Filling agglomerate for polypropylene wiredrawing and its preparation method

A technology for filling master batch and polypropylene, applied in the field of master batch and its preparation, can solve the problems of reducing cost and excessive mechanical properties, and achieve the effect of reducing cost, improving low temperature resistance and excellent ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

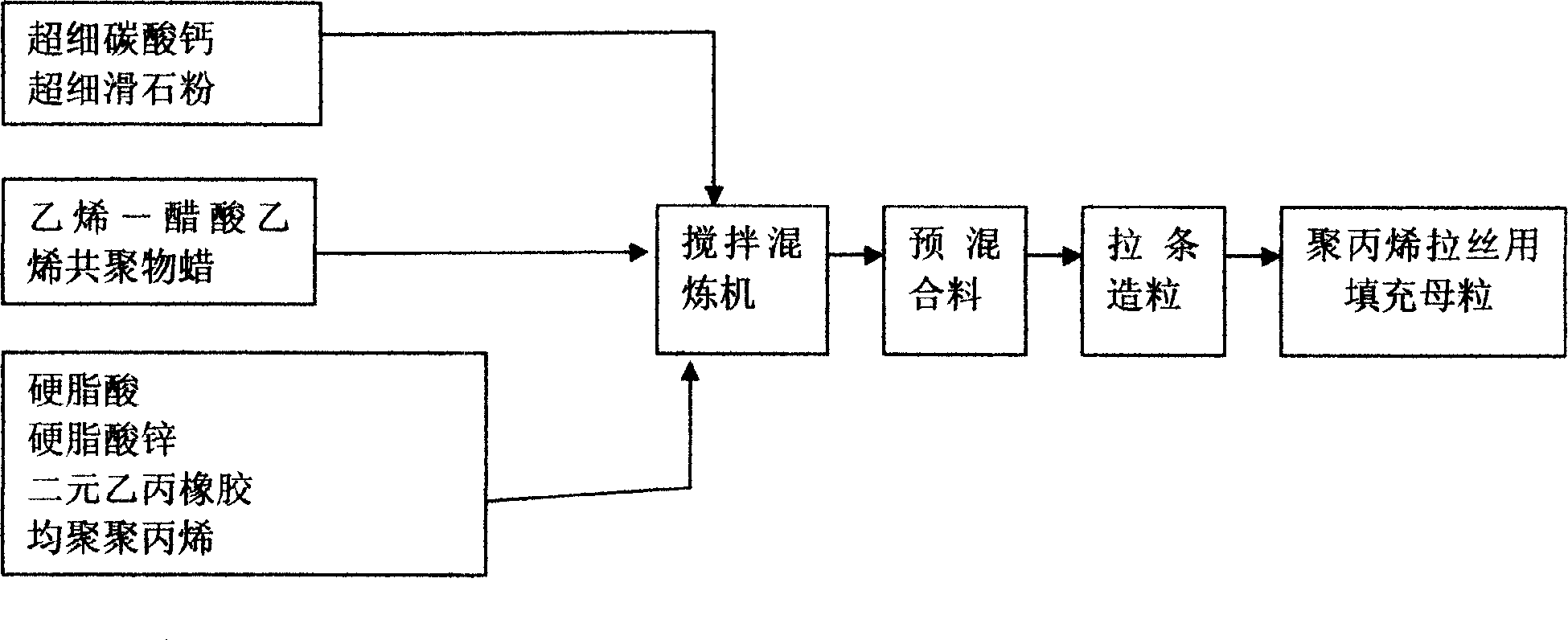

[0014] According to accompanying drawing, the selection of process circuit of the present invention:

[0015] There are mainly internal mixer method, reactor method and extruder granulation method to manufacture plastic masterbatch in the world today. According to the actual situation in China, the present invention selects twin-screw extruder granulation method. Its advantages are: easy processing, convenient management, high production efficiency, no pollution to the environment, etc.

[0016] The processing condition of filler masterbatch for polypropylene wire drawing of the present invention:

[0017] 1. Stirring mixer: heating range 0~200℃;

[0018] 2. Co-rotating twin-screw granulator; specification: φ75×36D

[0019] 1 heating

[0020] Screw speed: 5-120 rpm; granulator speed: 30-60 rpm; strand pelletizing.

[0021]

[0022]

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com