Process for magnetically separating and recovering iron and carbon from zinc volatilization kiln slag through dry method

A technology of zinc volatilization and magnetic separation, applied in recycling technology, mechanical material recovery, solid separation, etc., can solve problems such as single sorting materials, low sorting grade and recovery rate, and large-scale stacking pollution, so as to reduce environmental pollution Effects of pollution, improvement of magnetic separation index, and improvement of concentrate grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

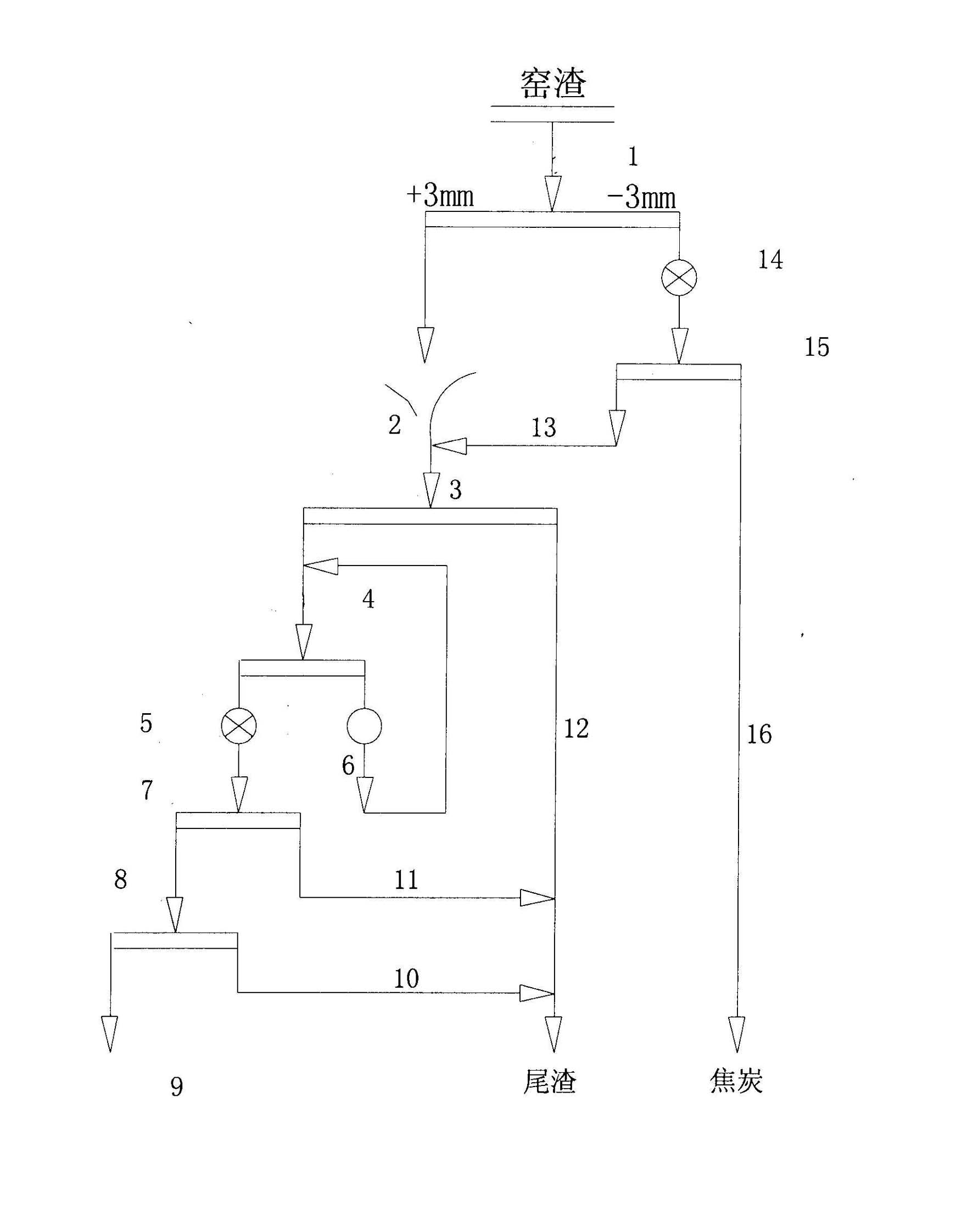

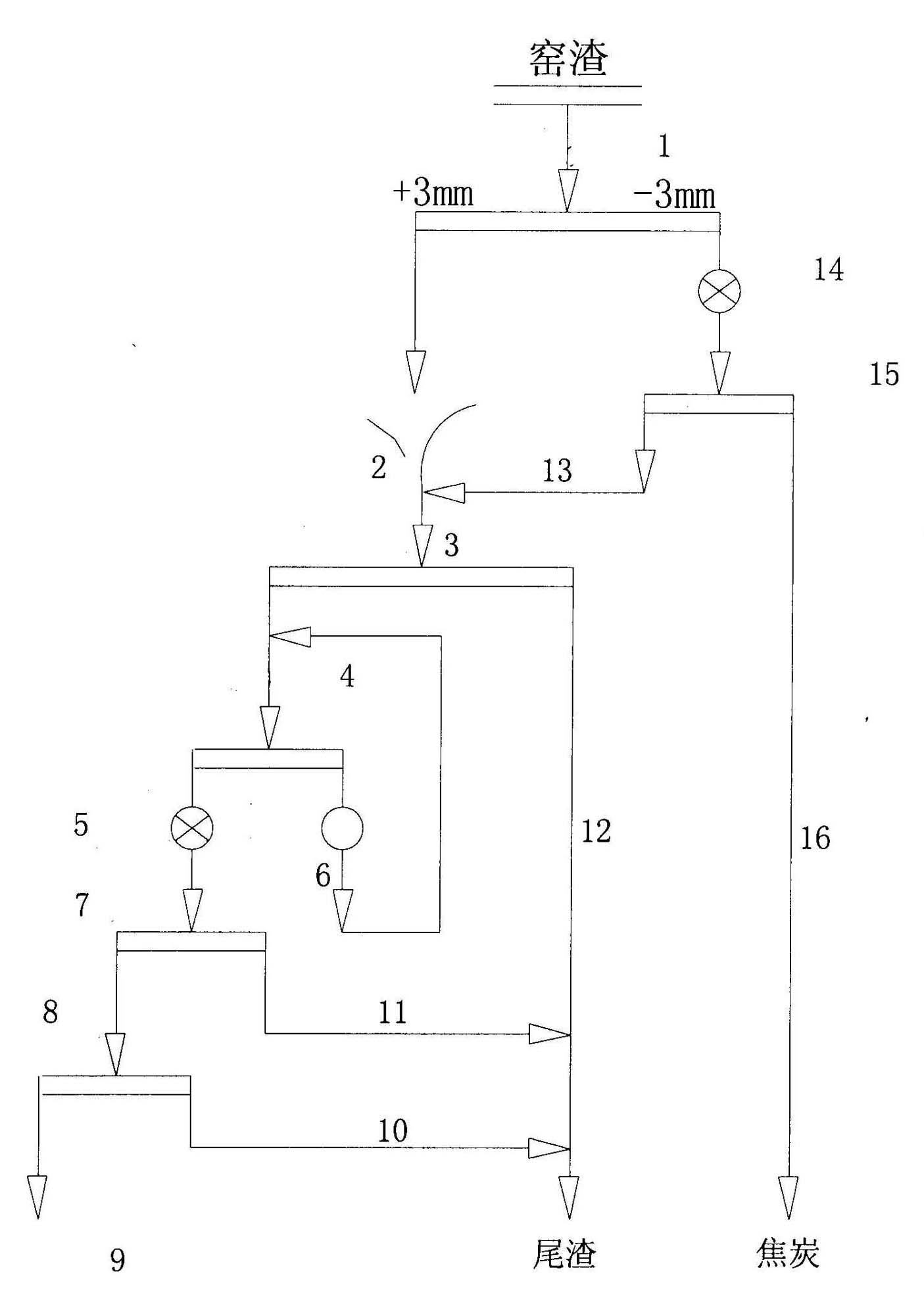

[0029] Such as figure 1 As shown, the pre-classification process of the kiln slag in the present invention, through the pre-selection air fluidized bed wind classification 1, the material classification particle size is determined to be +-3mm, and +3mm coarse-grained products and -3mm fine-grained products can be obtained. granular product. Among them, the +3mm coarse-grained product is used as the raw material for the coarse-grained iron separation process. The specific process includes: roughing and throwing tails 3. 7. Featured 8;-3mm fine-grained product as fine-grained microwave drying 14--Magnetic separation carbon collection process 15 raw materials.

[0030] Microwave drying of fine particles described in the present invention 14--Step magnetic separation carbon collection process 15 process, the specific separation process refers to: 1) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com