A kind of recycled PC/ABS alloy material and its preparation method using macromolecular chain extender original repair modification

An alloy material and chain extender technology, applied in the field of recycled PC/ABS alloy material and its preparation, can solve the problems of unsatisfactory heat resistance, weather resistance, mechanical properties, deterioration of interface bonding force, and comprehensive performance reduction, etc. Good social and economic benefits, improve the phase interface, increase the effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

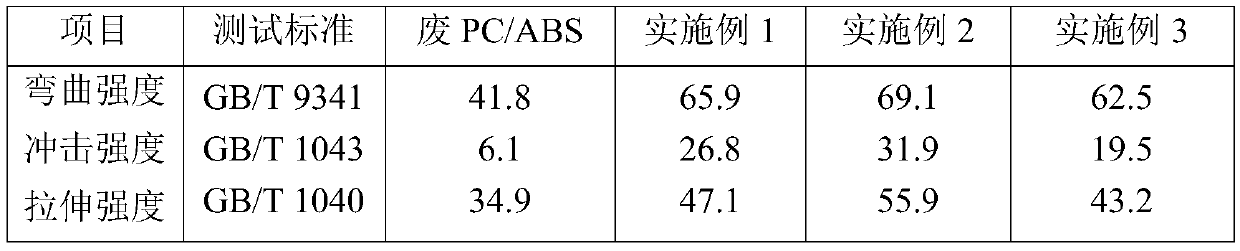

Examples

Embodiment 1

[0036] The regenerated PC / ABS alloy material provided in this embodiment is mainly composed of the following ingredients in proportions by mass:

[0037] Waste PC / ABS: 100

[0038] ABS-based macromolecular chain extender: 6

[0039] Chain extension accelerator: 1.

[0040] Wherein the ABS-based macromolecular chain extender is acrylonitrile-butadiene-styrene copolymer (ABS) grafted oxazoline, which is prepared by the following method: taking ABS high rubber powder, ethanolamine and zinc acetate as raw materials, 2 , 6-dichlorotoluene as a solvent, placed in a reaction vessel to adjust the temperature to 180 ° C cold reflux reaction for 2 hours, then freeze precipitation, suction filtration and drying, to obtain the macromolecular chain extender ABS grafted oxazoline.

[0041] The mass ratio of ABS high rubber powder, ethanolamine and zinc acetate is 100:30:2.

[0042] The consumption of 2,6-dichlorotoluene is 8 times of the total mass of raw material ABS high rubber powder....

Embodiment 2

[0049] The regenerated PC / ABS alloy material provided in this embodiment is composed of the following components by mass:

[0050] Waste PC / ABS: 100

[0051] Macromolecular chain extender: 8

[0052] Chain extension accelerator: 2.

[0053] Wherein the macromolecular chain extender is ABS grafted oxazoline, which is prepared by the following method: taking ABS high-glue powder, ethanolamine and zinc acetate as raw materials, 2,6-dichlorotoluene as solvent, and placing it in a reaction vessel to adjust The temperature is 170° C. after cold reflux reaction for 3 hours, and then the frozen precipitate is sucked and dried to obtain the macromolecular chain extender ABS grafted oxazoline.

[0054] The mass ratio of ABS high rubber powder, ethanolamine and zinc acetate is 100:50:3.

[0055] The consumption of 2,6-dichlorotoluene is 10 times of the total mass of raw material ABS high rubber powder.

[0056] Cryoprecipitates were cryoprecipitated in ethanol.

[0057] The chain ex...

Embodiment 3

[0062] The regenerated PC / ABS alloy material provided in this embodiment is mainly composed of the following ingredients in proportions by mass:

[0063] Waste PC / ABS: 100

[0064] Macromolecular chain extenders: 4

[0065] Chain extension accelerator: 0.5.

[0066] Wherein the ABS-based macromolecular chain extender is the same as in Example 2.

[0067] The chain extension accelerator is the same as in Example 1.

[0068] Waste PC / ABS is with embodiment 1.

[0069] The regenerated PC / ABS alloy material comprises the following steps: mixing the waste PC / ABS and the chain extension accelerator according to the above dosage relationship to obtain a mixed material, adding the mixed material from the main feeding device of the twin-screw extruder to melt, and controlling the screw speed From the twin-screw extruder processing zone 4, add ABS-based macromolecular chain extender and blend with the melted mixture according to the above dosage relationship, and then extrude, pull,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com