High heat-resistant crushing-resistant copolymerization composition and continuous preparation method

A technology of impact copolymerization and composition, which is applied in the field of high heat-resistant impact copolymer composition and its continuous preparation, and can solve problems such as difficult control, lack of hydrolysis resistance, heat resistance and thermal stability, and high viscosity of the system , to achieve the effects of simple process flow, wide adjustment range of compatibility and heat resistance, and high monomer conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

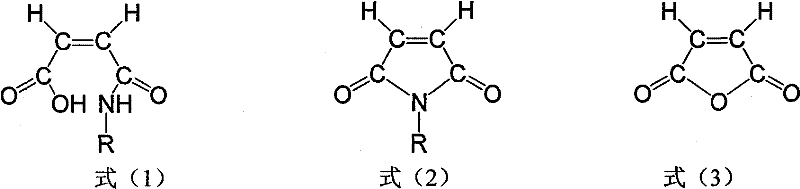

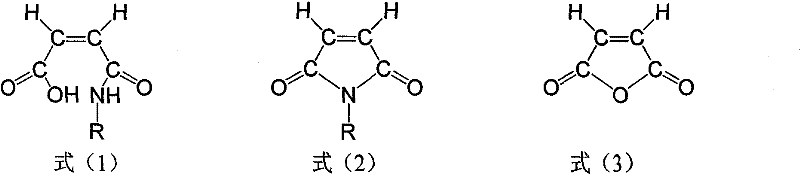

Method used

Image

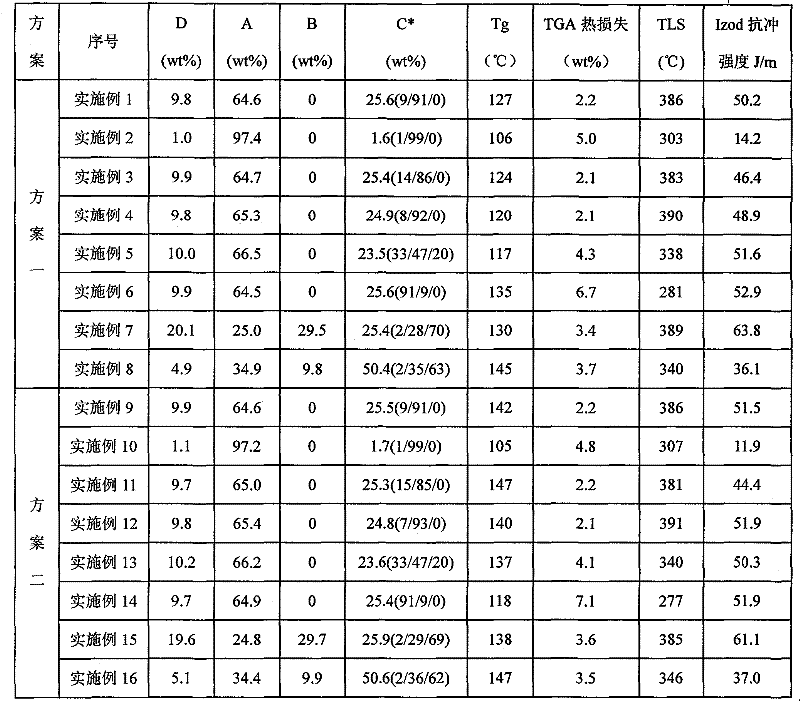

Examples

Embodiment 1

[0039] 1) Mix 10 kg of high-cis polybutadiene rubber, 37.5 kg of styrene, 7.5 kg of maleic anhydride, 0.3 kg of dibenzoyl peroxide (BPO), and 20 kg of butanone into the first reaction In the still, react at 130 ℃, the outlet conversion rate of the first reaction still is controlled at 40%;

[0040] 2) 37.5 kilograms of styrene, 7.5 kilograms of maleic anhydride, 0.3 kilograms of BPO, 20 kilograms of butanone and 25.6 kilograms of aniline were mixed and continuously added to the second reactor together with the effluent of the first reactor, reacted at 150 ° C, and The outlet conversion rate of the second reactor is controlled at 70%;

[0041] 3) Add 17.1 kg of aniline and the mixture of the effluent from the second reactor into a vented twin-screw extruder at a temperature of 230° C., a vacuum degree of 0.02 MPa at the vent port, and an average residence time of 10 minutes. , to obtain a high heat-resistant impact copolymer composition. Its composition and properties are rep...

Embodiment 2

[0043] Repeat embodiment 1, the high cis polybutadiene rubber addition in step 1) is reduced to 1 kilogram, and the styrene addition is improved to 68.6 kilograms, and the maleic anhydride addition is reduced to 0.7 kilogram, and the BPO consumption improves to 0.42 Kilogram, the methyl ethyl ketone consumption improves to be 28 kilograms, step 2) in the styrene addition is reduced to 29.4 kilograms, and the maleic anhydride addition is reduced to 0.3 kilogram, and the BPO consumption is reduced to 0.18 kilogram, and the butanone consumption is reduced to 12 kilograms, The amount of aniline added is reduced to 0, and the amount of aniline added in step 3) is reduced to 5.7 kg, and the data and results are recorded in Table 1.

Embodiment 3

[0045] Example 1 was repeated without the addition of BPO, and the data and results are reported in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com