Patents

Literature

139results about How to "Comply with energy saving and emission reduction policy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

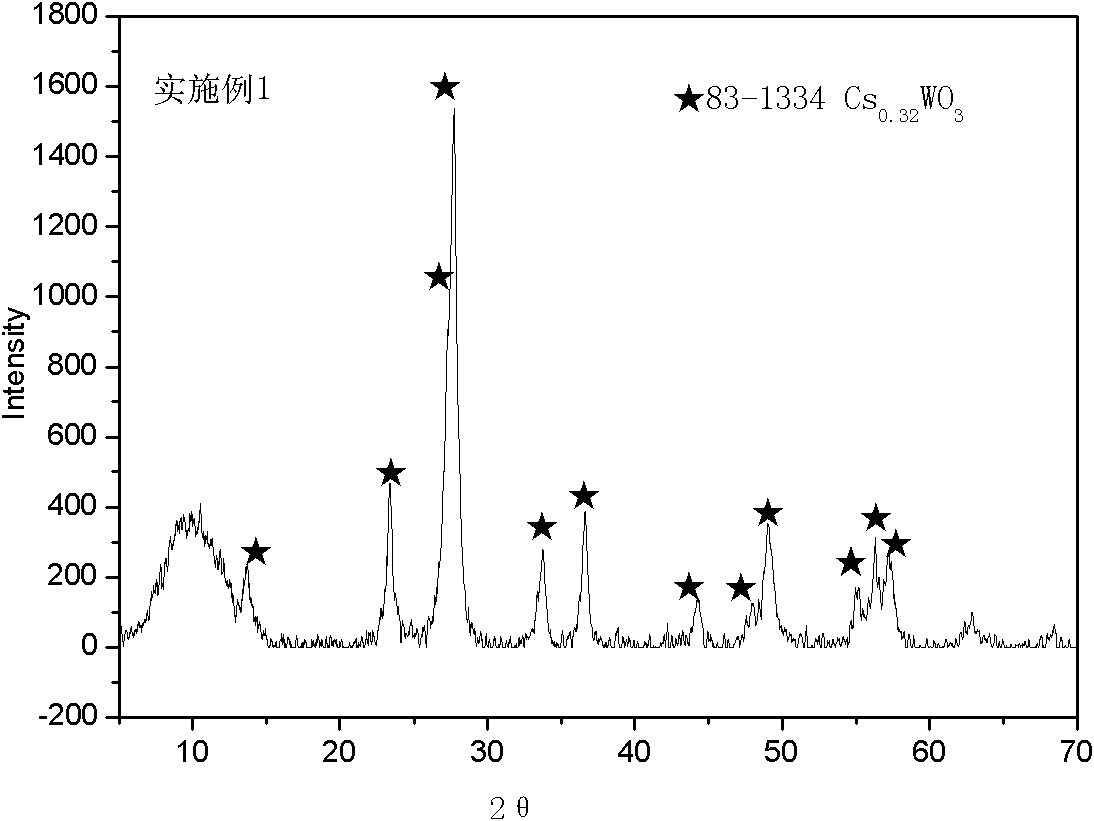

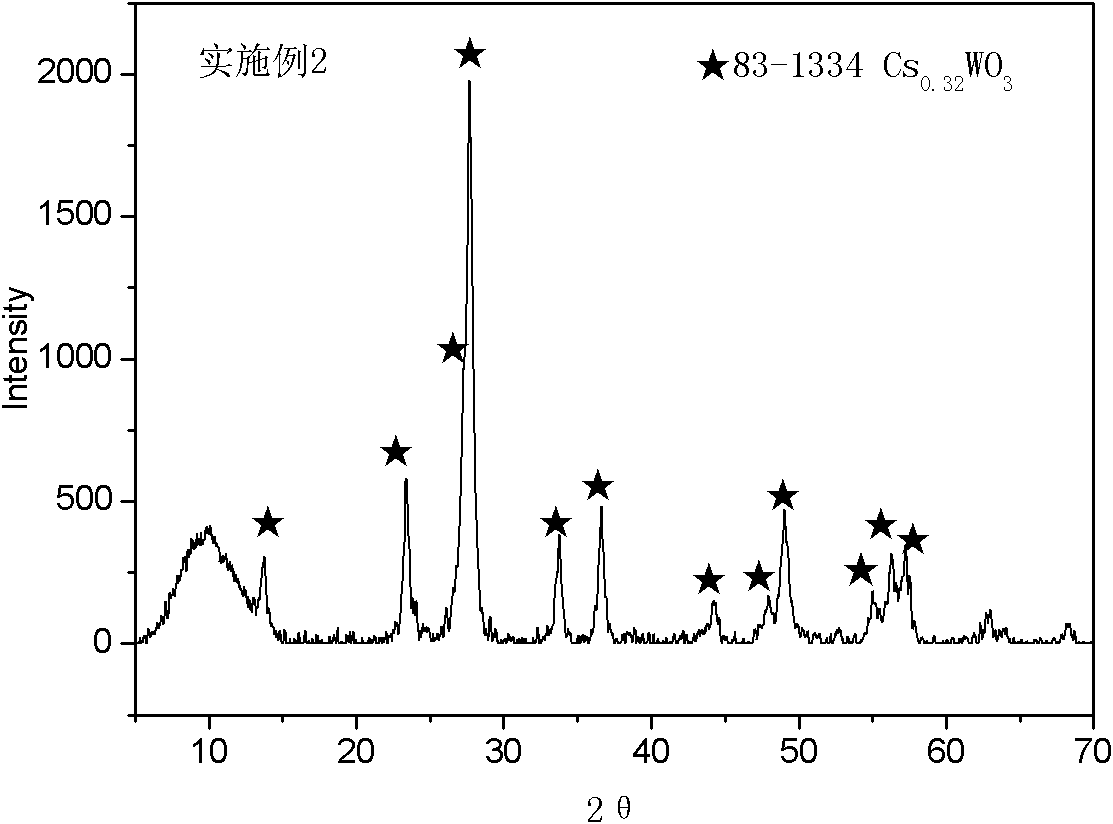

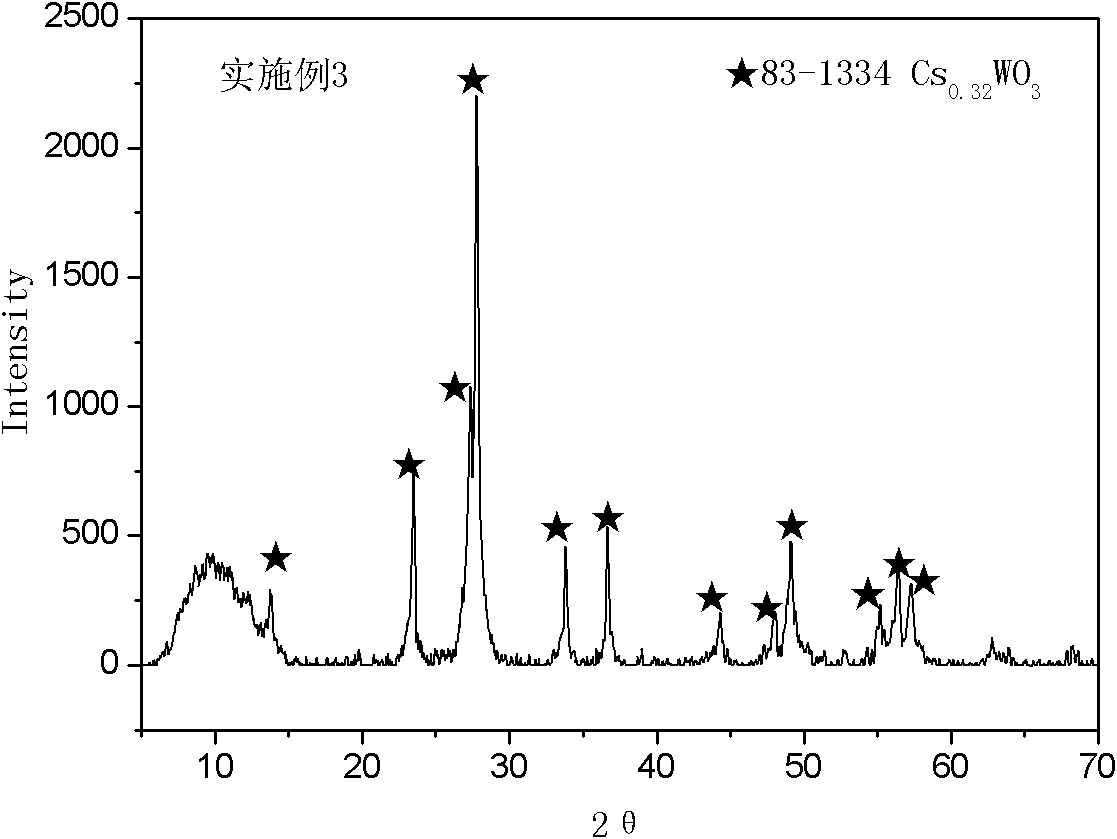

Cesium tungsten bronze powder and preparation method thereof

InactiveCN102320662AOptimal Control StructureReduce manufacturing costTungsten compoundsGranularitySolvent

The invention relates to cesium tungsten bronze powder and a preparation method thereof. The method comprises the following steps that: 1, precursor solution with tungstic acid, cesium carbonate and reducing substances is prepared according to a Cs / W mole ratio of 0.01 to 0.35 / 1, and the solvents are water or a mixture formed by ethanol and the water according to a volume ratio of 1 / 4 to 4 / 1; and 2, the precursor solution takes reaction for 1 to 3d under the condition of 180 to 200 DEG C in an autoclave, and the cesium tungsten bronze powder is obtained after the obtained precipitates are treated. The powder has the crystalline phase composition of Cs0.2WO3 or Cs0.32WO3, the size of the powder particle is 100 to 1300nm, and the specific surface area is 7 to 50m<2> / g. The synthetic process has the advantages that raw materials are cheap and mild, the operation is easy, the production cost can be reduced, in addition, the low-temperature (lower than or equal to 20 DEG C) synthesis is adopted, and the process is suitable for production and practical application. In addition, the product purposes are wide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for manufacturing once calcined glass ceramic brick

ActiveCN102390931AConcave-convex three-dimensional effect is obviousThe layout pattern is rich and realisticScreen printingBrick

The invention discloses a method for manufacturing a once calcined glass ceramic brick, which comprises the following steps: placing multicolor high-temperature clinkers in layers on a billet in proportion according to a stone-simulating effect; utilizing a roller having concave-convex patterns on the surface to roll or utilizing a screen printing plate to print a pigment clinker on the billet, thereby forming patterns; and then covering a transparent clinker; and lastly, once calcinating at a 1200-1230 DEG C high temperature. After a polishing and edging process is carried out, a glass ceramic brick which has a concave-convex stereoscopic effect and rich and vivid layout patterns is manufactured. According to the method, the glass ceramic brick is once calcined, thereby saving energy consumption. The industrial problem that the phenomena of contracted clinker and pinhole are obvious after once calcinating is carried out is solved. Compared with a traditional twice calcined glass ceramic compound brick, the glass ceramic brick manufactured according to the method provided by the invention has better abrasion resistance and stain resistance.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

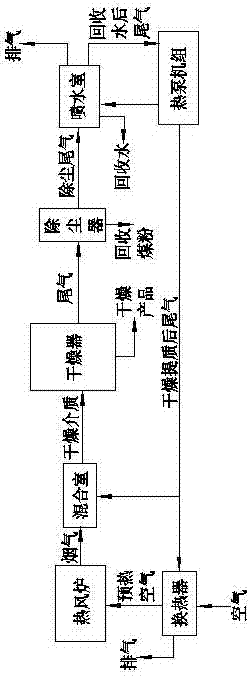

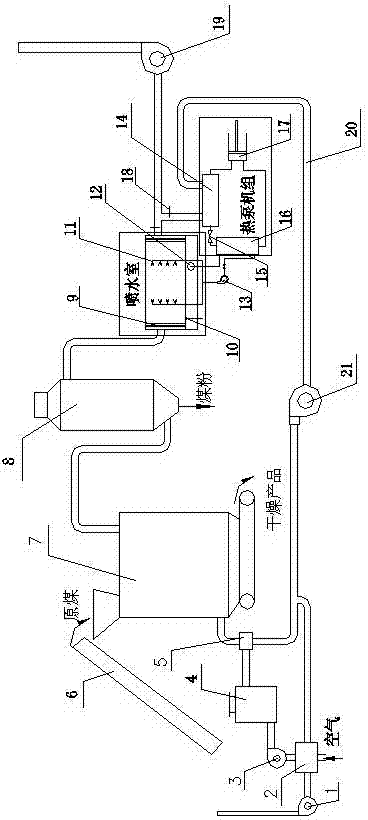

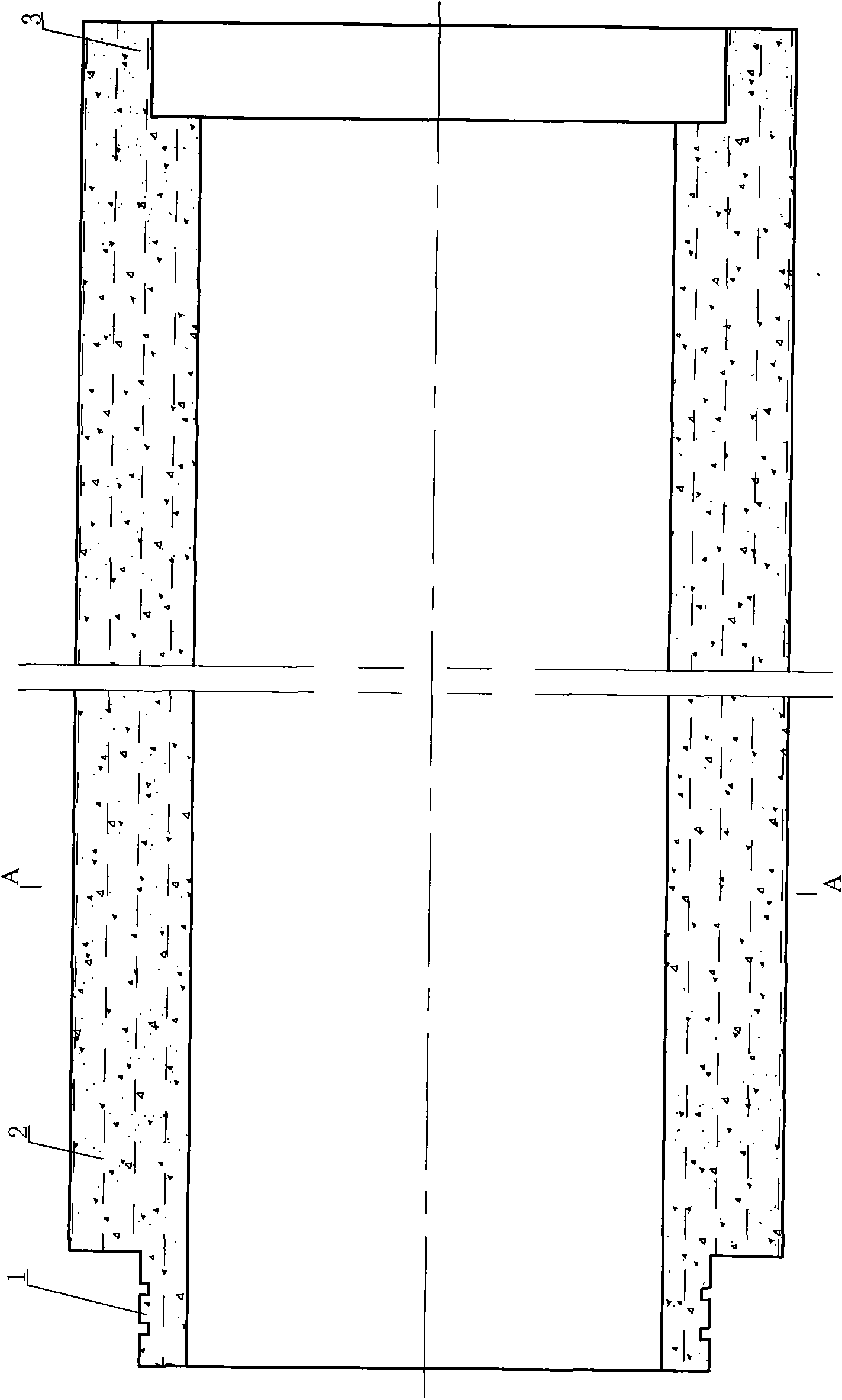

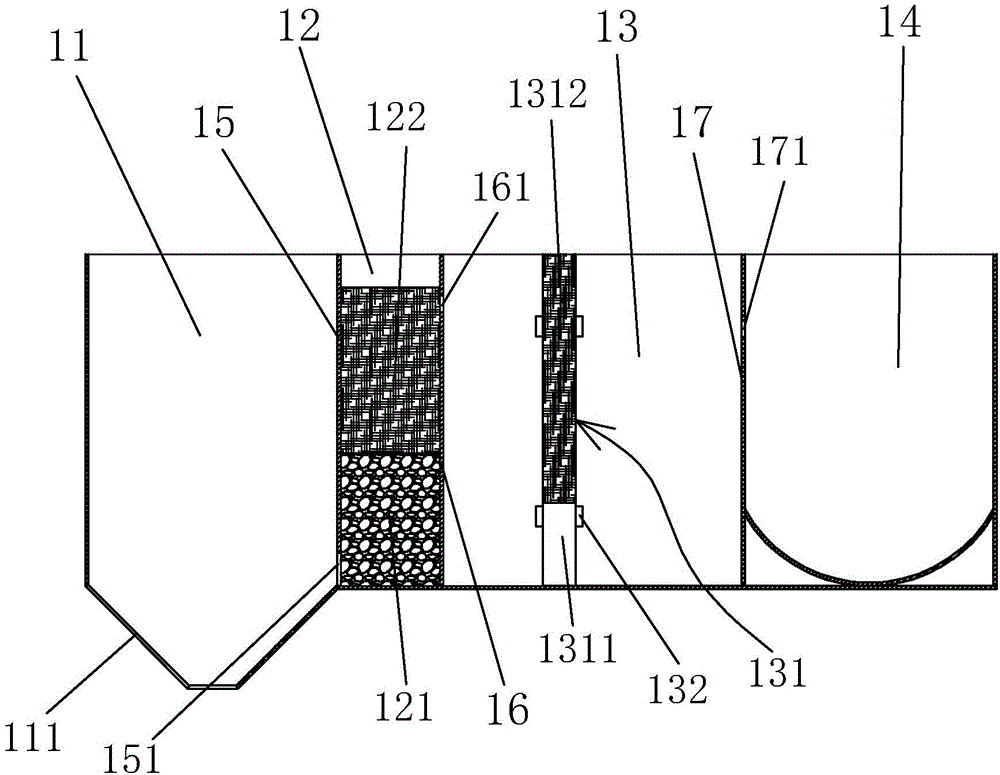

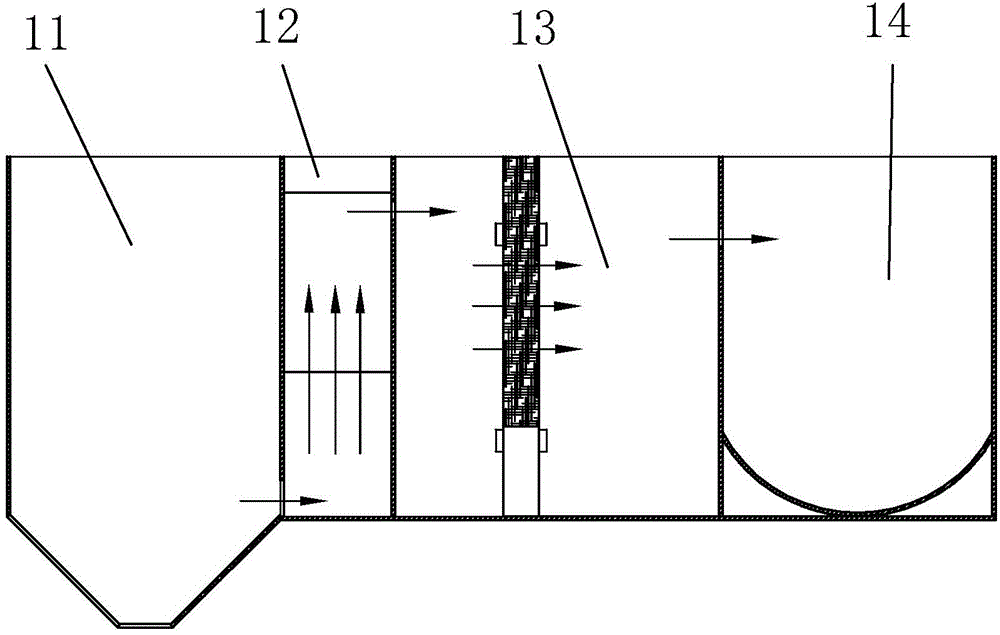

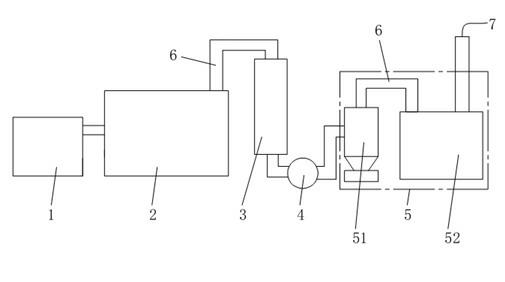

Lignite drying water recycling and drying tail gas recycling system

InactiveCN103575068AImprove recycling efficiencyPromote circulationDrying solid materials with heatDispersed particle filtrationWater useVolatiles

