The light corrosion resistant ABS (acrylonitrile-butadiene-styrene) composition comprises the following components by mass: 100 parts of ABS resin, 0.1-1 part of TiO2, 0.1-0.5 part of a light stabilizer, 0.1-1 part of an antioxidant and 0.1-1 part of a processing aid. On the premise of guarantee of material mechanical strength, the light corrosion resistant ABS composition provided by the invention has good light transparency and glossiness, and has the light corrosion resistant effect, therefore, after long-term exposure to a LED light source, a panel of the air conditioner made of the light corrosion resistant ABS composition is free of color difference in display, and the panel has a good display effect, and user satisfaction can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

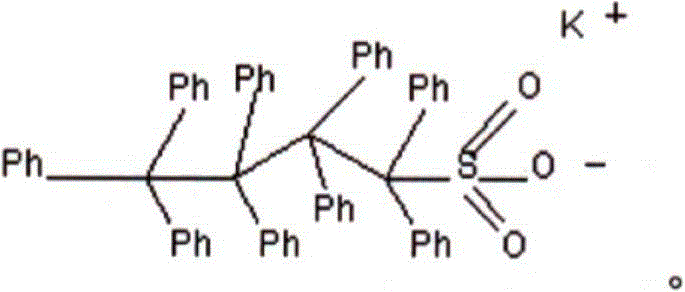

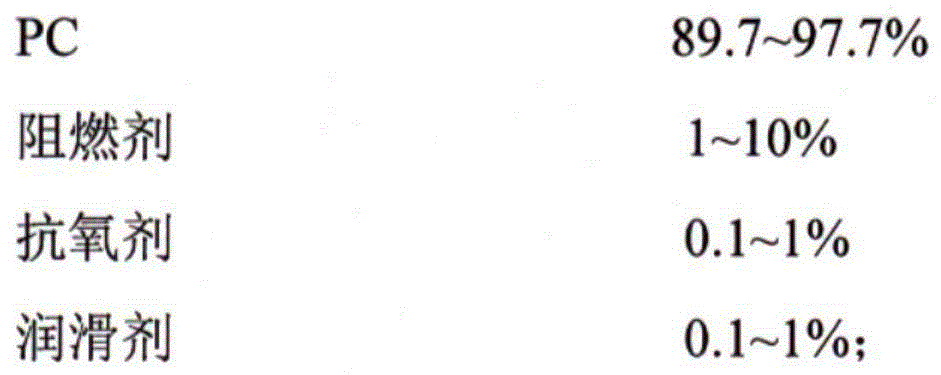

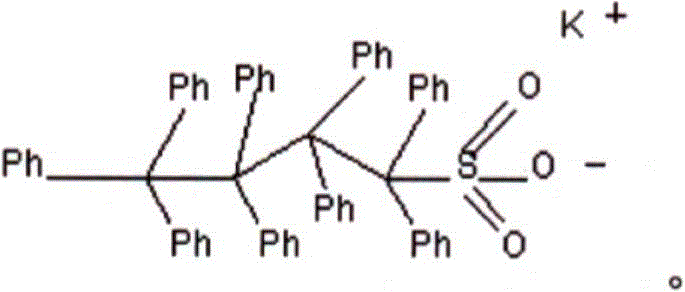

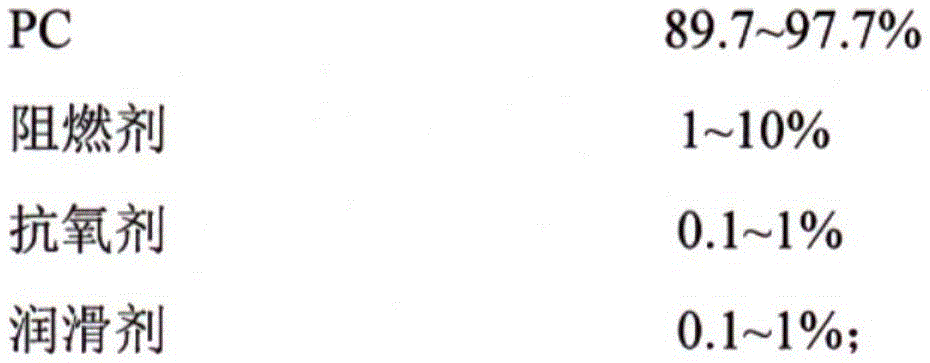

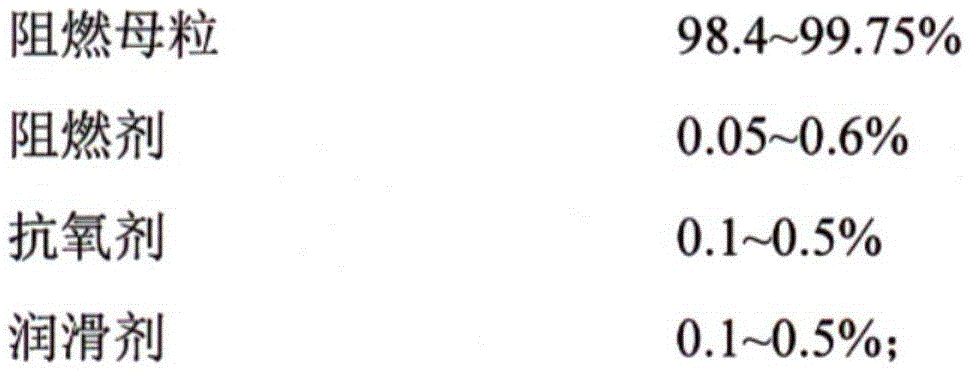

Transparent halogen-free flame-retardant polycarbonate resin and preparation method thereof

