Patents

Literature

86results about How to "Reduce burning costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ordinary fine procelain

ActiveCN101928132ALower firing temperatureHigh whitenessSolid waste disposalClaywaresBall millBone china

The invention relates to procelain production and aims to provide an ordinary fine procelain featuring low firing temperature and reduced production cost. The ordinary fine procelain of the invention comprises the following components in percentage by weight: 9-12% of Guangxi soil, 5-10% of Jingxing soil, 2-6% of Shanyin soil, 2-7% of Yusi soil, 2-8% of Tang county soil, 8-14% of Longyan soil, 22-28% of quartz, 24-30% of Datong soil, 8-14% of feldspar and 6-8% of fine bone china waste powder. Blank is crushed, processed into fine powder of 100 meshes and ball-milled in a wet-type ball mill while being added with water, blank: ball: water=1:2.5:1; the mixture is levigated for 18-20 hours; the mixture passes through a sieve of 250 meshes, the fineness of the mixture is 0.8%, the mixture is dehydrated by a mud press to have a water content of 21% and then vacuum pugging is carried out on the mixture for twice at a vacuum degree more than or equal to 0.09MPa.In the invention, the fine bone china waste powder is added to the production of the ordinary fine procelain, therefore the firing temperature of the ordinary fine porcelain in the invention is reduced by about 30 DEG C compared with the firing temperature of the traditional ordinary fine porcelain.

Owner:PINGDING YINGYU PORCELAIN

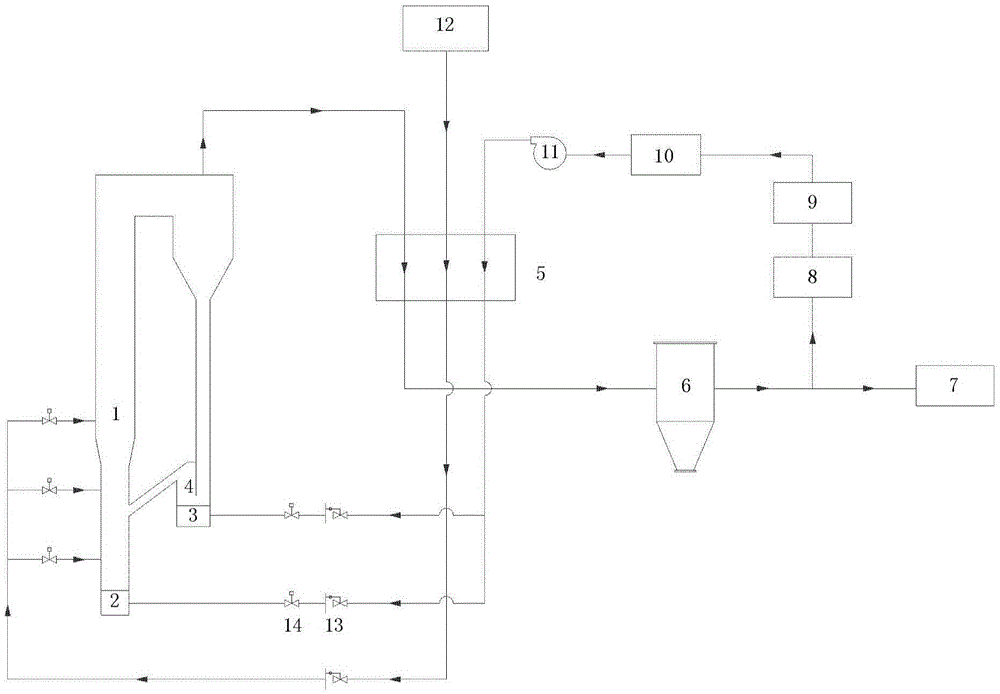

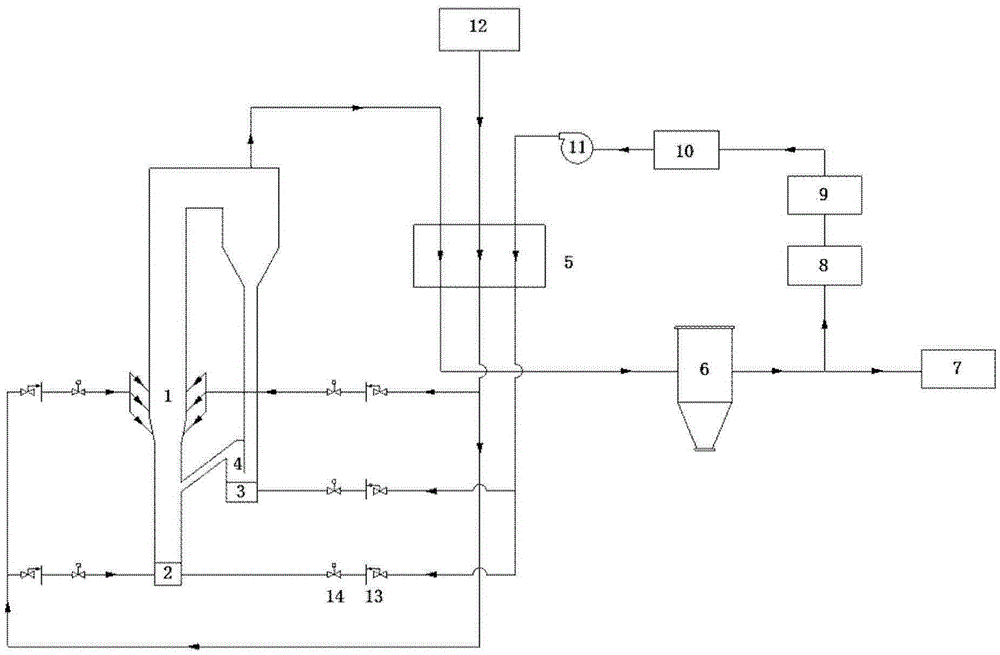

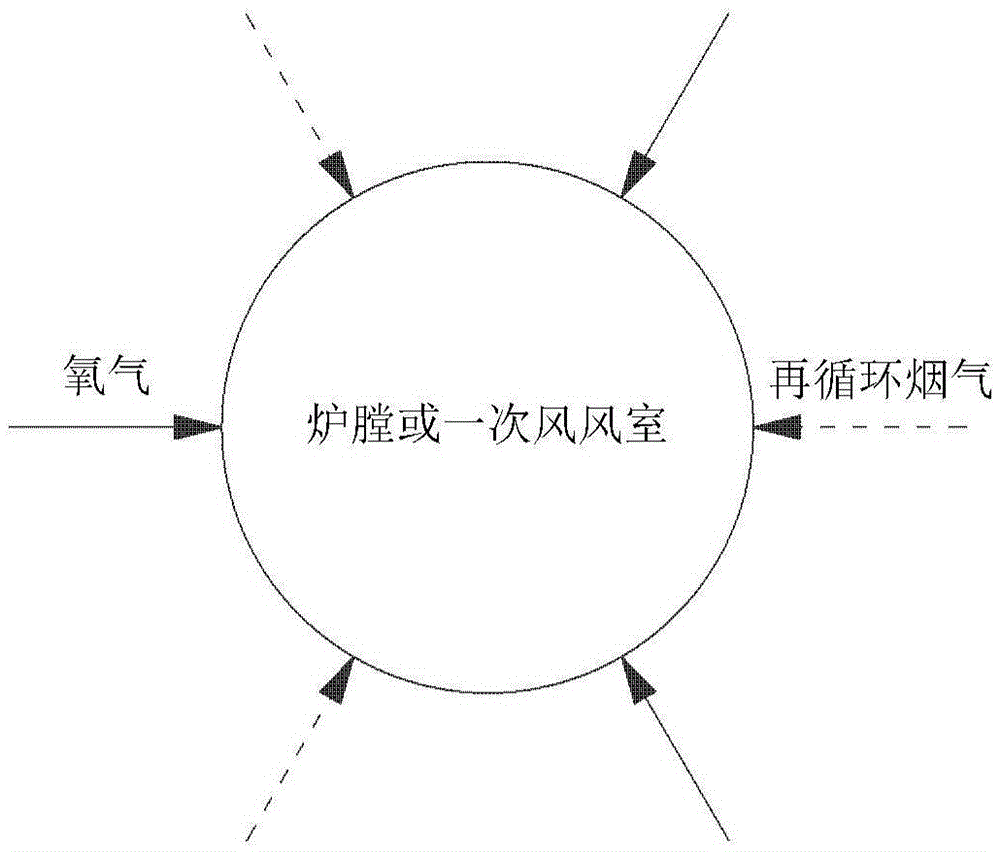

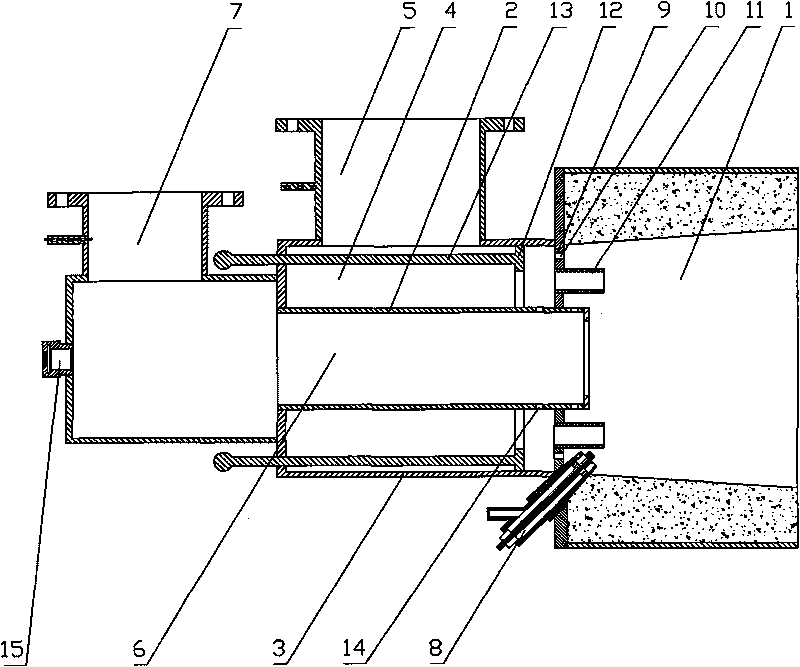

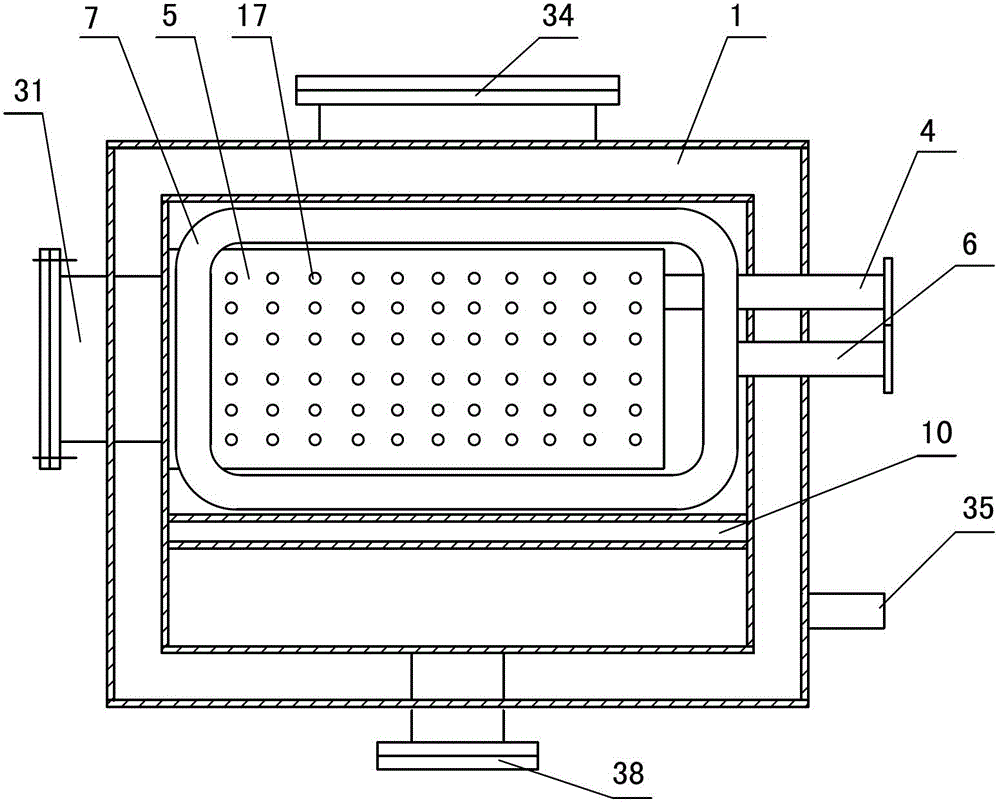

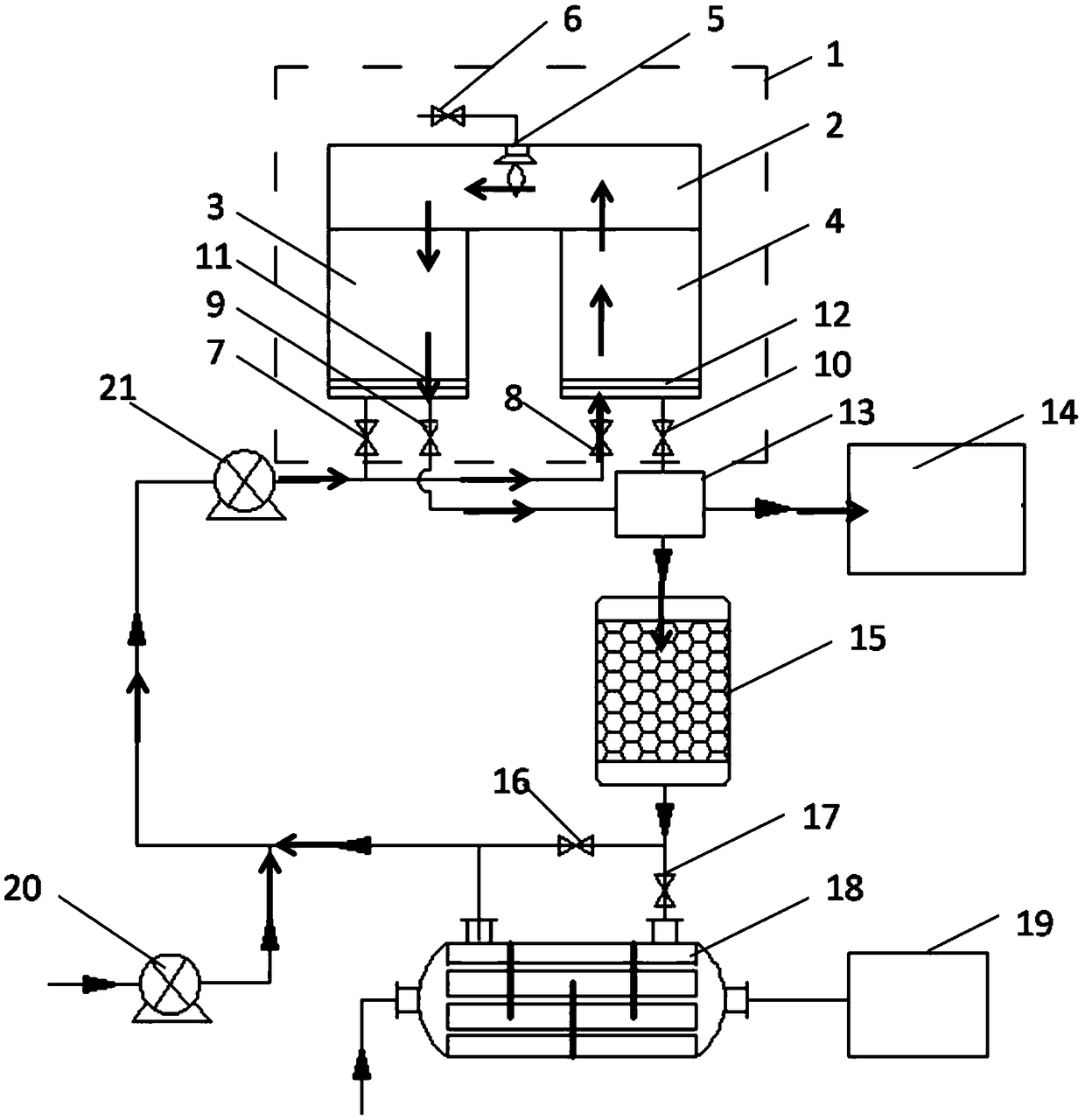

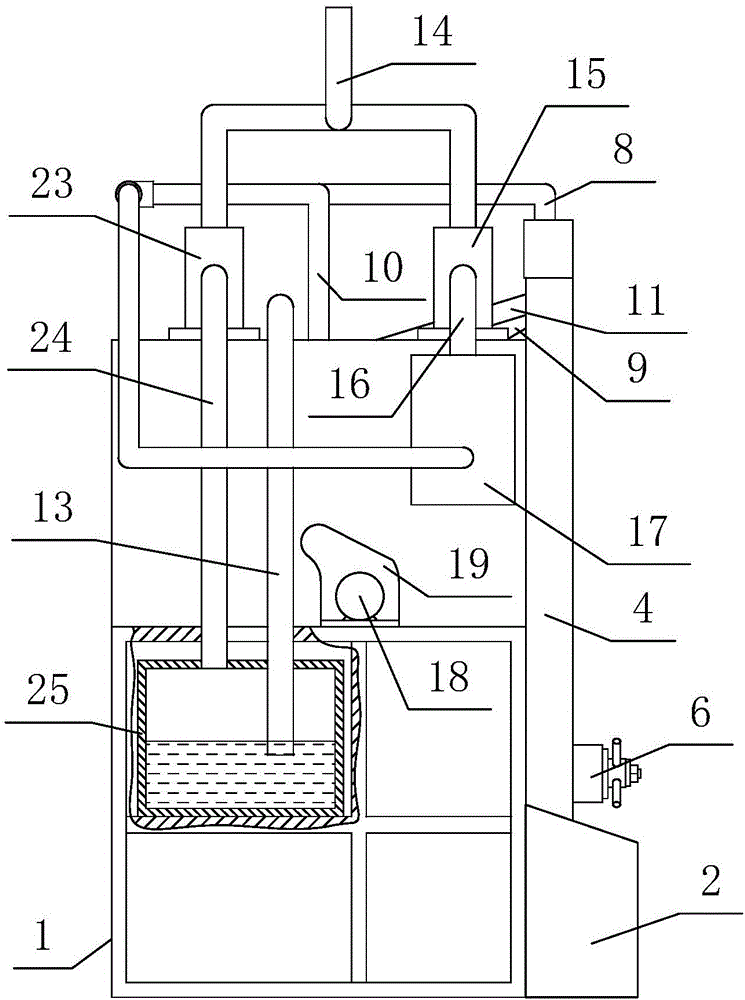

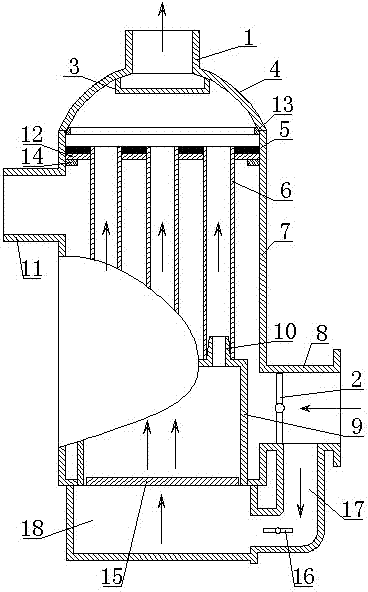

Oxygen-enriched combustion device of circulating fluidized bed and air supply method for oxygen-enriched combustion thereof

ActiveCN105650628AWill not cause safety accidentsImprove economic efficiencyFluidized bed combustionFluegas recirculationCombustionFluidized bed

An air supply method for oxygen-enriched combustion of a circulating fluidized bed comprises the steps of providing recirculating flue gas and oxygen for a fluidized bed body. The recirculating flue gas and the oxygen are led into the fluidized bed body respectively and then mixed. In addition, the recirculating flue gas and the oxygen are both preheated before entering the fluidized bed body. The invention also provides an oxygen-enriched combustion device of the circulating fluidized bed. According to the air supply method, the manner that the high temperature oxygen and the high temperature recirculating flue gas are not mixed before entering the fluidized bed body and are transported in respective pipes is adopted so as to prevent safety accidents during the conveying and mixing processes of the recirculating flue gas and the oxygen.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