The invention relates to a lignite drying water recycling and drying tail gas recycling system which comprises a hot blast heater, a drier, a dry type deduster, a heat pump machine set, a mixing chamber and a water spraying chamber, wherein the mixing chamber is used for mixing fume of the hot blast heater and a recycled tail gas heated by the heat pump machine set into low-temperature hot fume to be used as a drying medium of the drier; the dried tail gas and the cold water sprayed out from a nozzle of the water spraying chamber are sufficiently mixed and subjected to heat-humidity exchange in the water spraying chamber; part of steam in the dried tail gas is condensed into water to be recycled; at the same time, visible heat and latent heat of vaporization are released; the cold water used in the water spraying chamber is supplied by the heat pump machine set; the water recycled in the water spraying chamber flows out through an overflowing tube and is collected. The fume discharged from the water spraying chamber is heated by an air cooling condenser of the heat pump machine set, is subsequently fed into the mixing chamber, is mixed with the fume generated from the hot blast furnace, and is subsequently used as the drying medium of the drier. The system is at a low temperature and is dry, and the oxygen content of the drying medium is low, so that volatiles in coal are prevented from being lost, and precious water resource is recycled.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

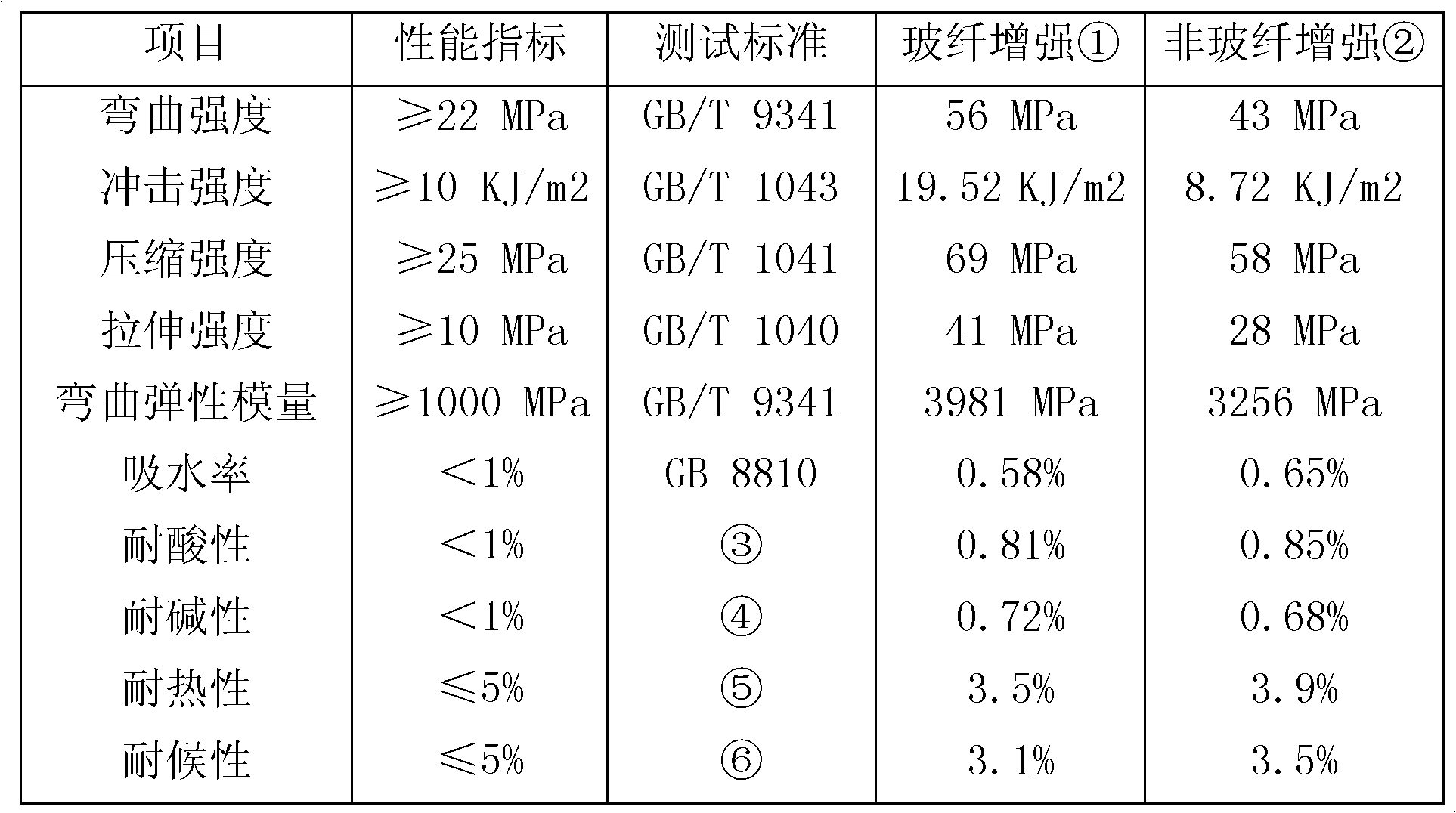

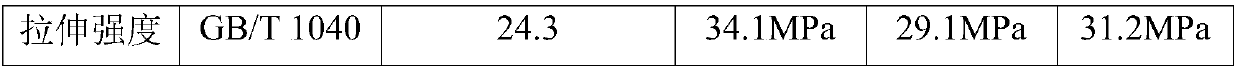

Recycled composite material for enhancing modified waste polypropylene by using waste printed circuit board powder/glass fiber and preparation method of recycled composite material

The invention discloses a recycled composite material for enhancing modified waste polypropylene by using a waste printed circuit board powder / glass fiber and a preparation method of the recycled composite material. The recycled composite material comprises the following raw materials in part by weight: 100 parts of waste polypropylene, 100-300 parts of waste printed circuit board powder, 5-15 parts of compatibilizer, 1-2 parts of antioxidant and 5-15 parts of alkali-free glass fiber. The preparation method comprises the following steps: mixing the waste polypropylene, the waste printed circuit board powder, the compatibilizer and the antioxidant according to a proportion; adding a blending material from a main feeding device of a double-screw extruder for smelting, wherein the rotating speed of a screw is 60 r / min; and adding the alkali-free glass fiber from a fourth processing area of the extruder according to a proportion and blending the alkali-free glass fiber with the smelt mixture; and carrying out extrusion, traction, cooling and particle dicing to obtain the recycled composite material of the modified waste polypropylene. According to the recycled material disclosed by the invention, the waste polypropylene can be effectively enhanced and toughened and the recycled composite material with excellent integrated performance is obtained; and in addition, the waste is fully utilized and energy economization and emission reduction are realized.

Owner:CHINA NAT ELECTRIC APP RES INST +1

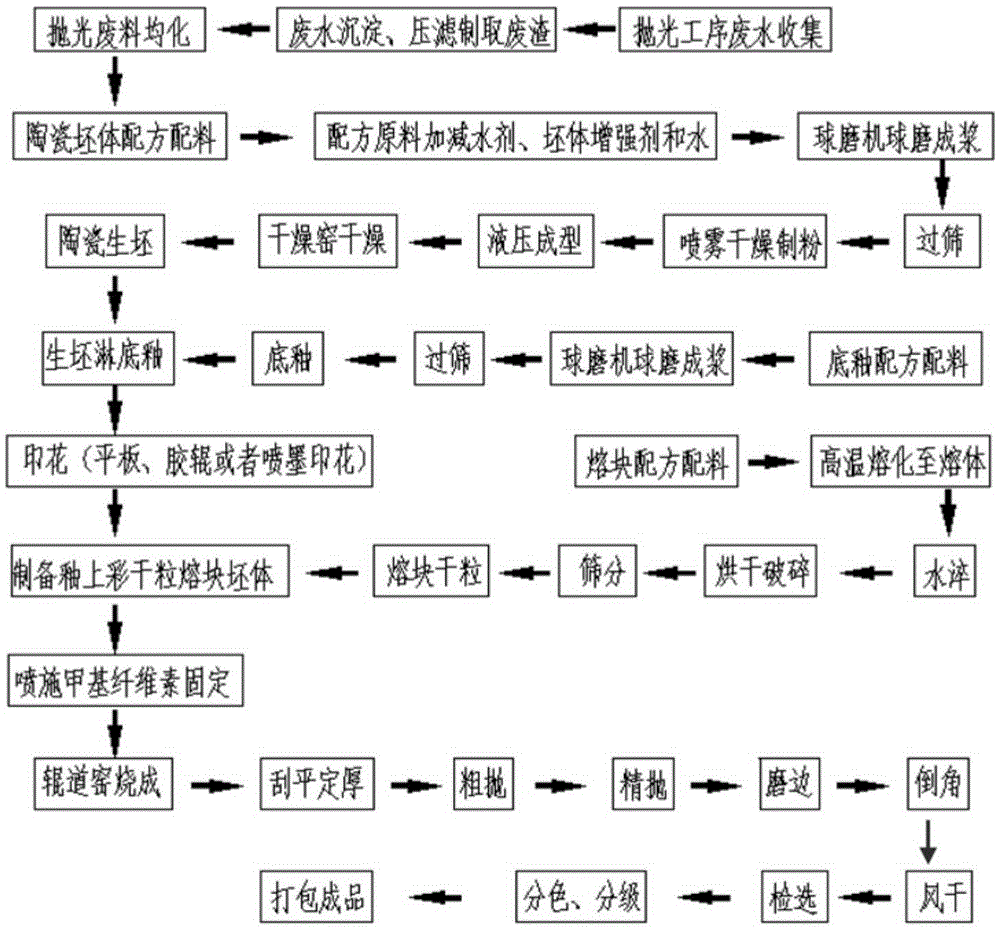

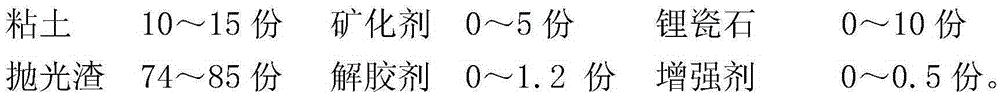

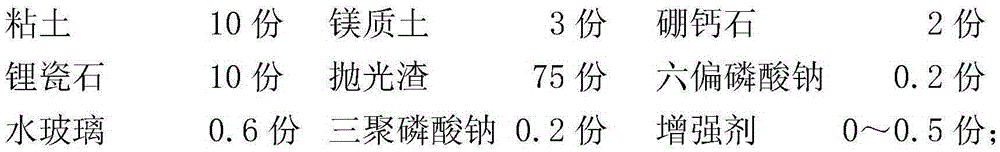

Single-fired glass ceramic composite brick and production method thereof

ActiveCN105272160AAvoid foamingAchieve recyclingCeramic materials productionClaywaresBrickChina stone

The invention relates to a single-fired glass ceramic composite brick and a production method. A blank of the ceramic brick is prepared from, by weight, 10-15 parts of clay, 0-5 parts of mineralizing agents, 0-10 parts of lithium china stones, 74-85 parts of tile-polished waste, 0-1.2 parts of peptizers and 0-0.5 part of reinforcing agents. The production method comprises the steps that the blank is processed through procedures of wet ball milling and spray drying and then processed through dry pressing to prepare a ceramic green blank; 2, the ceramic green blank is coated with a ground glaze after being dried and decorated through printing to form an overglazed color blank, and then microcrystalline glass frit dry grains are coated on the overglazed color blank to form a dry grain layer; 3, methylcellulose is sprayed and fixed on the surface of the dry grain layer, then the blank is put into a roller kiln to be fired, the firing temperature is set at 1000 DEG C-1048 DEG C, the firing time is set for 65-150 minutes, and a semi-finished product is prepared; 4, the semi-finished product out of the kiln is prepared into a finished produce after being processed through strickling for thickness fixation, rough polishing, fine polishing, edging, chamfering, air drying, inspecting and sorting, color separating and grading.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