The invention relates to a transparent halogen-free flame-retardant polycarbonate resin. The resin comprises the following components in percentage by weight: 98.4-99.75% of flame-retardant master batches, 0.05-0.6% of a fire retardant, 0.1-0.5% of an antioxidant and 0.1-0.5% of a lubricant. The preparation method comprises the following steps: preparing materials according to the components, adding PC, the fire retardant, the antioxidant and the lubricant in percentage by weight into a high-speed mixing machine, sufficiently mixing the PC, the fire retardant, the antioxidant and the lubricant, and placing the PC, the fire retardant, the antioxidant and the lubricant, which are mixed, into a screw rod machine for extruding and pelleting so as to obtain flame-retardant master batches; adding the flame-retardant master batches and the rest of the components into the high-speed mixing machine together, sufficiently mixing the flame-retardant master batches and the rest of the components, and then placing the flame-retardant master batches and the rest of the components, which are sufficiently mixed, into the screw rod machine for extruding and pelleting so as to obtain products. Compared with the prior art, the method disclosed by the invention fully uses phenyl butyl sulfonic acid potassium as the fire retardant, after the fire retardant, the antioxidant, the lubricant and the flame-retardant master batches are mixed, extruded and pelleted, the whole preparation technology is simple, a complex ladder temperature control step is not needed, the obtained products have the characteristics of transparence, thin walls, high impact strength, excellent flame retardant property, zero toxicity and zero harm, and the application range is wide.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Cement highly efficient intensifying agent

The invention relates to a cement addictive, which in detail is a high effective intensifier for cement production, solving problems of high cost, complex composition of the addictive used to improve the cement property, increase the cement intensity in the cement producing course and problem of not ideal effect of the intensity improved after cement hardened. The addictive comprises the following raw material with proportion by weight being: kalium sulphuricum industrial side product 70-85%, lime carbonate powder 5-20%, lime carbonate 5-20%. The cement intensifier mentioned in this invention can stimulate the cement intensity thoroughly, because of which the consumption of cement half-finished product chamotte can be reduced greatly, which saves large amount of mineral resources and energy and reduces cement production cost greatly.