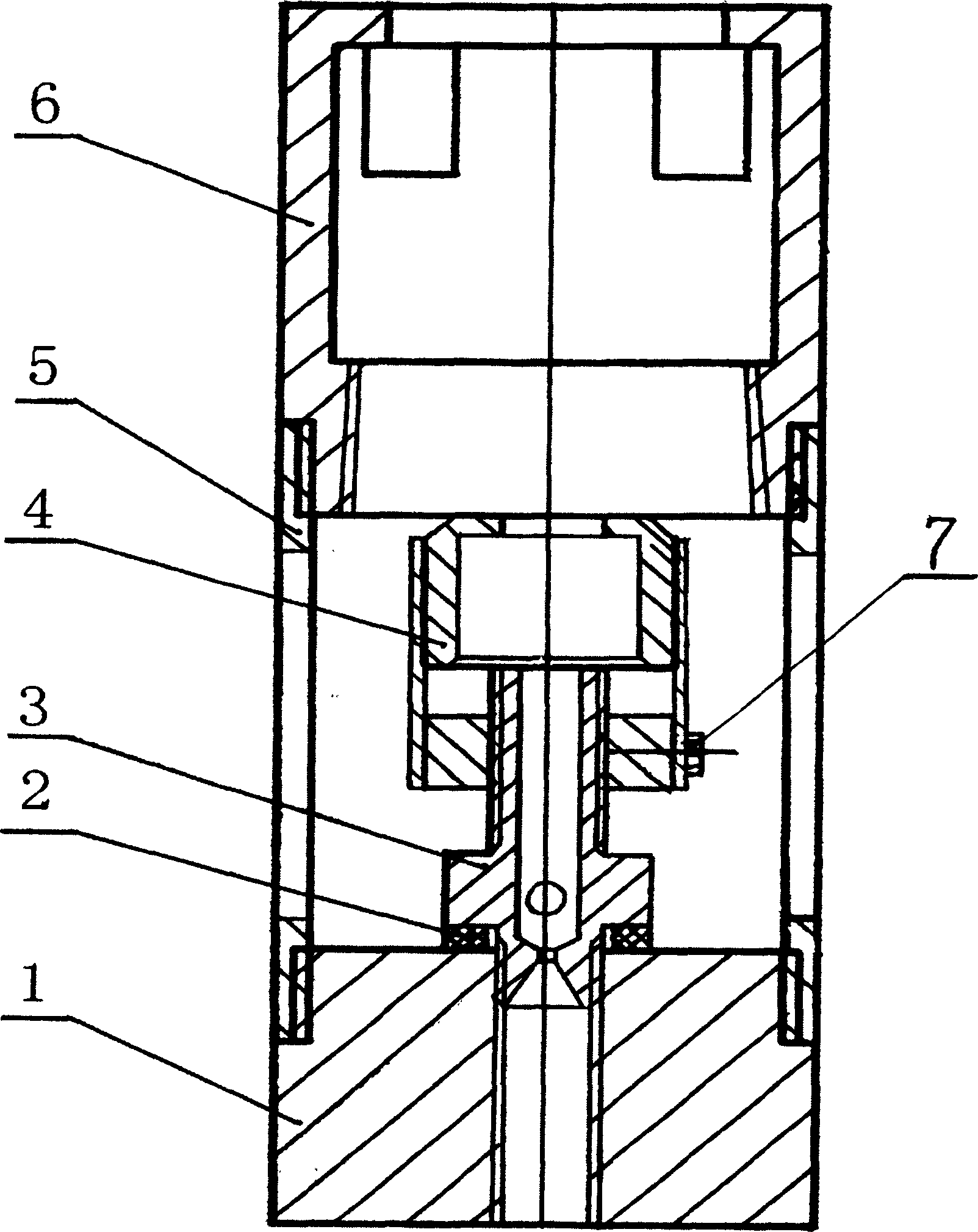

Combustion method of low-pressure and low-concentration methane gas and device

InactiveCN101713538AEfficient combustionImprove ejection abilityIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberProduct gas

The invention discloses a combustion method of low-pressure and low-concentration methane gas. In the combustion method, an inner pipe and an outer pipe which are communicated with a combustion chamber are adopted as an air inlet pipe, wherein the inner pipe is a fuel gas channel, and a channel between the inner pipe and the outer pipe is an air channel; air inside the air channel enters the combustion chamber at high speed and forms negative pressure at the outlet of the fuel gas channel; and the low-pressure and low-concentration methane gas inside the fuel gas channel is absorbed into the combustion chamber and combusts in the combustion chamber in a mixing mode. The invention also provides a combustion device for realizing the combustion method. By utilizing the negative pressure formed at the outlet of the inner pipe when the air enters into the combustion chamber through the air channel and a great injection action generated by the negative pressure on the low-pressure low-concentration methane gas inside the inner pipe, the invention promotes the low-pressure and low-concentration methane gas to enter into the combustion chamber to mix with the air for combustion, and has the advantages of low combustion cost and less discharged pollution of the combustion.

Owner:CHONGQING UNIV

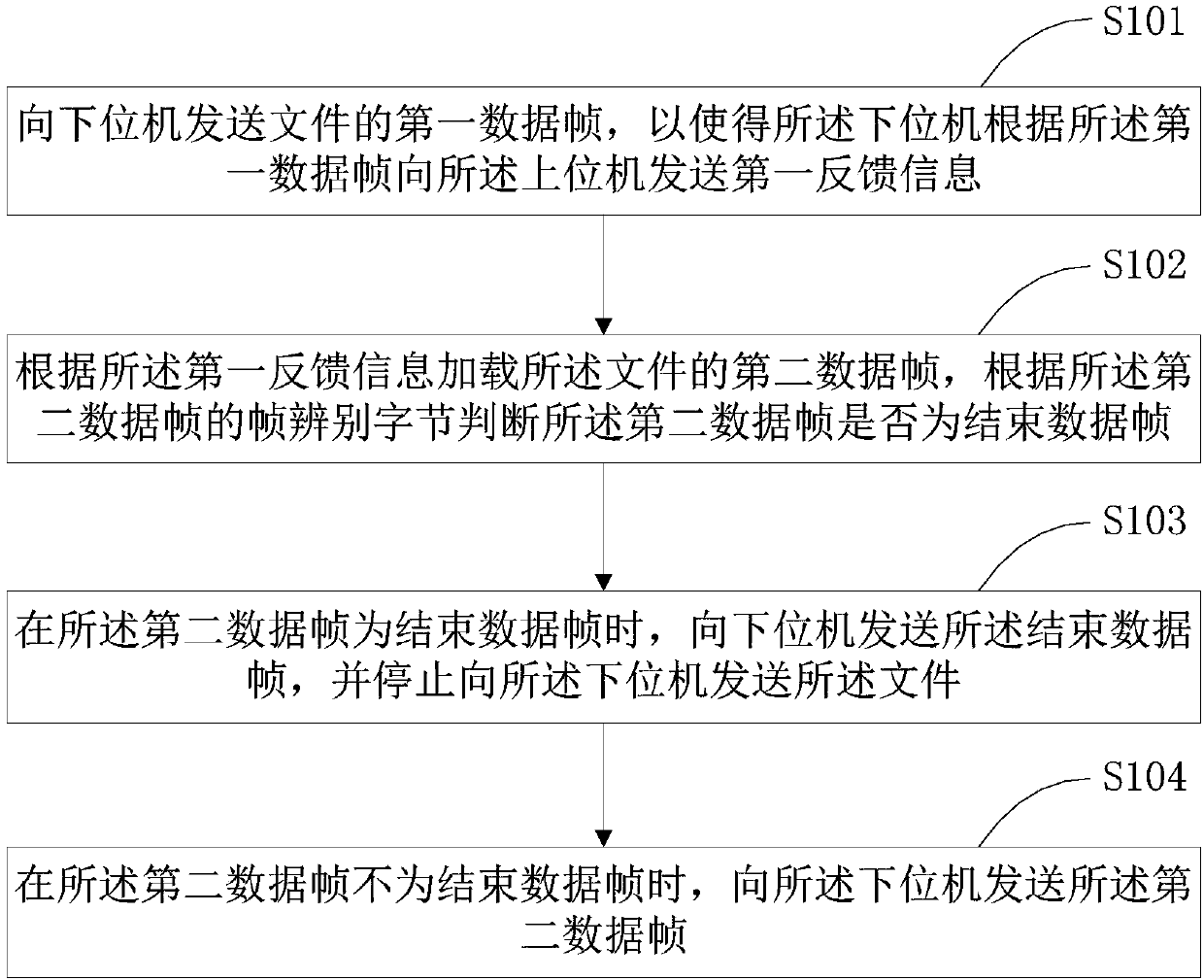

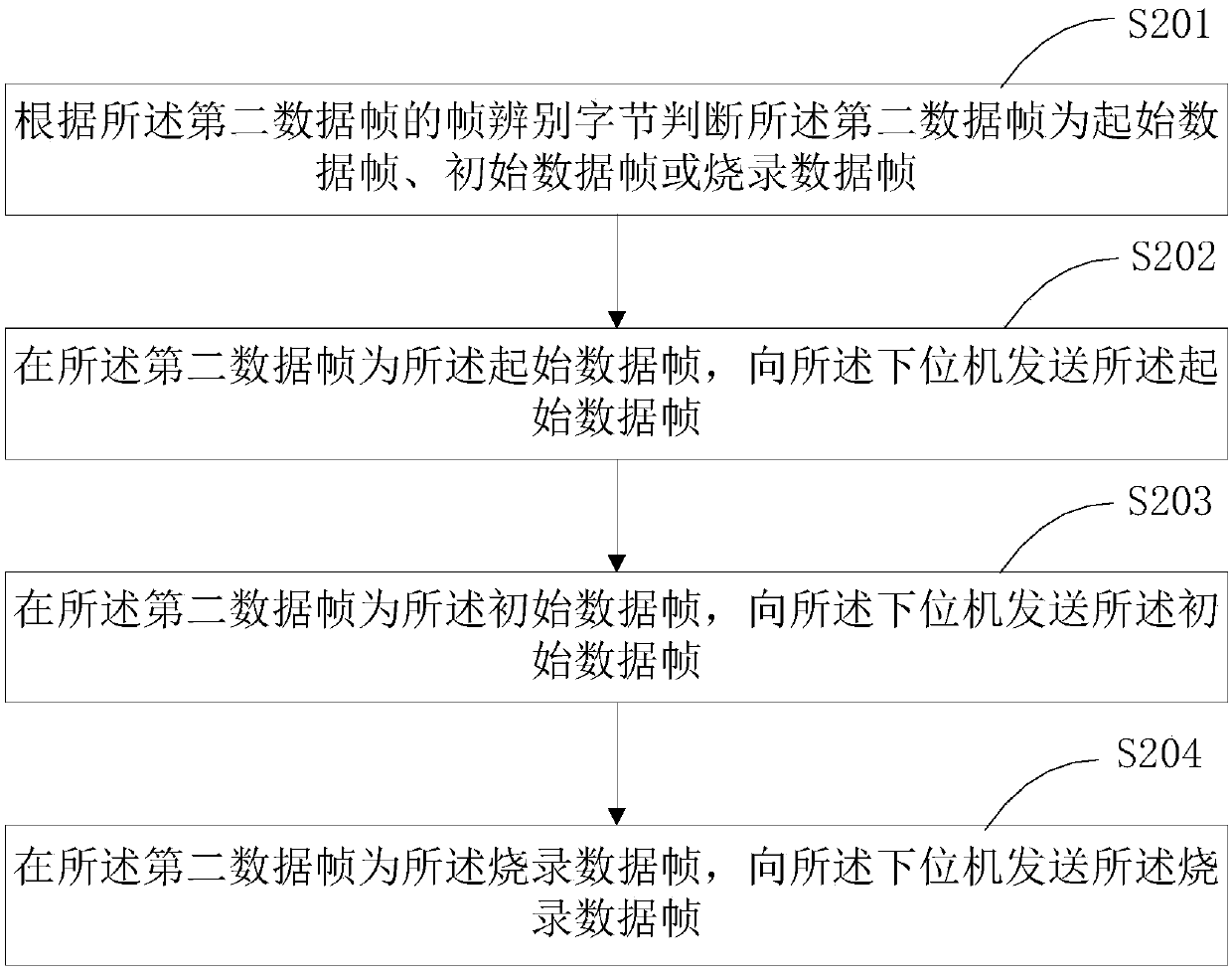

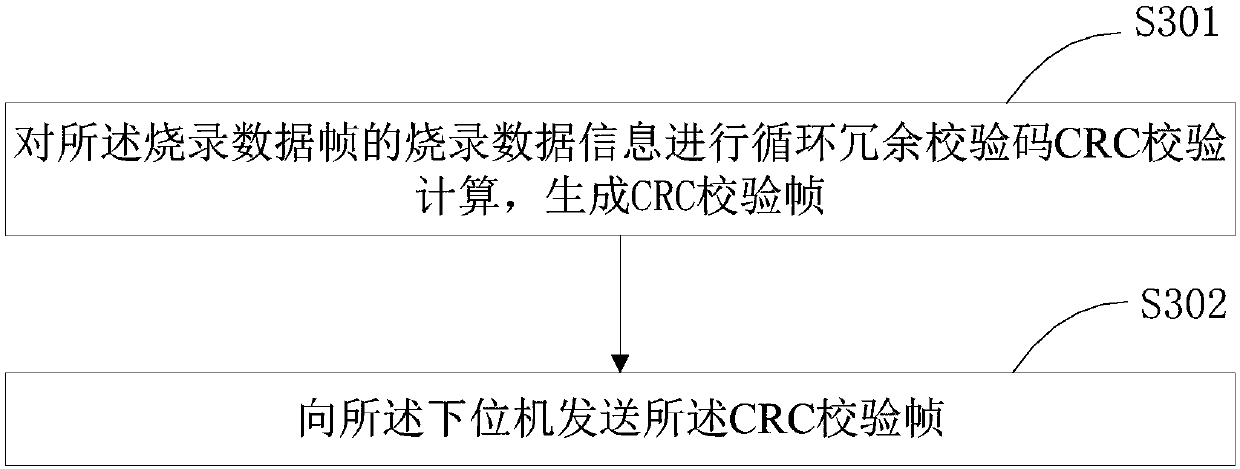

Software burning method and device

ActiveCN109976767ARealize automatic programmingReduce manual operationsProgram controlEnergy efficient computingComputer engineeringSoftware

The invention is applicable to the technical field of software program burning, and provides a software burning method and device. The method comprises the steps that an upper computer sends a first data frame of a file to a lower computer through a communication protocol, and the lower computer judges whether the received data frame is correct or not according to the first data frame and sends first feedback information to the upper computer; the upper computer loads a second data frame of the file according to the first feedback information, and judges whether the second data frame is an enddata frame of the file; if the file is the ending data frame, the upper computer sends the ending data frame to the lower computer and stops sending the file to the lower computer; and if not, the upper computer sends a second data frame to the lower computer. The chip can be automatically burnt through the communication bus, an extra burning hardware interface does not need to be reserved, meanwhile, chip program upgrading can be remotely controlled, manual operation is reduced, burning efficiency is improved, and burning cost is reduced.

Owner:UBTECH ROBOTICS CORP LTD

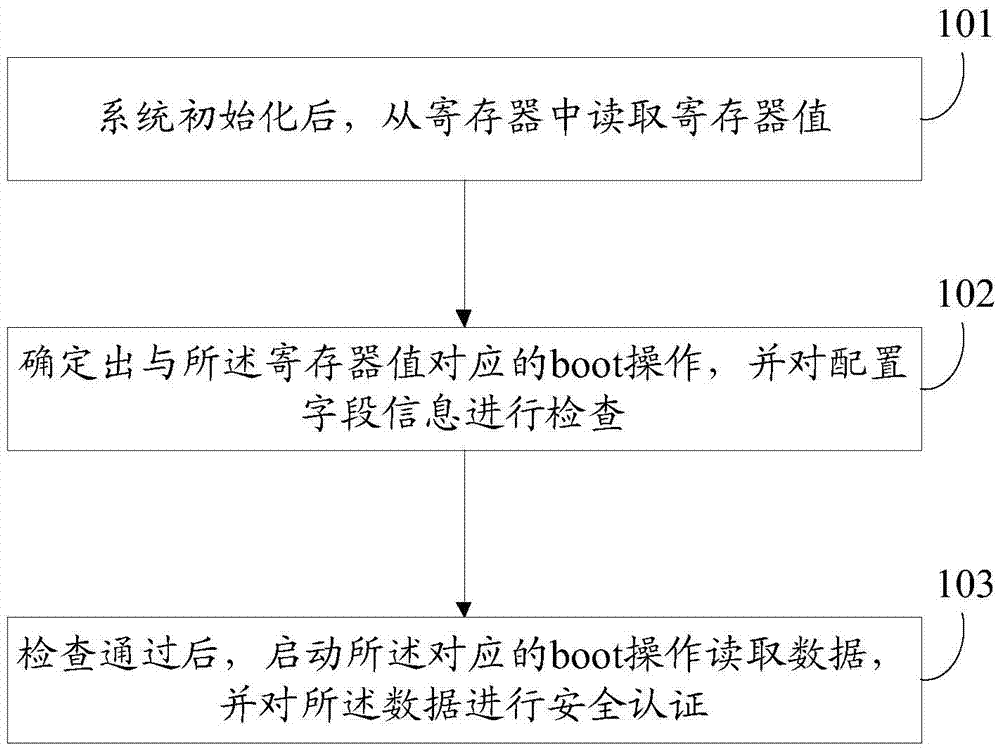

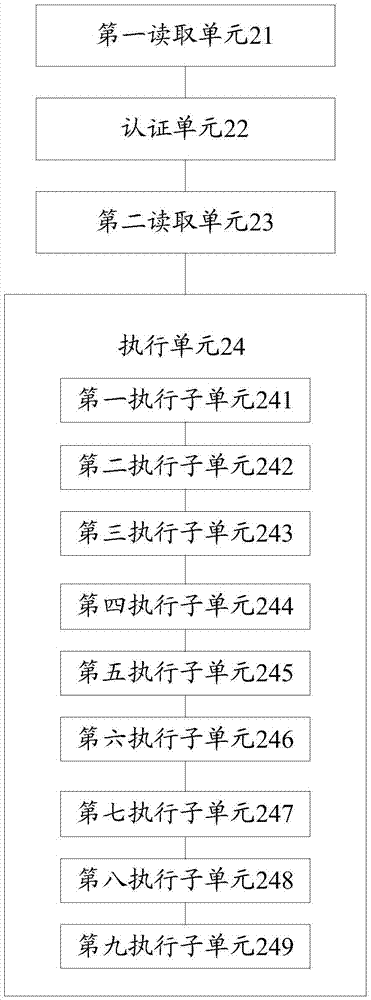

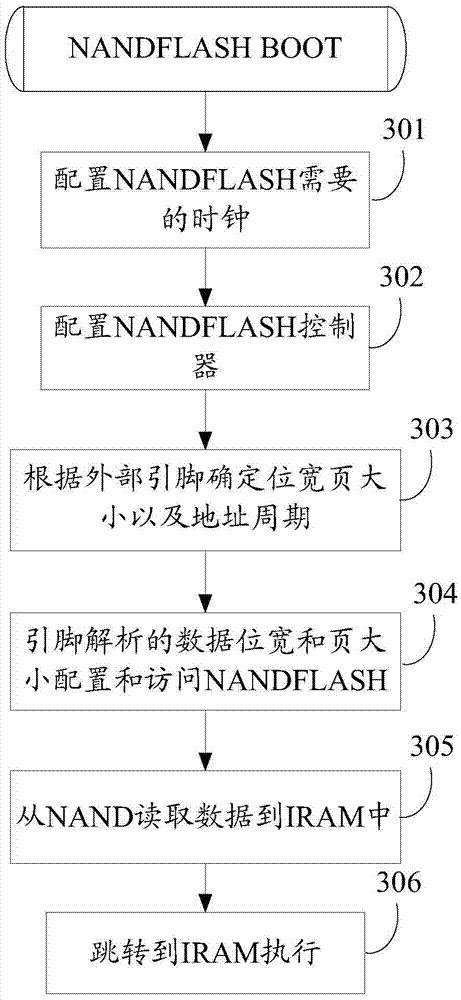

Chip supporting multi-security boot and startup method for chip

InactiveCN106897623AImprove production/maintenance efficiencyReduce hardware costsPlatform integrity maintainanceProgram loading/initiatingProcessor registerEmbedded system

The invention discloses a chip supporting multi-security boot and a startup method for the chip. The method comprises the steps of reading a register value from a register after system initialization; determining boot operation corresponding to the register value, and performing check on configuration field information; and after the check is passed, starting the corresponding boot operation to read data, and performing security verification on the data.

