Method for preparing polyorganosiloxane and gas phase hydrogen chloride by multi-stage continuously hydrolyzing dichlorosilane

A technology of polyorganosiloxane and dichlorosilane, which is applied in the direction of chlorine/hydrogen chloride, etc., can solve the problems of affecting hydrolysis reaction, high hydrochloric acid content, and affecting the speed of hydrolysis reaction, so as to avoid waste water discharge, reduce production cost, and reduce chlorine content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are non-limiting examples of the invention.

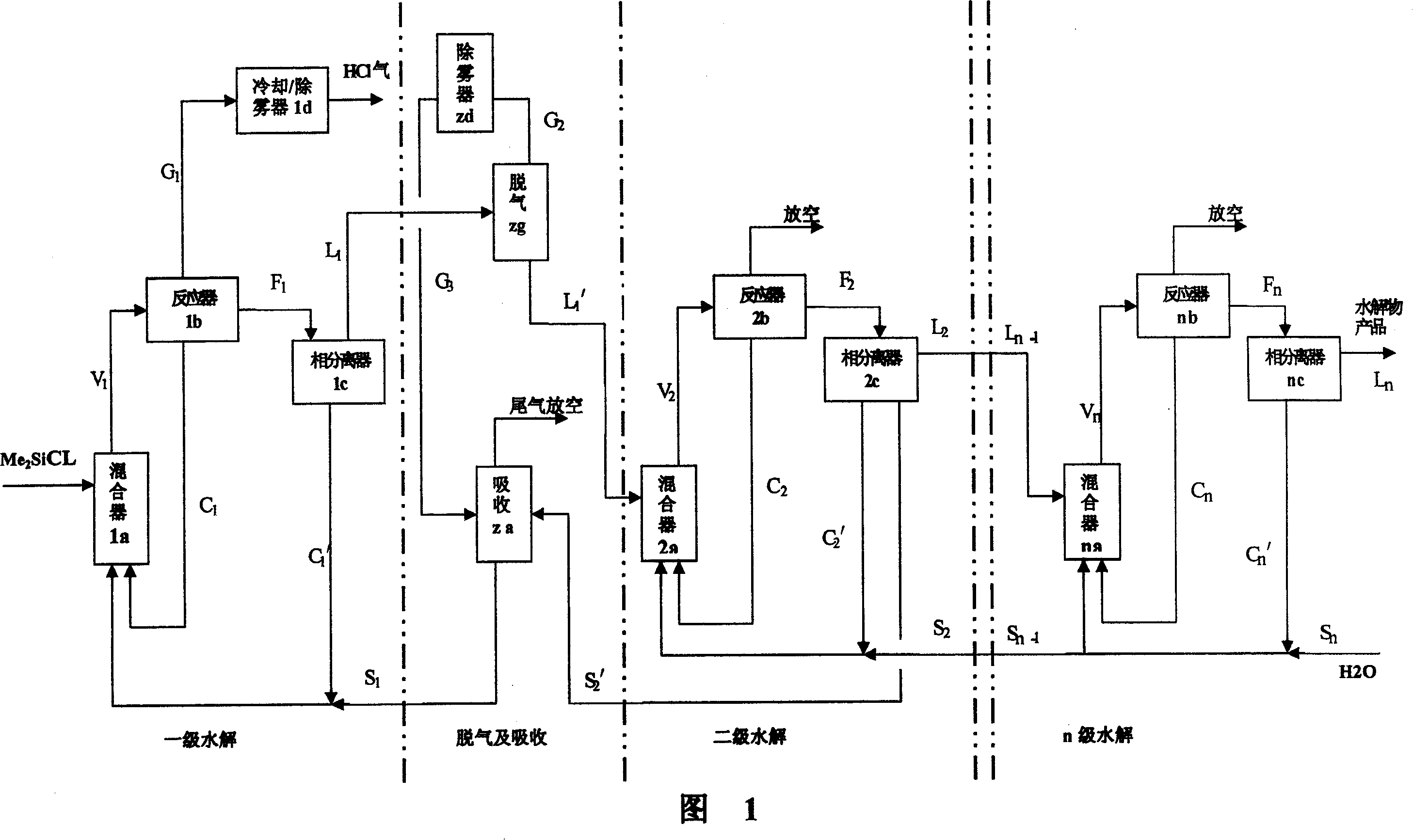

[0025] In this embodiment, the organodichlorosilane is dimethyldichlorosilane, and FIG. 1 is a flow chart of preparing polyorganosiloxane and gas-phase hydrogen chloride by hydrolysis of dimethyldichlorosilane.

[0026] The first stage hydrolysis reaction described in the present invention comprises the mixer 1a for the internal circulation system, and the internal circulation reaction starting material Me 2 SiCl 2 Added from the mixer, with material C circulated internally and externally 1 、C 1After being fully mixed, a three-phase material containing gas-liquid-liquid (that is, a three-phase material of gas phase, oil phase, and water phase) is formed, and enters the internal circulation reactor 1b, which is a pressurized gas-liquid-liquid Liquid three-phase reactor (hydrolysis reactor 1b is a general-purpose gas-liquid separator. In order to shorten the residence time in the liquid phase area, a large upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com