Owner:昝和平

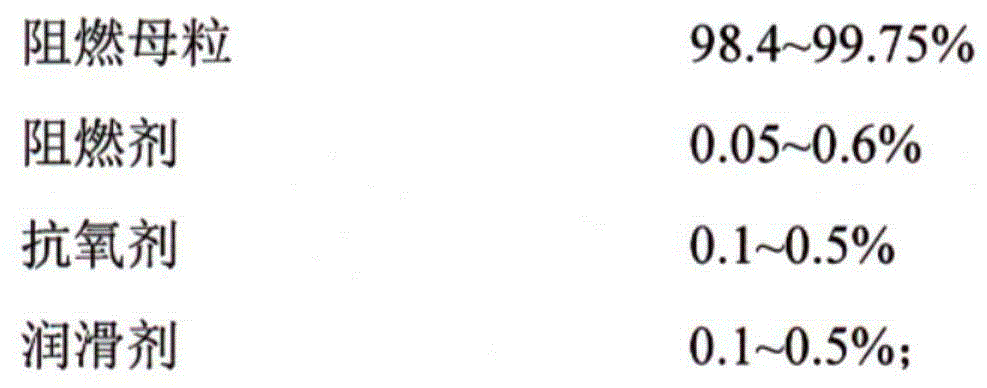

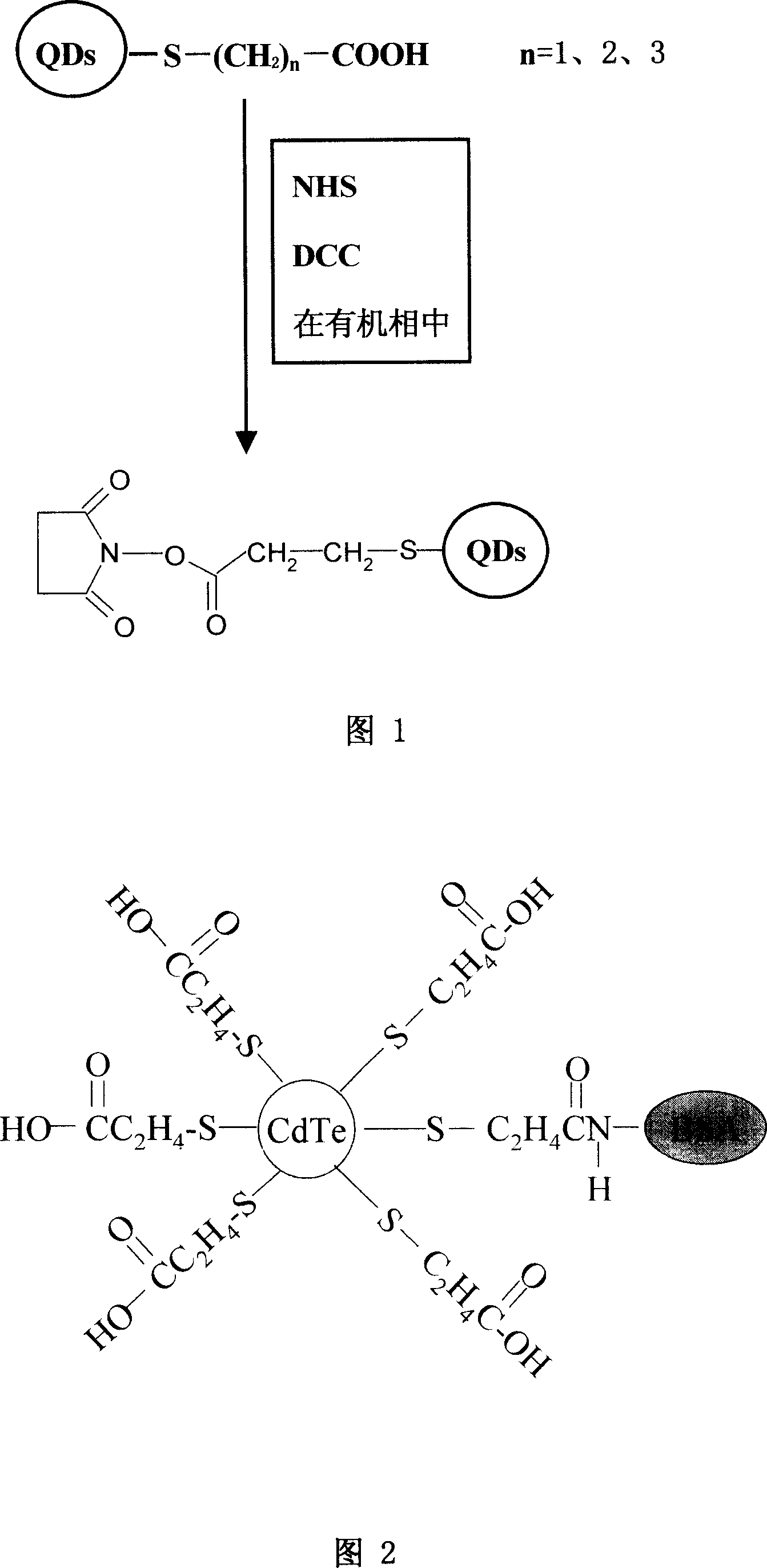

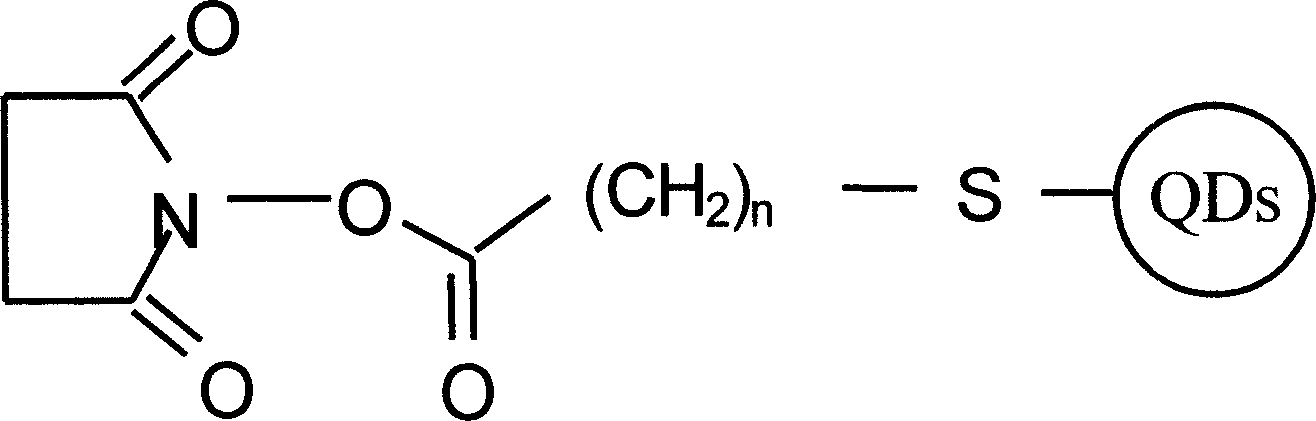

Functionalized quantum dot, process for preparation and use thereof

InactiveCN1952037AFor long-term storageChemical properties are not affectedLuminescent compositionsMaterial analysisChemical qualityQuantum dot

The invention relates to a kind of functional quanta spot. The producing procedure comprises the following steps: pretreating the quanta spot synthesized in stablizing agent; adding pretreated quanta spot to the dissolved N-hydroxyl succinimide then adding the dissolved cicyclohexylcarbodiimide to get the reacting solution; wrapping the solution with paper which can protect the solution from light and making the solution react on the shaker for at least 125h; packaging; evacuating and drying in freeze-vacuum concentrator to get the esterified quanta spot by N- hydroxyl succinimide. The invention has solved many technological problems in background skills such as low labeling rate, unable to keep the quanta for a long time and unable to extend the practical use. The product disclosed in the invention has many advantages: it's water-soluble so it's easier and more efficient to label the biomacromolecule; it has good stability and versatility; it can be preserved for a long time while keeping its physical and chemical qualities.