Owner:SANECHIPS TECH CO LTD

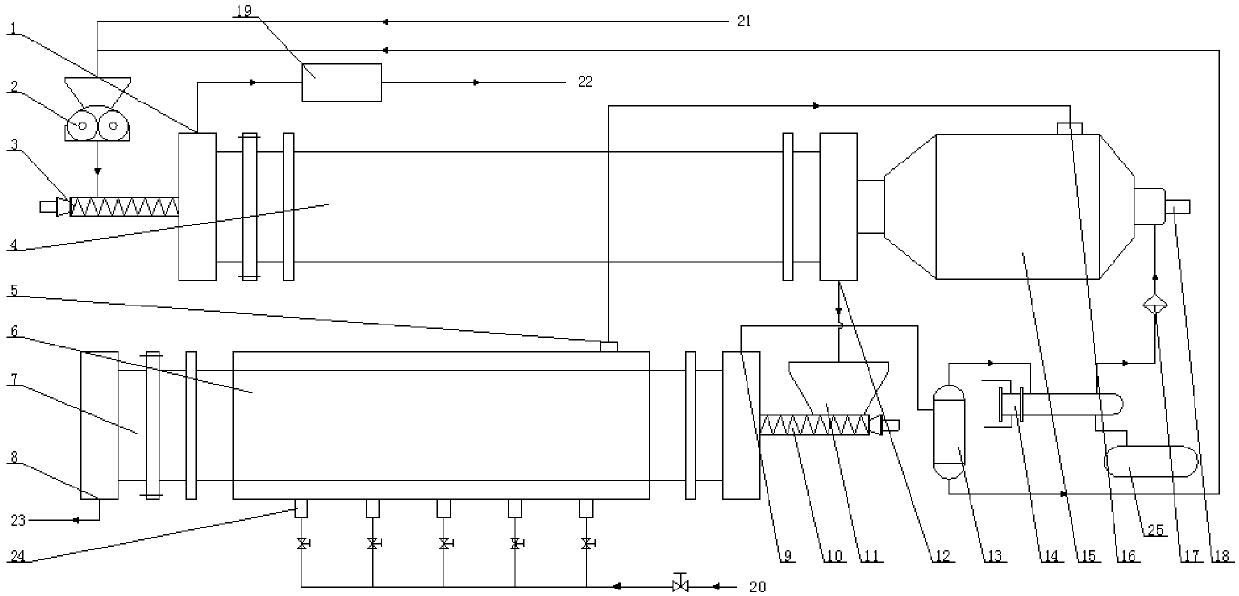

Oily sludge pyrolysis treatment process and apparatus

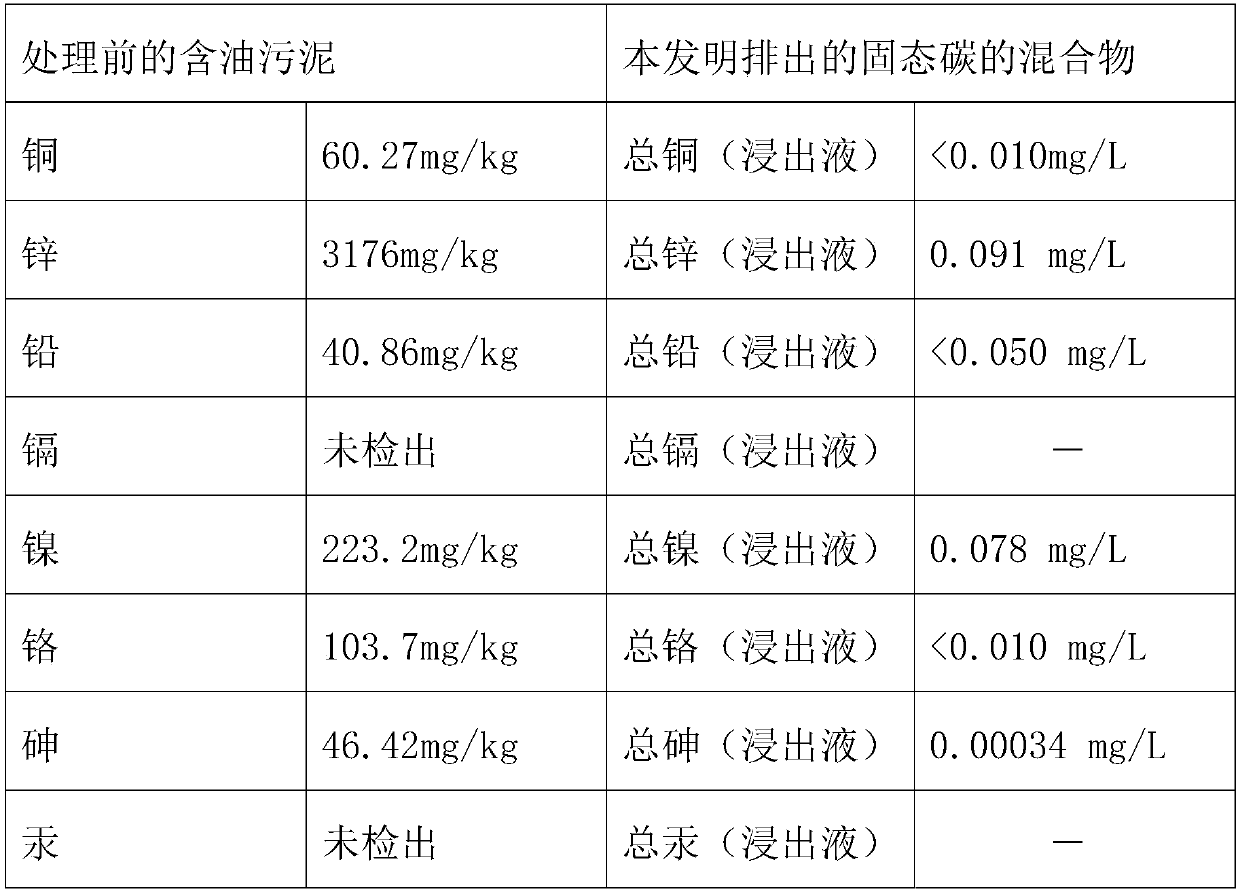

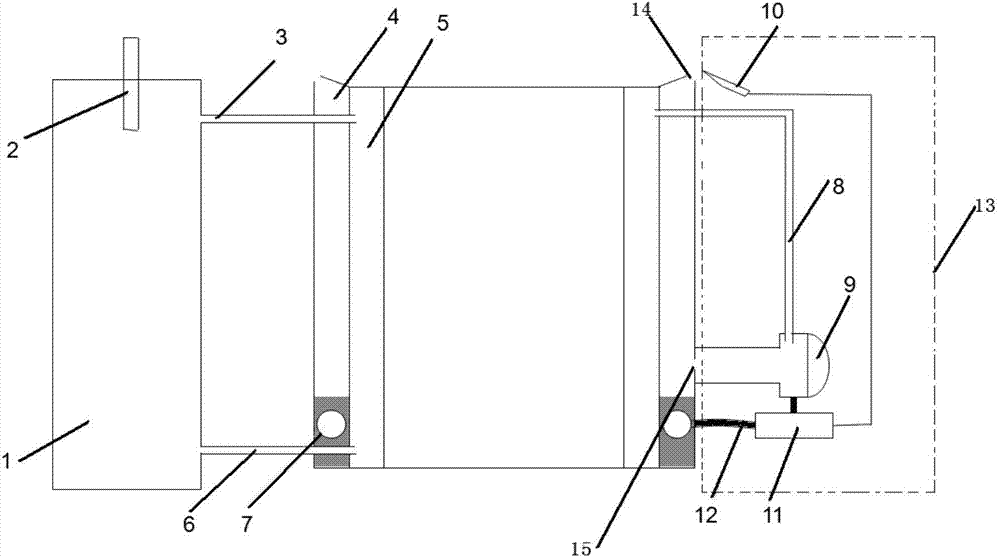

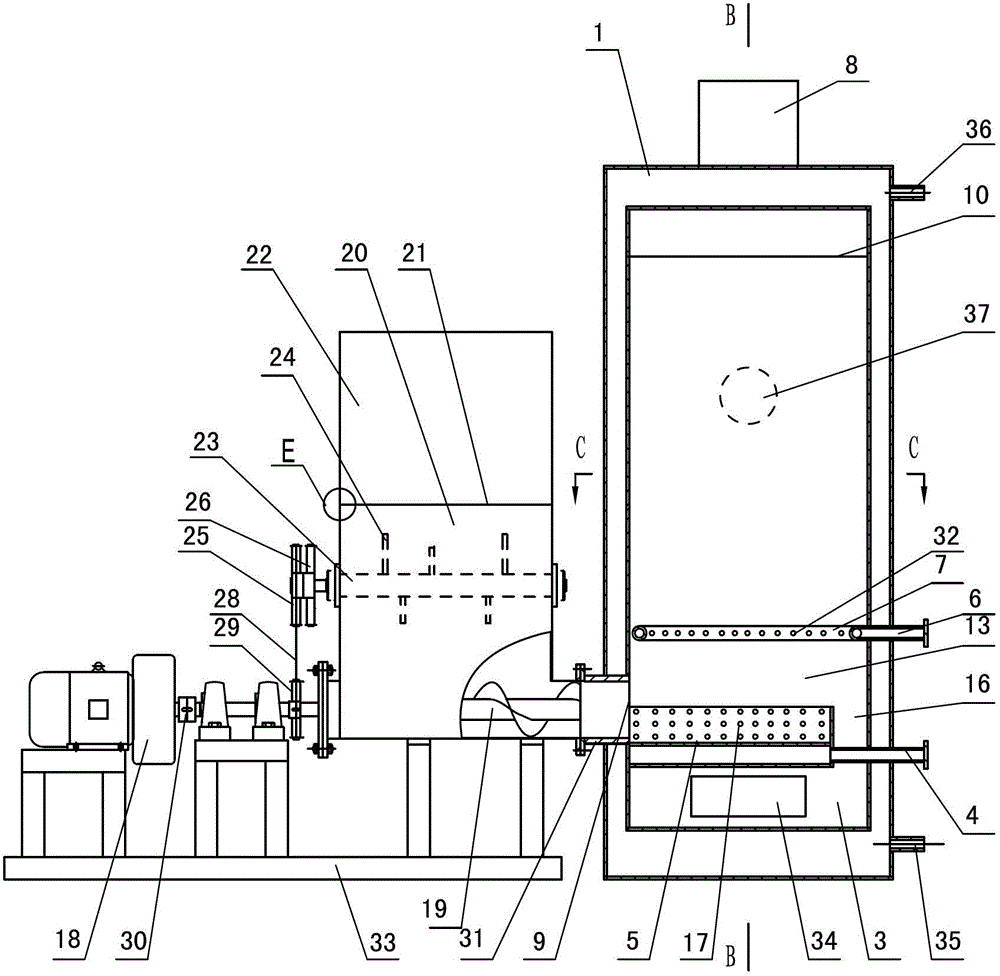

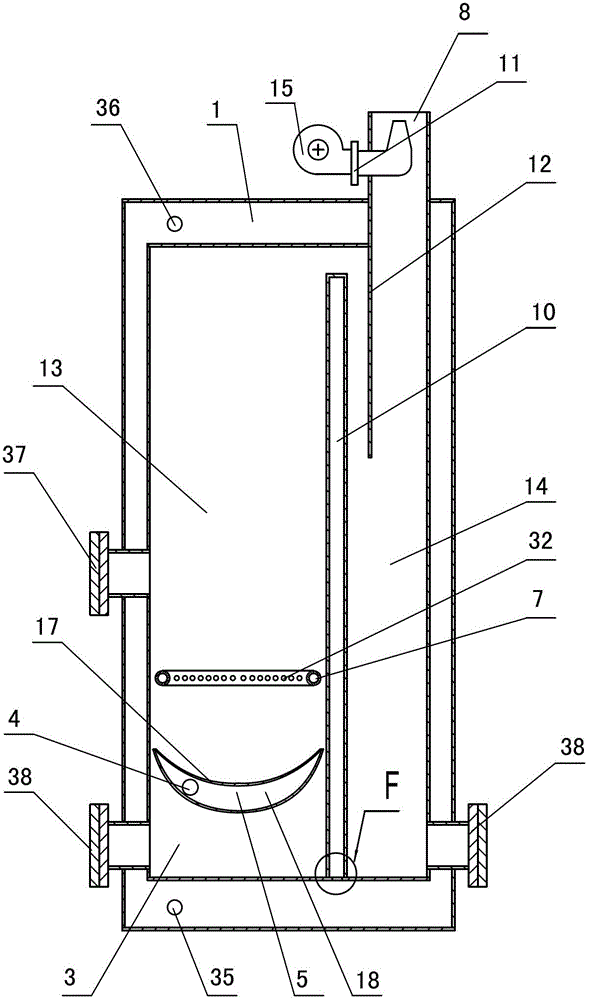

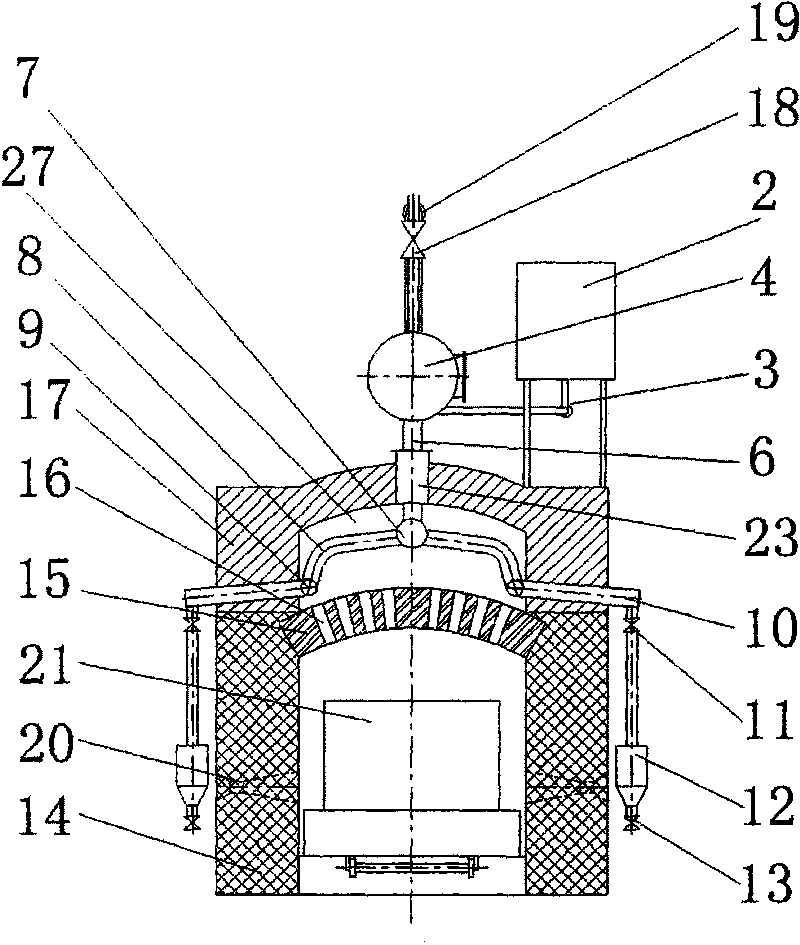

PendingCN109574444AStable stateAchieve reductionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSolid carbonSludge

The invention discloses an oily sludge pyrolysis treatment process and apparatus. The oily sludge pyrolysis treatment process comprises the steps: crushing oily sludge by virtue of a crusher, drying by virtue of an internal heating rotary kiln drying machine, performing the pyrolysis at a high-temperature oxygen-free state in a pyrolysis furnace, wherein main products are a gaseous mixture and a mixture of solid carbon, discharging the mixture of the solid carbon from a material outlet on the lower part of the pyrolysis furnace out of the apparatus, discharging the gaseous mixture from a pyrolysis furnace exhaust opening above the pyrolysis furnace into a tar washing separator to be washed and separated, conveying solid heavy components separated from the tar washing separator into the crusher to be crushed together with the oily sludge and to be continuously circulated in the system, decomposing and purifying tail gas in a tail gas roasting device at a high temperature, performing theconventional treatment for the tail gas, and discharging the tail gas. The oily sludge pyrolysis treatment process and apparatus are simple in production process, stable in product state, free from secondary pollution, and capable of realizing the thorough harmless closed cycling treatment for the oily sludge.

Owner:北京山水青源环保科技有限公司

Low-temperature semiwhite porcelain and manufacturing method thereof

The invention discloses a low-temperature semiwhite porcelain and a manufacturing method thereof, belonging to the technical field of ceramics. The blank of the low-temperature semiwhite porcelain comprises the following raw materials in parts by mass: 30-40 parts of Longyan clay, 25-35 parts of Gangxi kaolin raw ore, 20-28 parts of flint, 7-12 parts of feldspar, 2-9 parts of talcum and 5-10 parts of dolomite. The low-temperature semiwhite porcelain can be quickly fired at the low temperature of 1000 DEG C, and can be discharged out of the kiln only by 7-8 hours from firing to cooling. The linear shrinkage is low and can be kept at 12% or below. The low-temperature semiwhite porcelain has high hardness and excellent whiteness (85% or above), and has comparable whiteness with light-weight porcelain. The low-temperature semiwhite porcelain has low water absorptivity (which can be kept at 3% or below and can reach the porcelain industry standard), has the advantages of high strength excellent high temperature resistance and excellent microwave resistance, can be subjected to 180-DEG C drying oven testing more than twice, and can pass the microwave oven and dishwasher performance test. The low-temperature semiwhite porcelain has wide applicability, and can be widely used for producing medium / high-grade domestic ceramics.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

Methanol fuel gasification stove

InactiveCN104121608AAvoid insufficient combustionImprove burnout rateDomestic stoves or rangesLiquid heating fuelProcess engineeringDirect heating

The invention discloses a methanol fuel gasification stove which comprises an ignition device, a heating device, a gas distributing chamber, a gas producing chamber, a fuel tube, a pressurizing tube, a gas feeding pipe and a methanol storage device. Because the heating device is arranged in the gas distributing chamber, a liquid methanol fuel in the gas producing chamber is directly heated into a gas state by the heating device, the liquid methanol fuel is pre-heated so that the problem of insufficient combustion caused by direct heating of liquid methanol is prevented, and the burn-off rate is increased. Because the gaseous methanol fuel is supplied to the gas distributing chamber through the gas feeding pipe, the methanol fuel can directly enter the gas distributing chamber after being gasified, and the use of an air blower or a pressure container is reduced to a certain extent. Because the gas producing chamber is further connected with the pressurizing pipe, and the gaseous methanol fuel is conveyed to the methanol storage device through the pressurizing pipe to gradually fill a space occupied by the outflowing liquid methanol fuel and then extrude remained liquid methanol fuel to continuously flow into the fuel tube, so that the self circulation of combustion is further realized.

