Paste water-based isolation agent, preparation method and application method thereof

A release agent, water-based technology, applied in the direction of coating, etc., can solve the problems of rubber performance degradation, etc., and achieve the effect of good lubricity, good thixotropic effect and high colloid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

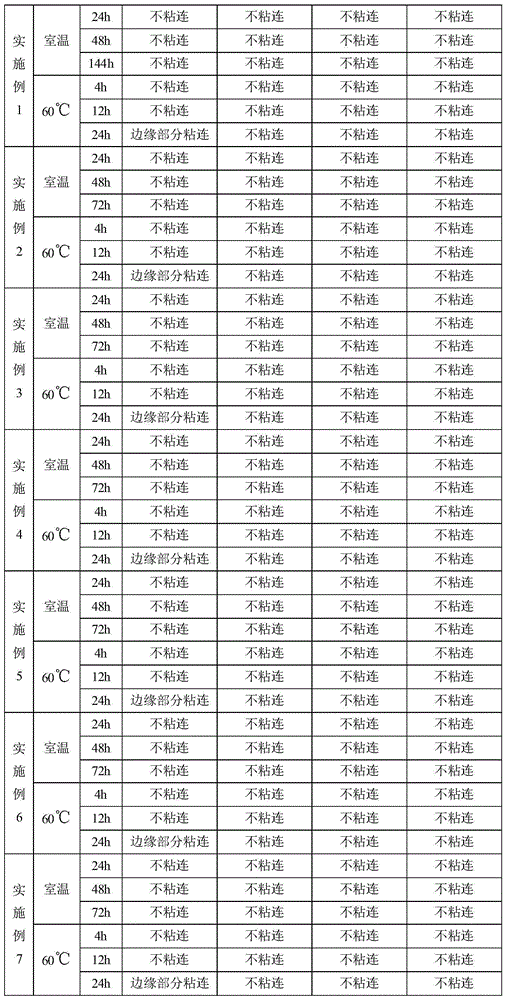

Examples

Embodiment 1

[0031] (1) The mass-number ratio of each component prepared by paste-like water-based rubber release agent is: 0.1 part of sodium oleate (industrial grade, commercially available, the same below), 0.5 part of OP-4, 1.0 part of OP-7, 1.0 part of OP-7, -10 4.0 parts (OP-4, OP-7, OP-10 are all provided by Jiangsu Haian Petrochemical Plant, the same below), diatomite (325 mesh, provided by Lingshou County Longtong Building Materials Factory, the same below) 2.0 parts , active ZnO (provided by HX-5 Copper Anode Chemical Factory, the same below) 0.5 parts, TiO 2 (rutile type, 325 mesh, commercially available, the same below) 0.5 part, bisphenol A polyoxyethylene ether (BPE-20, provided by Jiangsu Haian Petrochemical Factory, the same below) 1 part, sodium bentonite (natural grade, 325 10 parts of the mixture (the mass ratio of bentonite to silica is 10:1, the same below) and polyether Modified silicone oil (ZBH-207, provided by Qingdao Zhongbao Chemical Co., Ltd., the same below) 0...

Embodiment 2

[0038] (1) The mass-number ratio of each component prepared by the pasty water-based rubber release agent is: 0.5 part of sodium oleate, 0.5 part of sodium linoleate (industrial grade, commercially available, the same below), 0.5 part of OP-10, Ultrafine CaCO 3 Powder (CL-8030, 3000 mesh, provided by Hunan Chenglu Jufeng New Material Co., Ltd., the same below) 9 parts, diatomaceous earth 2.0 parts, active ZnO 0.5 part, TiO 2 0.5 parts, 2 parts of bisphenol A polyoxyethylene ether, 5 parts of a mixture of sodium bentonite and fumed silica, 0.5 parts of polyether modified silicone oil, and 90 parts of deionized water.

[0039] (2) Preparation method of water-based paste rubber release agent: Mix deionized water at 20-50°C with surfactants such as sodium oleate, sodium linoleate, and OP-10, stir and dissolve; add ultra-fine CaCO 3 , diatomaceous earth, active ZnO, TiO 2 Wait for inorganic powder, and add polyether modified silicone oil defoamer dropwise; speed up the stirring s...

Embodiment 3

[0044] (1) The mass-number ratio of each component prepared by paste water-based rubber release agent is: 0.5 part of sodium linoleate, 1.0 part of OP-4, 1.0 part of OP-7, 1.0 part of OP-10, superfine CaCO 3 6.0 parts of powder, 5.0 parts of diatomaceous earth, 0.5 parts of active ZnO, TiO 2 0.5 parts, 0.8 parts of bisphenol A polyoxyethylene ether, 8 parts of a mixture of sodium bentonite and fumed silica, 0.2 parts of polyether modified silicone oil, and 100 parts of deionized water.

[0045] (2) Preparation method of water-based paste rubber release agent: mix deionized water at 20-50°C with sodium linoleate, OP-4, OP-7, OP-10 and other surfactants, stir and dissolve; add super Fine CaCO 3 , diatomaceous earth, active ZnO, TiO 2 Wait for inorganic powder, and add polyether modified silicone oil dropwise; increase the stirring speed, add the mixture of sodium bentonite and fumed white carbon black in batches, then add bisphenol A polyoxyethylene ether, fully stir and grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com