Owner:SHANXI LIFEGEN

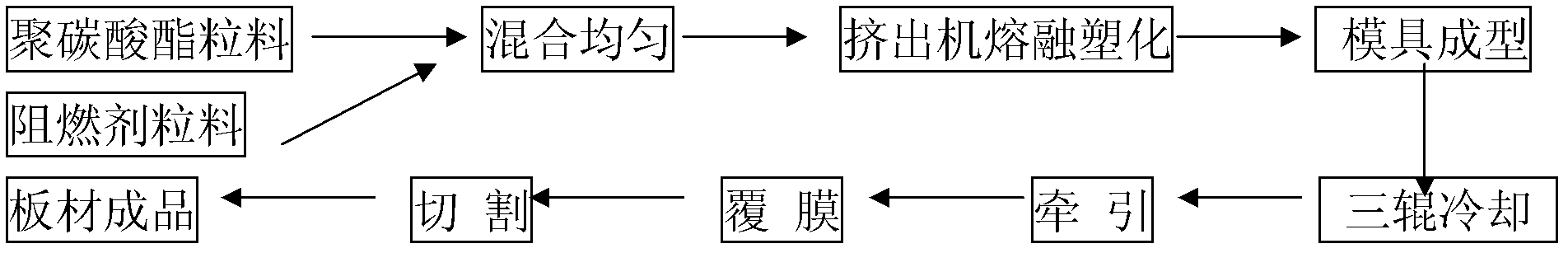

Polycarbonate flame retardant endurance plate and preparation method thereof

InactiveCN103183948AHigh strengthHigh toughness, high light transmittancePotassium perfluorobutanesulfonateNon toxicity

The invention relates to a polycarbonate flame retardant endurance plate. The flame retardant endurance plate is composed of the following components, by weight, 95%-99.5% of polycarbonate and 0.5%-5% of a flame retardant, wherein the flame retardant is modified potassium perfluorobutanesulfonate. A preparation method of the flame retardant endurance plate comprises the steps of (1) mixing carbonate particles and flame retardant particles uniformly, melting and plasticizing the mixture in an extruder; (2) shaping the plasticized material in a mold and cooling by a three-roller method; and (3) drawing, coating and cutting the cooled model. The polycarbonate flame retardant endurance plate provided by the invention has the advantages of thin thickness, high strength, strong toughness, high transparency, non-toxicity and harmlessness, etc. The polycarbonate flame retardant endurance plate can not release toxic and harmful gas to the environment, and fits ROHS environment-protecting directives.

Owner:SHANGHAI HUILI TUVGAL SHEETAB

Method for extracting raffinose

InactiveCN106967129APhysical properties are not affectedUnbreakableSugar derivativesOligosaccharidesSolid contentMacroporous resin

The invention discloses a method for extracting raffinose. The method includes steps of 1, carrying out pretreatment; 2, carrying out decolorization; 3, carrying out primary crystallization, to be more specific, concentrating decolorized raffinose solution under reduced pressures until the solid content is 40-70%, cooling the raffinose solution until the temperature of the raffinose solution reaches 0-10 DEG C, carrying out vacuum centrifugal separation on the raffinose solution to obtain raffinose crystallization crude products, desalting centrifuged residual liquid by the aid of macroporous resin and then spraying drying agents to obtain raffinose powder; 4, carrying out secondary crystallization, to be more specific, dissolving the raffinose crystallization crude products in water at the temperature of 60-80 DEG C to obtain crystallization systems with the solid contents of 43-60 DEG C, carrying out first-section cooling on the crystallization systems, joining the crystallization systems with crystal nucleuses, carrying out second-section cooling on the crystallization systems, drying the crystallization systems under normal pressures, centrifuging a finished product which is the raffinose and then crystallizing residual liquid at the step 3. The method for extracting the raffinose has the advantages of short process route, simplicity in operation, low requirements on equipment and low cost.

Owner:合肥云都棉花有限公司

A kind of pasty water-based release agent and its preparation method and application method

The invention discloses a paste-like water-based rubber release agent and its preparation method and application method. Its components include 3-15 parts of inorganic powder additives, 0.1-1.0 parts of anionic surfactant, and 0.5-1.0 parts of anionic surfactant in parts by mass. 5.5 parts of nonionic surfactant, 5-10 parts of thixotropic agent, 0.2-2.0 parts of thickener, 0.1-0.5 parts of defoamer, 60-100 parts of deionized water. Mix water and surfactant, stir to dissolve, add inorganic powder additives, add defoamer dropwise, add thixotropic agent and thickener in batches, stir well and grind until homogeneous to obtain the release agent. When in use, make an aqueous solution at a mass ratio of 1:3 to 15, add it to the water cooling tank of the film, the film is cooled by water while the release agent is applied, and it can be stacked after air drying on the hanging rod. The invention is easily soluble in water, non-toxic, tasteless, simple in process and low in cost, and basically has no influence on the subsequent processing performance of rubber.