Owner:深圳华琰科技有限公司

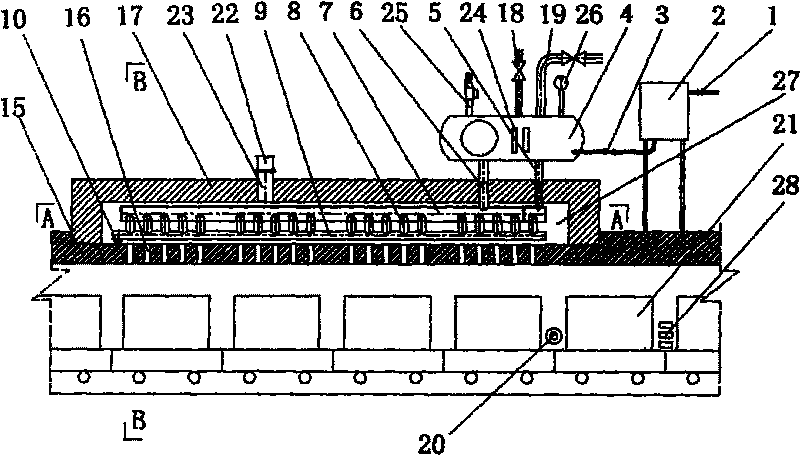

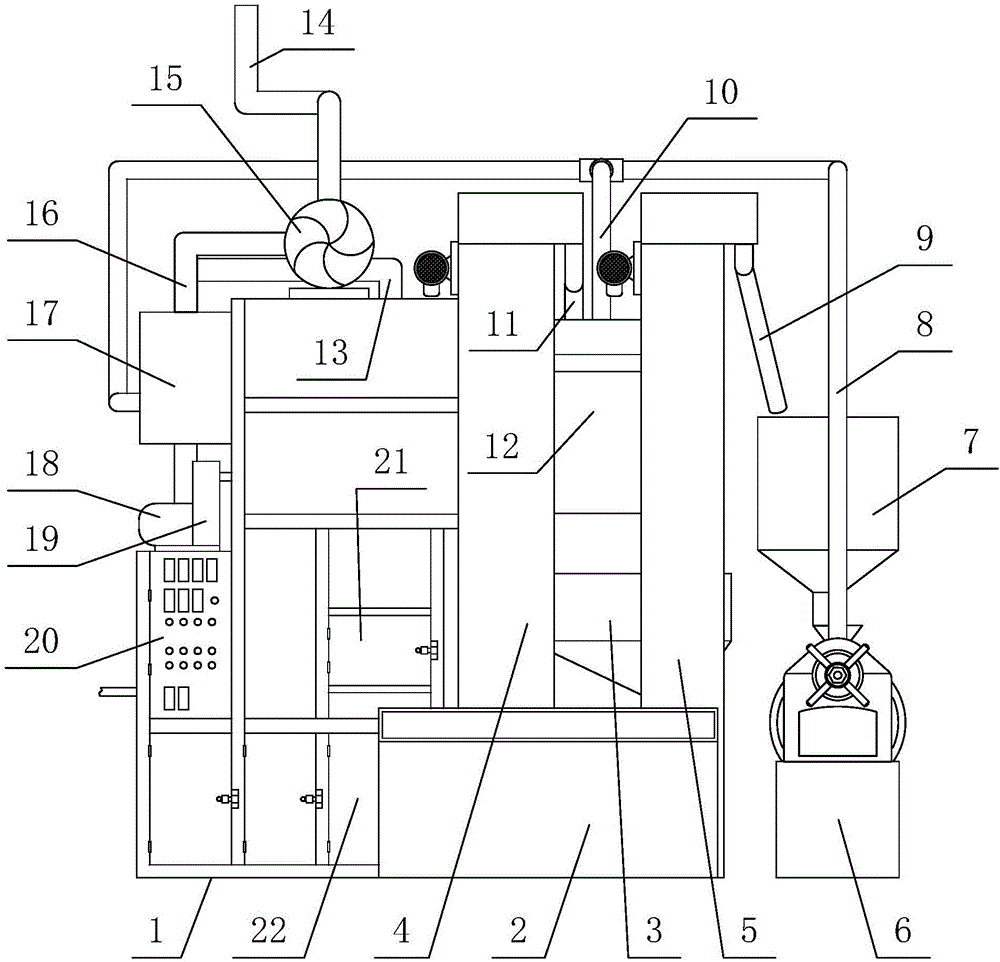

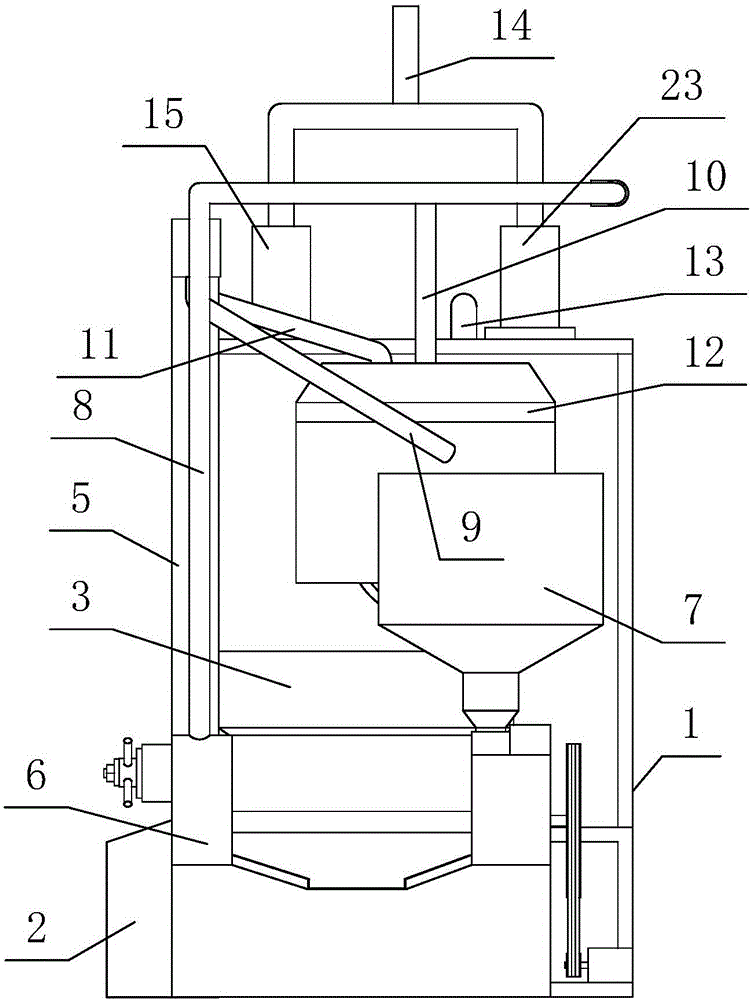

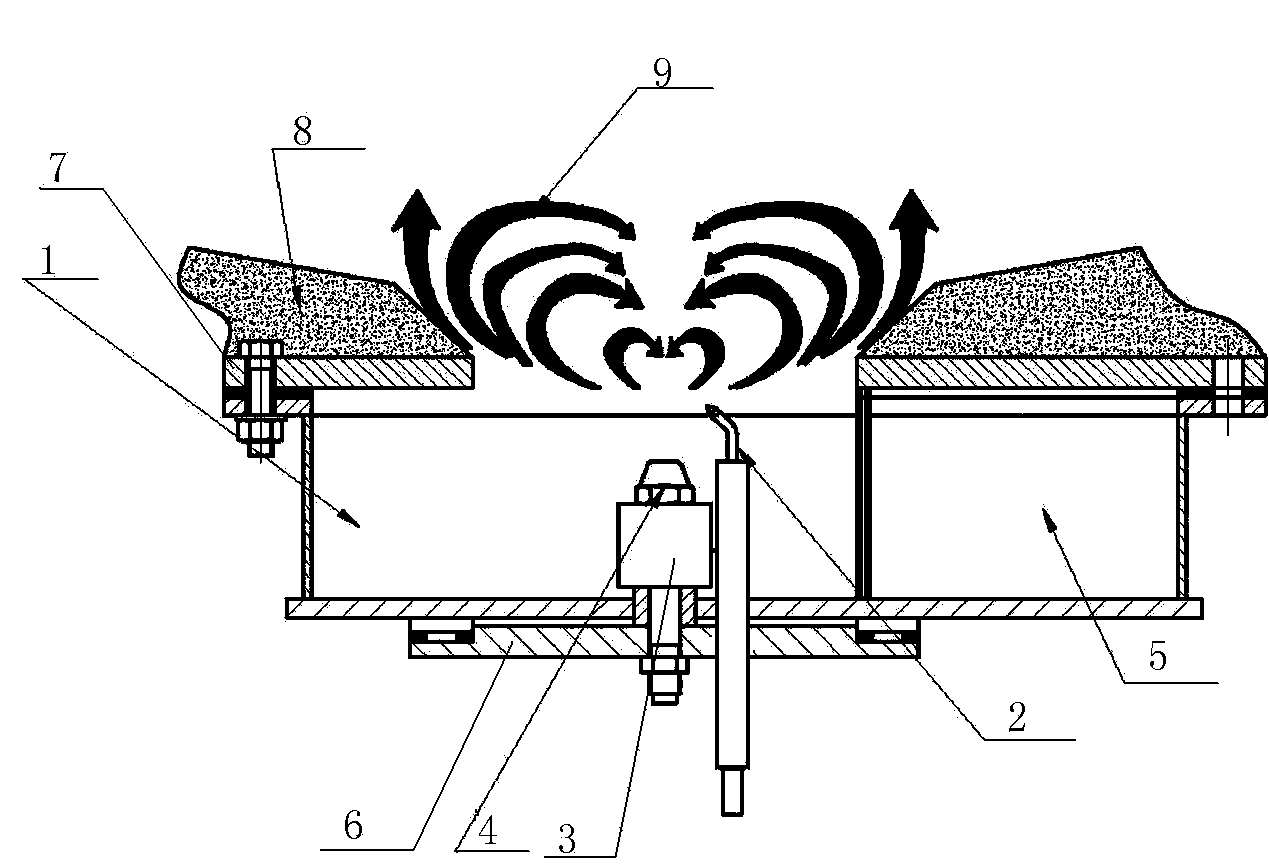

Small-sized biomass chopped-material direct-fired water boiler

InactiveCN102914046AImprove adaptabilityWon't clogWater heatersLump/pulverulent fuel feeder/distributionFlue gasHearth

The invention provides a small-sized biomass chopped-material direct-fired water boiler. The water boiler comprises an automatic feeding mechanism and a boiler body, wherein the automatic feeding mechanism consists of a loading box, a feed box, two horizontally placed ejecting rollers and a spiral auger, a draw plate is arranged at the bottom of the loading box, the feed box is positioned below the loading box, the ejecting rollers are mounted in the feed box and provided with radiant pick teeth, and the spiral auger of which the output end is communicated with a feed inlet of the boiler body through a feeding pipe is positioned below the ejecting rollers; and the boiler body consists of a dust collection room, a primary air inlet pipe, a primary air room positioned above the dust collection room and communicated with the primary air inlet pipe, a secondary air inlet pipe, a flue gas steering plate, a secondary air distribution pipe positioned above the primary air room and communicated with the secondary air inlet pipe, a smoke exhaust pipe arranged at the top of a hearth, a flue gas entrained flow air inlet pipe positioned on the side wall of the smoke exhaust pipe and a water jacket on the outer wall of the hearth. The small-sized biomass chopped-material direct-fired water boiler has the advantages of simple structure, low fuel and running costs, cleanliness and convenience in use and high heat efficiency, and is suitable for heating, bathing and the like in wide rural-urban fringe zones and small towns.

Owner:SHANDONG UNIV OF TECH

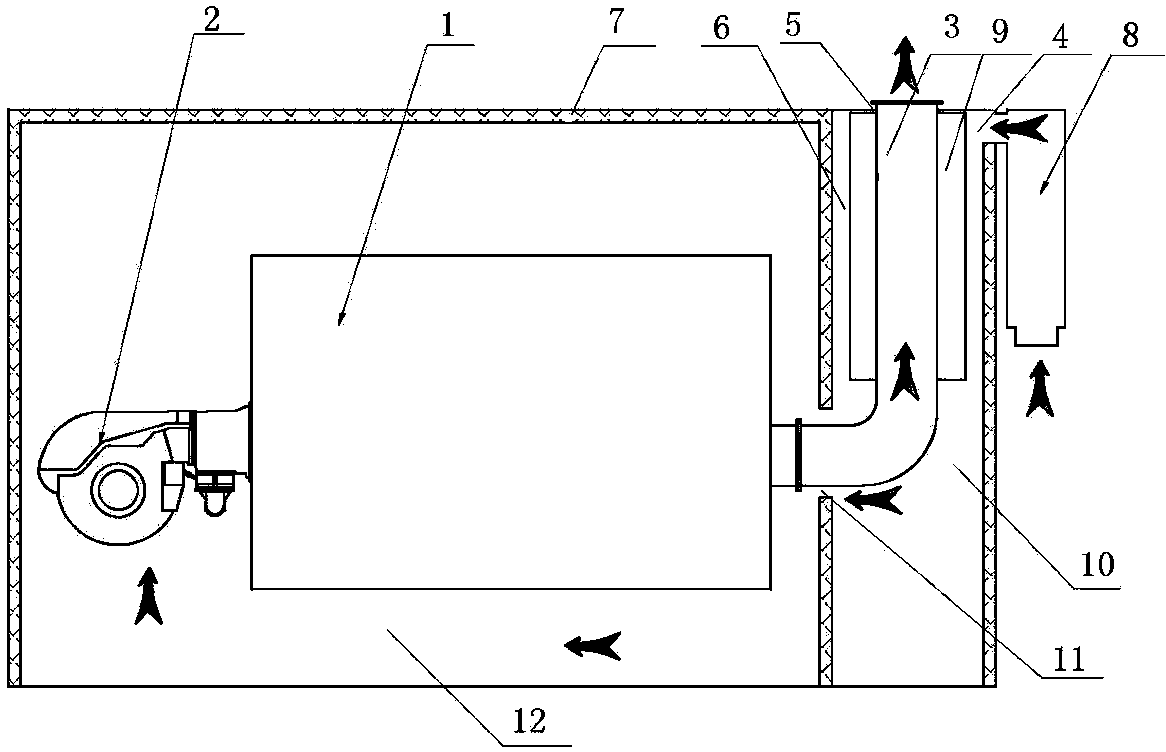

Low-noise boiler with air preheating

InactiveCN104266363AReduce noiseIncrease temperatureFluid heatersCombustion processLow noiseCombustor

The invention discloses a low-noise boiler with air preheating. The low-noise boiler with air preheating comprises a boiler body, a combustor connected to one side of the boiler body and a chimney connected to the other side of the boiler body, wherein a mute cover is arranged outside the boiler body; an air preheating region is arranged on one side of the mute cover; a smoke exhaust hole is formed in the top part of the air preheating region; the chimney is communicated with the smoke exhaust hole and a boiler smoke outlet; an air inlet vertical to the chimney is formed in one side of the upper part of the air preheating region; a first air channel is arranged in the air preheating region; the first air channel corresponds to the position of the chimney. The low-noise boiler with air preheating is simple and beautiful in overall structure, can reduce noise of the whole boiler, improves temperature of new air and reduces energy source needed for combustion, energy consumption and combustion cost as the air preheating region is arranged at one side of the boiler body, and the new air before entering into the combustor is preheated through the air preheating region in advance, and is energy-saving and relatively environment-friendly as heat energy of waste smoke can be further recycled.

Owner:LIJU THERMAL EQUIP TECH

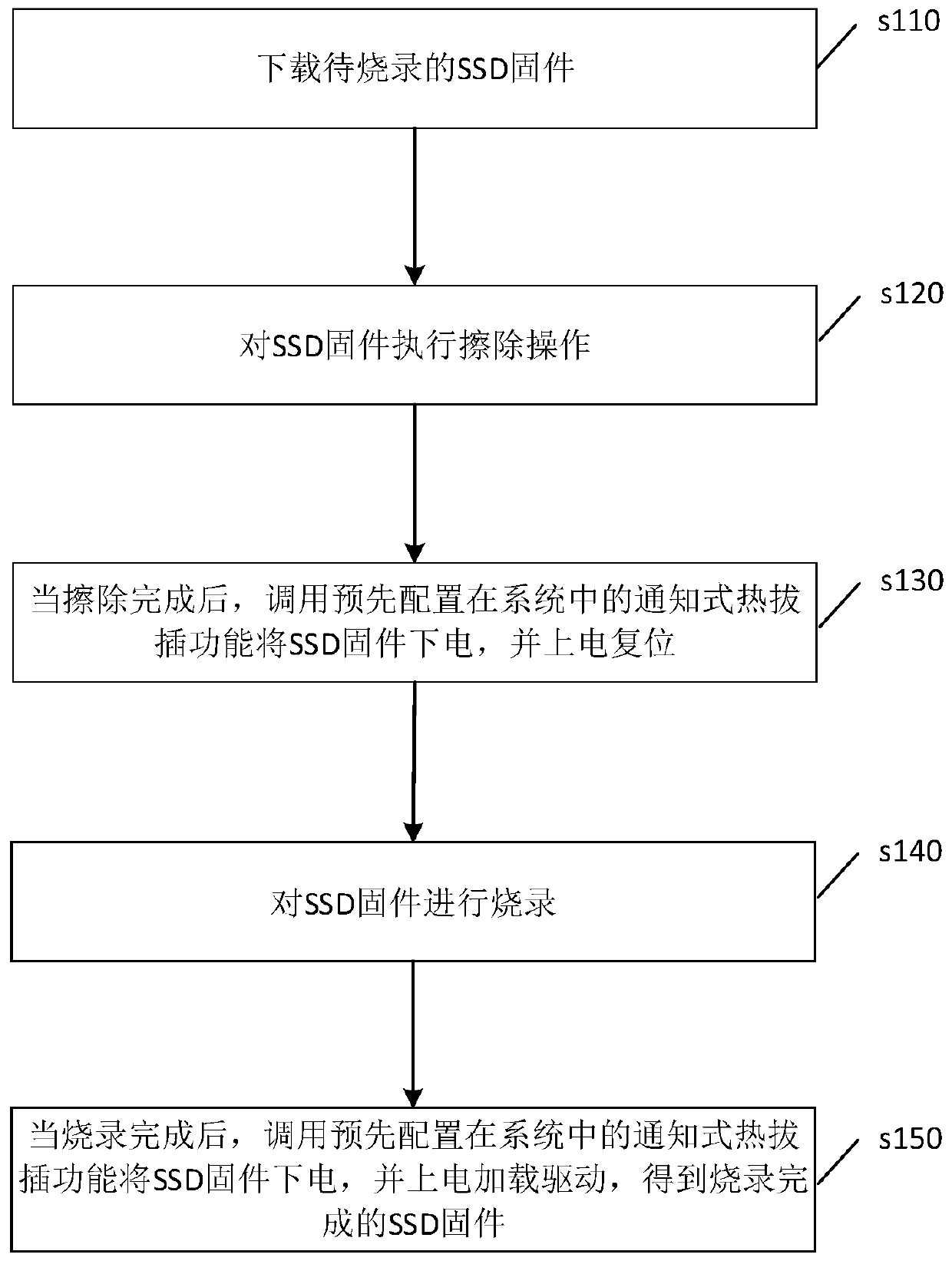

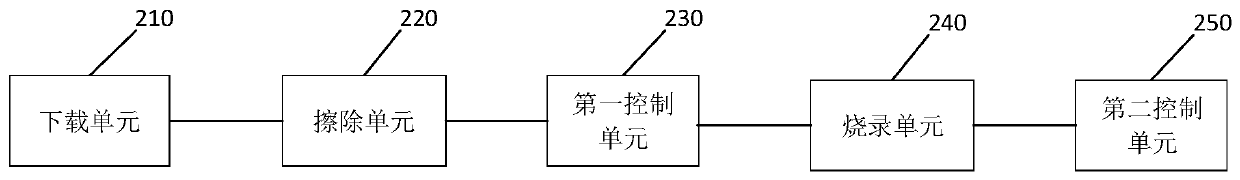

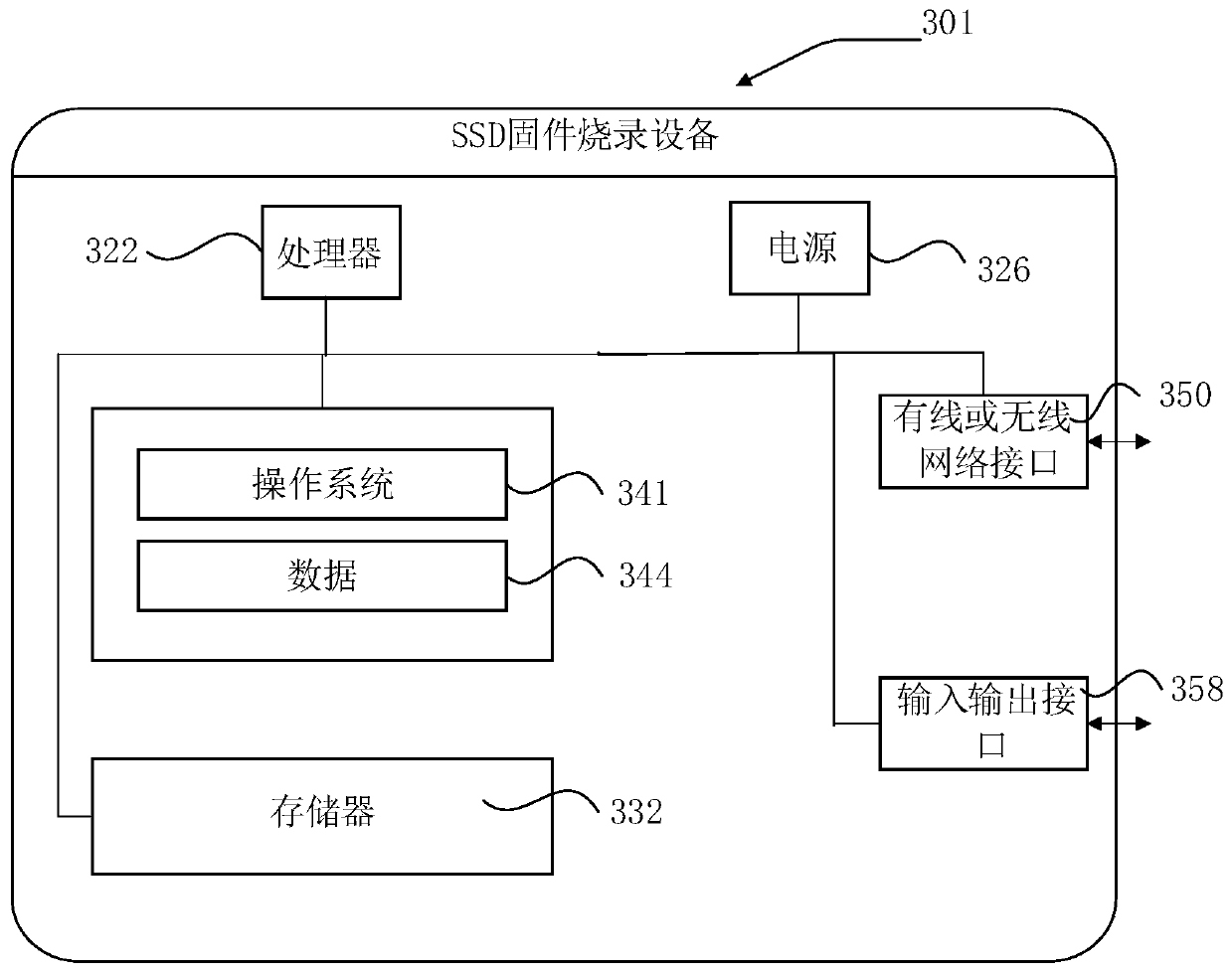

SSD firmware burning method and related components

PendingCN111552486AReduce manual unplugging actionAvoid workloadSoftware deploymentSoftware engineeringWorkload