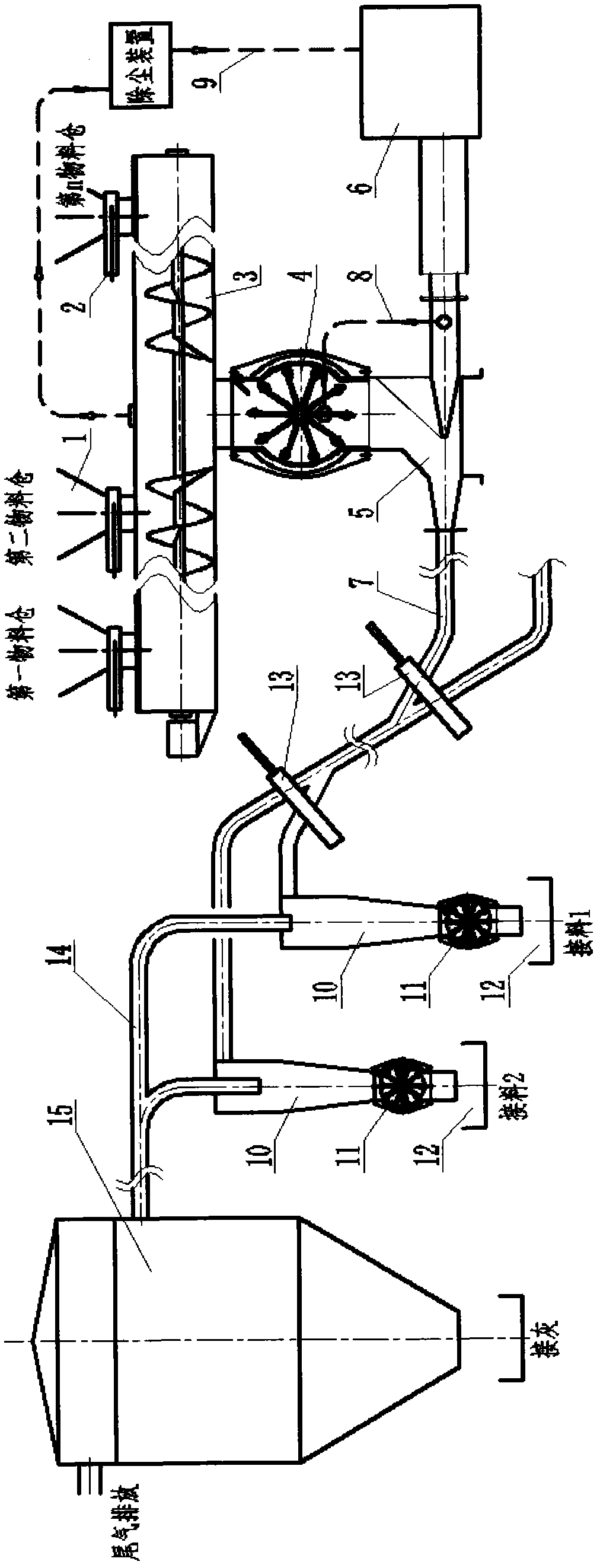

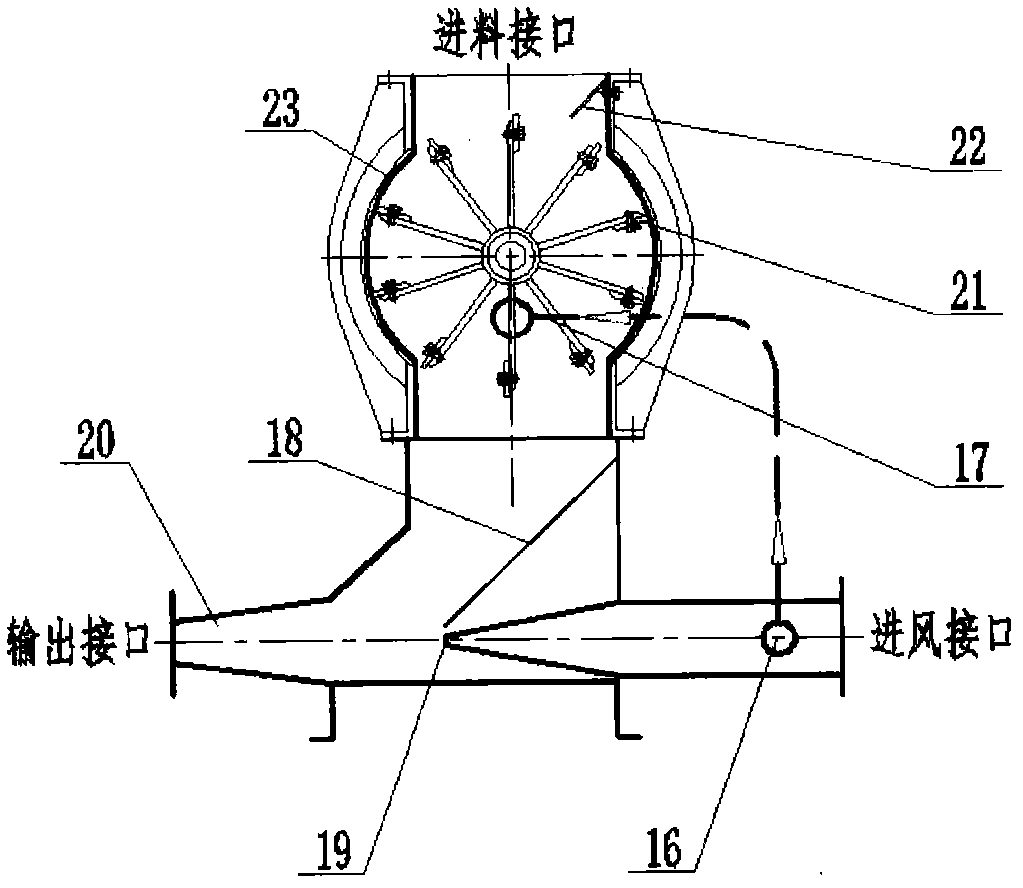

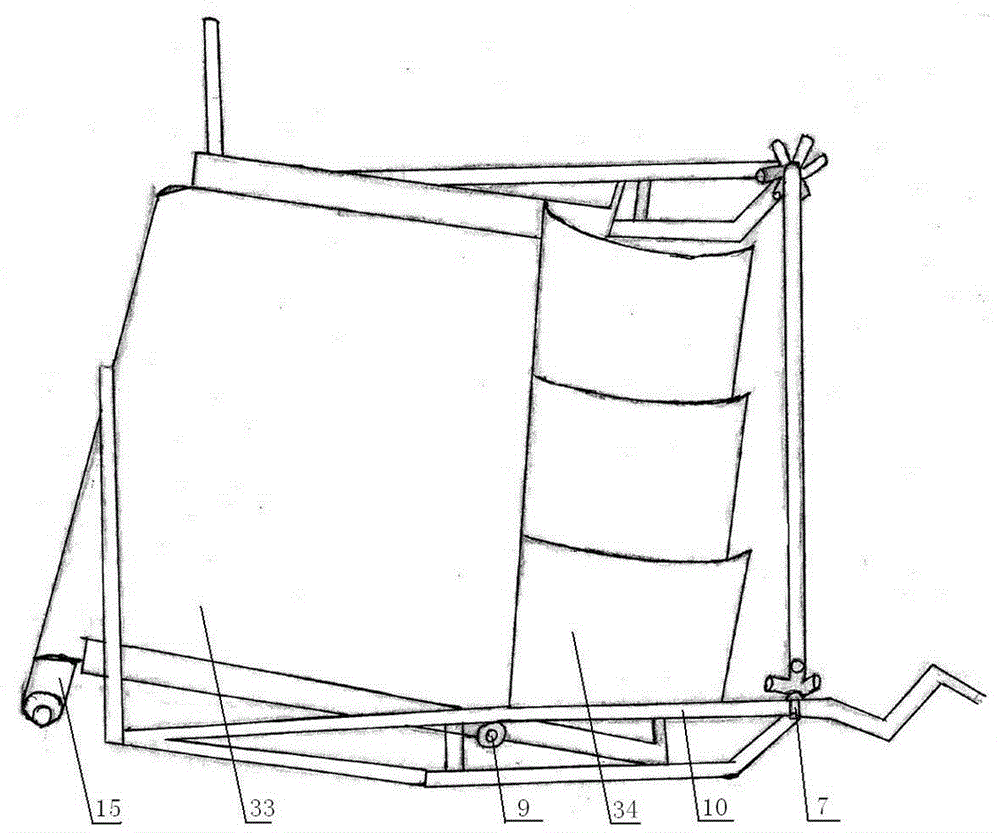

Biomass micro-positive-pressure pneumatic transmission system

InactiveCN103287857ASolve feeding difficultiesSmooth feedingBulk conveyorsHigh concentrationAutomatic control

The invention discloses a biomass micro-positive-pressure pneumatic transmission system which comprises a feeding system, a fan, a conveying pipeline system, a discharging system, a tail gas treatment system and an automatic control system, wherein the feeding system comprises a quantitative feeding device, a collecting device, a positive-pressure air sealing device, an accelerator, an air guide pipe and a return air treatment pipeline; the conveying pipeline system comprises a straight pipeline, a connecting flange and a plurality of quick-operating doors distributed on the pipeline as well as a transparent observation window. The biomass micro-positive-pressure pneumatic transmission system has the advantages that smooth feeding with higher concentration ratio can be achieved, the power consumption is low, the service life of the air sealing device is prolonged, the applicability and the pipeline durability of the conveying system are improved, the convenience is provided for pipeline smoothening and repairing, the environmental pollution can be avoided, and the automation level is high.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Wear-resisting alloy hammer head and preparation method thereof

InactiveCN106591715ASpeed up coolingUniform cooling rateFoundry mouldsFurnace typesEngineeringStructural engineering

The invention relates to a wear-resisting alloy hammer head and a preparation method thereof. The hammer head is characterized in that a strip-shaped gap is formed in the middle of an end part of the hammer head; the strip-shaped gap is as long as a hammer end and is 12-20 mm wide; and the depth of the strip-shaped gap is equal to the distance from the top of the hammer end to the bottom of the hammer end and is 25-30 mm. Since the end part of the hammer head is hollowed out in a thickness direction to form a 12-20 mm space, when the hammer head crushes materials, fine materials can easily pass through the space; and if large materials are embedded in the space, the effect that materials strike materials can be realized, and accordingly the crushing efficiency is improved. A wear-resisting high-Cr white cast iron piece can be embedded in the 12-20 mm space to form a composite hammer head, so that the service life of the wear-resisting alloy hammer head can be further prolonged.

Owner:YINGKOU LONGCHEN MINE VEHICLE MFG CO LTD

Production method for N35 lanthanum-cerium-neodymium-iron-boron magnet material

The invention discloses a production method for an N35 lanthanum-cerium-neodymium-iron-boron magnet material. The production method comprises the following steps of: weighing the following raw materials in percentage by weight: 15.0 percent of praseodymium-neodymium (Pr-Hd), 20.0 percent of lanthanum-cerium (La-Ce), 0.75 percent of niobium (Nb), 0.9 percent of aluminum (Al), 0.25 percent of copper (Cu), 1.15 percent of boron (B) and 61.95 percent of iron (Fe); filling the raw materials into a smelting furnace for smelting; fully fusing, standing and casting into an ingot; cooling with cooling water at the temperature of 30 DEG C for 40 minutes; sintering a formed block, namely sintering at the temperature of 1,120 DEG C for 3.5 hours, then sintering at the temperature of 920 DEG C for 2 hours and then sintering at the temperature of 565 DEG C for 3.5 hours; finally cooling to 60 DEG C to discharge; and detecting and warehousing qualified products. The lanthanum-cerium-neodymium-iron-boron magnet material reaches N35 level; the production cost is reduced; and the resource consumption is reduced.

Owner:孙允成

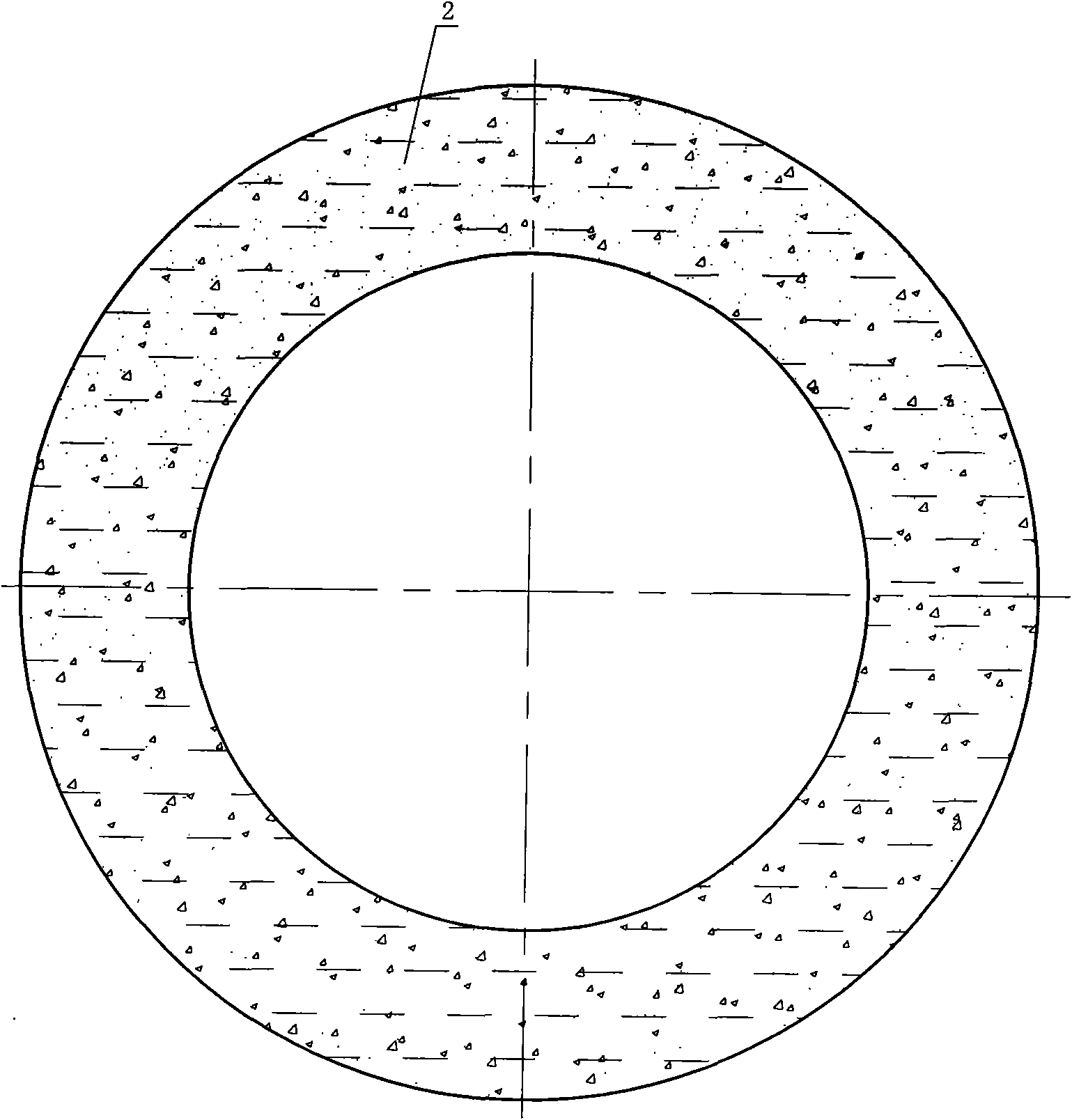

Mixed fiber concrete pipe

The invention relates to a mixed fiber concrete pipe, wherein mixed fiber concrete for forming the pipe comprises the following components according to the parts by weight: 322-540 parts of cement, 140-220 parts of water, 475-828 parts of sand, 864-1,306 parts of cobbles, 0.2-20 parts of polymer fibers and 20-140 parts of steel fibers. The mixed fiber concrete pipe has low raw material cost, light weight, high tensile strength, flexural strength, shearing strength and torsional strength, better durability and fatigue resistance, stronger capacities of shock resistance, abrasion resistance and cavitation resistance and better crack resistance, conforms to an energy saving and emission reduction policy and is a renewal product of the existing concrete pipes.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

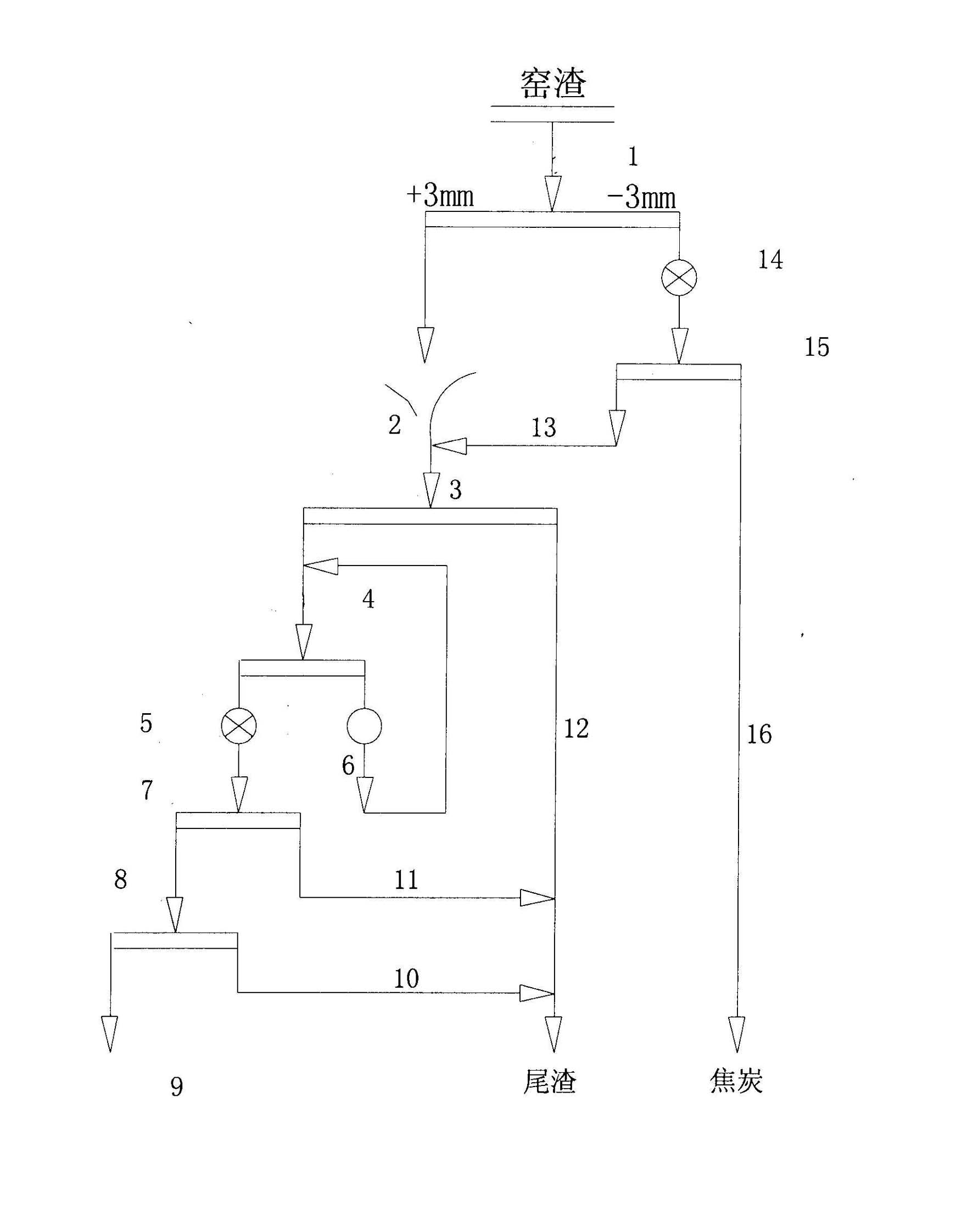

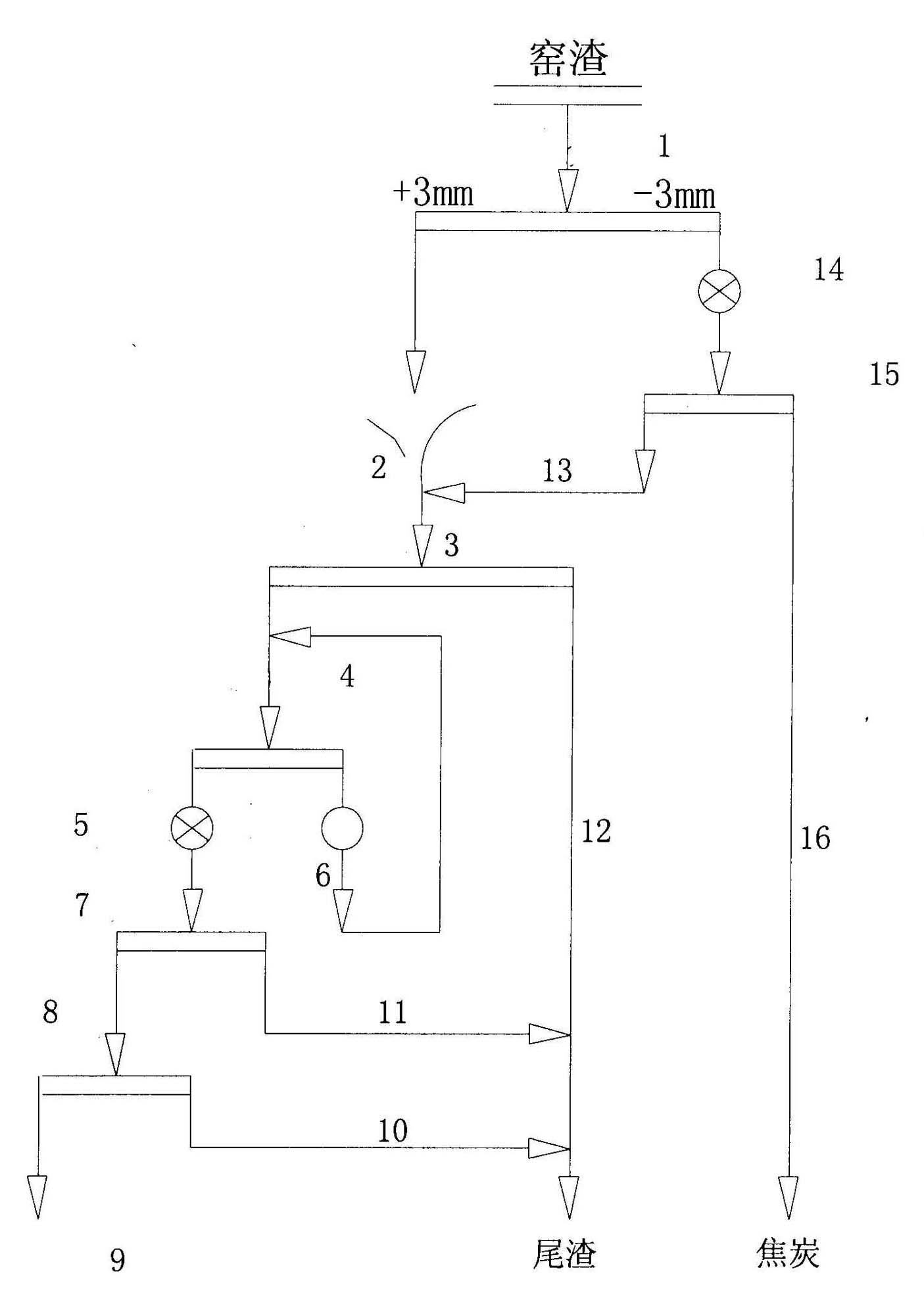

Process for magnetically separating and recovering iron and carbon from zinc volatilization kiln slag through dry method

InactiveCN102029223ASave waterReduce electricity consumptionSolid separationMechanical material recoverySlagZinc

The invention discloses a process for magnetically separating and recovering iron and carbon from zinc volatilization kiln slag through a dry method, which is characterized by comprising the following processes of: pre-grading before kiln slag separation, performing fine-grain microwave drying-gradient magnetic separation and carbon collection, and separating iron from coarse grains, wherein the process of separating iron from coarse grains comprises the steps of: performing two-stage crushing, performing primary pre-magnetic separation tailings-discarding, performing air classification-dry ball-milling, and performing microwave drying-secondary magnetic separation and cleaning. The method can improve the separating grade of the product, realizes resource recycling, and can be popularized to the field of separating materials with obvious magnetic difference and the like from solid wastes.