Owner:江苏益路昇新材料有限公司

A kind of PC alloy with high hardness, high transparency and high fluidity and preparation method thereof

The invention belongs to the technical field of high molecular alloy materials, and particularly relates to a high-hardness high-transparency high-flowability PC (polycarbonate) alloy and a preparation method thereof. The PC alloy comprises the following components in parts by weight: 80-95 parts of PC resin, 10-20 parts of PS (poly styrene), 6-10 parts of transparent toughener, 1-5 parts of SMA (styrene maleic anhydride) random copolymer, 0.06-0.1 part of transparent PC halogen-free flame retardant, 0.2-2 parts of main antioxidant, 0.2-2 parts of auxiliary antioxidant and 0.2-1 part of silane coupling agent. Alternatively, the PC alloy comprises the following components in parts by weight: 80-95 parts of PC resin, 6-10 parts of transparent toughener, 10-20 parts of SMA random copolymer, 0.06-0.1 part of transparent PC halogen-free flame retardant, 0.2-2 parts of main antioxidant, 0.2-2 parts of auxiliary antioxidant and 0.2-1 part of silane coupling agent. According to the invention, the PC alloy material is prepared through a melt blending method, the preparation method is convenient, the technological operation is easy to realize, the cost is low, and the period is short; and the surface hardness and flowability of the alloy are simultaneously improved under the condition of keeping high transparency, so that the alloy has excellent physical and chemical properties on the whole. Thus, the invention is suitable for popularization.

Owner:DALIANG PLASTIC2 SHUNDE FOSHAN

Anti-light corrosion type abs composition, light-transmitting board and air conditioner

The invention provides a light corrosion resistant ABS (acrylonitrile-butadiene-styrene) composition, a light-passing plate and an air conditioner. The light corrosion resistant ABS (acrylonitrile-butadiene-styrene) composition comprises the following components by mass: 100 parts of ABS resin, 0.1-1 part of TiO2, 0.1-0.5 part of a light stabilizer, 0.1-1 part of an antioxidant and 0.1-1 part of a processing aid. On the premise of guarantee of material mechanical strength, the light corrosion resistant ABS composition provided by the invention has good light transparency and glossiness, and has the light corrosion resistant effect, therefore, after long-term exposure to a LED light source, a panel of the air conditioner made of the light corrosion resistant ABS composition is free of color difference in display, and the panel has a good display effect, and user satisfaction can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