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

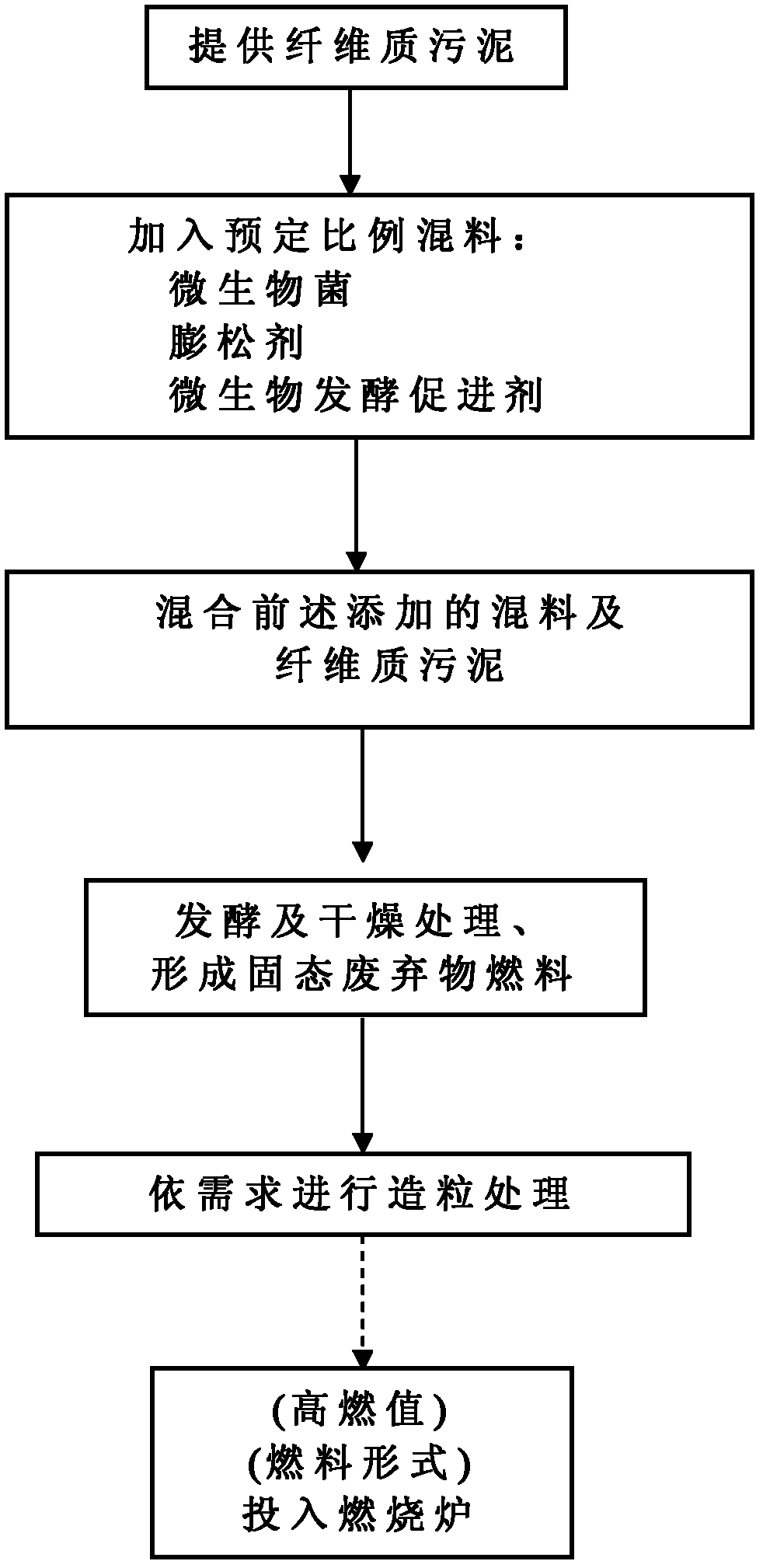

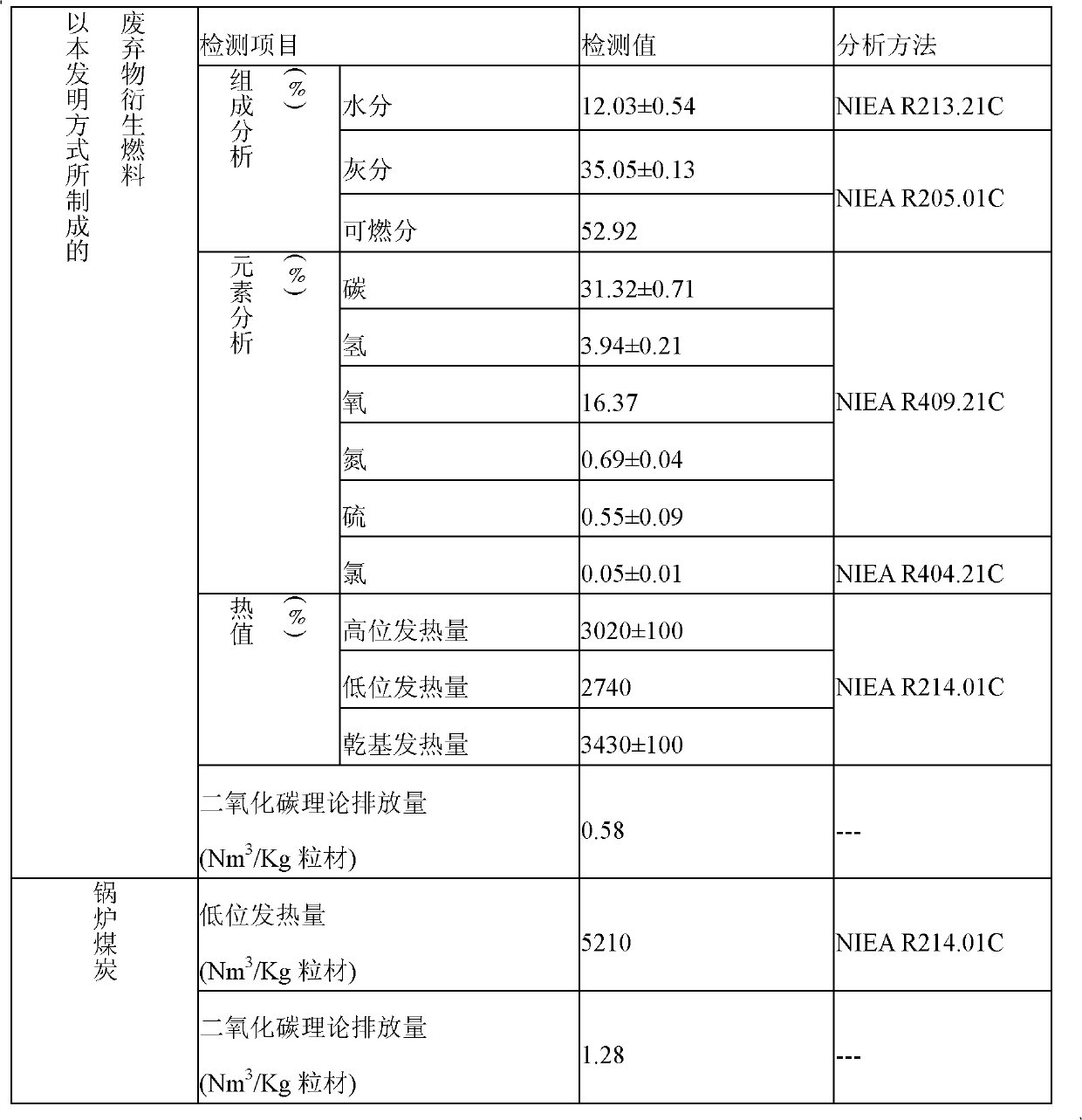

Preparation method of refuse derived fuel

A preparation method of a refuse derived fuel comprises the following steps of: providing fiber sludge, adding a mixed material containing microbial flora, a bulking agent and a microbial fermentation promoter which are mixed according to a predetermined proportion, uniformly mixing, and carrying out fermentation on the uniformly-mixed materials and fiber sludge for a period of time so as to form the solid refuse fuel.

Owner:MINGDA BIOTECH

Tunnel kiln waste heat boiler

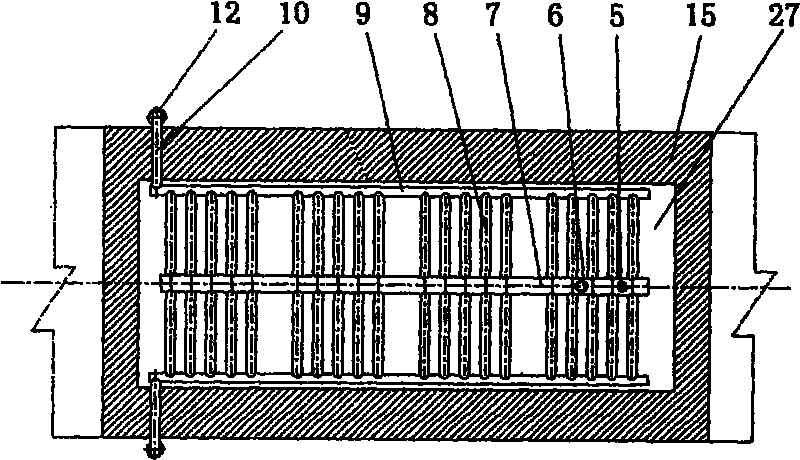

InactiveCN101694353ALess varietyAchieve energy saving and emission reductionIncreasing energy efficiencySteam generation using hot heat carriersTunnel kilnAir pump

The invention relates to a tunnel kiln waste heat boiler which is characterized in that a water supply pipeline is connected to a water supply tank, the bottom of the water supply tank is sequentially connected with valves and a steam storage tank by pipelines; a steam output pipe provided with the valve and a steam discharge pipe provided with the valve are connected on the steam storage tank, and the bottom surface of the steam storage tank is connected with an upper pipe of a multi-pipe evaporation pot by a thick connecting pipe and a thin connecting pipe; and the multi-pipe evaporation pot is formed by the upper pipe, an arc-shaped pipe, a lower pipe and a drain pipe. An inner arch top of a tunnel kiln cooling zone is built with an outer arch top with a certain distance from the inner arch top, the inner arch top is provided with a grate hole which is used for pumping hot air and communicated with the interior of a tunnel kiln, the outer arch top is provided with a hot air suction hole which is communicated with a suction pipe of a hot air pumping machine by the pipeline to form a hot air furnace, and the multi-pipe evaporation pot is positioned inside the hot air furnace. The tunnel kiln waste heat boiler realizes energy conservation and emission reduction, and replaces a coal burning boiler by the waste heat boiler, thus reducing the fuel varieties, simplifying the production technique and lowering the burning cost.

Owner:袁奕明

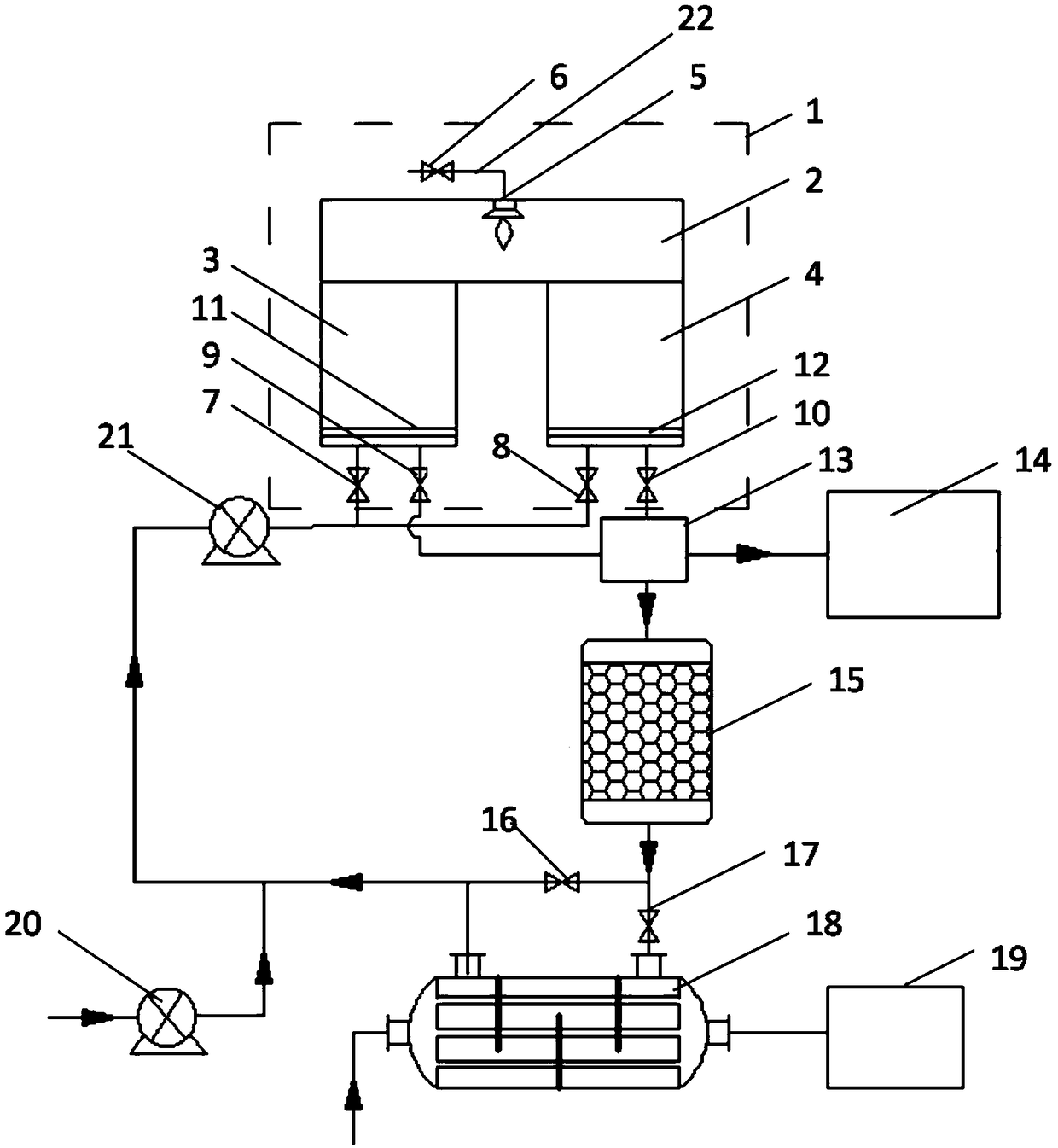

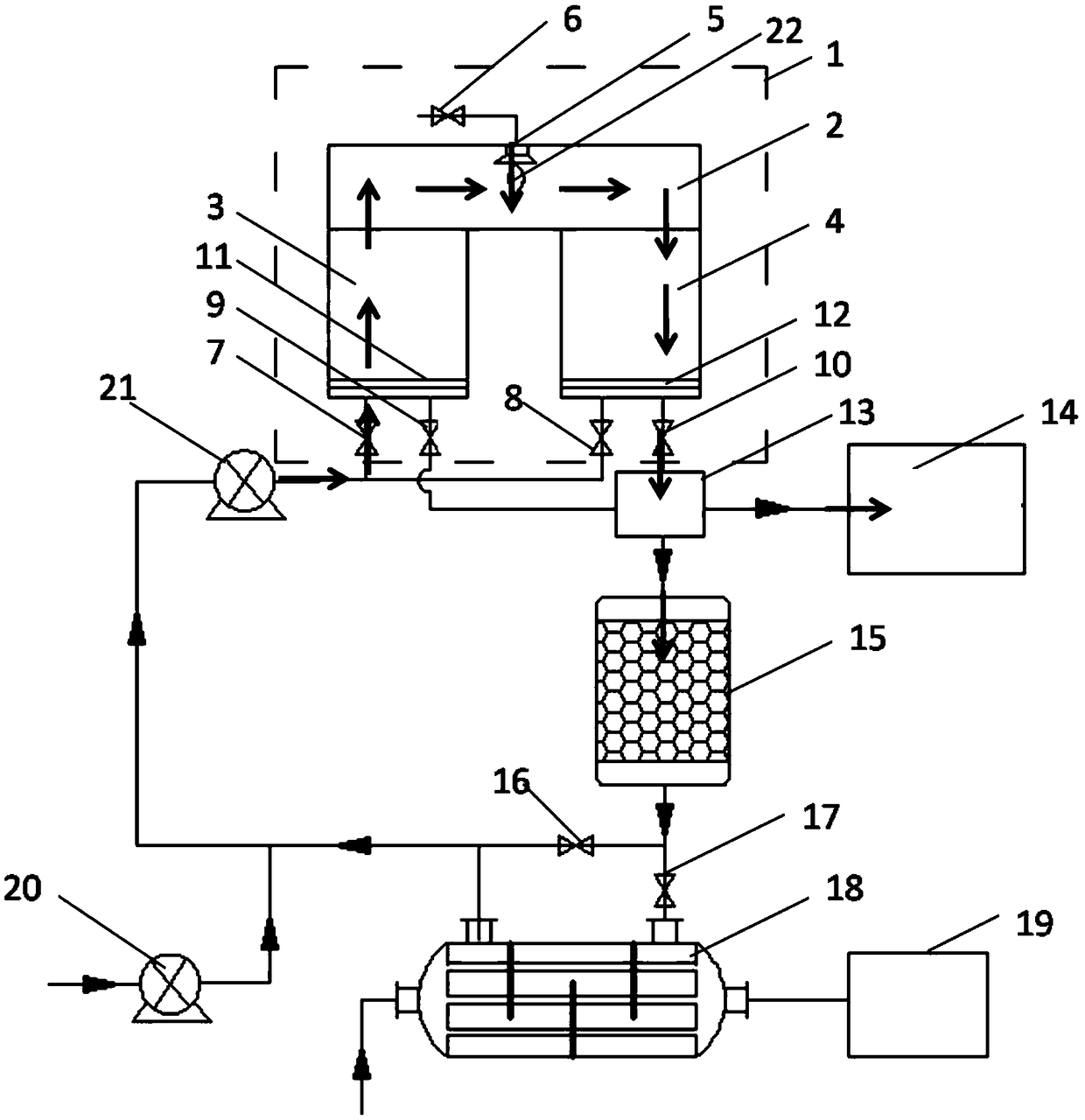

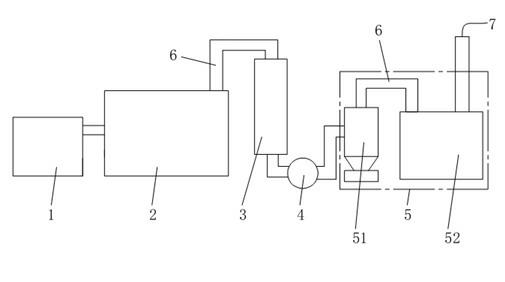

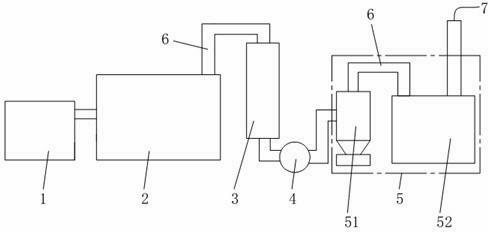

VOCs thermal oxidation treatment-based comprehensive waste heat recycling system and recycling method

ActiveCN109000269AImprove combustion efficiencyImprove utilization efficiencyClimate change adaptationIncinerator apparatusWaste heat recovery unitCombustion chamber

The invention discloses a VOCs thermal oxidation treatment-based comprehensive waste heat recycling system and recycling method. The system comprises a heat storage type incinerator, a flow divider, an absorption type refrigerating machine, an adsorption bed, a circulating fan and an air supplementing fan. The method comprises the following steps that part of smoke generated by a combustion chamber is conveyed to the absorption type refrigerating machine, the other part is conveyed to the adsorption bed, desorbed gas discharged from the adsorption bed is conveyed into the combustion chamber for combustion, part of the generated secondary smoke is conveyed to the absorption type refrigerating machine, the other part of the generated secondary smoke is conveyed to the adsorption bed, and then the secondary desorbed gas discharged from the adsorption bed is conveyed into the combustion chamber for combustion; Air supplementing processes are carried out in the whole process. According to the system and the method, the waste heat recovery adopts echelon heat extraction, specifically, the heat storage chamber is used for storing heat, the absorption type refrigerating machine is used forextracting heat, domestic hot water is used for heating and desorption hot air sources are used, and according to the gas temperature requirements of different waste heat utilization modes, the wasteheat is utilized to the maximum extent, and the energy utilization efficiency is improved.

Owner:TONGJI UNIV

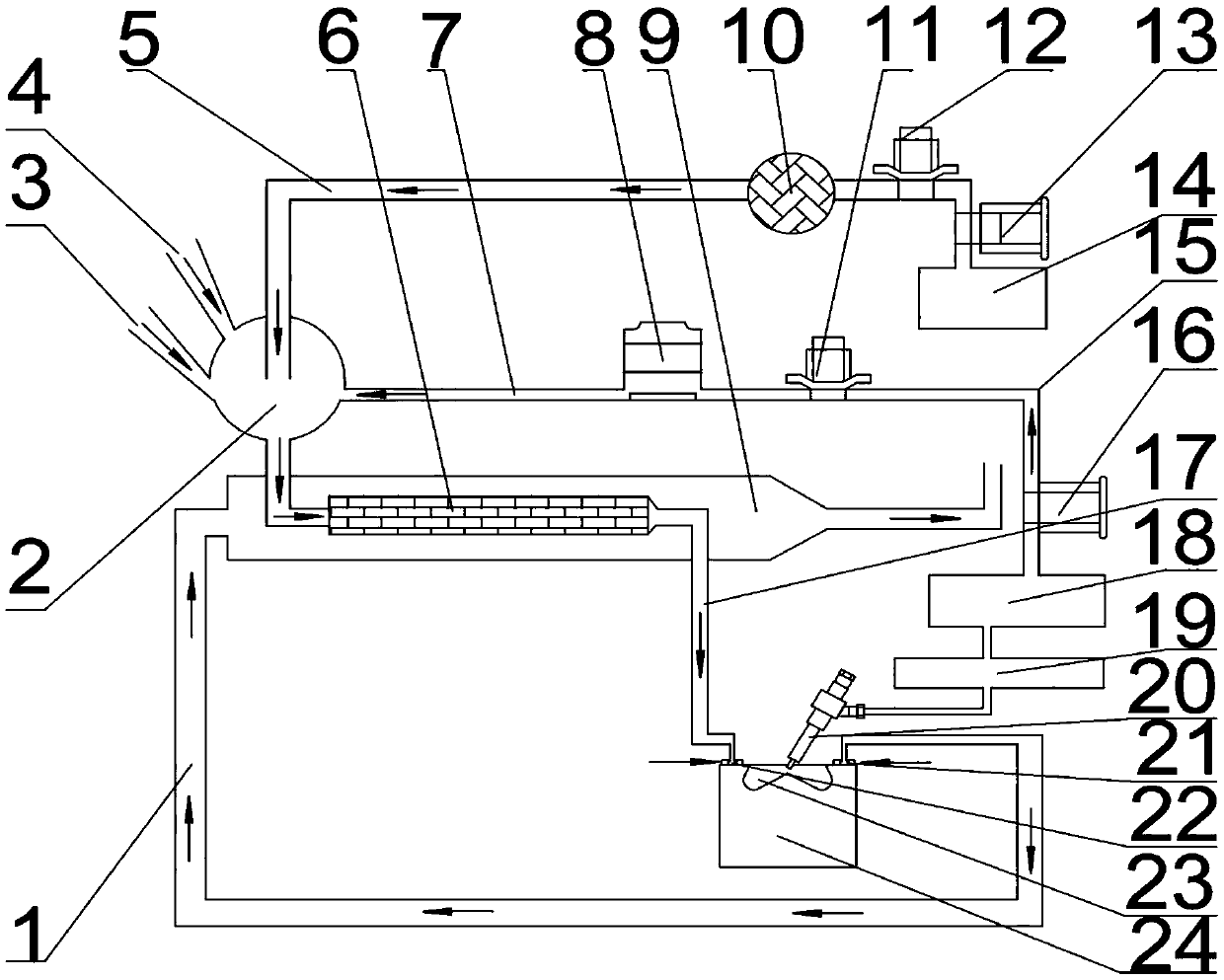

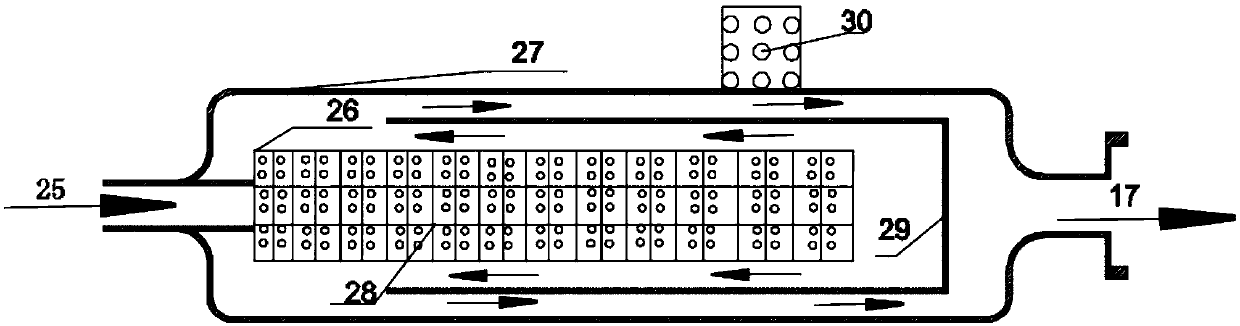

Efficient energy-saving biomass burner system

InactiveCN102679379AIncrease profitReduce burning costsLighting and heating apparatusWaste heat recovery unitAtmospheric air

The invention belongs to the technical field of boilers and particularly relates to an efficient energy-saving biomass burner system which comprises a boiler main body, wherein a biomass burner, a waste heat recovery device and a dedusting device are arranged on one side of the boiler main body, the biomass burner provides heat for the boiler main body, the waste heat recovery device recovers heat in smoke exhausted from the boiler main body, the dedusting device removes dust in the smoke after heat recovery through the waste heat recovery device, and a draught fan is arranged between the waste heat recovery device and the dedusting device. The efficient energy-saving biomass burner system has the advantages that the biomass burner which is low in burning cost is used for providing heat for the boiler main body; the waste heat recovery device treats high-temperature smoke exhausted from a smoke exhaust port of the boiler main body and recovers heat in the smoke, so that energy use ratio is improved and cost is reduced; and the smoke after dedusting by aid of the dedusitng device does not have any influence to the surrounding environment when being exhausted to the air, and the national energy conservation and emission reduction policy is met.

