Jet and oxygen-enriched combustion method for gas fuel and burner therefor

A gas fuel and oxygen-enriched combustion technology, which is applied to gas fuel burners, combustion methods, burners, etc., can solve problems such as energy waste, complex structure, and high-temperature combustion that cannot be organized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

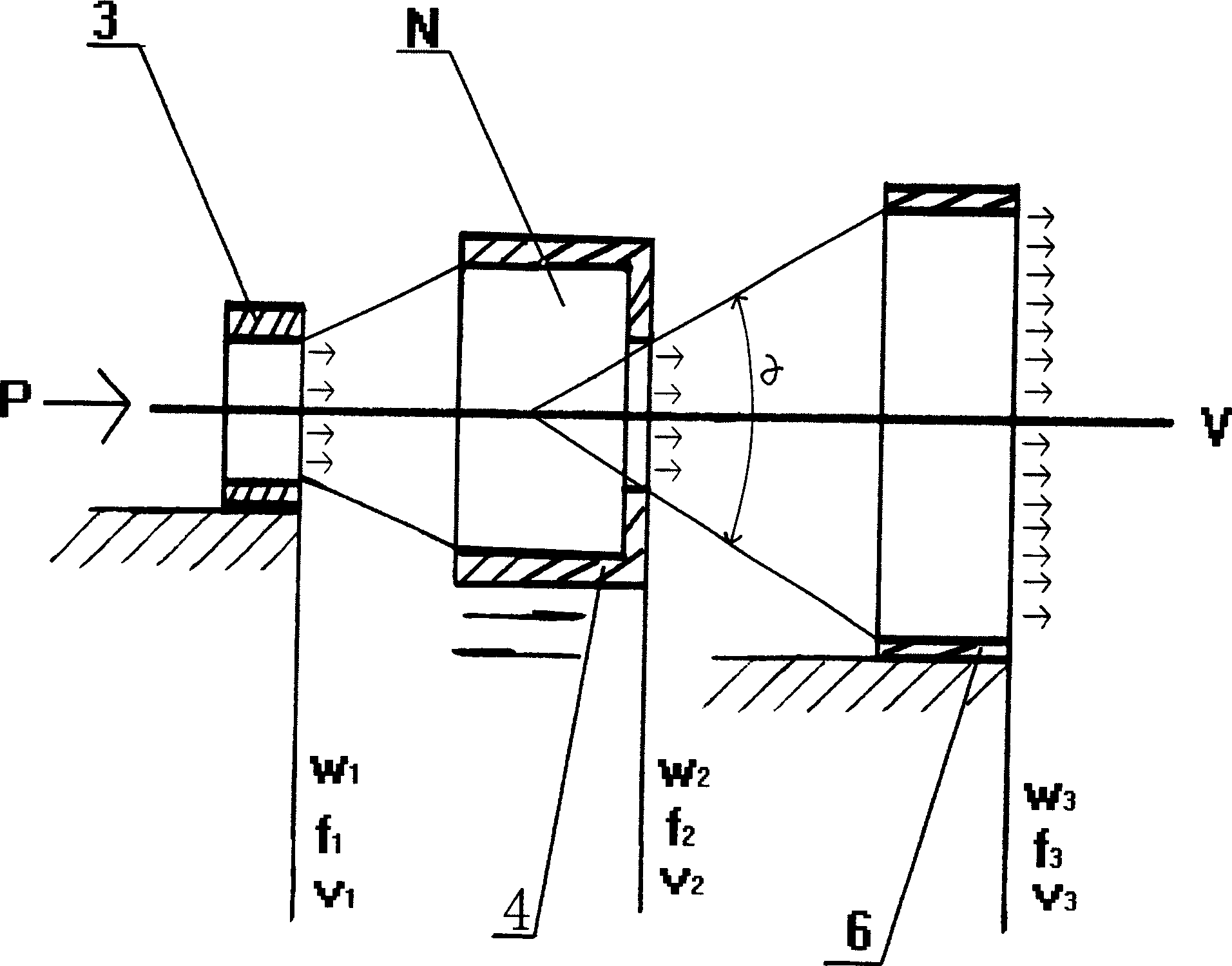

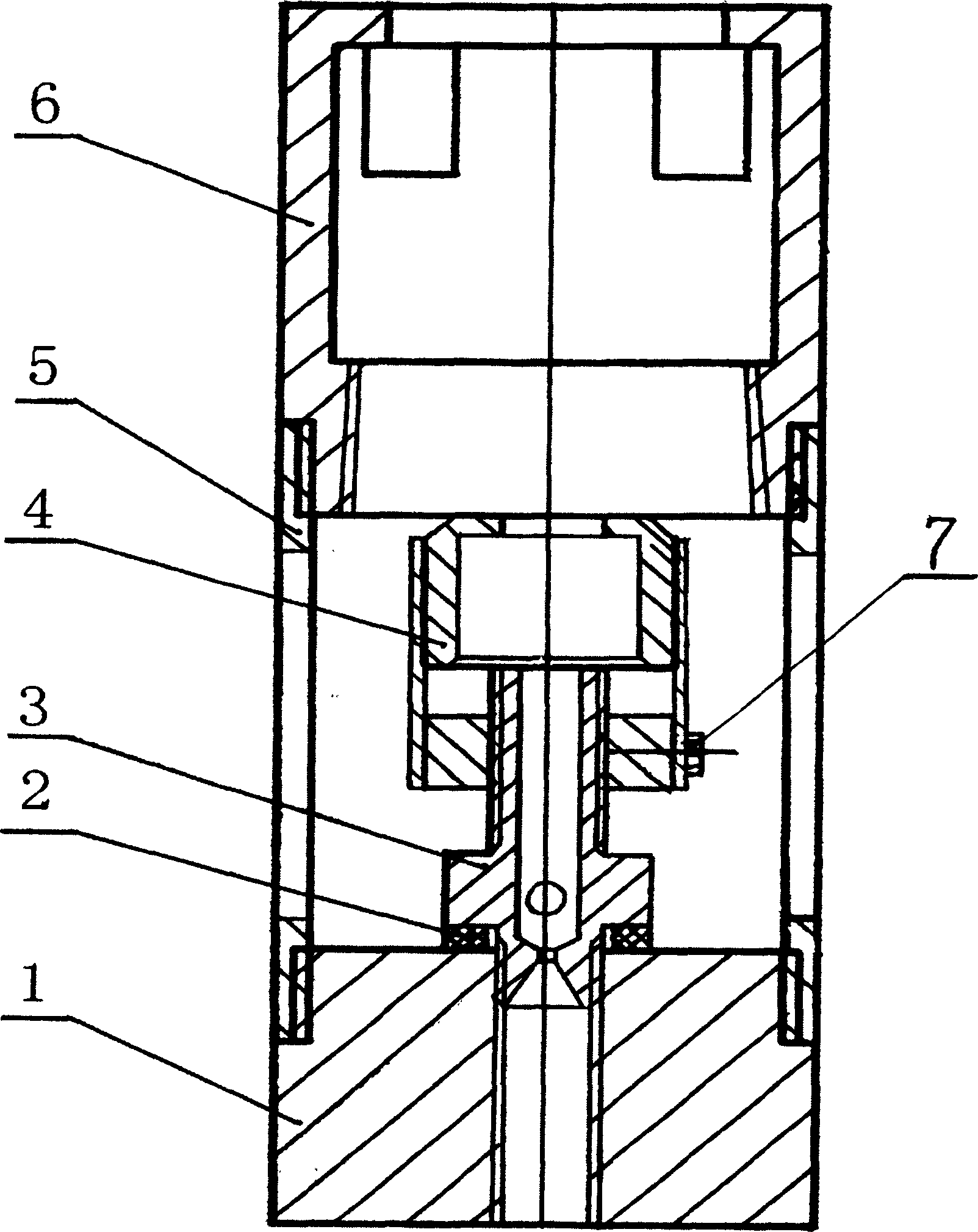

[0060] one, figure 2 Shown is a structural scheme of the gas fuel jet oxygen-enriched burner of the present invention. In this embodiment, the gas fuel jet oxygen-enriched burner consists of a connector 1, a gasket 2, a nozzle 3, an injector 4, Connecting sleeve 5, injection pipe combustion chamber 6, set screw 7 constitute, for the convenience of manufacture and processing, above-mentioned each parts all make circle shape.

[0061] 2. The connector 1 is a cuboid or a cube. There is a threaded hole in the center of the top surface to communicate with the air source and connect to the nozzle 3. The top of the connector 1 is made with external threads. The remaining five surfaces of the connector 1 can be used according to different requirements. If necessary, introduce air source, fix the position, connect other devices, etc.

[0062] The nozzle 3 is the main part to control the calorific value of the jet-flow oxy-fuel burner. The nozzle 3 is processed from a hexagonal bar, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com