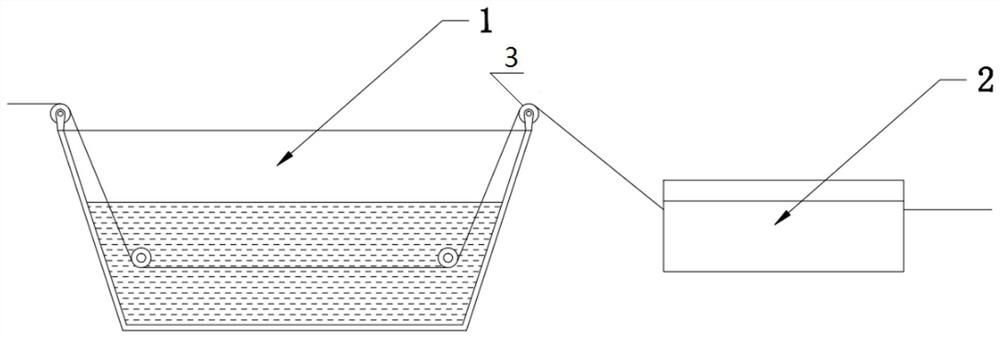

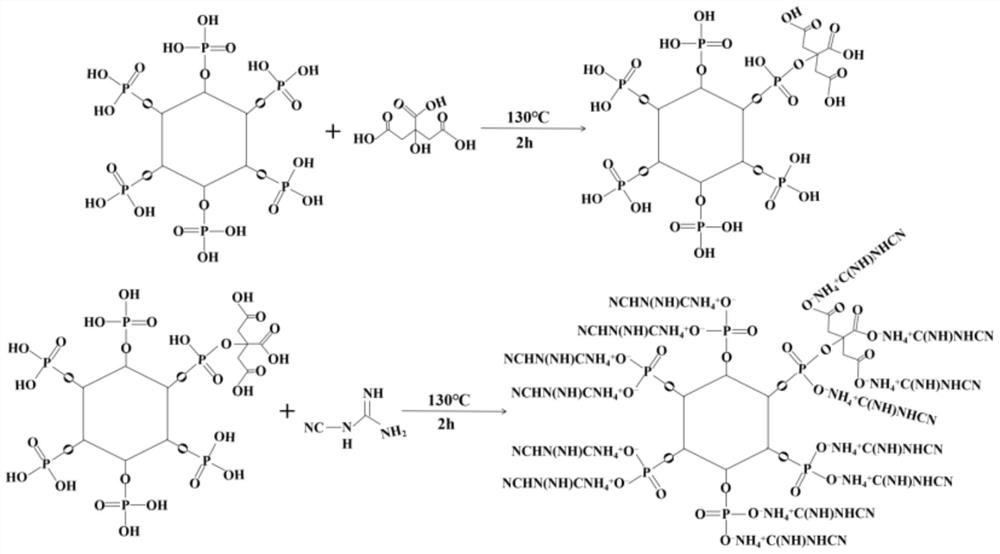

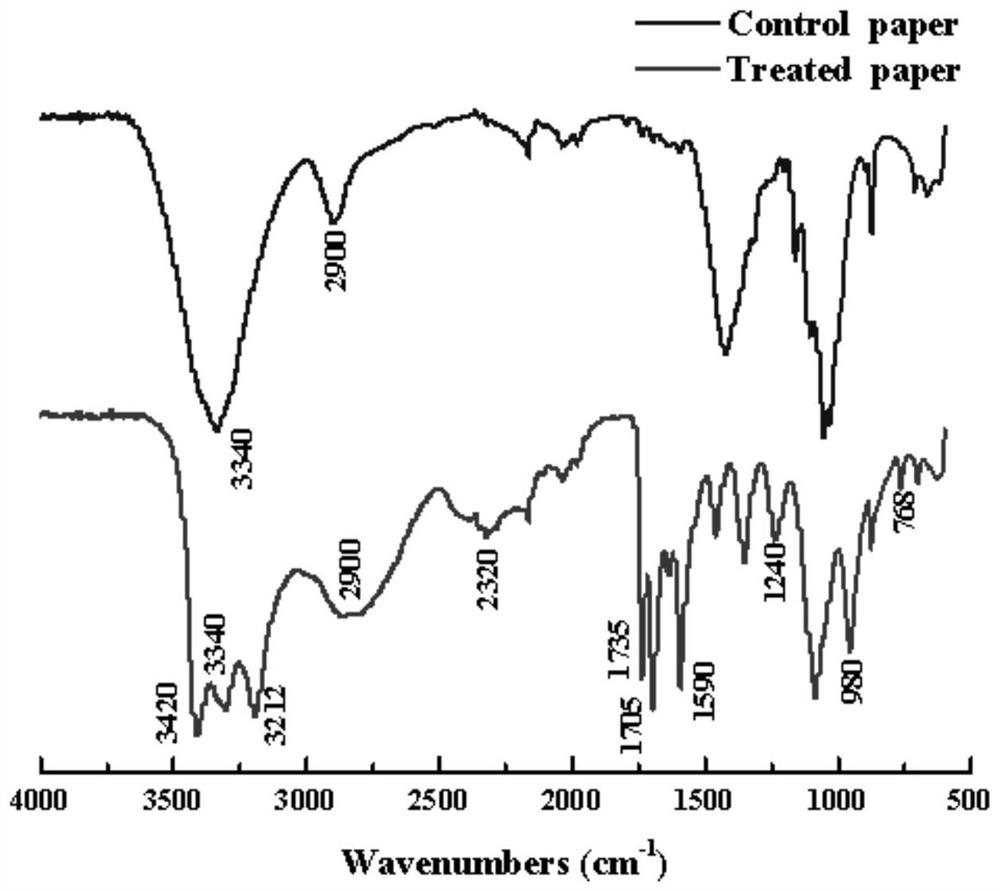

Simple, convenient, efficient and environment-friendly preparation method of flame-retardant office paper

PendingCN113215859AImprove flame retardant performanceInhibit flammabilitySpecial paperPaper/cardboardPhytic acidProcess engineering

The invention belongs to the technical field of flame-retardant paper preparation, and particularly relates to a simple, convenient, efficient and environment-friendly preparation method of flame-retardant office paper. The preparation method comprises the following specific steps: S1, synthesizing a flame retardant; and S2, carrying out flame retardant treatment on the paper, namely adding the flame retardant powder obtained in the step S1 into deionized water by adopting a dipping container and drying equipment to prepare finishing liquid, putting the finishing liquid into a dipping container, then, guiding raw paper into the dipping container at the room temperature, smoothly impregnating the raw paper with the finishing liquid for 15 seconds, and then, drying the impregnated raw paper in drying equipment to obtain the flame-retardant office paper. The efficient and environment-friendly office paper flame retardant is successfully synthesized by taking phytic acid and citric acid as main raw materials. The flame retardant property of the A4 office paper is improved through dipping and drying processes. The problem of flammability of the paper is effectively inhibited, and the printing effect and the physical properties of the paper are hardly influenced.