Owner:马鞍山永强节能技术股份有限公司

Novel high-performance mixed fuel oil

The invention relates to a novel high-performance mixed fuel oil. The invention aims to provide the high-performance mixed fuel oil, which is low in cost and high in performance. The invention adopts a technical scheme that: the novel high-performance mixed fuel oil comprises 45 to 55 volume parts of nonstandard diesel, 25 to 35 volume parts of aviation kerosene and 15 to 25 volume parts of heavy aromatics. As the nonstandard diesel can be extracted from recovered diesel to be reused, so the cost is very low. The novel high-performance mixed fuel oil can be used in place of No.0 diesel on various large transport vehicles, boilers and medium and low engines, particularly engines for tractors.

Owner:上海烨燃石油化工有限公司

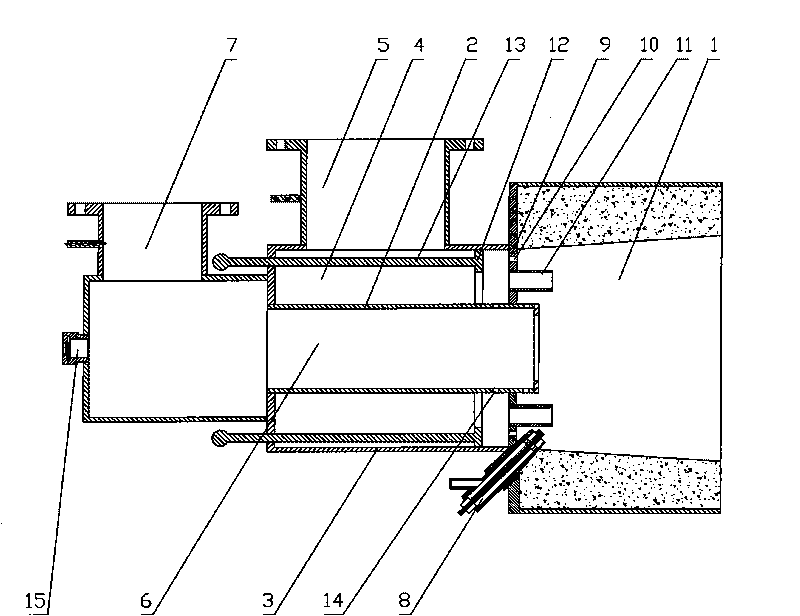

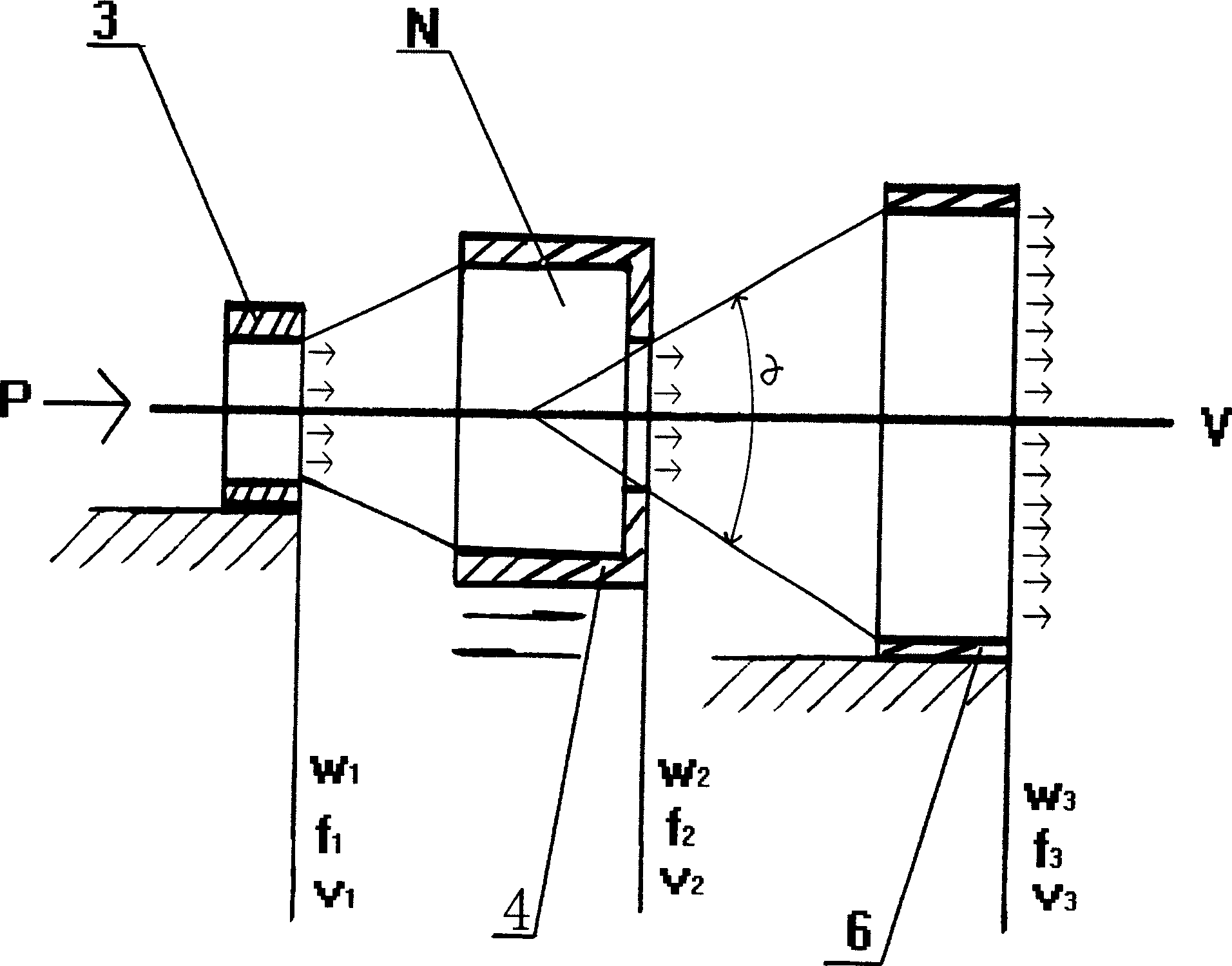

Jet and oxygen-enriched combustion method for gas fuel and burner therefor

InactiveCN1800710ABurn fullyIncrease combustion heatIndirect carbon-dioxide mitigationGaseous fuel burnerTemperature controlCombustor

The invention can utilize the pressure and ejection characters of gas fuel, and the burning energy to arrange the nozzle, ejector and ejection pipe in one axes. The ends of nozzle and the ejection pipe are fixed, while the ejector can axially move in middle stroke. The invention discloses a gas fuel ejection rich-oxygen burner for using ejection rich-oxygen burning method, to combine the nozzle, ejector, and ejection pipe burning room into one ejection rich-oxygen burner. The nozzle is designed as micro-ejection pipe; the ejector is designed as high-efficiency mixed non-stepped speed changer; the ejection pipe burning room has a multifunctional device, while they individually form the lower, middle, and higher temperature burning section. The invention can realize the fire temperature control of fire outlet and transforming the layer burning into whorl burning, which has 100% improved heat efficiency and reduced burning cost than traditional burning method.

Owner:范先宝 +1

High heat value fuel and preparation method thereof

The invention provides a high heat value fuel and a preparation method thereof. According to the present invention, methanol is used as a main material, and is supplemented with polyethylene glycol 400, an organic nano-modified nickel-aluminum-molybdenum alloy is introduced, and a gelled structure is formed through a photopolymerization reaction, wherein the organic nano-modified nickel-aluminum-molybdenum alloy is chemically bonded to the pores of the gelled structure, has a stable structure, and has a heat value synergistic effect on methanol and polyethylene glycol 400, and the gelled structure can increase the contact area between oxygen and fuel, promote the complete combustion of sufficient fuel, reduce the combustion cost, and greatly increase the heat value of the product.

Owner:重庆品坊新能源技术开发有限公司

Light hydrocarbon/diesel fuel reforming system and reforming method

ActiveCN109630245AReduce heating linksReduce the temperatureInternal combustion piston enginesNon-fuel substance addition to fuelWater vaporGas cylinder

The invention discloses a light hydrocarbon / diesel fuel reforming system and a reforming method. The reforming system comprises a light hydrocarbon fuel supply device, a diesel supply device, a reforming reaction device and a gas mixer. The gas mixer is provided with a carrier gas inlet pipe and a water vapor gas inlet pipe, the light hydrocarbon fuel supply device is used for supplying atomized light hydrocarbon fuel, and the diesel supply device is used for supplying atomized diesel. The atomized light hydrocarbon fuel and diesel enter the gas mixer through a pipeline to form mixture gas with carrier gas and water vapor, the mixed gas enters the reforming reaction device for reforming reaction, and reforming gas generated in the reforming reaction device is sent into a combustion chamberof an engine gas cylinder to participate in combustion through the pipeline. The reforming reaction device is arranged in a tail gas exhaust pipe of the gas cylinder. According to the light hydrocarbon / diesel fuel reforming system and the reforming method, the reforming reaction device is directly heated by using the high temperature waste heat of engine tail gas as a heat source, the energy is saved, after the reforming of the diesel and light hydrocarbon, the combustion efficiency of the diesel is greatly improved, and engine knocking and the emission of nitrogen oxide are suppressed.

Owner:WUHAN UNIV OF TECH

Full-automatic oil pressing system and oil pressing method

PendingCN106433960AEnough oxygenWill not polluteRevolving grateRocking grateOil processingCombustion chamber

The invention relates to a full-automatic oil pressing system. The full-automatic oil pressing system comprises a casing sequentially provided with a hearth and a combustion chamber from top to bottom, a material stir-frying device located in the hearth and in rotary connection with the casing, a first power device providing power for the material stir-frying device, a combustion smoke purifying device, a first exhaust fan, an outward discharge flue, a raw material container for containing raw materials, a first lifter for delivering raw materials in the raw material container to the material stir-frying device, a cooked material container for receiving and containing a cooked material discharged out of the material stir-frying device, an oil press for conducting oil pressing processing on the cooked material and a second lifter for lifting and delivering the cooked material in the cooked material container to the oil press, wherein the combustion smoke purifying device, the first exhaust fan and the outward discharge flue are sequentially communicated with the hearth. The process of oil pressing processing of the full-automatic oil pressing system is clean, hygienic, dust-free and environmentally friendly. The invention further provides an oil pressing method adopting the full-automatic oil pressing system. Automatic material frying and oil pressing processing is achieved.

Owner:周俊

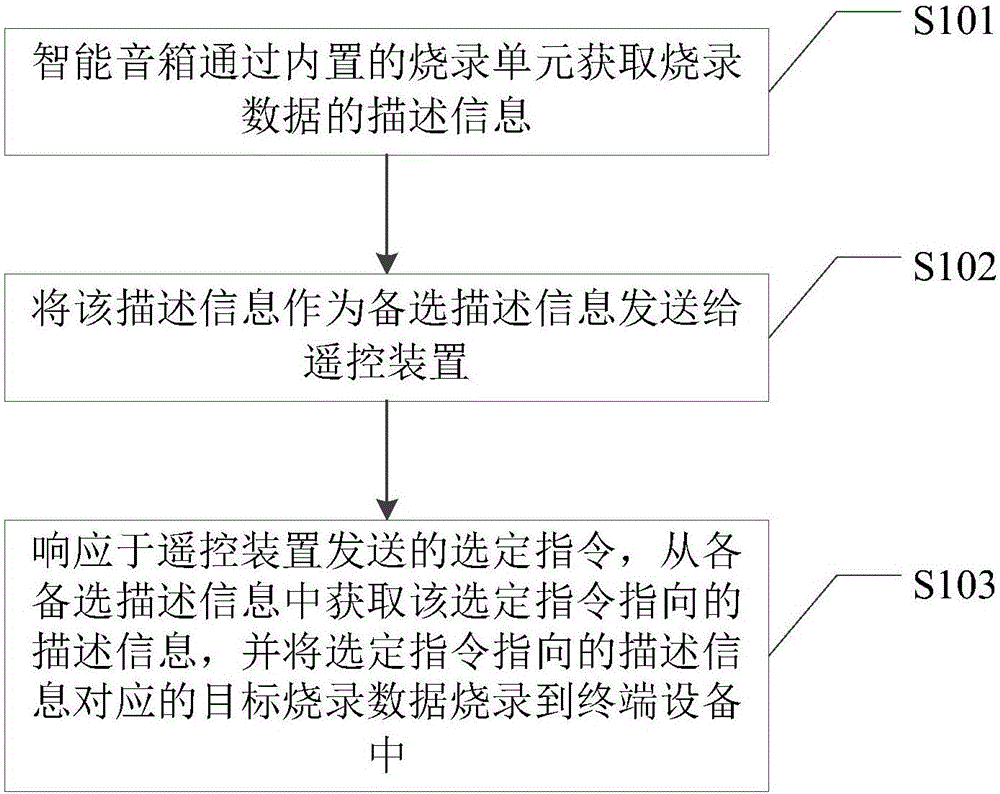

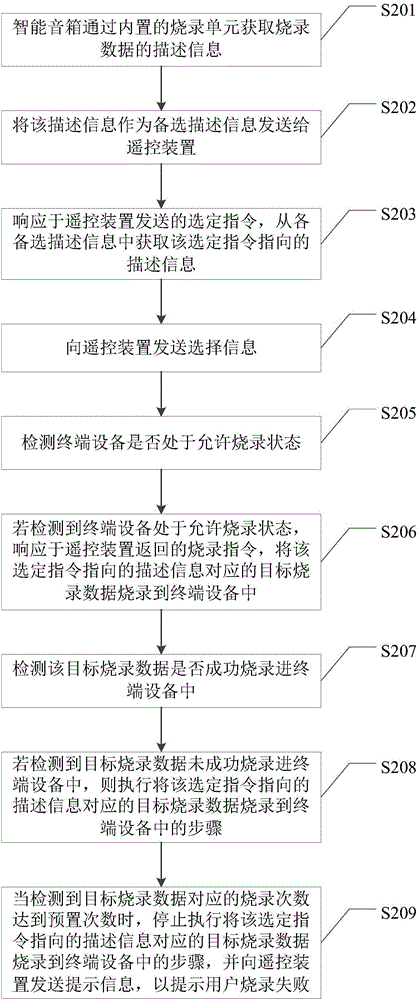

Burning method and device

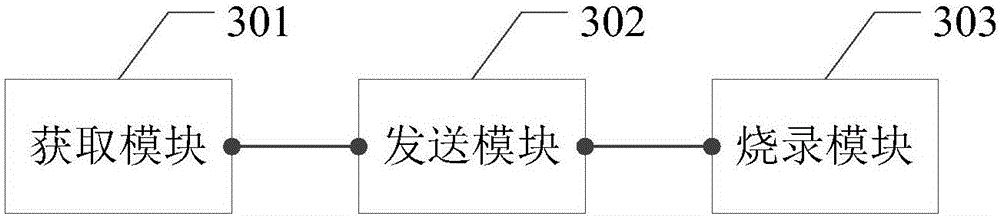

InactiveCN106569852AImprove convenienceRealize data burning operationProgram loading/initiatingSoftware deploymentBurn unitsRemote control

The embodiment of the invention is applicable to the technical field of terminals, and provides a burning method and a burning device. The method comprises the following steps: an intelligent loudspeaker acquires description information of burn data via a burning unit arranged in the intelligent loudspeaker; the description information serving as an alternative description information is sent to a remote control device; and the description information to which a selection commands points is acquired from each alternative description information and the target burn data corresponding to the description information to which the selection command points is burned into terminal equipment in response to the selection command sent by the remote control device. On the one hand, as a burner is integrated into the intelligent loudspeaker, original hardware resources of the intelligent loudspeaker is fully used for achieving a data burning operation based on the intelligent loudspeaker, so that a user does not need to buy expensive burning equipment independently for burning the data, and thus a utilization rate of the equipment can be improved, and burning cost is reduced; and on the other hand, the intelligent loudspeaker is controlled by the remote control device to complete a burning action, and convenience of the burning operation can also be improved.

Owner:LETV HLDG BEIJING CO LTD +1

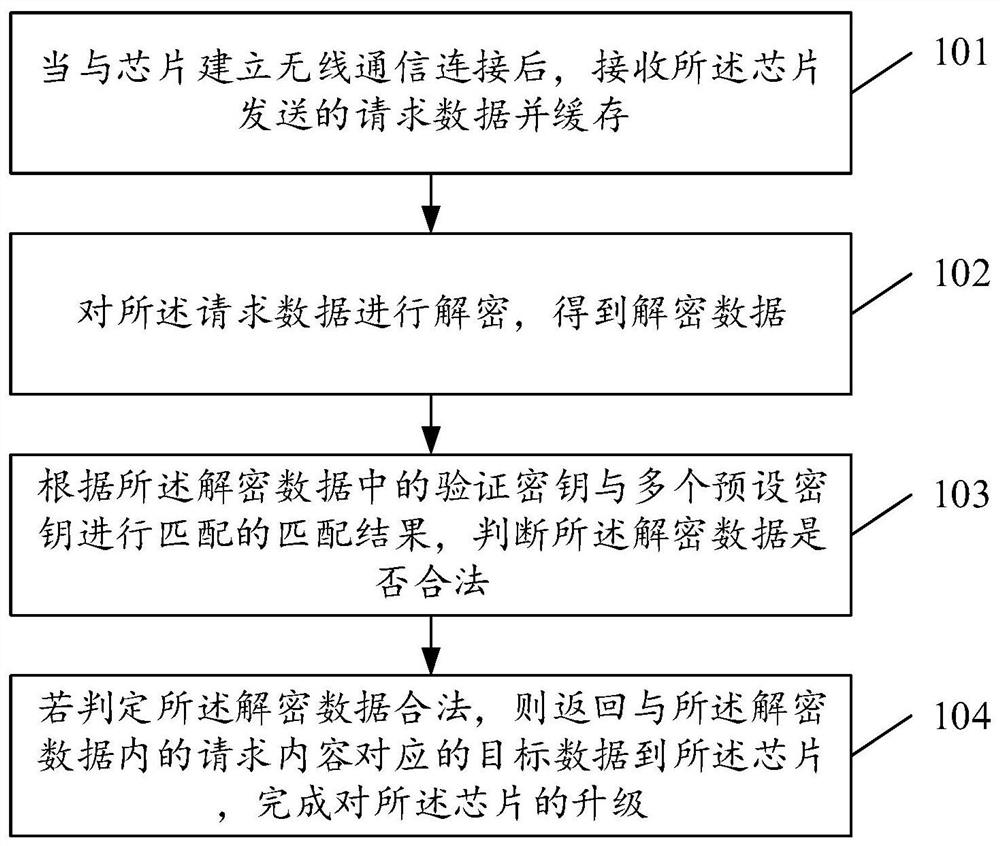

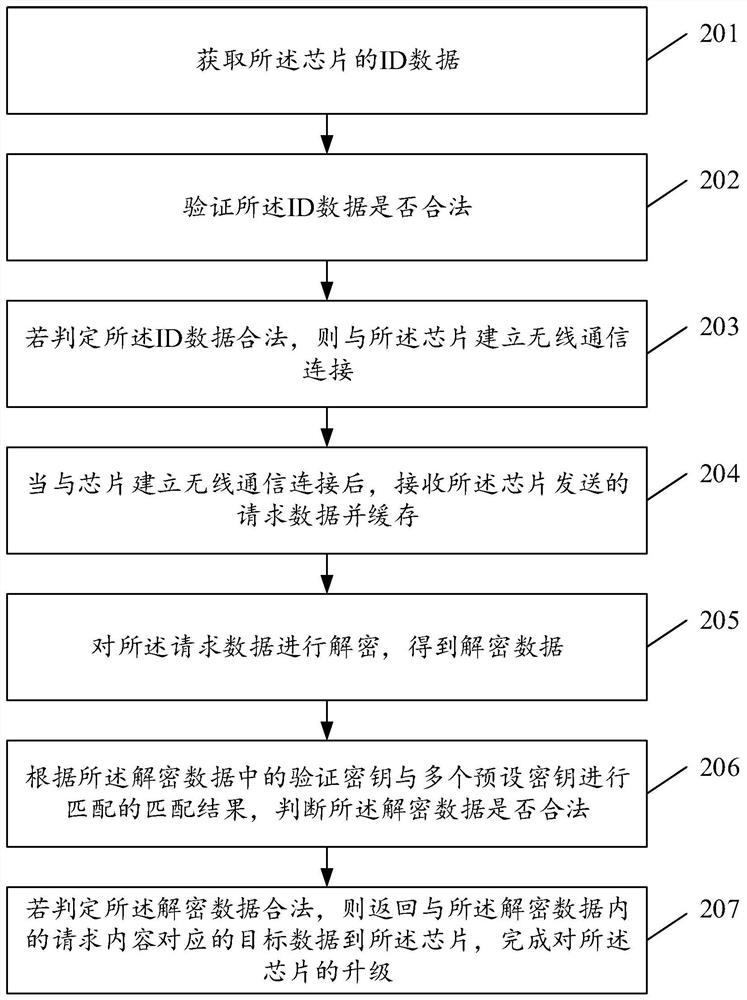

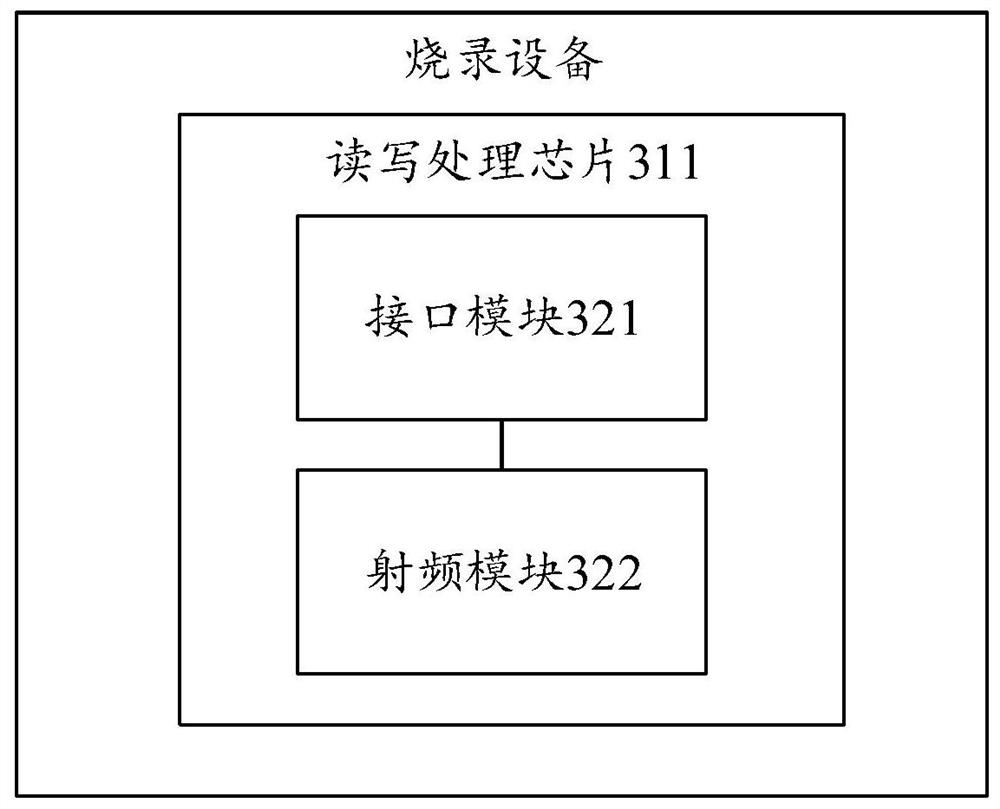

Chip upgrading method, burning equipment and chip upgrading system

PendingCN112905202AImprove programming convenience and programming efficiencyReduce burning costConnection managementTransmissionEmbedded systemRadio frequency