Owner:HENAN POLYTECHNIC UNIV

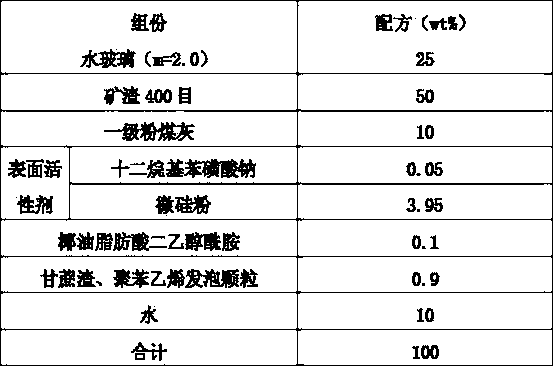

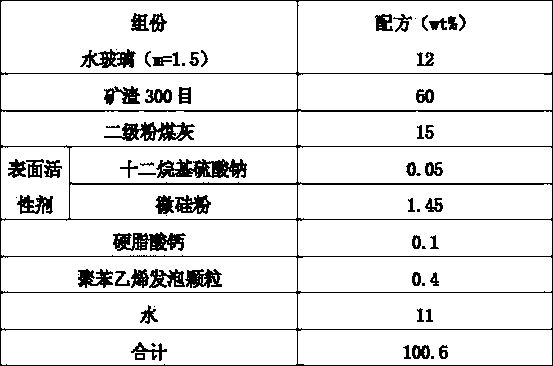

Sandwich layer used for making light partition wall batten

InactiveCN103482950ALow thermal conductivityReduce weightSolid waste managementSlagAdditional values

The invention discloses a sandwich layer used for making a light partition wall batten. The sandwich layer mainly comprises 12-35 parts of water glass, 45-60 parts of superfine slag powder, 1-15 parts of coal ash, 1.5-5.5 parts of surfactants, 0.02-0.1 part of foam stabilizer, 0.03-1 part of light packing and 10-20 parts of water. The invention further discloses a method for making the light partition wall batten through the sandwich layer. The method mainly includes the steps of evenly mixing raw materials, stirring, placing a model, grouting the model, carrying out maintenance and the like. The main raw materials of the sandwich layer are ground polymer, the ground polymer raw materials are rich in source and environmentally friendly, the light partition wall batten made through the sandwich layer made of the ground polymer is low in heat conductivity coefficient, light in weight, good in sound insulation and high in production efficiency, and the product is low in cost and high in additional value, can be planed, nailed and drilled, is convenient to install and construct and meets the national energy-saving and emission-reduction policy. After fiber reinforcement is carried out, the sandwich layer can be further used for making various GRC components.

Owner:刘海锋 +1

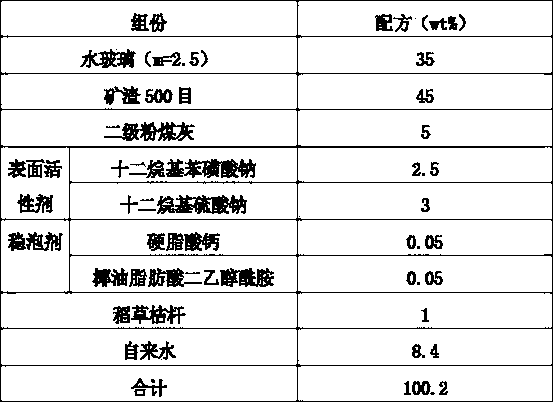

Smelting residue flash magnetizing roast comprehensive recycling technology

ActiveCN102912116ANo accumulationNo consequences of hot wind blowingProcess efficiency improvementEconomic benefitsMoisture

The invention belongs to the metallurgical industry, and particularly relates to a smelting residue flash magnetizing roast comprehensive recycling technology. The technology is realized as follows: drying and thrashing smelting residues to obtain a powdery material with the moisture content not more than 3% and the particle size of -0.074 not less than 80%; preheating the powdery material and then roasting in a magnetized roaster at the temperature of 750-780 degree C; separating gas from solid and cooling; grinding, grading and concentrating roasted ore; all-sliming cyanidation leaching gold and silver; recycling gold and silver through carbon absorption to obtain gold and silver active carbon; and cyaniding tailings and performing magnetic separation to obtain iron ore concentrate. The technology disclosed by the invention can solve problems about treatment of gold, silver and iron smelting residues, not only can comprehensively recycle gold, silver and iron, but also can reduce pollution of the smelting residues to the environment, as a result, the waste is turned into the wealth, the national policy of energy conservation and emission reduction is met, certain economic benefits are created for an enterprise, and the pollution to the environment is reduced.

Owner:河南黄金产业技术研究院有限公司

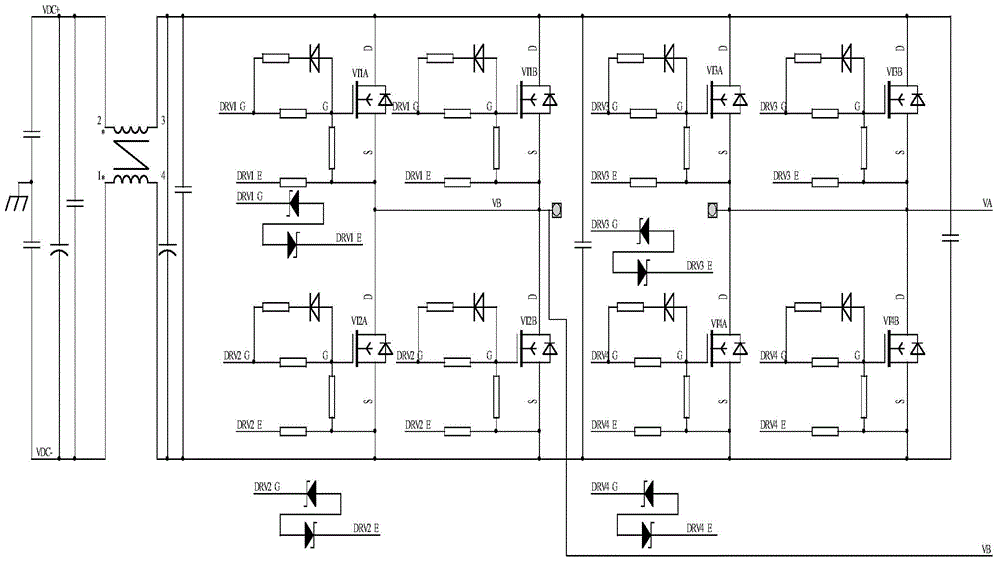

Storage battery activation grid-connected discharging device

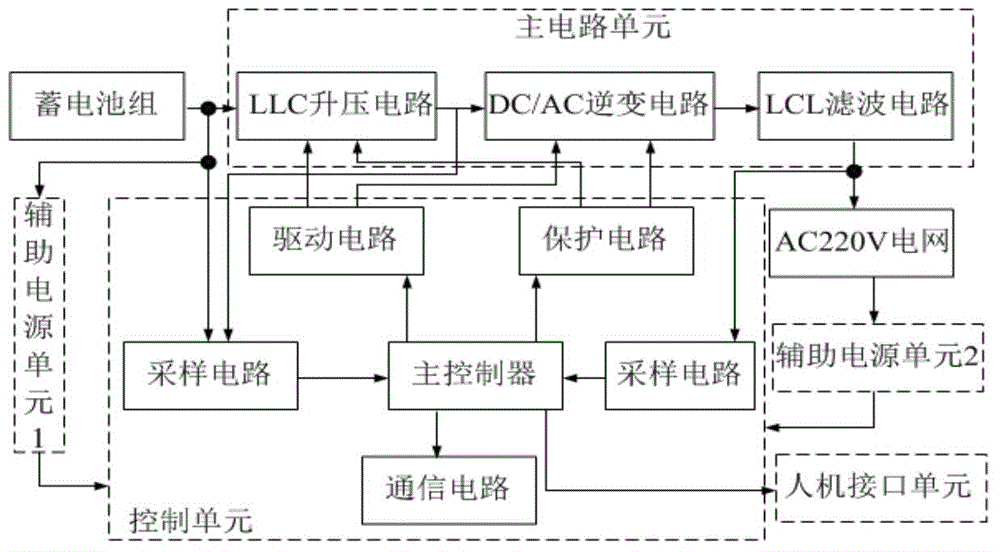

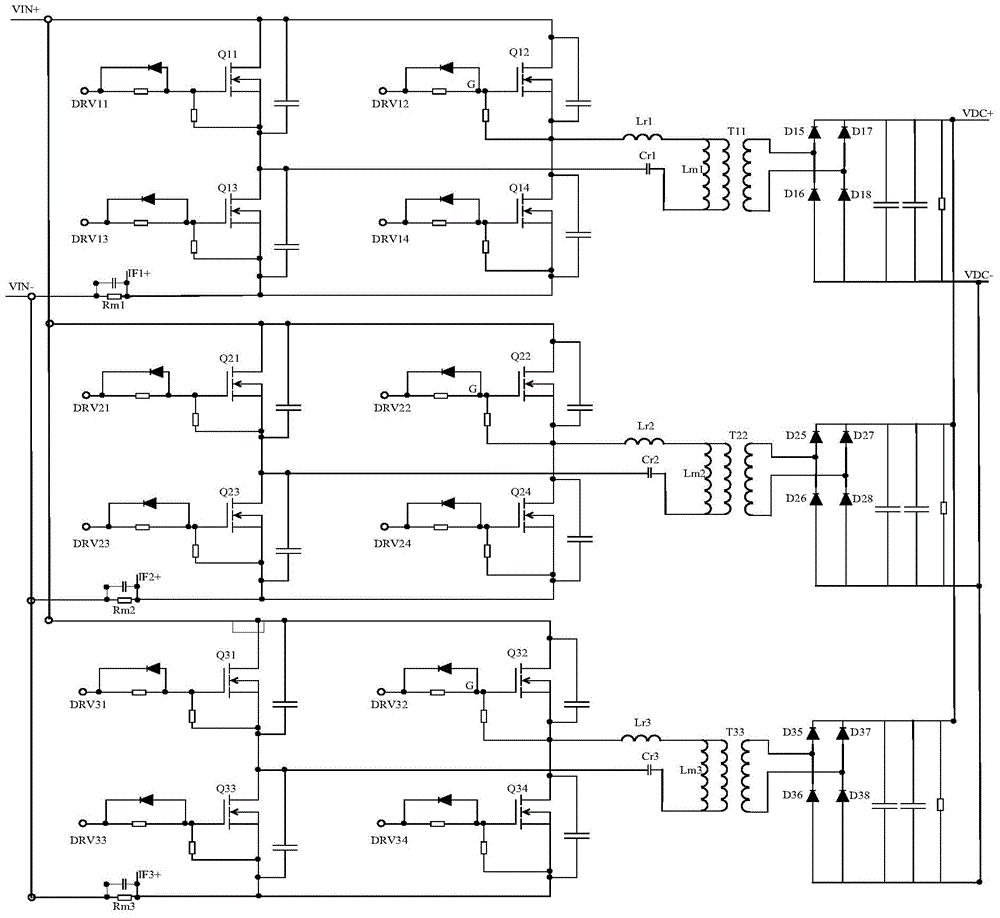

ActiveCN104600775AReduce lossesComply with energy saving and emission reduction policySingle network parallel feeding arrangementsElectric powerDriver circuitControl manner

The invention relates to a storage battery activation grid-connected discharging device which comprises a main circuit unit and a control unit. The main circuit unit comprises a booster circuit, an inverter circuit and a filter circuit which are sequentially connected, a storage battery is connected with an input end of the booster circuit, an output end of the filter circuit is connected with a power grid, the control unit comprises a controller and a driving circuit, the controller is connected with the driving circuit in a controlling manner, and the driving circuit is used for driving power tubes in the booster circuit and the inverter circuit. By the aid of the booster circuit, the inverter circuit and the filter circuit, electric energy of the storage battery is fed back to the power grid, a traditional heating discharging method is replaced, energy loss is greatly decreased, and the national policy of energy conservation and emission reduction is met.

Owner:XJ ELECTRIC +1

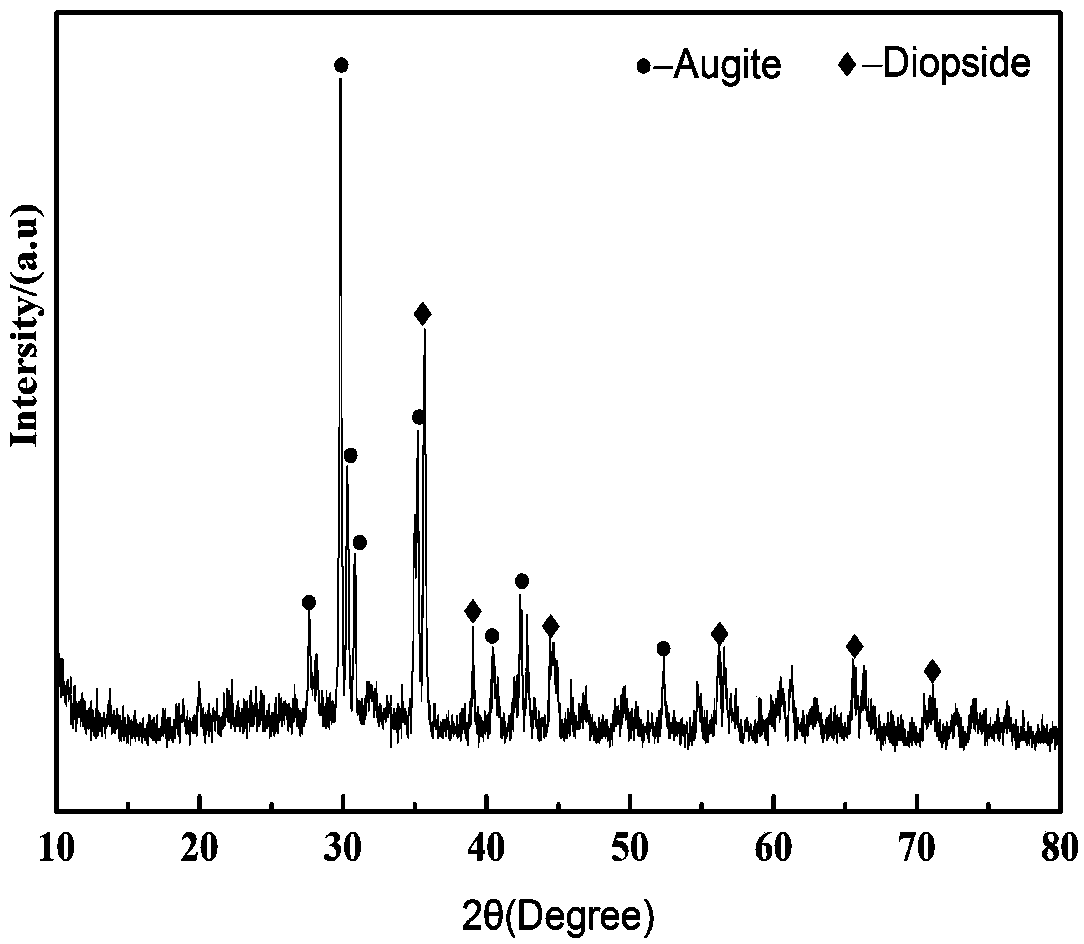

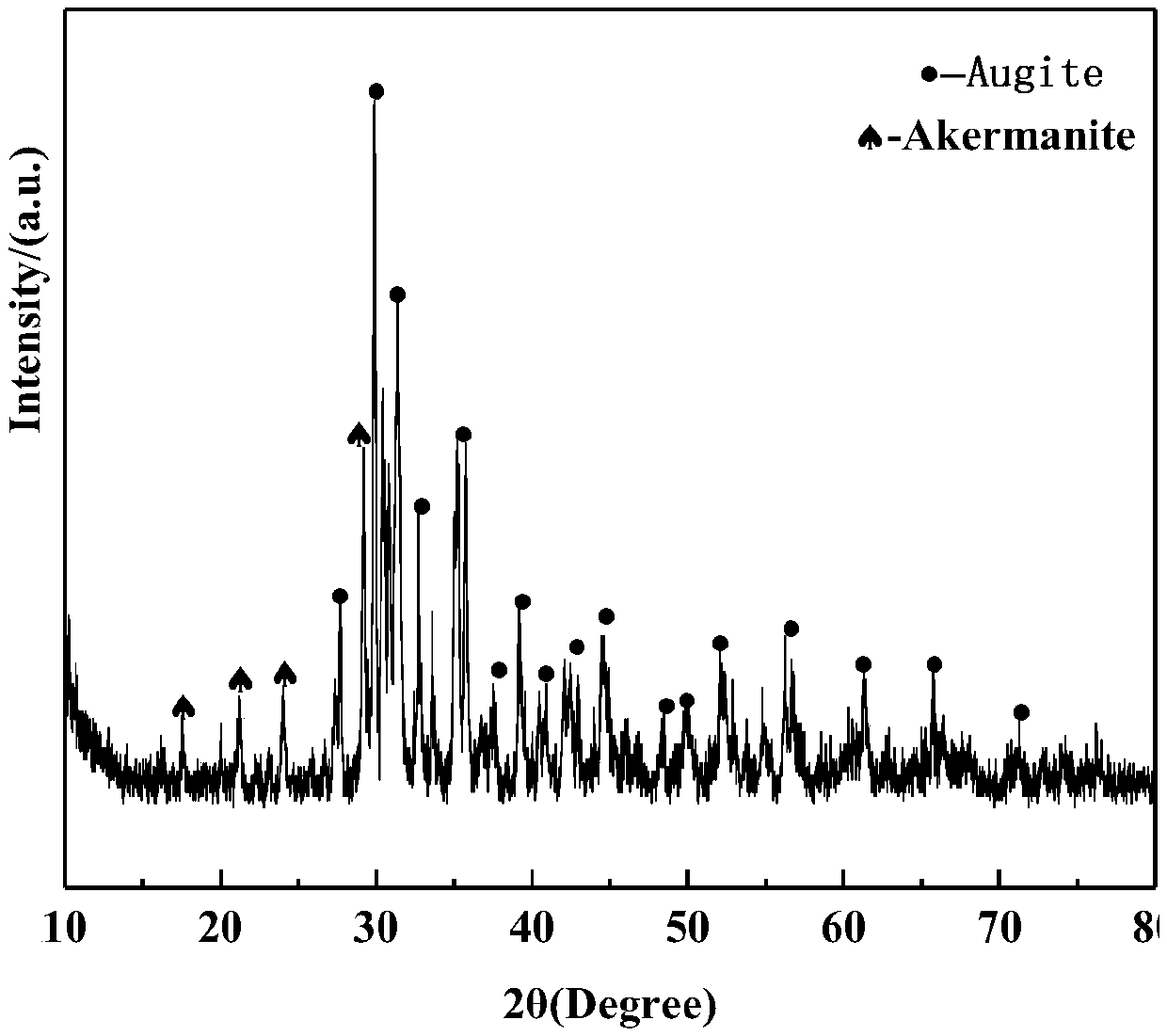

Method for preparing foamed ceramic by microwave sintering of cobalt smelting waste slag