Owner:ANHUI POLYTECHNIC UNIV

High-tenacity waterproof and fireproof board specially used for tunnel and preparation method thereof

InactiveCN101638991BImprove fire resistanceImprove toughnessUnderground chambersSolid waste managementEpoxyFiber

The invention relates to a high-tenacity waterproof and fireproof board specially used for a tunnel and a preparation method thereof, wherein the high-tenacity waterproof and fireproof board is made by pressing one or two kinds of medium-alkali glass fiber cloth and non-woven fabric which are taken as basal materials and waterproof and fireproof components; and the waterproof and fireproof components comprise the following components in percent by weight: 48.7-29.8 percent of magnesium oxide, 2.4-7.4 percent of expanded perlite, 4.4-19.9 percent of filling aggregate, 43.9-37.2 percent of magnesium chloride, 0.12-3.89 percent of medium-alkali glass fiber yarn, 0.24-1.07 percent of polybutadiene epoxy resin and 0.24-0.74 percent of aluminum dihydrogen phosphate water-repellent agent. By adopting the effective matching of the components, the invention can greatly improve the fire resistance endurance and the tenacity of boards to better apply to the tunnel.

Owner:湖南立磐威特消防新材料科技有限公司

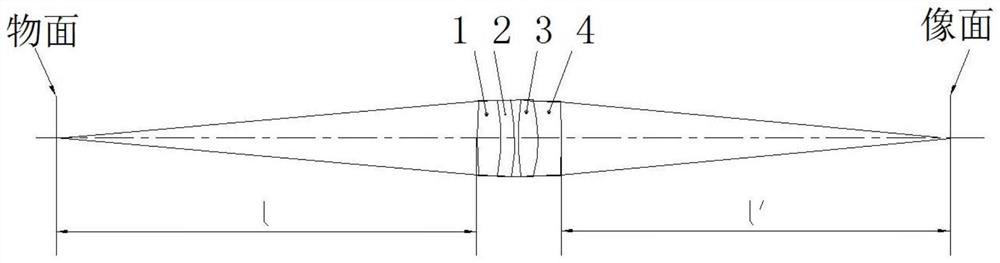

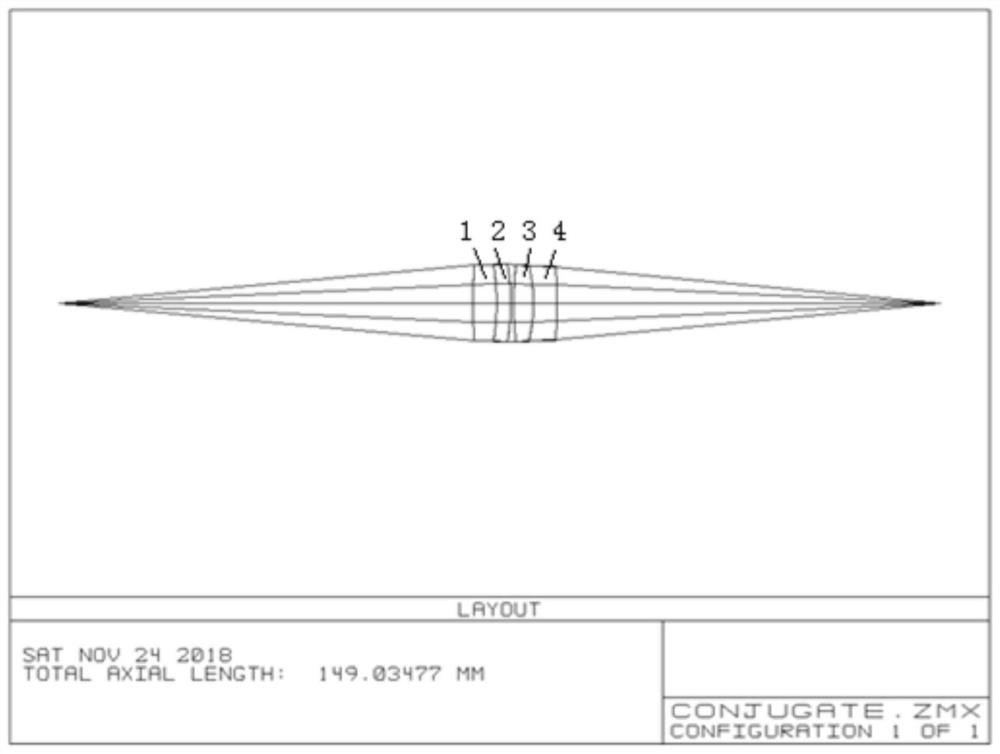

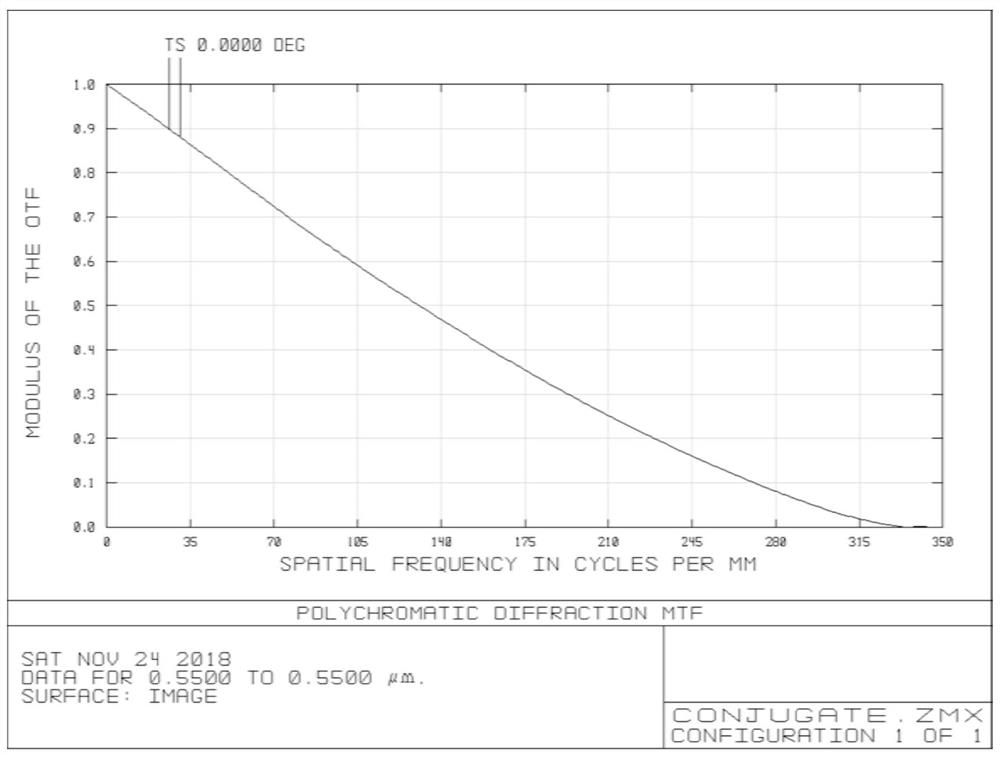

A Finite Conjugate Optical System with Equidistant Object and Image

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A kind of preparation method of graphene

The invention discloses a preparation method of graphene, which comprises the following steps: 1) dispersing graphite in an organic foaming agent solution, stirring at constant temperature for 30 minutes-1 hour, and carrying out ultrasonic oscillation for 10-30 minutes; 2) keeping the product in the step 1) at constant temperature in a 150-280-DEG C oil bath for 30 minutes-5 hours; 3) cooling the product in the step 2) to normal temperature, adding into a mixed solution of ethanol and concentrated nitric acid in a volume ratio of 30:1-50:10 to form a uniformly-dispersed 0.003-0.05g / mL suspension, carrying out hydrothermal reaction on the suspension at 80-160 DEG C for 6-48 hours, cooling the suspension, filtering, precipitating, washing, and drying; and 4) adding the product in the step 3) into a sodium hydroxide solution with the pH value of 7.5-11, and stirring at 180-260 DEG C for 30 minutes-1 hour. The preparation method disclosed by the invention greatly enhances the graphene yield.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

A kind of transparent halogen-free flame-retardant polycarbonate resin and preparation method thereof

Owner:SHANGHAI KUMHO SUNNY PLASTICS

