Dry desulfurization agent production process and system

A technology of dry desulfurization and production process, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of complex production methods of dry desulfurization agents, affecting desulfurization efficiency, product quality, and insufficient reaction, etc., to achieve improvement Desulfurization effect, beneficial to energy consumption, and the effect of improving the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

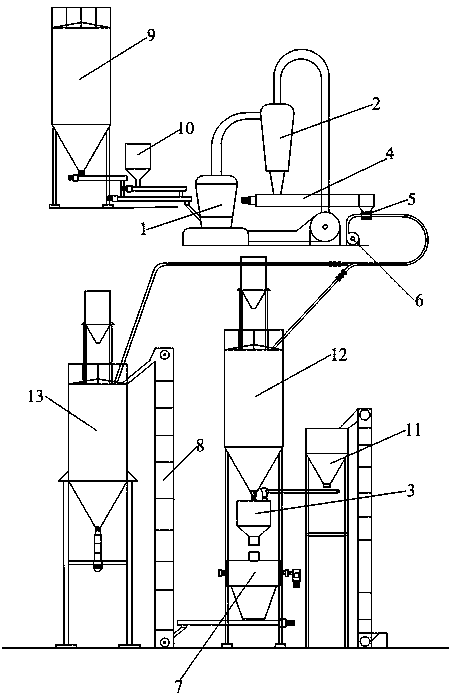

[0045] This embodiment relates to a dry desulfurization agent production process and the process system used therein.

[0046] The dry desulfurizer involves the following ingredients: calcium-based materials: calcium carbide slag, quicklime; reducing agent: urea, ammonium formate; catalyst: iron powder, copper slag, steel slag; auxiliary agent: fluorine slag.

[0047]The calcium-based material and additives are sent into the material bin 9 according to the ratio, the catalyst is sent into the catalyst bin 10, and the reducing agent is sent into the reducing agent bin 11. After the raw materials in the material bin 9 are measured by a single screw scale, they are sent to the mill 1 for grinding together with the catalyst in the catalyst bin 10 after being weighed by a belt conveyor scale, and the powder is ground to 600 mesh to obtain dry desulfurization Then use the cyclone dust collector 2 to send the ground semi-finished product and the qualified material in the cyclone dust...

Embodiment 2

[0051] This embodiment relates to a dry desulfurization agent production process and the process system used therein.

[0052] The dry desulfurizer involves the following ingredients: calcium-based material: calcium carbide slag; reducing agent: urea, ammonium formate; catalyst: iron powder, sulfuric acid slag; auxiliary agent: manganese slag; auxiliary materials: dispersant, stabilizer.

[0053] The calcium-based material and additives are sent into the material bin 9 according to the ratio, the catalyst is sent into the catalyst bin 10, the reducing agent is sent into the reducing agent bin 11, and the auxiliary materials are sent into the auxiliary material bin. After the raw materials in the material bin 9 are measured by a single screw scale, they are sent to the mill 1 for grinding together with the catalyst in the catalyst bin 10 after being measured by a belt conveyor scale. In order to increase the uniformity and stability of the materials, a Also sent in is the auxil...

Embodiment 3

[0057] This embodiment relates to a dry desulfurization agent production process and the process system used therein.

[0058] The dry desulfurizer involves the following ingredients: calcium-based materials: slaked lime, carbide slag; reducing agent: urea, ammonium formate, ammonium acetate; catalyst: iron powder, steel slag; auxiliary agent: fluorine slag; auxiliary materials: dispersant, stabilizer agent.

[0059] The calcium-based material and additives are sent into the material bin 9 according to the ratio, the catalyst is sent into the catalyst bin 10, the reducing agent is sent into the reducing agent bin 11, and the auxiliary materials are sent into the auxiliary material bin. After the raw materials in the material bin 9 are measured by a single screw scale, together with the catalyst in the catalyst bin 10 measured by the belt conveyor scale, they are sent to the mill 1 for grinding to 650 mesh to obtain dry desulfurization Then use the cyclone dust collector 2 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com