InactiveCN109553393AMass consumptionSolve environmental problemsCeramic materials productionCeramicwareHigh energySlag

The invention belongs to the technical field of resource utilization of solid wastes, and particularly relates to a method for resource utilization of cobalt smelting waste slag. The invention provides the method for preparing foamed ceramic by microwave sintering of the cobalt smelting waste slag. The method comprises the following steps: carrying out proportioning by using the cobalt smelting waste slag, filler, a liquid phase agent, a plasticizer and a foaming agent, carrying out grinding, mixing, granulating, and mold pressing or mold powder accumulation to prepare a green body; and carrying out microwave sintering to prepare the foamed ceramic. The microwave heating method is adopted, and compared with a conventional electric heating or fuel heating mode, the microwave heating methodhas the advantages that the foaming temperature is greatly reduced, the foaming time is shortened, and therefore energy consumption is greatly reduced. According to the method, the problems of high energy consumption in existing formed ceramic industry and high additional value comprehensive utilization of the cobalt smelting waste slag are solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

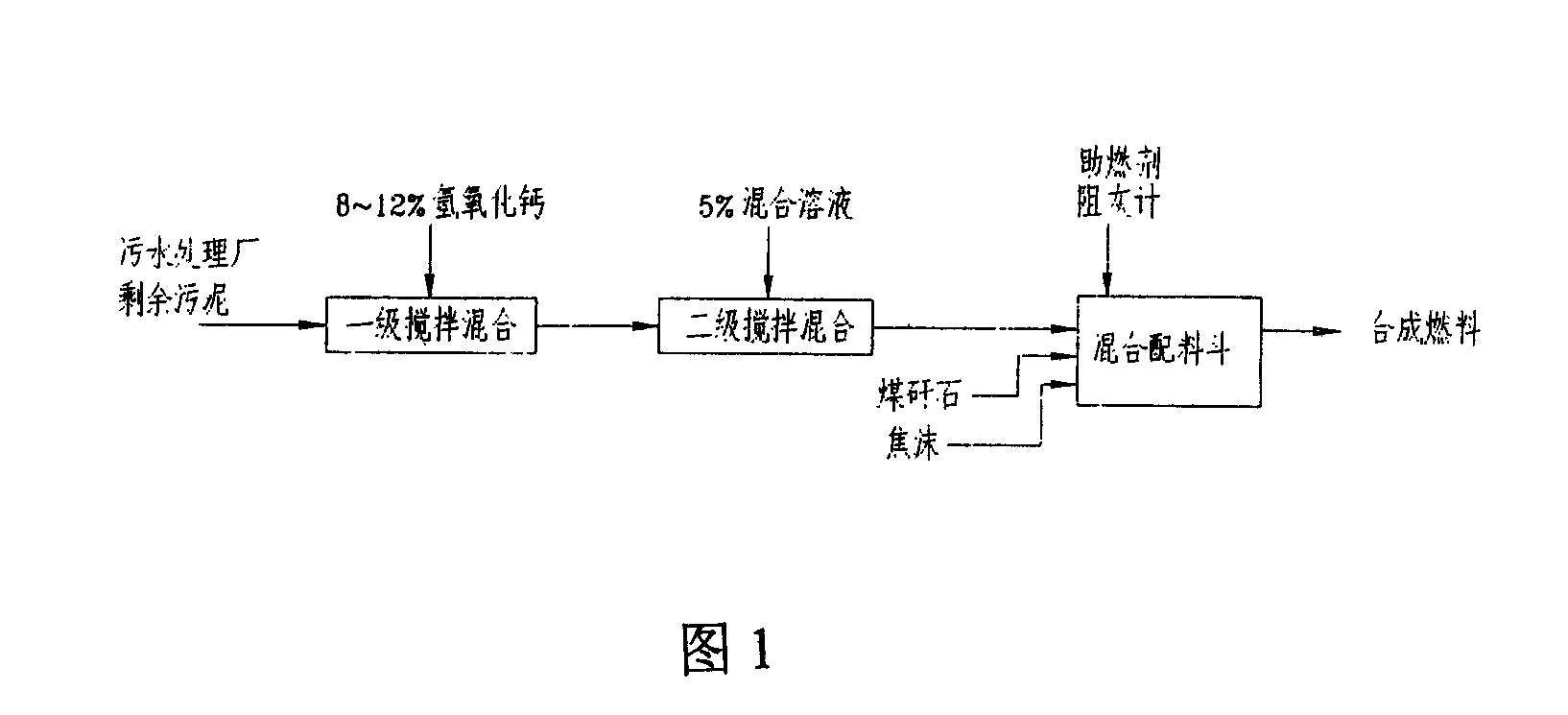

Technique for producing synthetic fuel by sludge of municipal sewage plant

InactiveCN101250456ARealize harmless disposalRealize resourcesBiofuelsSolid fuelsDeodorantWastewater

The invention relates to a technological method which utilizes sludge from wastewater treatment plant to prepare synthetic fuel, which comprises the following steps: firstly, feeding sludge whose water content is 80% after being dewatered by a municipal wastewater treatment plant into a stable stirring tank, adding CaO which is 8-12% of the amount of sludge, stirring for 10 minutes, lowering water content to 65%, feeding sludge whose water content is lowered to 65% into a deodorant stirring tank, adding Fe2(SO4), FeSO4(NH4)SO4.6H2O, CuSO4, CO(NH2)2 and water to prepare mixed solution which is 5%, stirring and mixing for 5 minutes, leading sludge to be totally loosed and stable to be end product sludge, feeding 30-40% end product sludge, 40-50% coke foam and 20% coal gangue into an automatic batch hopper, simultaneously adding 0.05-0.1g Fe2O3, stirring, mixing for 5 minutes, and preparing synthetic fuel. The invention achieves innocent treatment and resource treatment of sludge, and achieves comprehensive utilization of coal making industry.

Owner:刘志刚 +1

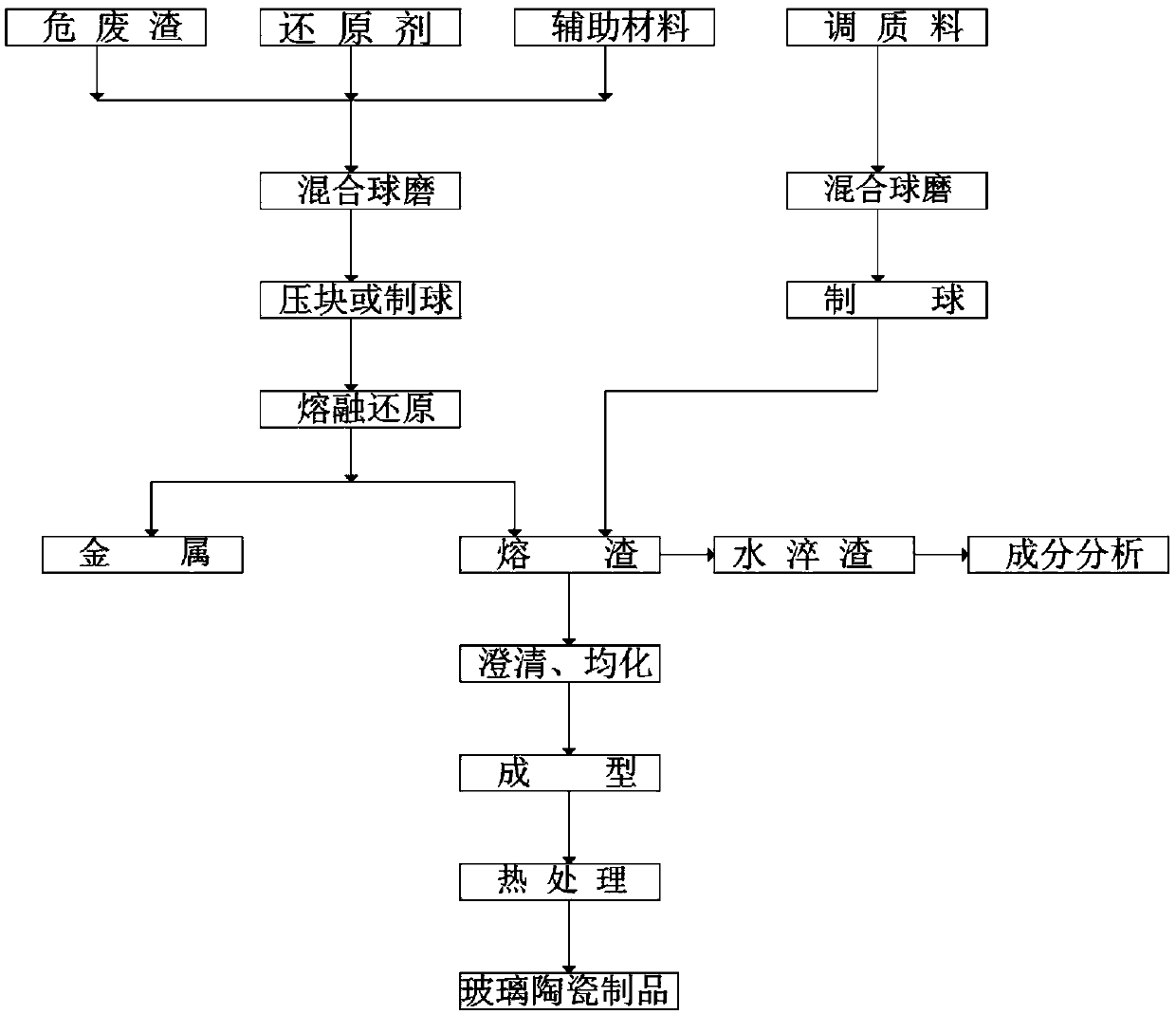

Method for preparing glass ceramic from waste residues related to severe hazards

The invention provides a method for preparing glass ceramic from waste residues related to severe hazards. The high-entropy glass ceramic can be prepared by the aid of the method at a low cost in an environment-friendly manner. The method has the advantages that the problem of high energy consumption in high-entropy glass ceramic production procedures can be pertinently solved by the aid of the method; hot melt residues at the temperatures higher than 1100 DEG C are utilized, heat supplementing, quenching and tempering are carried out by the aid of residue melting furnaces, accordingly, the high-entropy glass ceramic can be produced by the aid of the method, energy consumption can be reduced to a great extent, the method conforms to the current national energy conservation and emission reduction policy and is important technical innovation for production in the national hazardous waste industry, and the hazardous waste recycling and reusing additional values can be sufficiently maximized; diversified trace heavy metal elements in the hazardous waste residues which are subjected to high-temperature melting-reduction treatment are excellent nucleating agents, accordingly, the anticorrosion and abrasion-resistant high-entropy glass ceramic which is high in strength and hardness and excellent in high-temperature heat stability can be prepared without optional additional nucleatingagents in tests, the manufacturing cost of the glass ceramic further can be reduced, and the method is extremely high in market competitiveness.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

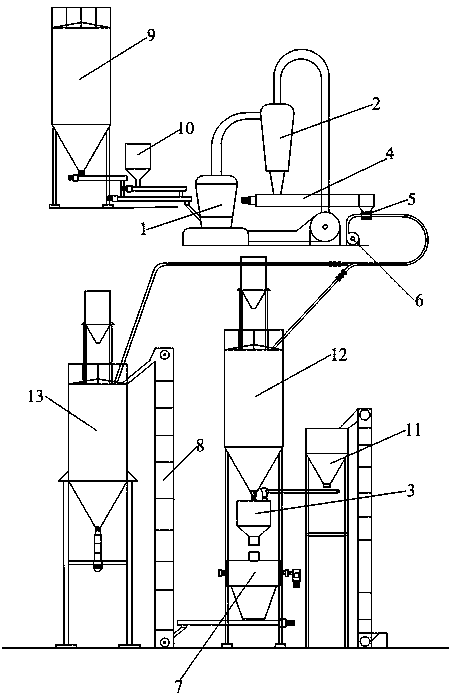

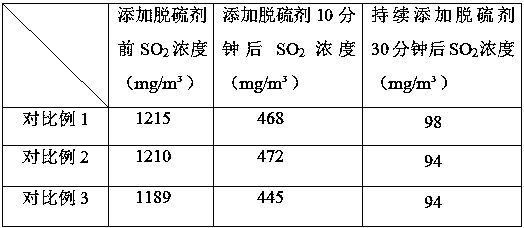

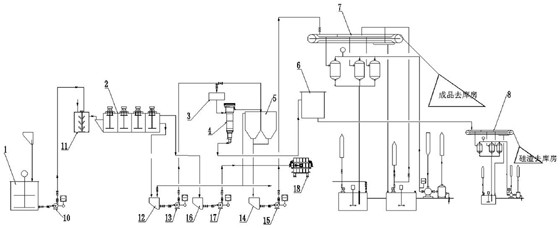

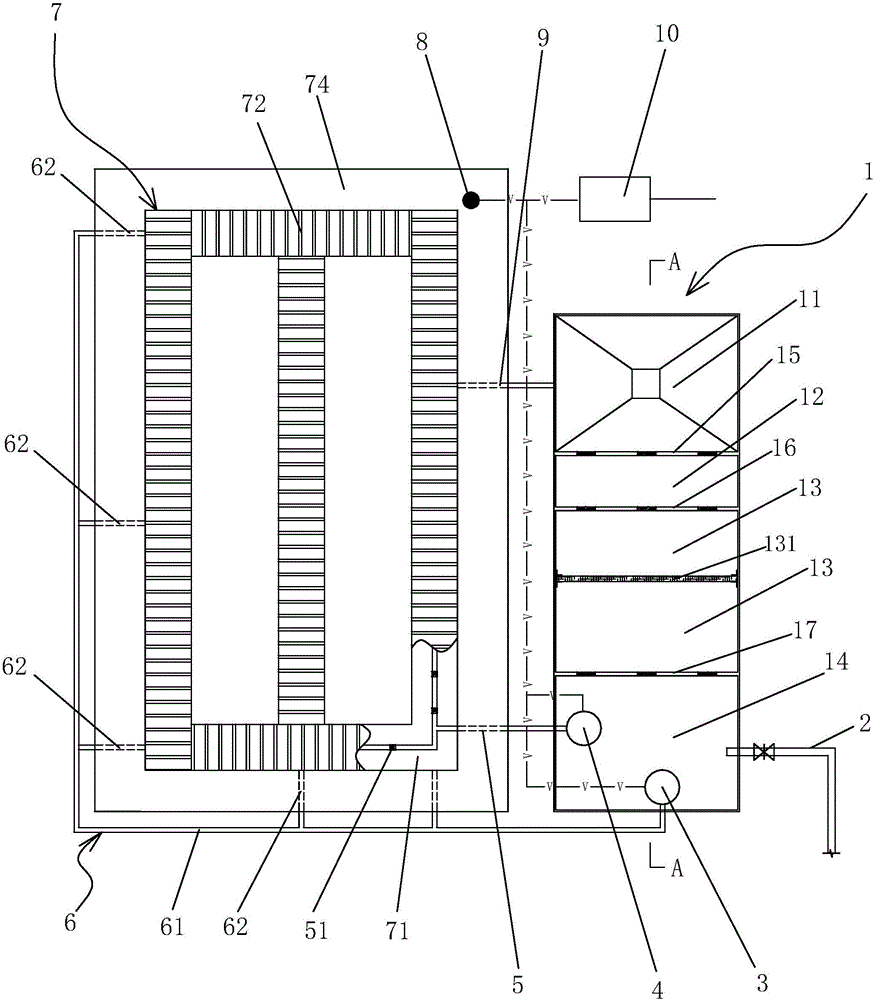

Dry desulfurization agent production process and system

InactiveCN110605014AAvoid product qualityImprove desulfurization efficiencyGas treatmentDispersed particle separationWork in processPollution

The invention discloses dry desulfurization agent production process and system. A calcium-based material, a reducing agent, a catalyst and an auxiliary agent are mainly used as raw materials; a milland a mixing and stirring main machine are the main components of the system. The preparation method comprises the following steps: feeding a calcium-based material, a catalyst and an auxiliary agentinto a mill for grinding to obtain a semi-finished product; feeding the semi-finished product and a reducing agent into a mixing and stirring main machine for mixing and stirring the components, thereby obtaining the dry desulfurization agent. By means of the process and system, the problems that in the prior art, a dry desulfurization agent production method is complex; the technical problems ofunstable blanking, insufficient reaction, influence on the desulfurization efficiency and the product quality and the like of the existing dry desulfurization agent are solved; moreover, the high-stability desulfurization and denitrification absorbent can be produced, the desulfurization efficiency is high, secondary pollution is avoided, the production process is simple, and the operability is high.

Owner:JIAHUA SPECIAL CEMENT

Hot pressing-free discharge printing technology of denim fabric

InactiveCN102400400AReduce governanceReduce loadBiochemical fibre treatmentDry-cleaning apparatus for textilesAdditional valuesMechanical engineering

The invention relates to a hot pressing-free discharge printing technology of a denim fabric. The hot pressing-free discharge printing technology of a denim fabric comprises the following steps of carrying out printing pretreatment on denim clothes, carrying out printing by a white discharge sizing agent, drying in an oven, carrying out alkali discharge treatment, washing by hot water and liquid soap, washing by water and drying in the oven. The hot pressing-free discharge printing technology of a denim fabric is simple, realizes quality stabilization, saves energy, accords with a national energy saving and emission reduction policy, and improves levels and additional values of denim clothes.

Owner:CHANGSHU YALAN GARMENTS

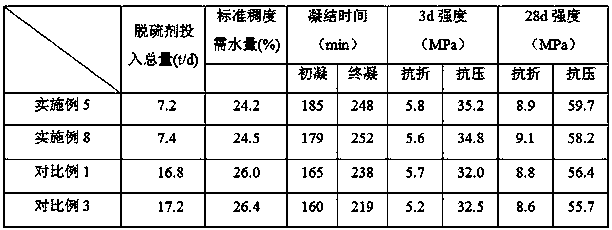

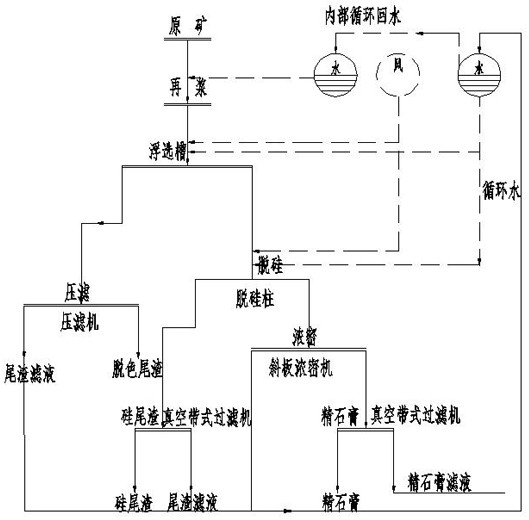

Method for purifying byproduct phosphogypsum of wet-process phosphoric acid

The invention relates to a method for purifying byproduct phosphogypsum of wet-process phosphoric acid, which comprises the following steps of S1, flotation tank decolorization: adding water into byproduct phosphogypsum in the phosphoric acid process to regulate ore pulp, proportionally adding a decolorization reagent, and overflowing to enter a flotation tank, S2, jigging reselection column desilicication: supplementing water to the decolorized ardealite concentrate pulp obtained in the step S1, pumping the decolorized ardealite concentrate pulp into a desilicication reselection column for jigging classification, and filtering the silicon tailing pulp in a belt filter to obtain silicon tailings, and feeding top overflow concentrate pulp for thickening and filtering, S3, filtering, washing and dephosphorizing: pumping the desiliconized ardealite concentrate pulp obtained in the S2 into an inclined plate thickener for thickening and dewatering, obtaining ardealite concentrate pulp through underflow, then pumping the ardealite concentrate pulp into a belt filter for filtering, and discharging a washed filter cake into a warehouse, so as to obtain a refined ardealite product. The method is suitable for a large-scale industrial device, can realize continuous, stable and reliable production, has strong adaptability to the byproduct phosphogypsum, and is especially suitable for the byproduct phosphogypsum of a phosphoric acid device using low-quality phosphate ore at present.