The invention discloses a chip upgrading method, burning equipment and a chip upgrading system. The method is applied to a read-write processing chip in the burning equipment, and the method comprises the following steps: after wireless communication connection with the chip is established, receiving and caching request data sent by the chip; decrypting the request data to obtain decrypted data; judging whether the decrypted data is legal or not according to a matching result obtained by matching the verification key in the decrypted data with a plurality of preset keys; if it is judged that the decrypted data are legal, returning the target data corresponding to the request content in the decrypted data to the chips, and finishing upgrading of the chips, so that upgrading of the multiple chips is completed at the same time in a wireless radio frequency mode, the burning convenience and the burning efficiency are improved, and the burning cost is reduced.

Owner:GUANGZHOU ZHONO ELECTRONICS TECH CO LTD

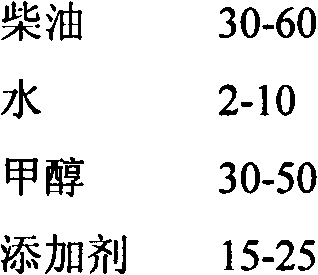

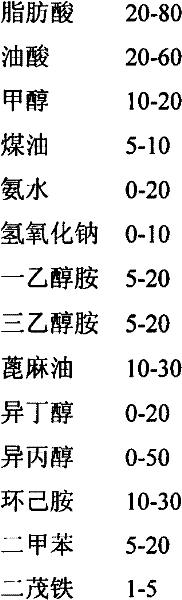

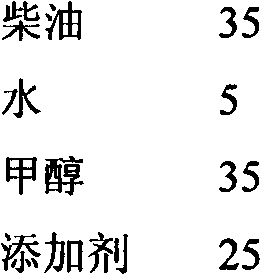

Methanol diesel fuel for stoves

InactiveCN102676244AExtended shelf lifeSimple production processLiquid carbonaceous fuelsManufacturing technologyCLARITY

The invention relates to high-clean methanol diesel fuel and belongs to petrochemical products. The high-clean methanol diesel fuel is designed for stoves in hotel kitchens, school canteens and the like, and develops a fuel almost capable of replacing diesel oil completely. The high-clean methanol diesel fuel comprises diesel oil, methanol, water, and additive, wherein the diesel oil accounts for 30 to 60 proportions by weight, the water accounts for 30 to 50 proportions by weight, and the additive accounts for 15 to 25 proportions by weight. The high-clean methanol diesel fuel provided by the invention has the advantages that the manufacturing technology is simple, the diesel oil, the methanol, the water, and the additive are added into a stirring tank according to required proportions under normal temperature and normal pressure, and the stirring is performed until clarity is achieved according to the size of electric power.

Owner:SHANGHAI JINTYO INDAL

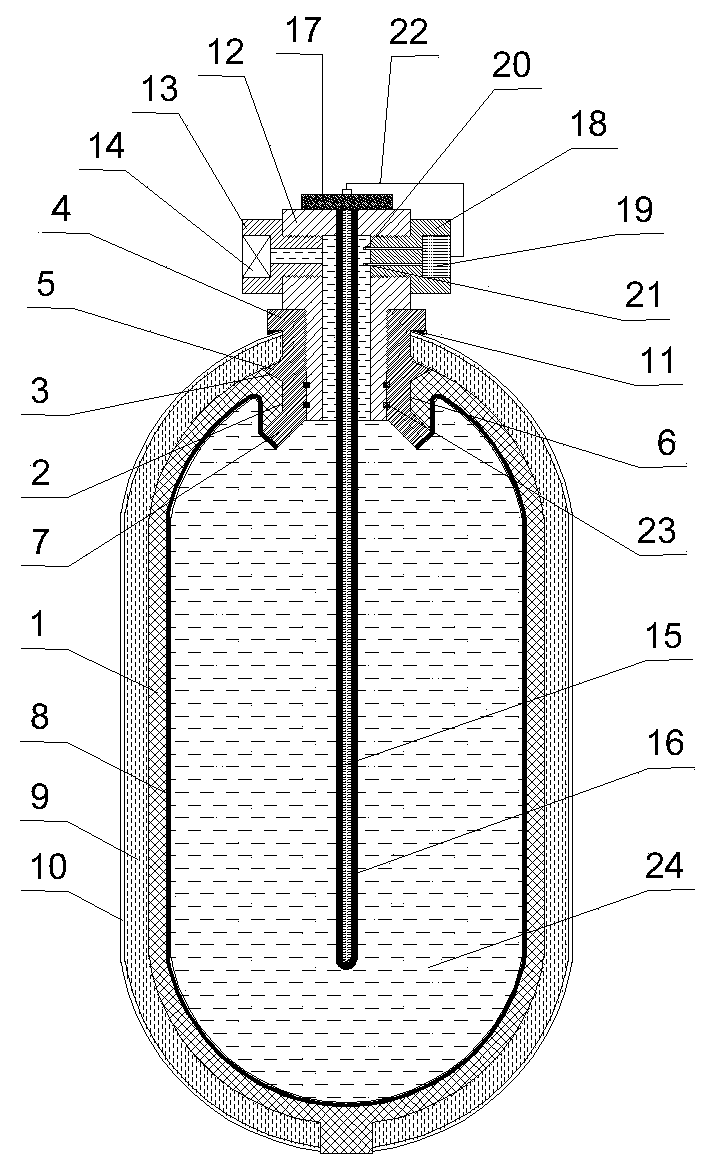

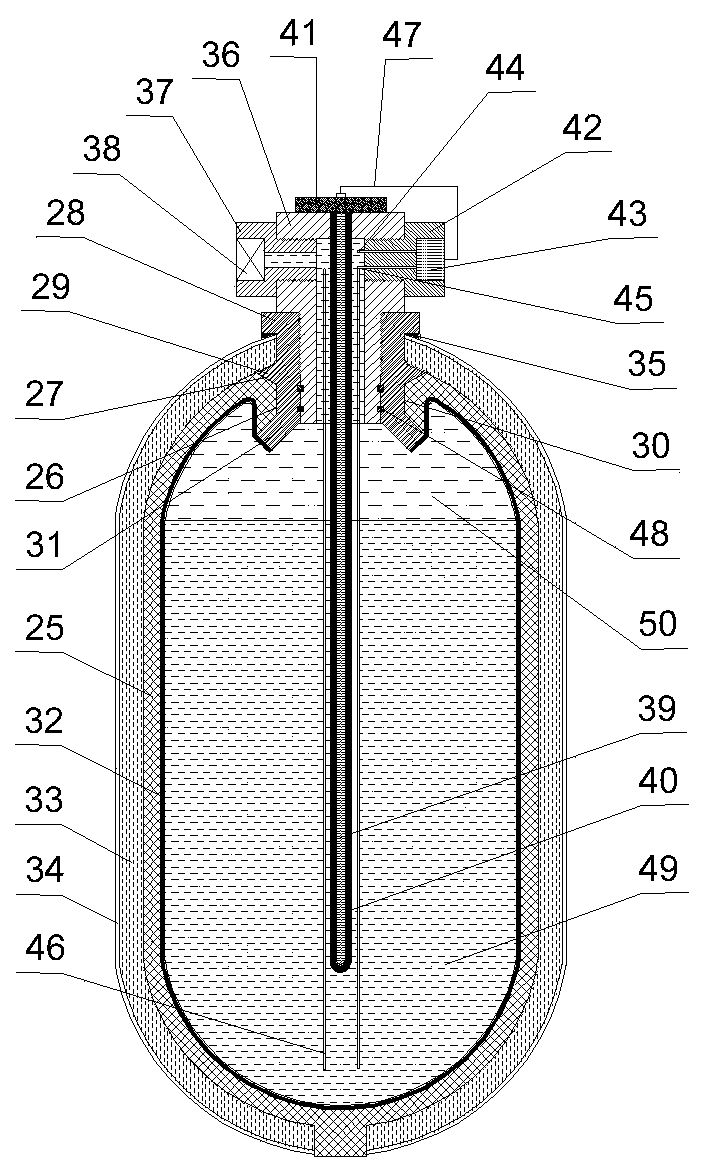

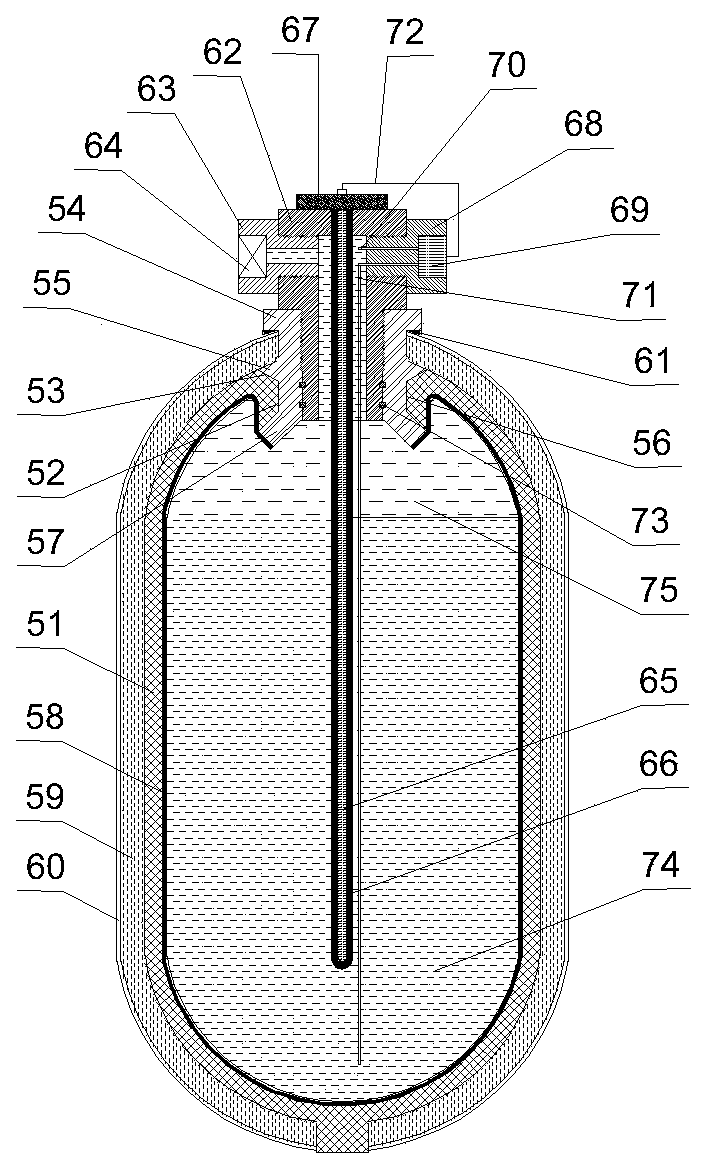

Gas storage bottle with electric temperature control system and preparation method of gas storage bottle

PendingCN111457248ASolve temperature problemsSolve problemsContainer filling methodsFluid handledPhysicsElectric heating

The invention discloses a gas storage bottle with an electric temperature control system. A sensor and an electric heating temperature control device are installed on an inlet and outlet bottle valveof the gas storage bottle, the inlet and outlet bottle valve of the gas storage bottle is installed at a gas storage bottle opening, the sensor and the electric heating temperature control device stretch into a gas storage bottle cavity, the sensor detects the temperature and pressure of gas in the gas storage bottle, and the electric heating temperature control device heats or cools the gas in the gas storage bottle cavity.

Owner:王广武

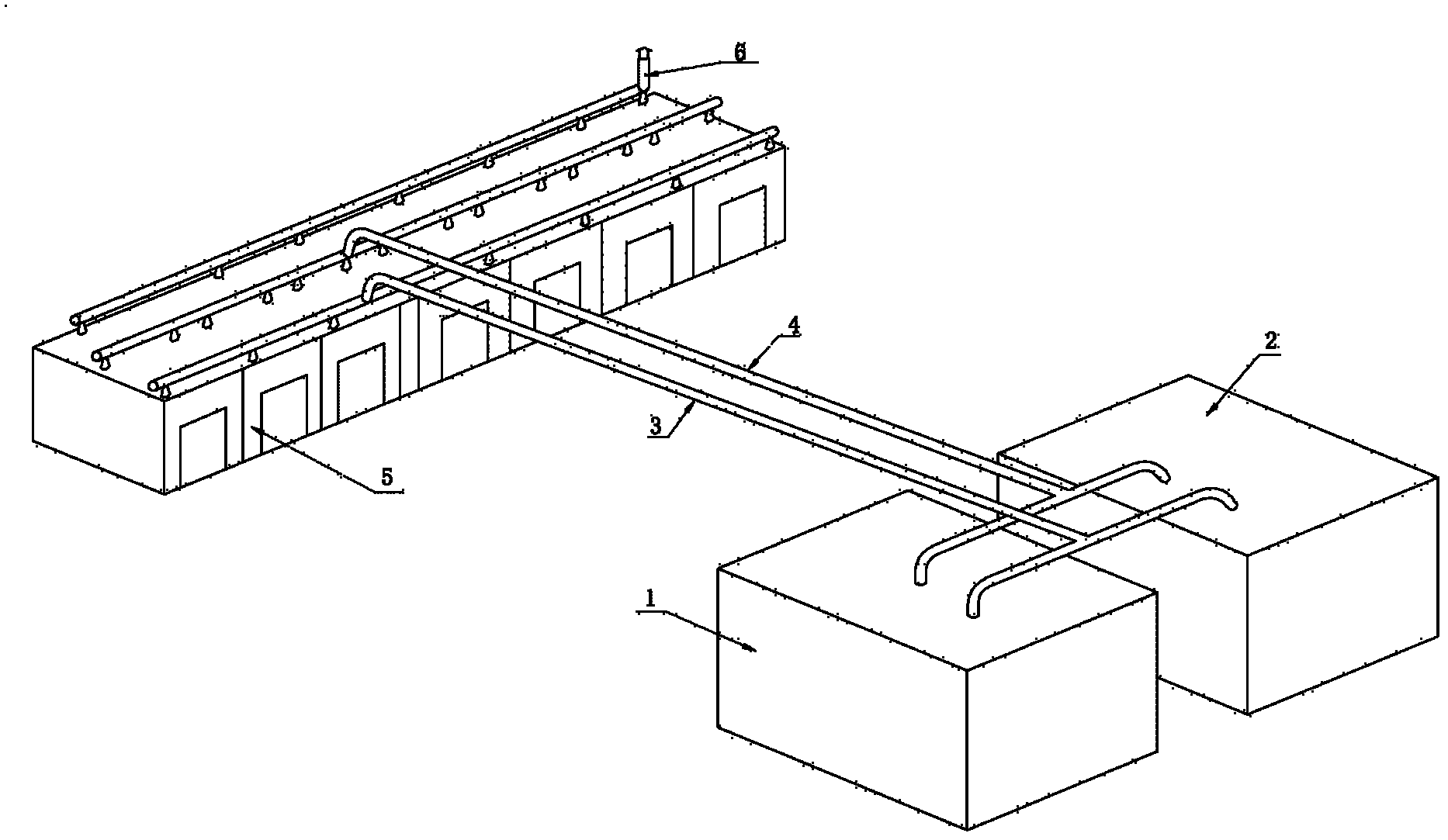

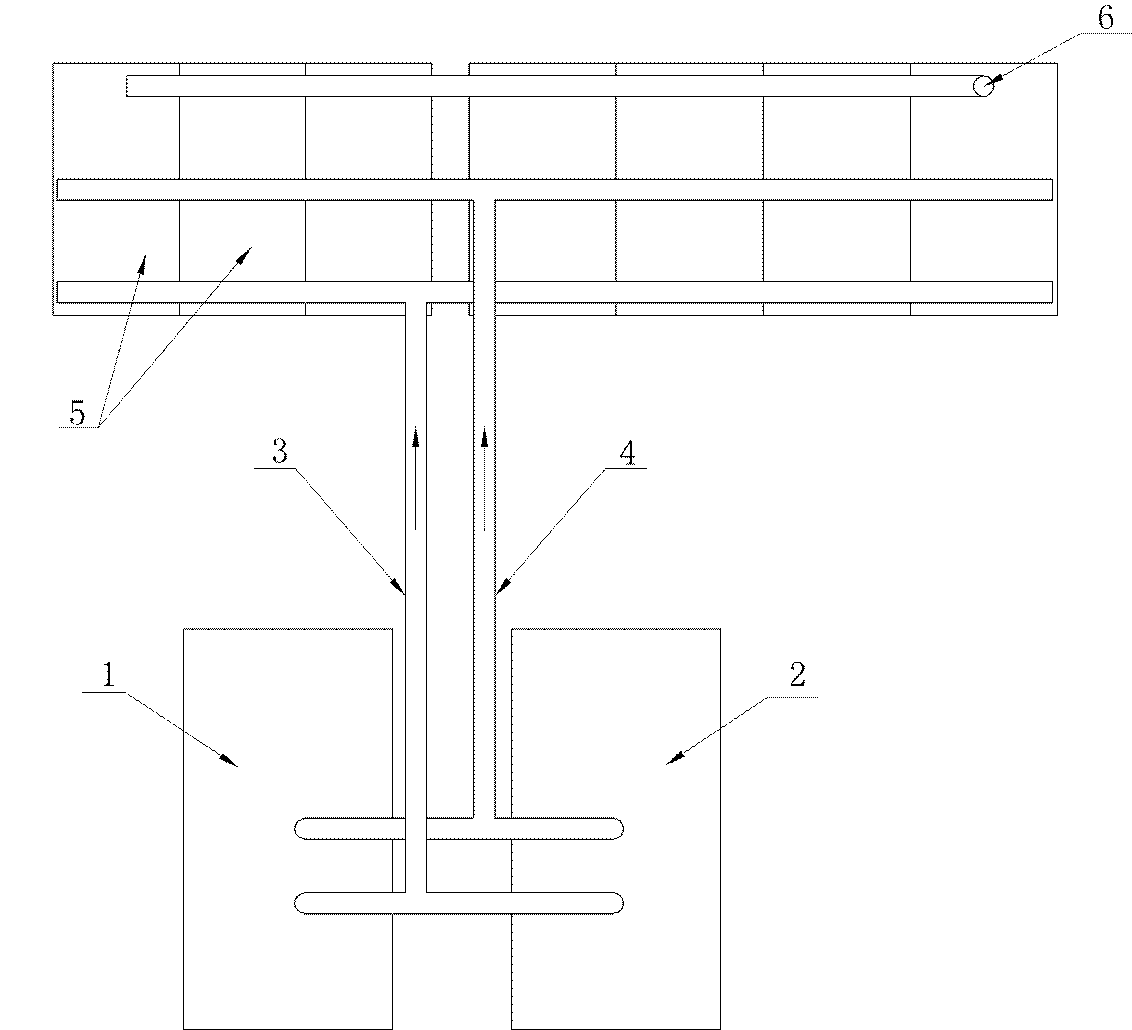

Method and device utilizing kiln waste heat for rapidly drying electrotechnical porcelain

InactiveCN102519237AShorten the production cycleOptimize the drying processDrying gas arrangementsDrying chambers/containersHot air ovenProcess engineering

The invention relates to a method and a device utilizing kiln waste heat for rapidly drying electrotechnical porcelain, wherein the kiln waste heat is fully utilized with the assistance of an air heater serving as a heat source, and then is transferred to an underground pipe network of a drying house through two kiln waste heat utilization systems; during the time from the ignition of the kiln to the stop of the kiln, one of the heat source auxiliary transference system is utilized for transferring heat radially through the underground pipe network of the drying house; and when the kiln is stopped, the other heat source auxiliary transference system is utilized for directly transferring heat through the underground pipe network of the drying house. In the invention, the drying time is reduced to 48 to 96 hours, the turnaround time of the drying house per month increases to 6 to 10 times, as a result, not only is the production period greatly shortened, but also the waste heat is fully completely utilized at the same time; and the heat energy circulates repeatedly from the bottom to the top to form thermal current, so that the heat efficiency is improved and the drying effect is extremely remarkable.