A kind of transparent electrode and preparation method thereof

InactiveCN106847942BImprove conductivityHigh Conductivity Low ResistanceFinal product manufactureSemiconductor devicesDielectricResonance

The present invention provides a transparent electrode and a preparation method thereof; the transparent electrode of the present invention includes: a transparent substrate and a first high dielectric film layer, a metal film layer, and a second high dielectric film layer sequentially arranged on the transparent substrate; The metal film layer mentioned above is a continuous metal film layer; the dielectric constant of the high dielectric film layer is greater than or equal to 6.25. The invention utilizes the electromagnetic resonance characteristic of the high dielectric material to realize the design and preparation of the transparent electrode material with high conductivity and high light transparency. The transparent electrode of the present invention utilizes the electromagnetic resonance characteristics of the high dielectric film layer and its coupling input and output effects with incident light; the composite structure of the high dielectric film layer and the continuous metal film layer can provide broadband light transparency and cover the spectrum range From visible light to infrared light, it greatly expands the optoelectronic application range of this type of transparent electrode in different frequency bands; at the same time, it has strong bending and flexibility, and is easy to integrate with external structural units including other active layers or photoelectric control modules or flexible substrates integration.

Owner:JIANGXI NORMAL UNIV

A kind of preparation method of eucommia gum mixed rubber for normal temperature molding processing

ActiveCN107415074BExcellent formabilityPhysical properties are not affectedPolymer scienceGutta-percha

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

A kind of environment-friendly rubber release agent

The invention discloses an environment-friendly rubber isolation agent. The isolation agent comprises the following components in parts by weight: 24-36 parts of polyoxyethylene sorbitan monooleate, 2-4 parts of waterborne polyamide wax, 30-38 parts of calcium stearate, 18-30 parts of hydrated silicon dioxide, 8-14 parts of potassium stearate, 2-5 parts of silicone oil defoaming agents and 2-6 parts of sodium carboxymethylcellulose. The isolation agent is excellent in compatibility, long in actual effect and low in addition amount, and is green and environmentally friendly; the preparation process of the environment-friendly rubber isolation agent is simple and feasible; the cost is low.

Owner:JIANGSU KAOU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com