Owner:HUBEI XINYANGFENG NEW BUILDING MATERIAL TECH CO LTD

Environment-friendly and energy-saving assembling type automatic car washing equipment in building site

InactiveCN104309585AImprove car wash efficiencySave labor costsCleaning apparatus for vehicle exteriorsWater filterWater resources

The invention relates to environment-friendly and energy-saving assembling type automatic car washing equipment in a building site. The automatic car washing equipment comprises a water pond, a car washing pump, a mud cleaning pump, a car washing pipeline, a mud cleaning pipe, a car washing platform, a pollutant discharging pipeline, an infrared probe and a control tank, wherein the water tank comprises a mud storing pond, a water filtering pond, a water separating pond and a water storing pond which are sequentially arranged, the car washing platform comprises a car washing table and pipe ditches, the pipe ditches are covered with a pipe ditch covering board, the car washing pipeline is arranged inside the pipe ditch, a plurality of car washing spraying heads are connected to the car washing pipeline, the mud cleaning pipeline comprises a mud cleaning main pipeline and a plurality of mud cleaning branch pipelines, one end of the pollutant discharging pipeline is connected with one pipe ditch close to the mud storing pond, and the other end of the pollutant discharging pipeline is connected with the mud storing pond. The environment-friendly and energy-saving assembling type automatic car washing equipment in the building site can simultaneously and automatically wash a car and discharge pollutant, the car washing working efficiency is improved, the cleaned polluting water can be used in a recycling way after being precipitated and filtered, and the water resource and the car washing cost are lowered.

Owner:GUANGXI CONSTR ENG GROUP THE THIRD CONSTR ENG +1

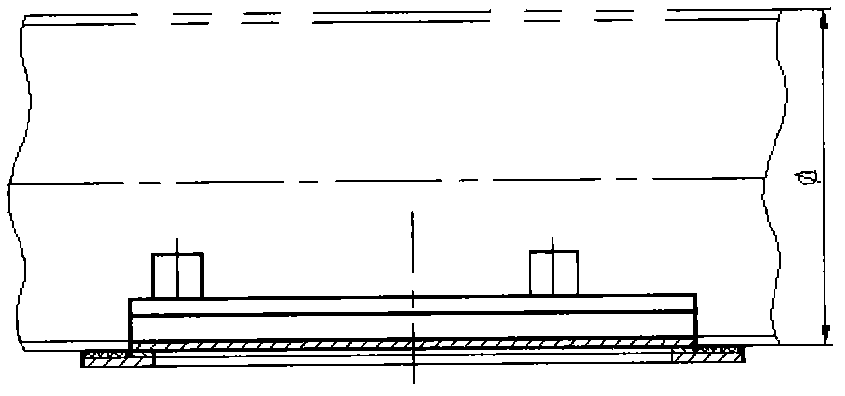

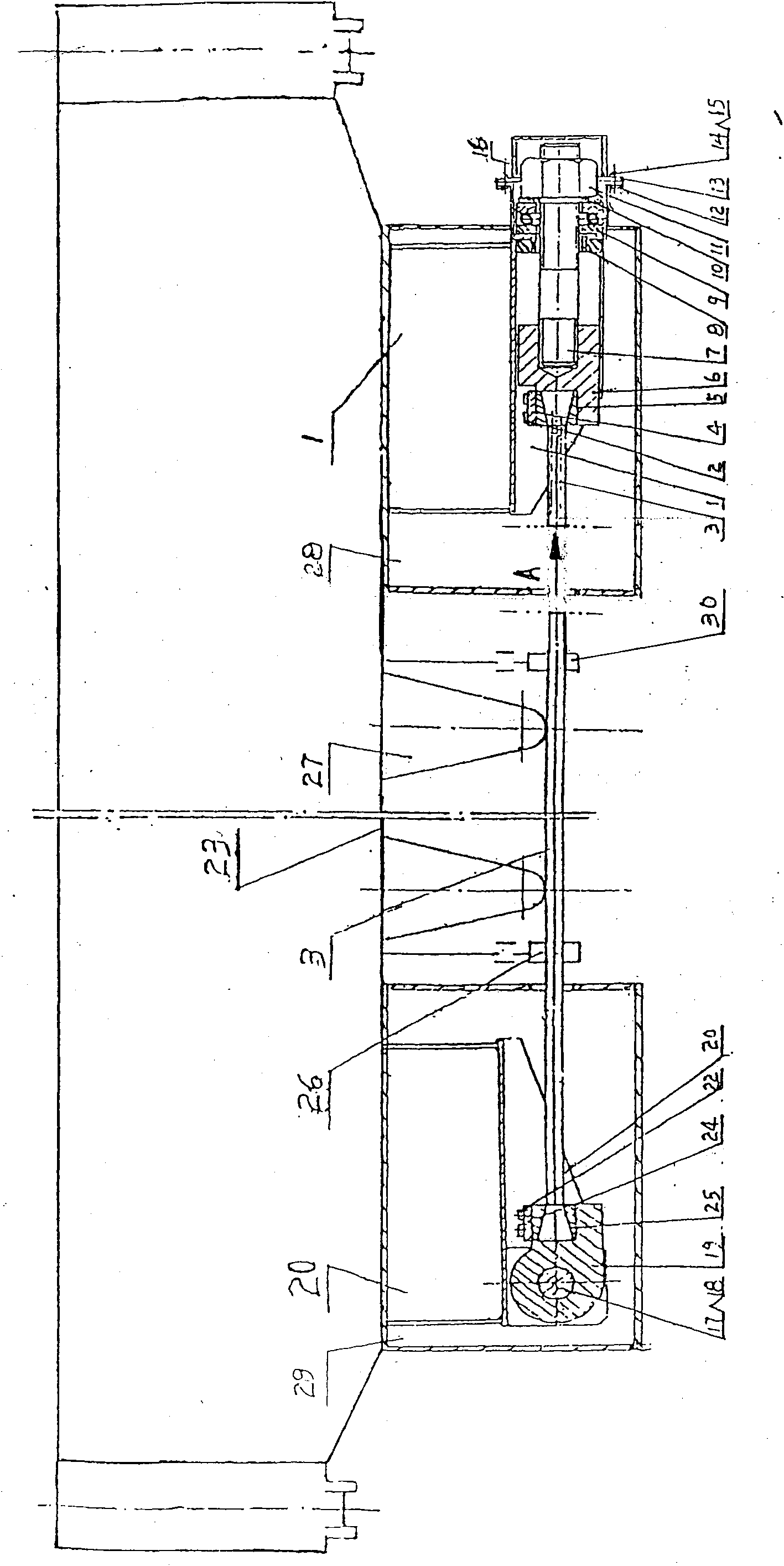

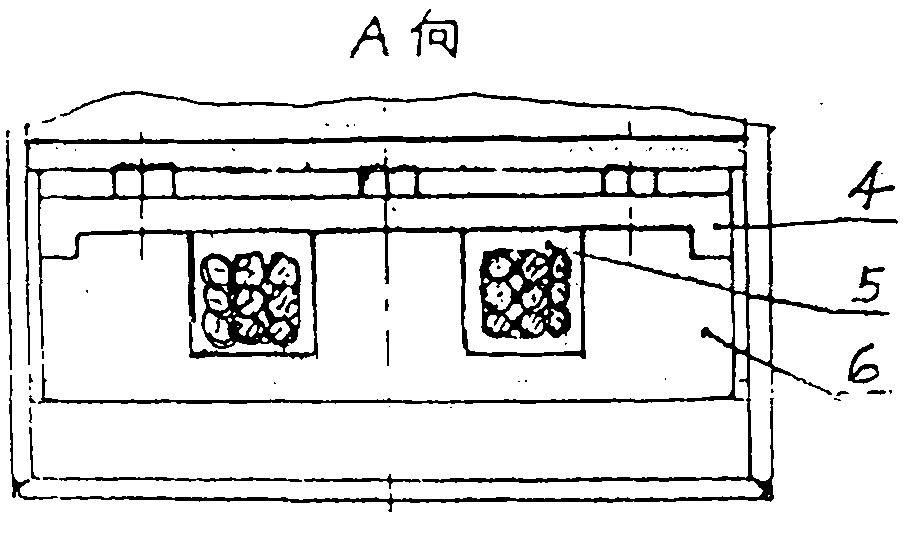

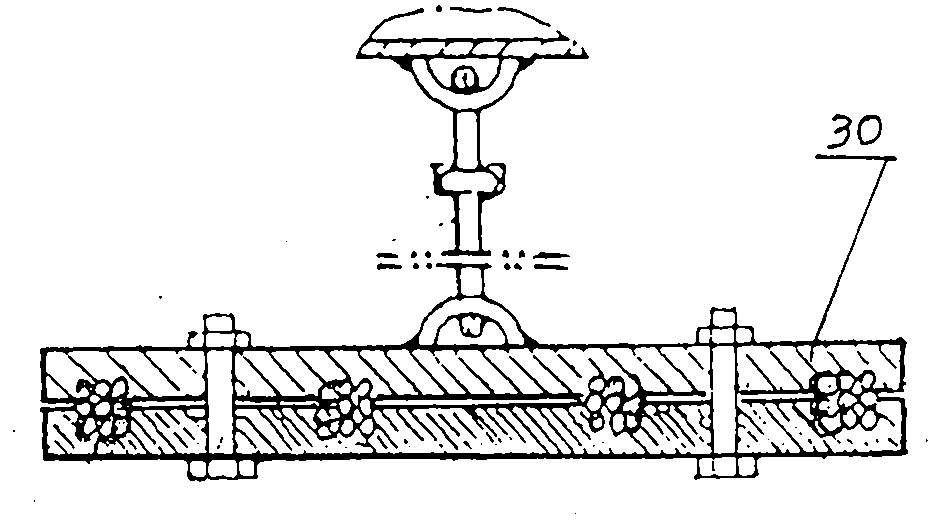

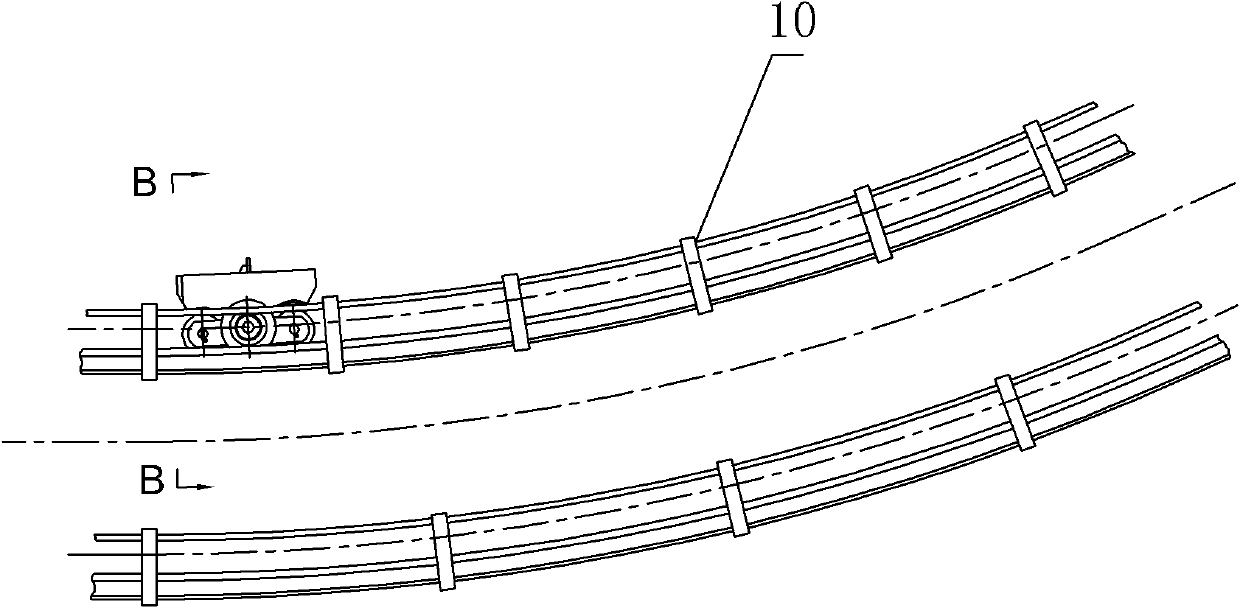

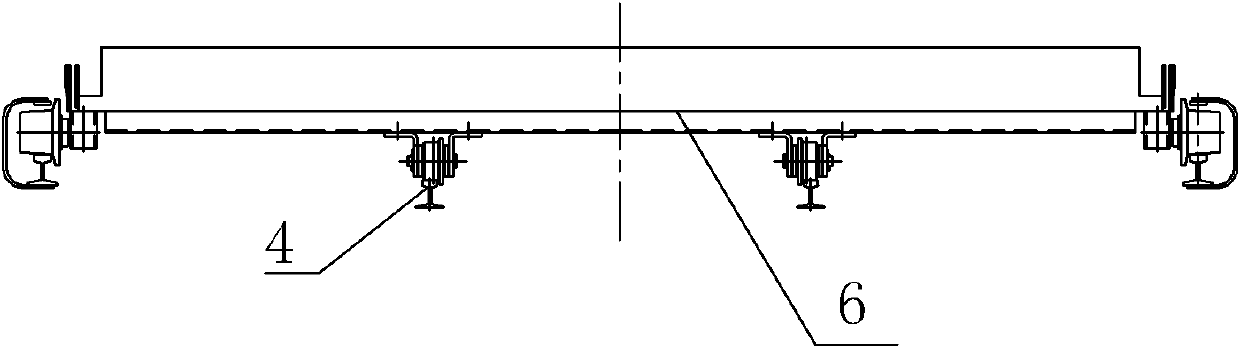

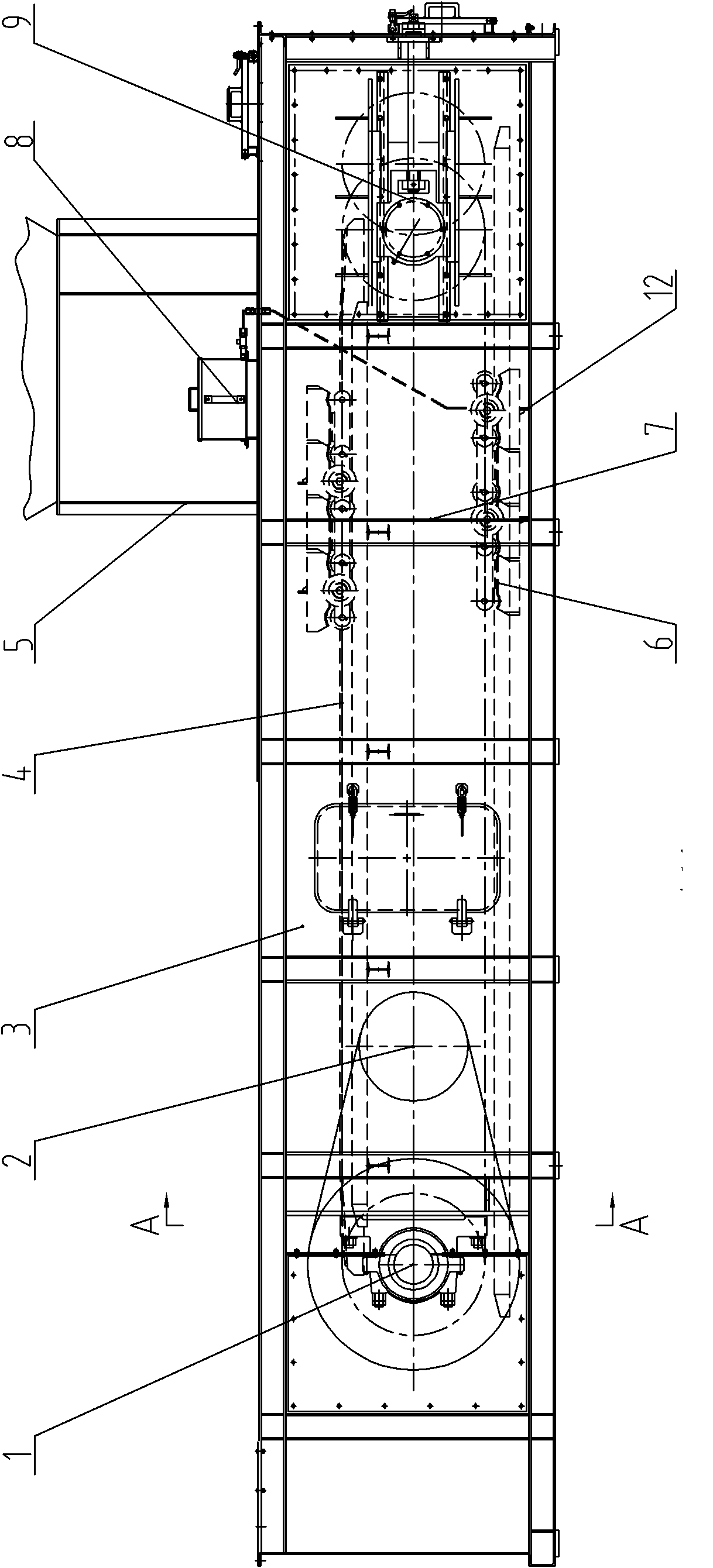

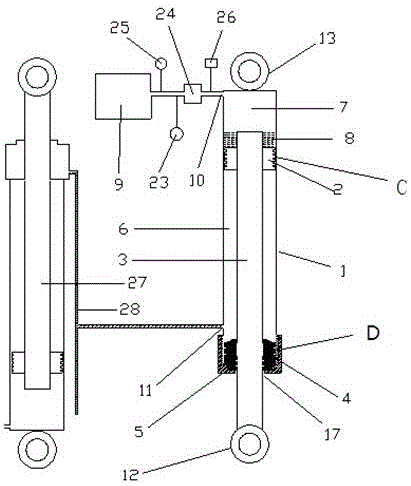

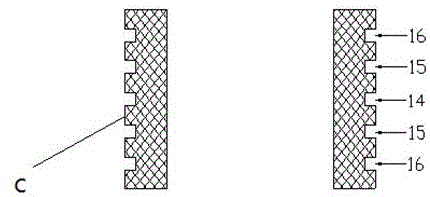

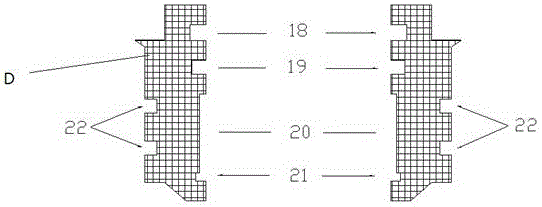

Manufacturing process of girder of overhead or gantry crane

The invention discloses a manufacturing process of a girder of an overhead or gantry crane, a threaded pull rod 7 in a box body 1 of a tensioning device is connected with a connecting seat 6, and the manufacturing process is characterized in that two wedge-shaped grooves are formed on the connecting seat 6, two rope head casting ports 5 with wedge-shaped outer shapes and square cone-shaped inner cavities are mounted in the grooves, two wedge-shaped grooves are formed on a fixed hinge 19 at the other end of a steel wire rope 3, and the rope head casting ports 25 with the wedge-shaped outer shapes and the square cone-shaped inner cavities are mounted in the grooves. The manufacturing process adopts the two groups for tensioning, the two groups are mounted on the same girder, and the ultimate tensioning force is great, thereby being applicable to manufacturing the girders of the cranes with the hoisting capacity of below 400 tons. The manufacturing process has the advantages of easy manufacturing, low cost and convenient construction, and is particularly applicable to manufacturing the gantry cranes with the span of above 60m in ports and the shipbuilding industry. The arch difference of the girder of the crane manufactured by adopting the invention can be controlled within 0-1mm, which is better than the international standard; furthermore, the manufacturing process can increase the cutting area of the girder structure, improve the strength, the static stiffness and the hoisting capacity of the girder, save steel, reduce the cost by 15-20%, be in line with the policies of energy conservation and emission reduction and prolong the service life of equipment.