Owner:殷杨合

Hot-blast stove with double-flip-plate linkage type ash cleaning device

ActiveCN103697586ASolve the problem that combustion performance is affected by dust accumulationReduce pollutionAir heatersCombustionEngineering

The invention relates to a hot-blast stove with a double-flip-plate linkage type ash cleaning device. The hot-blast stove with the double-flip-plate linkage type ash cleaning device is used for solving the problem of the existing hot-blast stoves that the combustion performance is affected by accumulated dust. The hot-blast stove comprises a stove body, an end enclosure, a smoke tube, an internal stove container, a plurality of fire tubes, a grate and an ash accumulating room, wherein the end enclosure and the smoke tube are arranged at the top of the stove body, the internal stove container and the end enclosure are communicated by the fire tubes, the grate is arranged at the bottom of the internal stove container, and the ash accumulating room is arranged at the bottom of the stove body corresponding to the position of the grate; the stove body is provided with an air inlet and an air outlet. The hot-blast stove is characterized in that an ash cleaning passage is connected between the air inlet and the ash accumulating room, an ash cleaning flip plate is arranged in the ash cleaning passage, and an air blasting flip plate which is used for blocking or opening an air inlet passage in the stove is arranged at the air inlet. The hot-blast stove has the advantages of reasonable structure and good ash cleaning effect.

Owner:北镇市青岩节能设备制造有限公司

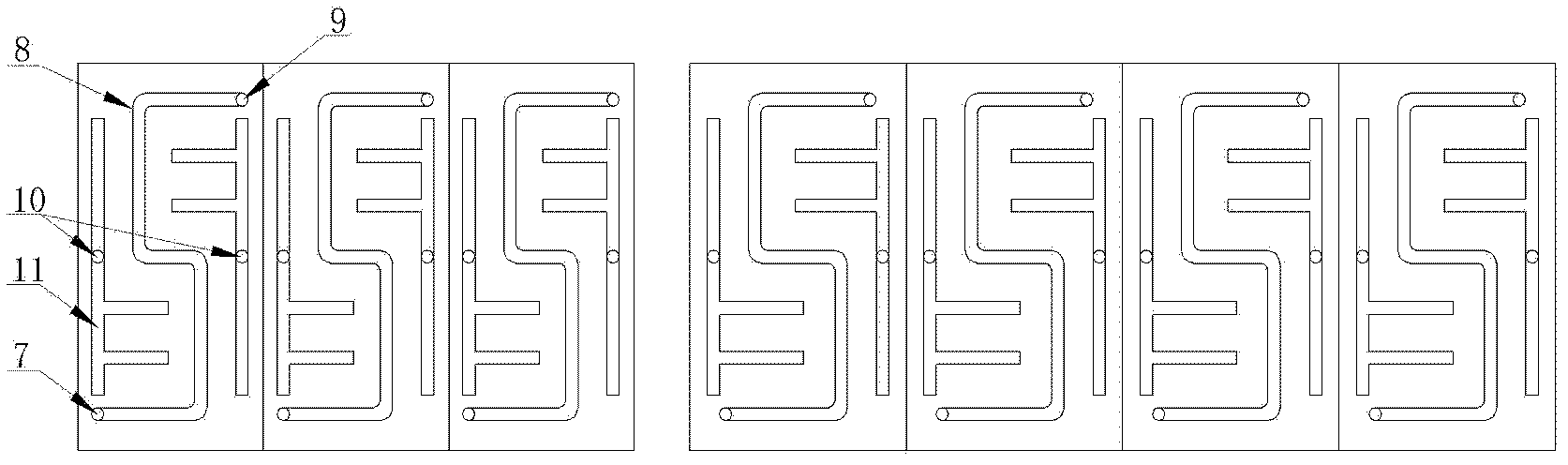

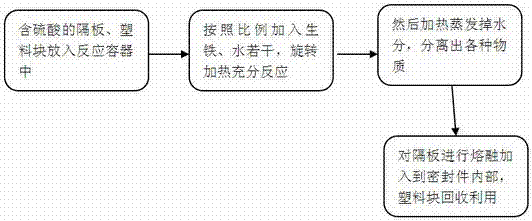

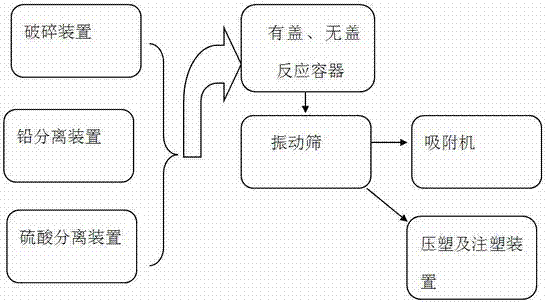

Dry cleaning technology and dry cleaning processing system of waste lead-acid storage battery plastic

PendingCN106876820AImprove rigidityHigh reuse rateWaste accumulators reclaimingBattery recyclingConveyor beltWaste material

The invention discloses a dry cleaning technology and a dry cleaning processing system of waste lead-acid storage battery plastic. The dry cleaning technology comprises the following steps: weighing broken plastic blocks and partition boards, pouring the broken plastic blocks and partition boards into a reaction container without a cover, adding cast iron and water, carrying out physical collision, carrying out stirring rotation in the container, heating to carry out a chemical reaction, after the water is distilled completely, and after opening an emptying valve, inflowing the materials including the plastic blocks, the partition boards, the cast iron, aluminum and impurities in the container into a vibrating screen, wherein an adsorption machine for adsorbing bubbles is arranged on a conveyor belt, a rapid sulfuric acid testing device is arranged on the conveyor belt, and sulfuric acid is returned into the reaction container to carry out the reaction again when the tested sulfuric acid concentration is higher than a concentration set value; the system is further provided with a compression molding and injection molding device, the compression molding and injection molding device is used for fusing the partition boards, or mineral waste residue and impurities are added for fusion pressure casting under the condition that the partition boards are fused. Secondary waste water cannot be generated, the problems that the partition boards cannot be recycled, a great deal of incineration cost is needed and the environment is polluted can be solved, the waste materials are changed into things of value, the method is simple and high in recycling utilization rate, and the technology has great economic values and market values.

Owner:重庆鼎同科技发展有限公司

Copper silicon alloy sputtering target material and copper silicon alloy recording layer

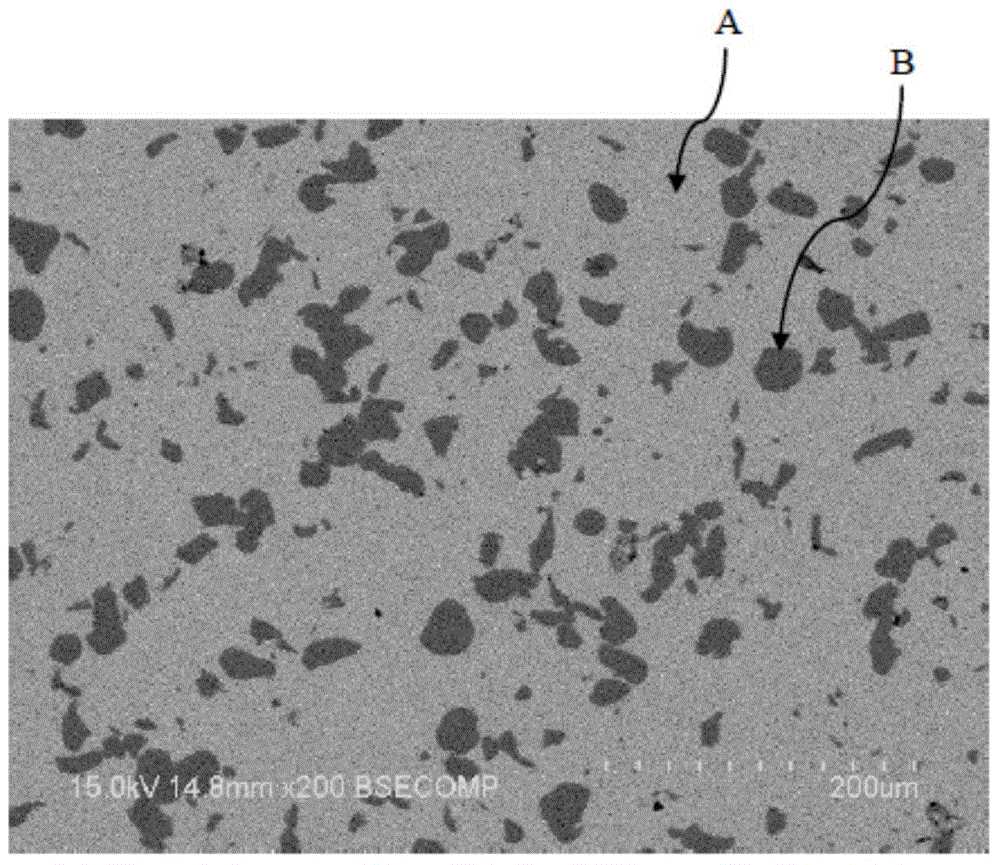

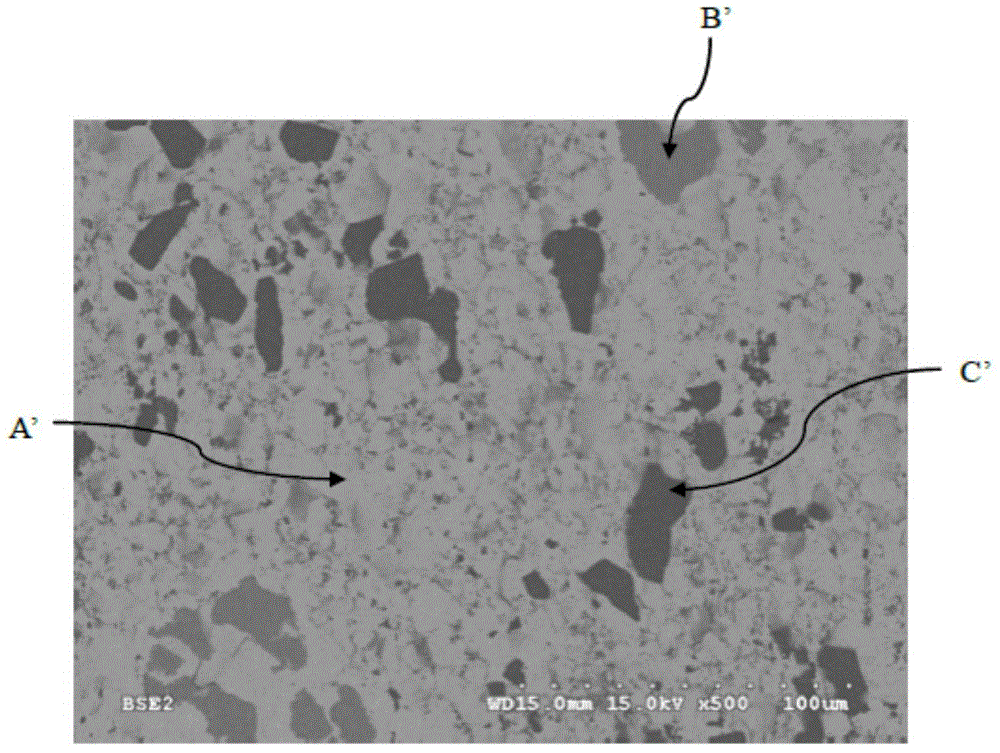

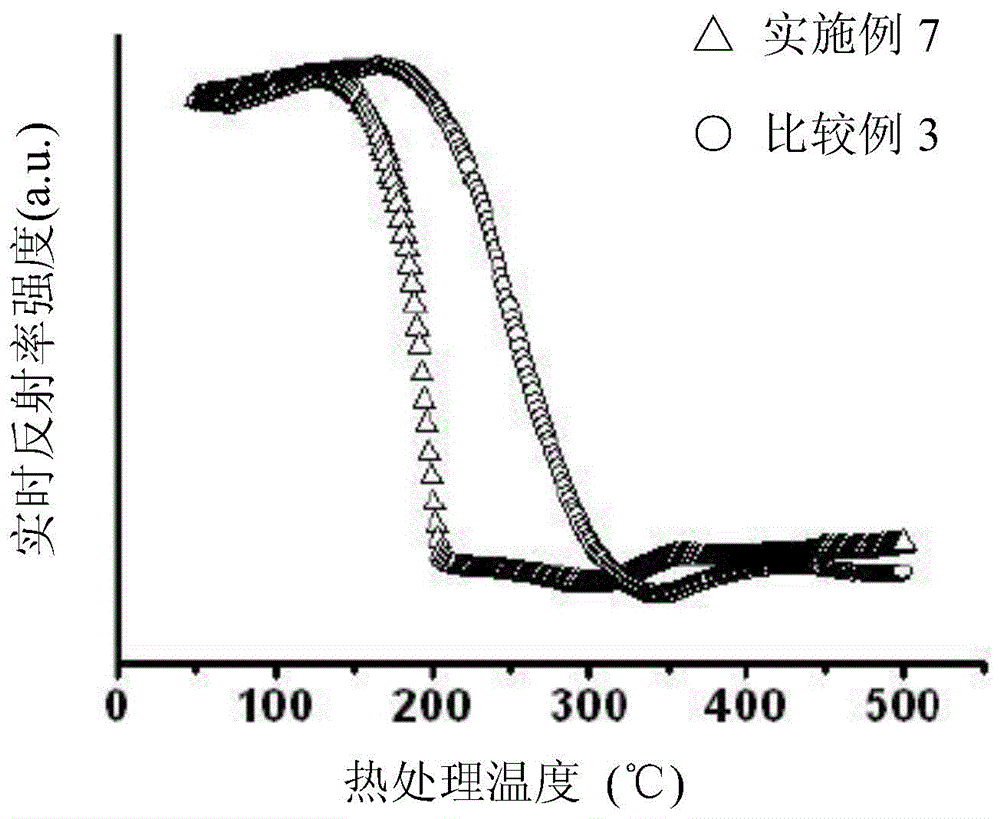

InactiveCN104575532AHigh modulation valueRaise the contrast valueRecord information storageOptical record carrier manufactureSilicon alloyTitanium

The invention provides a copper silicon alloy sputtering target material and a copper silicon alloy recording layer. The copper silicon alloy sputtering target material and the copper silicon alloy recording layer both consist of CuaSibMc alloy, wherein M is nickel, chromium, molybdenum or titanium, a is 0.55-0.93, b is 0.05-0.25, c is 0.02-0.20, and the sum of a, b and c is 1. The copper silicon alloy recording layer contains copper, silicon, nickel, chromium, molybdenum or titanium with appropriate contents, so that a phase transition temperature is higher than 150 DEG C and is lower than 500 DEG C, and when being applied to optical recording media, the copper silicon alloy recording layer can obtain favorable recording quality, favorable stability and higher programming speed.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

Liao dynasty ceramic hand-making and firing technology

The invention discloses a liao dynasty ceramic hand-making and firing technology, which comprises: carrying out ball milling on raw materials of 60% of raw ore and 40% of coal gangue in a ball mill toform mud strips, and then sequentially carrying out manual billet throwing forming, bonding and fettling to form a billet; and carrying out scratching, carving, removing, sticking and various operations on the billet to decorate, wherein 40% of the raw materials are selected from coal gangue in a coal mine, the coal gangue in the coal mine is repeatedly utilized, and the coal gangue comprises thefollowing components in percentage by weight: 65.43% of silicon dioxide, 15.32% of aluminum oxide, 2.18% of ferric oxide, 0.42% of titanium dioxide, 0.55% of potassium oxide, 0.62% of sodium oxide, 0.83% of calcium oxide, 0.34% of magnesium oxide and 14.31% of burning loss. According to the invention, the repeated utilization rate of coal gangue in a coal mine is solved, the environment is protected, the liao dynasty ceramic production is improved, the firing cost is effectively reduced, and the property and personal safety of citizens is guaranteed.

Owner:辽宁省龙呈文化创意产业园有限公司

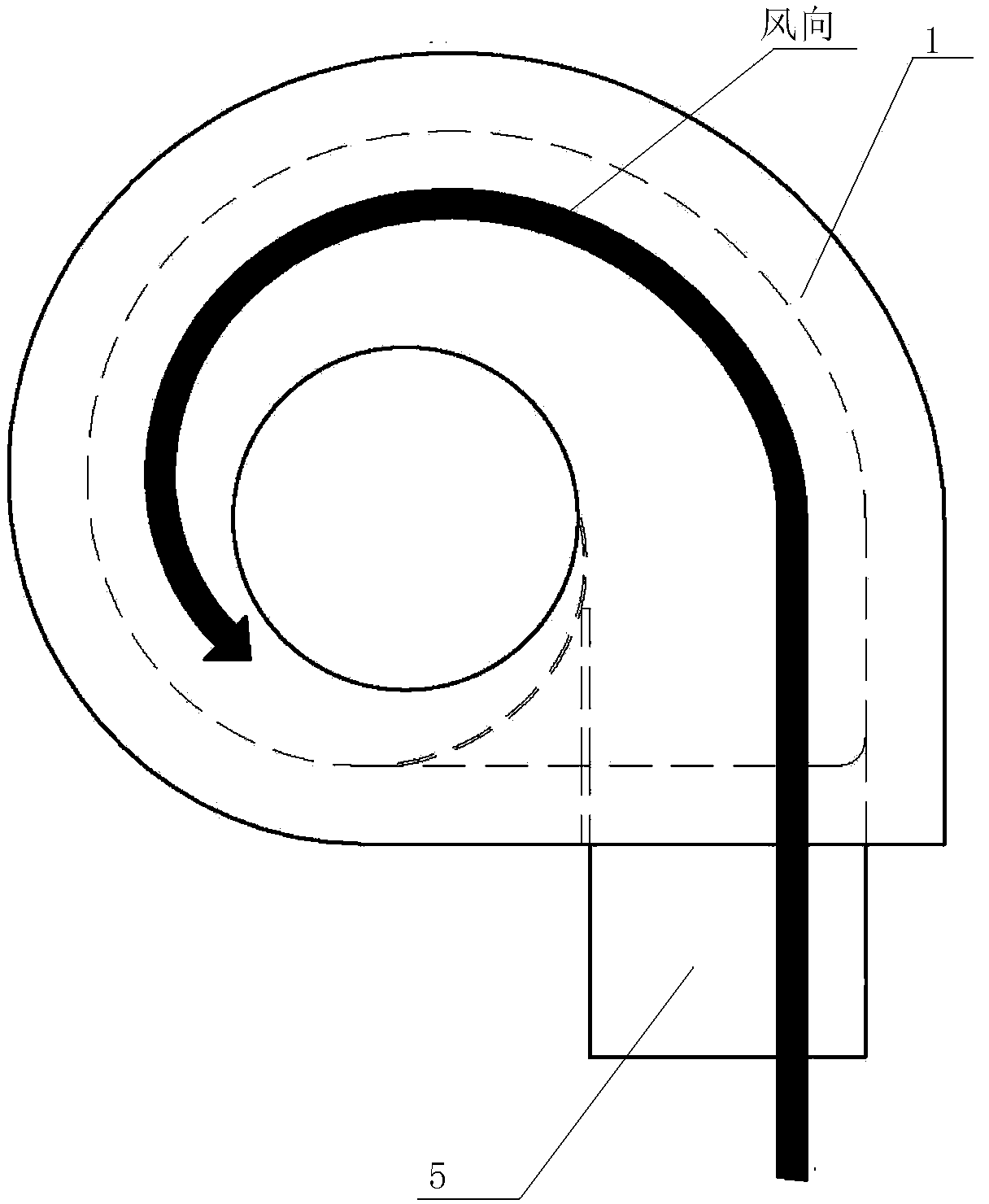

Short-flame and large-diameter diesel burner

The invention relates to a burner, in particular to a short-flame and large-diameter diesel burner. The short-flame and large-diameter diesel burner comprises a burner shell, an ignition rod and a diesel sprayer, wherein the ignition rod and the diesel sprayer are arranged in the burner shell. The burner shell is a spiral volute, an air inlet is formed in one side of an outer ring of the volute, an air outlet is formed in an inner ring of the volute, the direction of the air inlet is coincident with the tangent direction of the volute, the position of a diesel spraying nozzle of the diesel sprayer corresponds to the position of the air outlet of the volute, and the ignition position of the ignition rod is located above the diesel spraying nozzle and the air outlet. According to the short-flame and large-diameter diesel burner, the burner shell is designed into the volute, air enters the burner in the tangent direction of the volute, the air and diesel are mixed and burnt through centrifugal force, the structure is simple and attractive, the air and the atomized diesel can be more sufficiently mixed, losses of the atomized diesel can be reduced, the diameter of a hearth can be reduced, the size of a boiler can be reduced, and the burning cost can be reduced.

Owner:LIJU THERMAL EQUIP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com