PLA biodegradable composite material and preparation method thereof

A composite material and biodegradation technology, applied in the field of PLA biodegradable composite materials and its preparation, can solve the problems of narrow processing range, low melt strength, poor heat resistance, etc., and achieve improved compatibility, phase interface improvement, impact The effect of strength and tensile strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

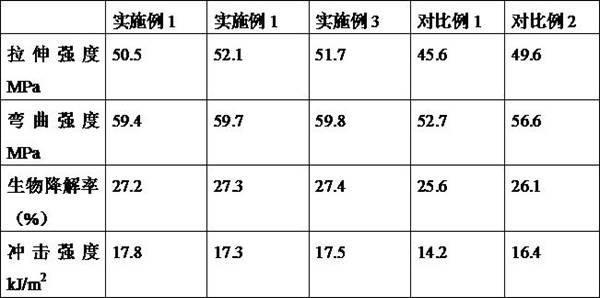

Examples

Embodiment 1

[0019] A PLA biodegradable composite material comprises the following raw materials in parts by weight: 100 parts of PLA, 20 parts of PBAT, 10 parts of polyester, 2 parts of fatty acid glyceride, 3 parts of corn oil and 1 part of polycaprolactone. The PLA density is 1.24g / cm 3 , is a semi-crystalline material.

[0020] A preparation method of PLA biodegradable composite material, comprising the following steps:

[0021] (1) Place PLA and PBAT in a vacuum drying oven and dry at 60°C for 12 hours to remove small molecule residues and moisture;

[0022] (2) Mix the dried PLA, PBAT, polyester parts, fatty acid glycerides, vegetable oil and compatibilizer, then add them to the twin-screw extruder, melt, extrude, pelletize, repeat the extrusion steps three times, and dry Composite materials are produced.

[0023] Among them, the temperatures in zones 1-9 of the extruder are 155°C, 155°C, 165°C, 165°C, 170°C, 170°C, 170°C, 165°C, 165°C, and the head temperature is 170°C.

Embodiment 2

[0025] A PLA biodegradable composite material, comprising the following raw materials in parts by weight: 120 parts of PLA, 30 parts of PBAT, 15 parts of polyester, 5 parts of fatty acid glycerides, 8 parts of sunflower oil and 4 parts of maleic anhydride graft compatibilizer share. The PLA density is 1.24g / cm 3 , is a semi-crystalline material.

[0026] A preparation method of PLA biodegradable composite material, comprising the following steps:

[0027] (1) Place PLA and PBAT in a vacuum drying oven and dry at 60°C for 12 hours to remove small molecule residues and moisture;

[0028] (2) Mix the dried PLA, PBAT, polyester parts, fatty acid glycerides, vegetable oil and compatibilizer and add them to the twin-screw extruder, and repeat the steps of melting, extruding, pelletizing and extruding four times, Dry to obtain a composite material.

[0029] Among them, the temperatures in zones 1-9 of the extruder are 155°C, 155°C, 165°C, 165°C, 170°C, 170°C, 170°C, 165°C, 165°C,...

Embodiment 3

[0031] A PLA biodegradable composite material comprises the following raw materials in parts by weight: 110 parts of PLA, 25 parts of PBAT, 12 parts of polyester, 3 parts of fatty acid glyceride, 6 parts of peanut oil and 2 parts of polycaprolactone. The PLA density is 1.24g / cm 3 , is a semi-crystalline material.

[0032] A preparation method of PLA biodegradable composite material, comprising the following steps:

[0033] (1) Place PLA and PBAT in a vacuum drying oven and dry at 60°C for 12 hours to remove small molecule residues and moisture;

[0034] (2) Mix the dried PLA, PBAT, polyester parts, fatty acid glycerides, vegetable oil and compatibilizer, then add them to the twin-screw extruder, melt, extrude, pelletize, repeat the extrusion steps three times, and dry Composite materials are produced. The temperatures in zones 1-9 of the extruder are 155°C, 155°C, 165°C, 165°C, 170°C, 170°C, 170°C, 165°C, 165°C respectively, and the head temperature is 170°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com