Owner:傅萍 +2

Ultra-wide apron conveyer

Owner:宜都中起重工机械有限公司

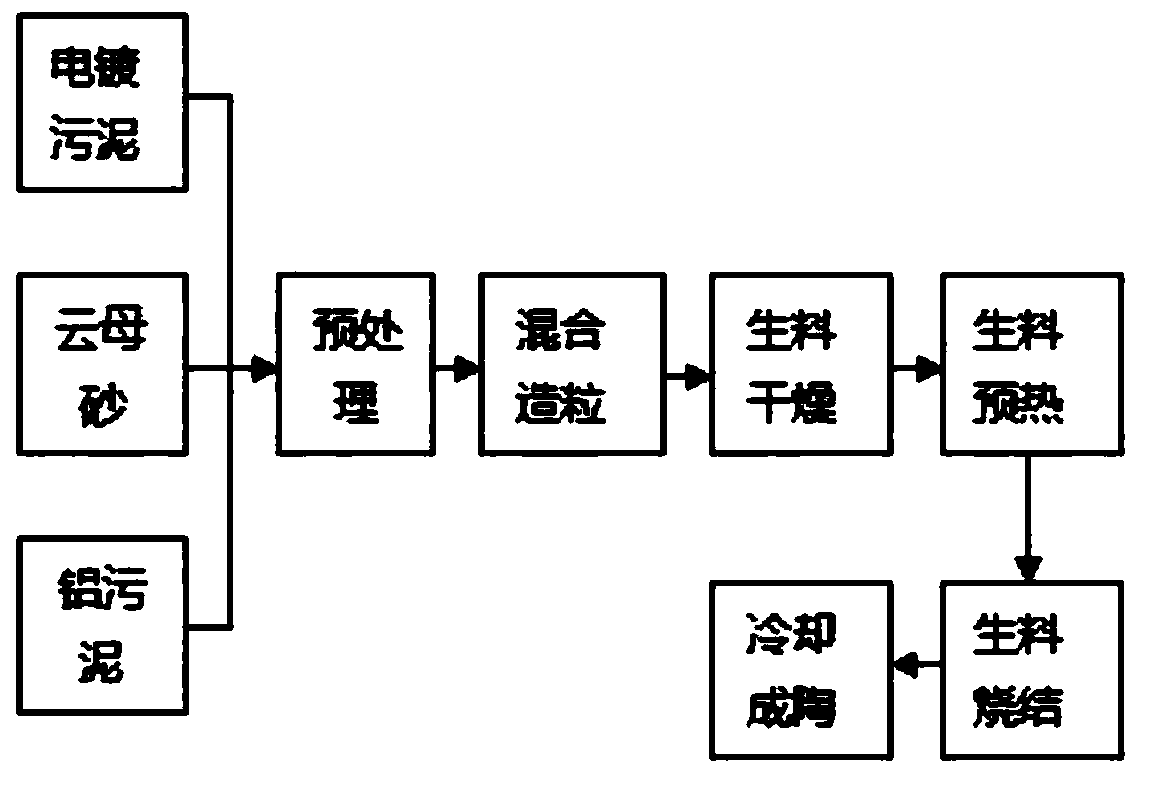

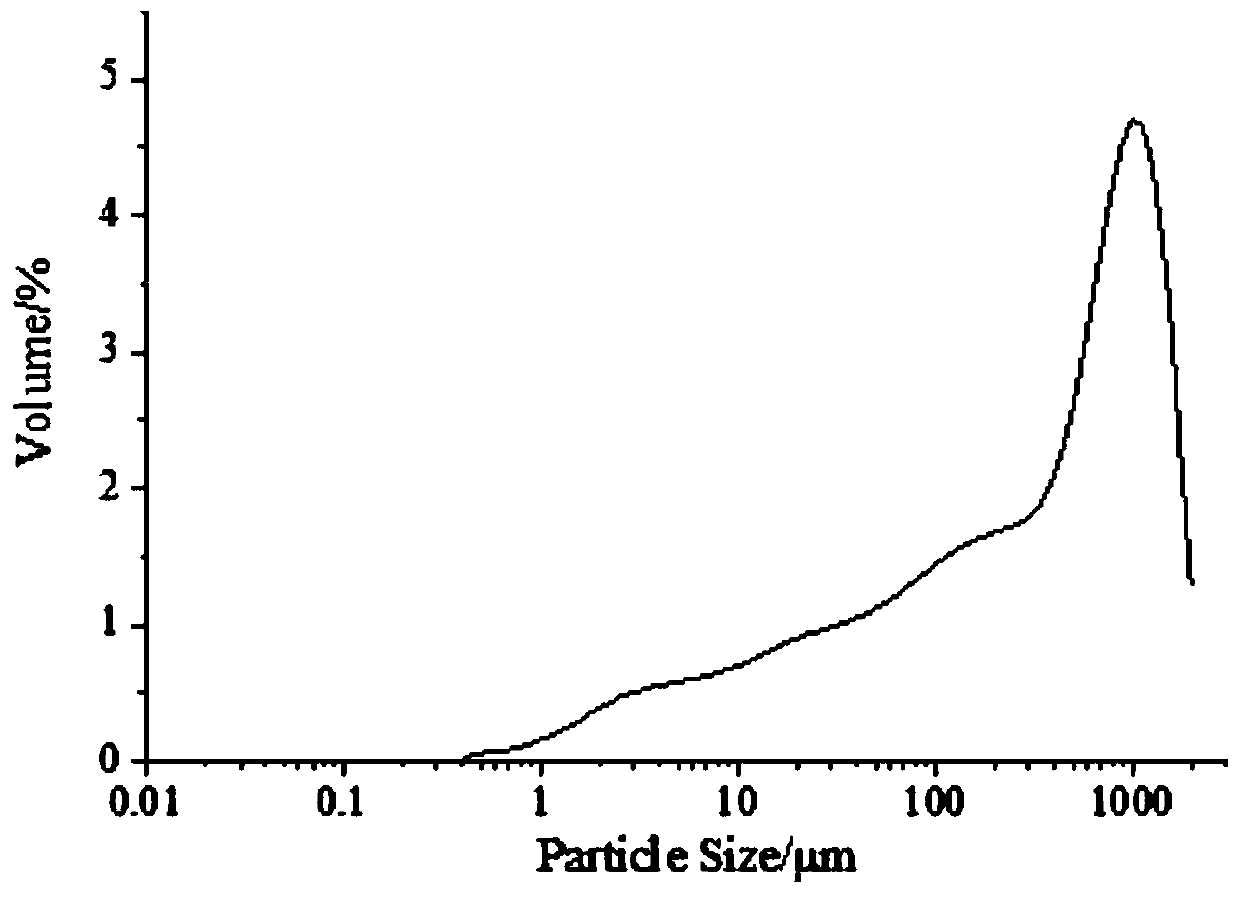

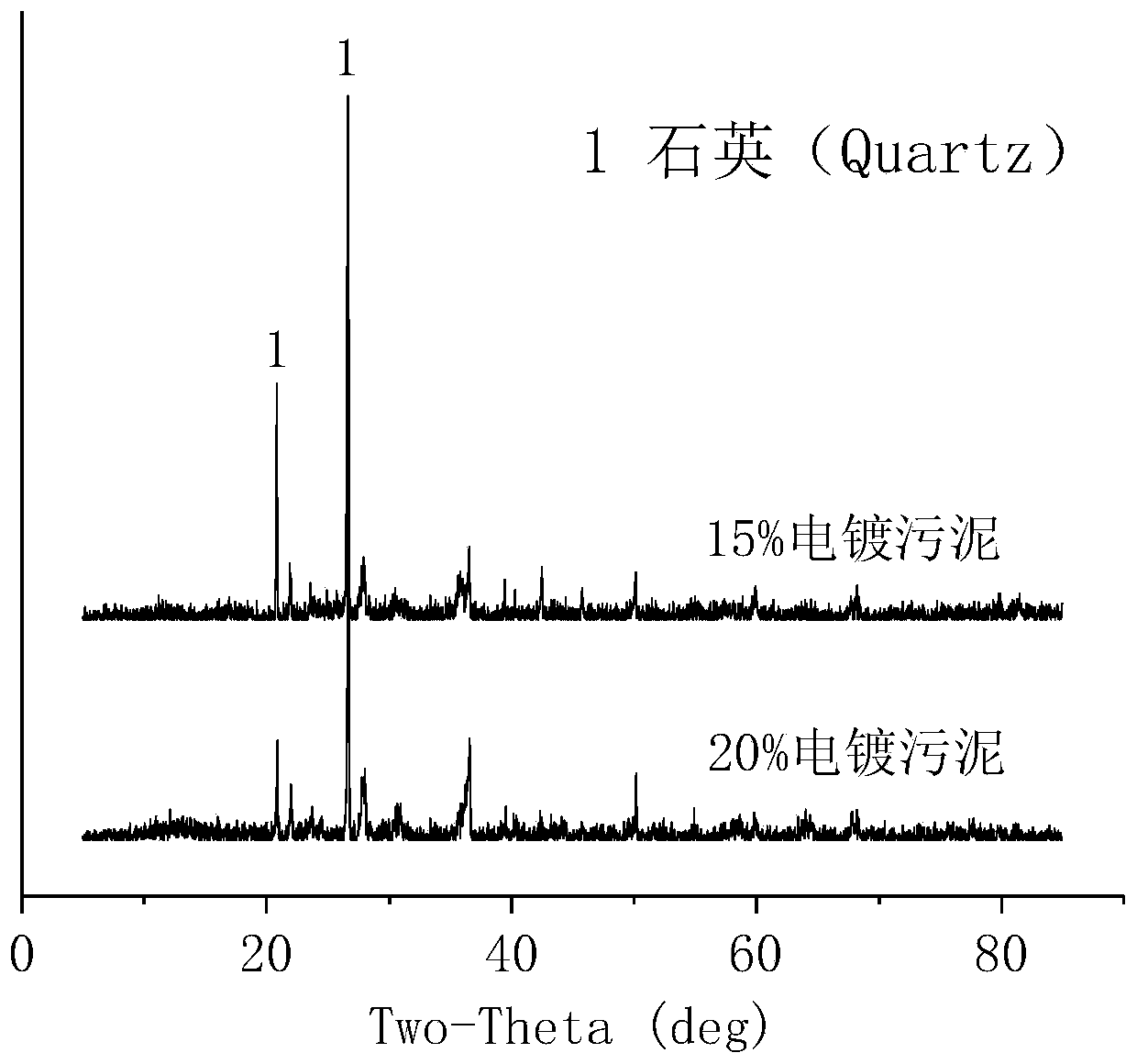

Preparation method used for sintering of building ceramsite from electroplating sludge

The invention discloses a preparation method used for sintering of building ceramsite from electroplating sludge. The ceramsite raw materials comprise 50 to 70% of micaceous sand (gold mine separationtailing), 20% of water supply plant aluminium sludge, and 10 to 30% of electroplating industrial park electroplating sludge. The preparation method comprises following steps: the raw materials are dried, crushed, and grinded for pretreatment, and are mixed to be uniform, 3 to 5% of sodium silicate solution is added as a ceramsite binder, mixing granulation is carried out to obtain raw ceramsite;and then drying, pre-heating, sintering, and cooling are carried out to obtain the ceramsite. According to the preparation method, aluminium sludge and micaceous sand are adopted to replace clay to provide Al2O3 and SiO2, the electroplating sludge is adopted to provide a fluxing agent, so that ceramsite manufacturing cost is reduced obviously, the prepared ceramsite is high in compression strength, and low in leaching toxicity; large scale processing of electroplating sludge and water supply plant sludge can be realized; harmlessness treatment of harmful waste is realized; resource utilizationis realized; electroplating sludge and aluminium sludge processing cost is saved; and the obtained product can be taken as building material, and excellent economical benefit and social benefit are achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Sand-in-sand multicolor interior and exterior wall building coating material and preparation method thereof

The invention discloses a sand-in-sand multicolor interior and exterior wall building coating material and a preparation method thereof, and relates to the field of building coating materials, whereinthe components of the formula comprise: a granulating agent, cellulose, a pH value regulator, a bactericide, inorganic bentonite, an anti-freezing agent, a film forming aid, a granulating emulsion, sand, an emulsion, a dispersing agent and titanium dioxide. The preparation method comprises: preparing a white base paint, preparing a granulating agent system, granulating, preparing a real stone paint and preparing a finished product. According to the invention, based on the sand-in-water multicolor coating material, through the specially-made granulating agent adding and the process, the sand-in-water color particles have characteristics of low use amount of, various colors, stone-like fidelity and the like, the real stone paint has advantages of favorable constructability, high storage stability and favorable texture effect, and the sand-in-water color particles and the real stone paint are combined to form the completely-new sand-in-sand multicolor coating material, so that the existing technical difficulties are solved, and the existing comprehensive advantages are retained.

Owner:河南裕彩科技研发有限公司

Gas lifting jack for excavator

ActiveCN106429944AReduce output powerSolve the disadvantage of not being able to support the vehicleLifting devicesSoil-shifting machines/dredgersCylinder headGas cylinder

The invention discloses a gas lifting jack for an excavator and relates to the technical field of excavators. A piston rod and a piston are arranged in a cylinder body, one end of the piston rod is connected with the piston, the other end of the piston rod stretches out of one end of the cylinder body, and a first flying ring is arranged at the stretching-out end and connected to a rotary disc big frame of the excavator. The upper portion of the cylinder body is connected with a cylinder head, the cylinder head is fixed into the cylinder body through a cylinder cover, and a second flying ring is arranged at the other end of the cylinder body and connected to a big arm of the excavator. The piston divides the interior of the cylinder body into two cavities, the piston rod is arranged in one chamber serving as a rod end chamber, and the piston rod is not arranged in the other chamber serving as a non-rod end chamber. The rod end chamber is connected with a rod end chamber oil pipe of a big arm oil cylinder of the excavator, the non-rod end chamber is communicated with a high-pressure gas bottle, a first sealing structure is arranged between the piston and the cylinder body, a second sealing structure is arranged between the piston rod and the cylinder head, high-pressure nitrogen is used in the non-rod end chamber for work, hydraulic oil is used in the rod end chamber for work, the output power of an engine is reduced, and lifting force of a working device is improved.

Owner:沈阳双壹市政工程有限公司

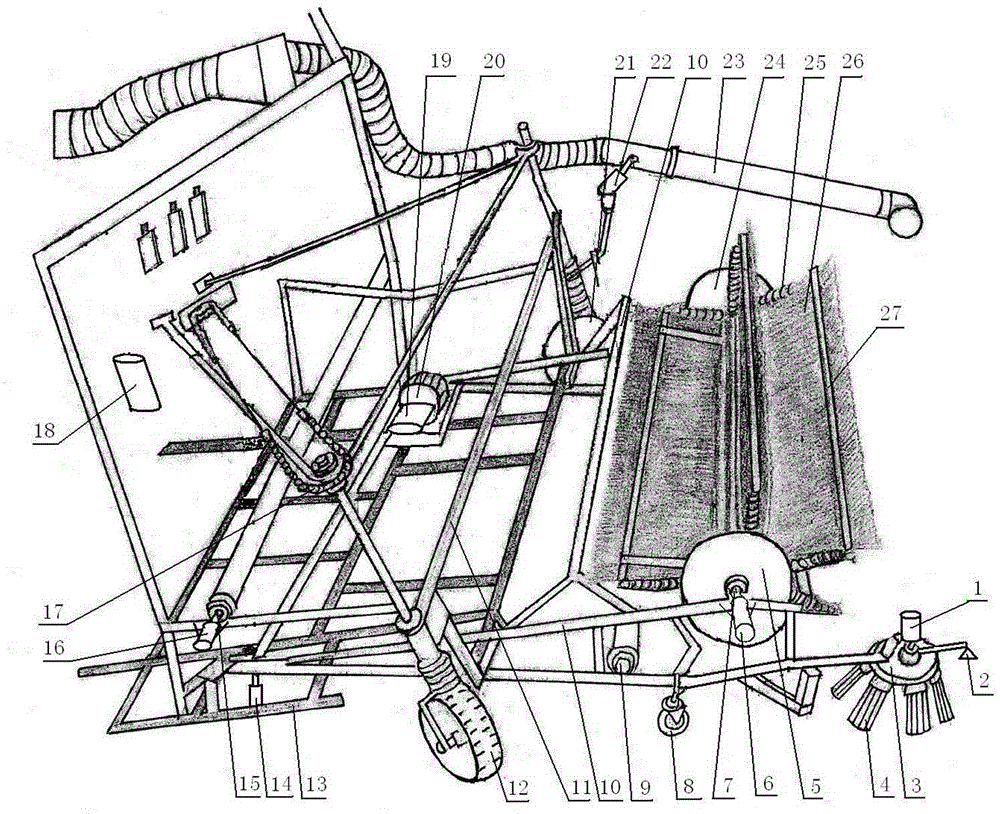

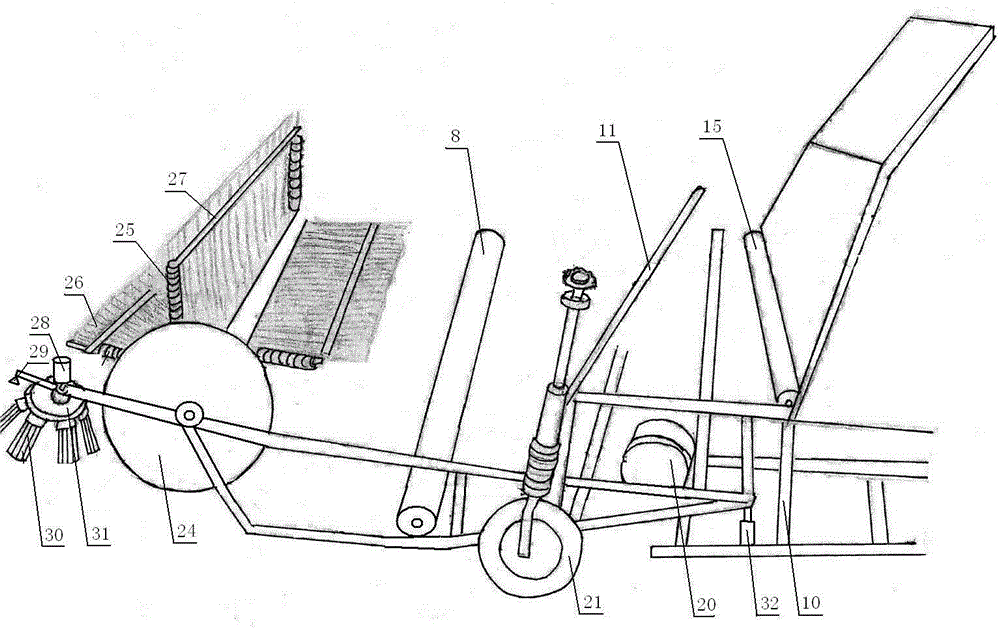

Energy-saving environmentally-friendly garbage sweeper

The invention provides an energy-saving environmentally-friendly garbage sweeper. The garbage sweeper is characterized in that a sweeping frame is arranged on a sweeper body chassis in the front of a cab, a transverse sweeping brush is arranged at the front end of the sweeping frame, edge brushes rotating inwards are arranged on the portions, on the two sides of the transverse sweeping brush, of the sweeping frame respectively, and a washboard is arranged on the portion, below the transverse sweeping brush, of the sweeping frame. A conveying belt is arranged on the portion, behind the washboard, of the sweeping frame. A motor on the sweeping frame drives a transverse shaft hydraulic motor at the transverse shaft end, edge brush hydraulic motors on the two edge brushes and a conveying belt hydraulic motor on the conveying belt through a hydraulic pump. A garbage collection box is arranged below the rear portion of the conveying belt. A dust sucking device is arranged on the rear portion of a sweeper body. Compared with a traditional vacuum sweeper, by means of the energy-saving environmentally-friendly garbage sweeper, garbage on roads can be swept thoroughly, energy is saved, the environment is protected, and the sweeper is easy to operate and low in manufacturing and use cost.

