A kind of preparation method of microalgae oil modified rubber asphalt

A technology of modified rubber and modified asphalt, which is applied in the direction of grease/fat production, building components, building insulation materials, etc., can solve the problems of unfavorable construction, low temperature performance, insufficient storage stability, etc., and achieve the improvement of excessive viscosity, The effect of improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

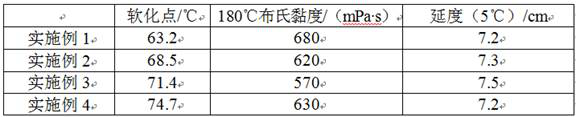

Examples

Embodiment 1

[0022] Example 1 Preparation of rubber powder modified asphalt as a comparative example

[0023] Heat 100 parts of base asphalt to 160~170°C, then slowly add 20 parts of rubber powder and 0.4 parts of cracking agent (using octyl phosphate) into the base asphalt, and shear at 3500~4000r / min at 180~185°C Cutting and stirring for 70 minutes, and then developing at a low speed of 500-1000 r / min at 160-170 °C for 50 minutes to obtain rubber powder modified asphalt.

Embodiment 2

[0024] Example 2 Preparation of 1# microalgae oil modified rubber asphalt

[0025] 1. First extract microalgae oil

[0026] In the first step, use 0.7~0.8mW / cm 2 UV exposure concentration 10 4 ~10 5 Individual / mL microalgae liquid 5h, add Bacillus, make Bacillus concentration reach 10 6 ~10 7 cfu / mL, placed at room temperature for 22 hours to fully degrade the microalgae by bacteria;

[0027] The second step: using a centrifugal filter to separate the water-soluble protein in the microalgae liquid obtained in the first step to obtain a microalgae residue solution;

[0028] The third step: put the microalgae residue solution in the second step in an oven at 100°C until the water is completely evaporated to obtain the microalgae residue;

[0029] Step 4: Add n-hexane to the microalgae residue, stir for 1.5 hours, let it stand for 22 hours, and then filter out the insoluble matter in the solution to obtain a n-hexane solution containing microalgae oil;

[0030] The fifth s...

Embodiment 3

[0033] Example 3 Preparation of 2# microalgae oil modified rubber asphalt

[0034] The method for extracting microalgae oil is the same as in Example 2.

[0035] The method for preparing 2# microalgae oil modified rubber asphalt is as follows: take 100 parts of rubber powder modified asphalt prepared in Example 1 and 30 parts of microalgae oil and preheat them to 160~170°C respectively, and then slowly add microalgae oil into Mix rubber powder modified asphalt at 160-170°C with high-speed shear of 3500-4000r / min for 20 minutes to obtain 2# microalgae oil modified rubber asphalt product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com