Owner:王天君

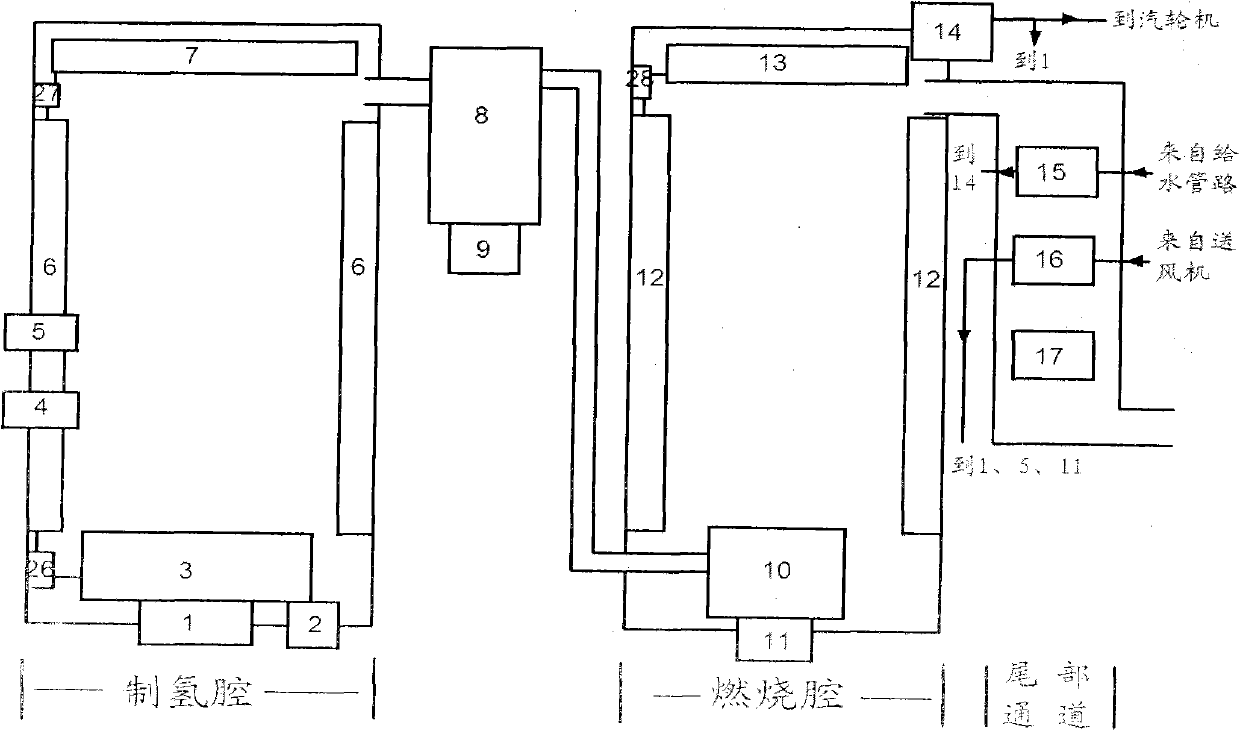

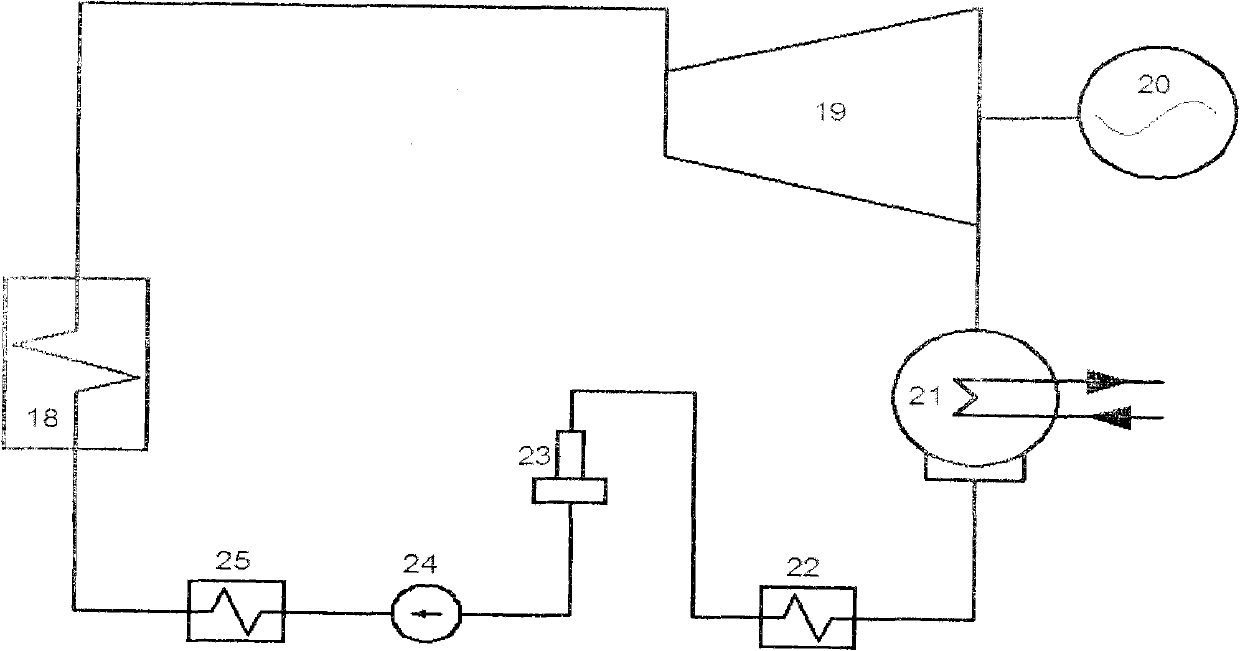

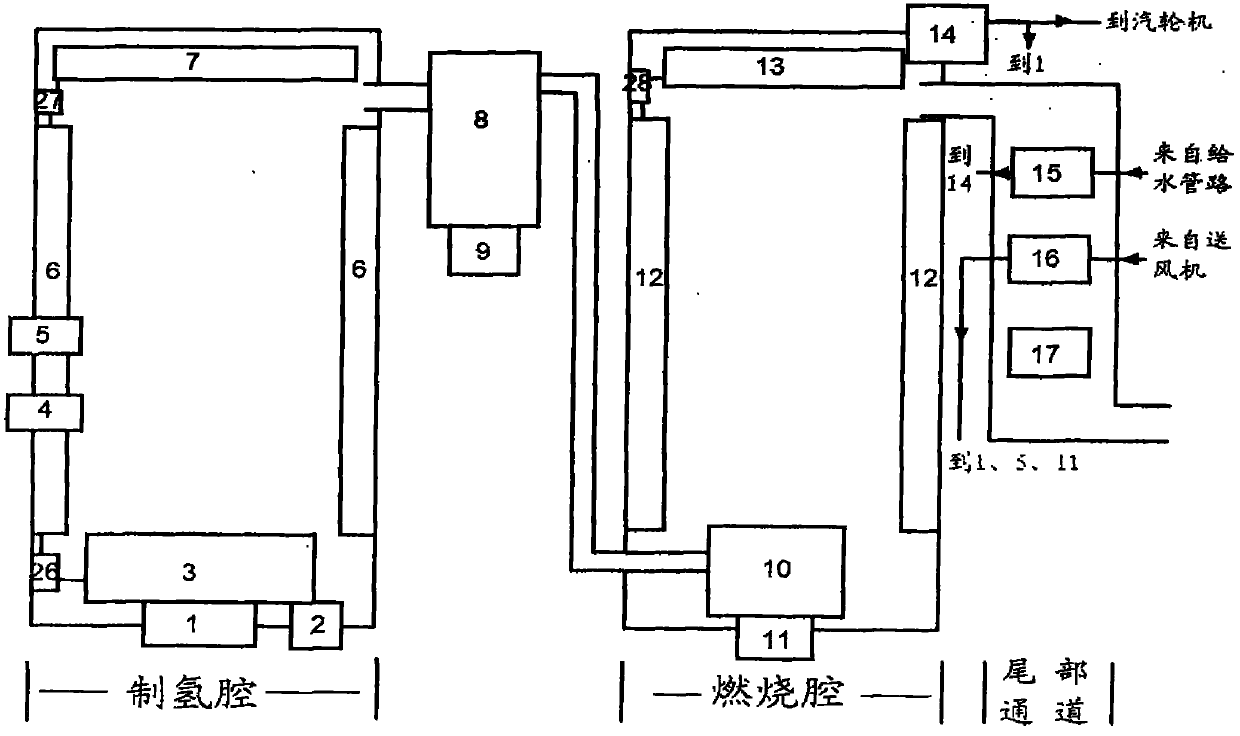

System for generating power by utilizing magnesium energy and hydrogen energy

The invention discloses a system for generating power by utilizing magnesium energy and hydrogen energy, which belongs to the technical field of new energy power generation. In the system, magnesium reacts with water to generate heat energy; meanwhile, hydrogen generated by reaction is combusted for heating working medium water together; and generated steam pushes a steam turbine to do work for carrying out power generation. A magnesium energy and hydrogen energy steam generating device is mainly divided into a hydrogen producing cavity and a combustion cavity. Magnesium reacts with steam to generate hydrogen in the hydrogen producing cavity and generate heat for heating the working medium water in a heat exchanger; and in the combustion cavity, the hydrogen prepared by the hydrogen producing cavity and air carry out mixed combustion for further heating the working medium water in the heat exchanger so as to generate steam for pushing the steam turbine to rotate and driving a power generator to generate power. The system prevents emission of harmful gases, reduces environmental pollution, and is convenient for construction, simple to control and easy for carrying out market popularization.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

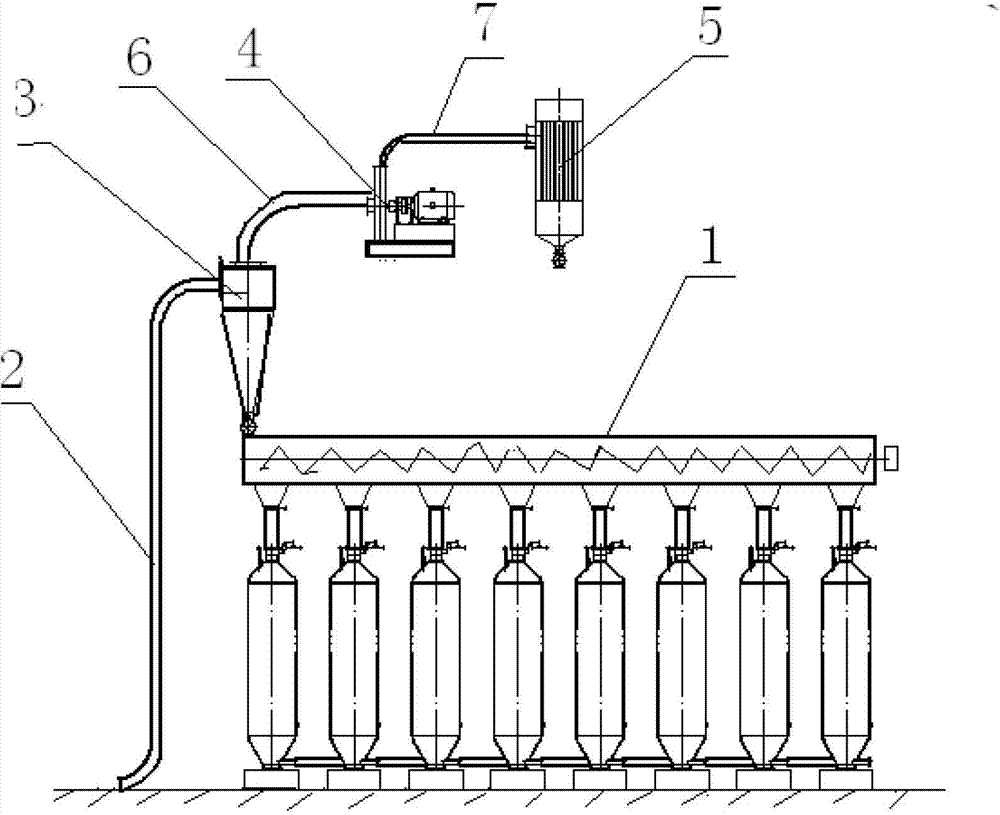

Furfural production process system for conveying raw materials in closed mode

InactiveCN102774656AImprove delivery efficiencyCompact appearanceBulk conveyorsProcess systemsBaghouse

The invention discloses a furfural production process system for conveying raw materials in a closed mode. The system consists of a plurality of hydrolysis reactors and a feeding system, wherein a material cabin is arranged above the hydrolysis reactors, a screw conveyer is embedded in the material cabin, the feeding system utilizes a pipeline negative pressure conveying device, the pipeline negative pressure conveying device comprises a cyclone separator which is installed on an inlet of the hydrolysis reactor material cabin, an air outlet at the top of the cyclone separator is connected with an exhaust tube, a feeding port at the side of the cyclone separator is connected with a feeding tube, the exhaust tube is connected with an air inlet of an exhaust fan, the feeding tube extends downwards into a material stack, and an air out of the exhaust fan is connected with a pulse type bag dust remover through a pipeline. Accordingly, the conveying efficiency of the pipeline negative pressure conveying device is high, and the conveying is in a closed mode, so that the system is free from dust and noise pollution, the whole process line is compact in appearance, attractive in appearance, energy-saving, environment-friendly, and requirements of the energy-saving and emission-reduction policy which is advocated by China are met.

Owner:肥城金威机械有限公司

Efficient energy-saving biomass burner system

InactiveCN102679379AIncrease profitReduce burning costsLighting and heating apparatusWaste heat recovery unitAtmospheric air

The invention belongs to the technical field of boilers and particularly relates to an efficient energy-saving biomass burner system which comprises a boiler main body, wherein a biomass burner, a waste heat recovery device and a dedusting device are arranged on one side of the boiler main body, the biomass burner provides heat for the boiler main body, the waste heat recovery device recovers heat in smoke exhausted from the boiler main body, the dedusting device removes dust in the smoke after heat recovery through the waste heat recovery device, and a draught fan is arranged between the waste heat recovery device and the dedusting device. The efficient energy-saving biomass burner system has the advantages that the biomass burner which is low in burning cost is used for providing heat for the boiler main body; the waste heat recovery device treats high-temperature smoke exhausted from a smoke exhaust port of the boiler main body and recovers heat in the smoke, so that energy use ratio is improved and cost is reduced; and the smoke after dedusting by aid of the dedusitng device does not have any influence to the surrounding environment when being exhausted to the air, and the national energy conservation and emission reduction policy is met.

Owner:马鞍山永强节能技术股份有限公司

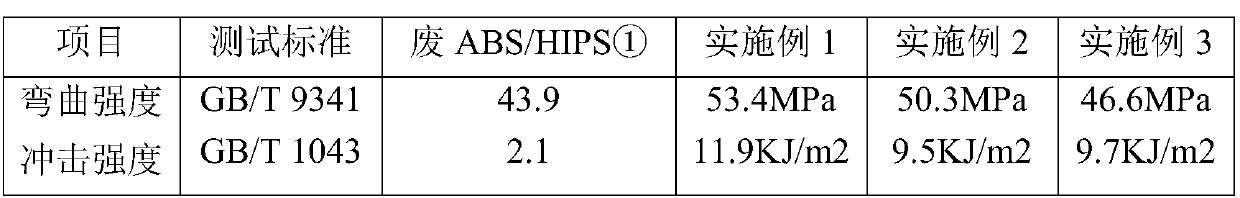

In situ chain extension repairing-based regenerated ABS/HIPS alloy material and preparation method thereof

The invention discloses an in situ chain extension repairing-based regenerated ABS / HIPS alloy material. The in situ chain extension repairing-based regenerated ABS / HIPS alloy material comprises, by weight, 100 parts of a waste ABS and waste HIPS mixture, 1-5 of an ABS-based macromolecular chain extender and 1-5 parts of an HIPS-based macromolecular chain extender. The in situ chain extension, thein situ compatibilization and the toughening effects of the macromolecular chain extender are used to realize growth and repairing of the broken chain, improve the phase interface, increase the compatibility and improve the glue content, so the regenerated plastic-alloy material having reduced flow and excellent comprehensive performances is prepared, wastes are fully utilized, and energy saving and emission reduction are achieved. The invention also discloses a preparation method of the regenerated alloy material.

Owner:CHINA NAT ELECTRIC APP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com