Oily sludge pyrolysis treatment process and apparatus

A treatment process and sludge technology, which is applied in pyrolysis treatment of sludge, dehydration/drying/concentration sludge treatment, petroleum industry, etc., can solve the problems of secondary pollution, high cost, and inability to deal with oily sludge, and achieve No secondary pollution, stable state and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

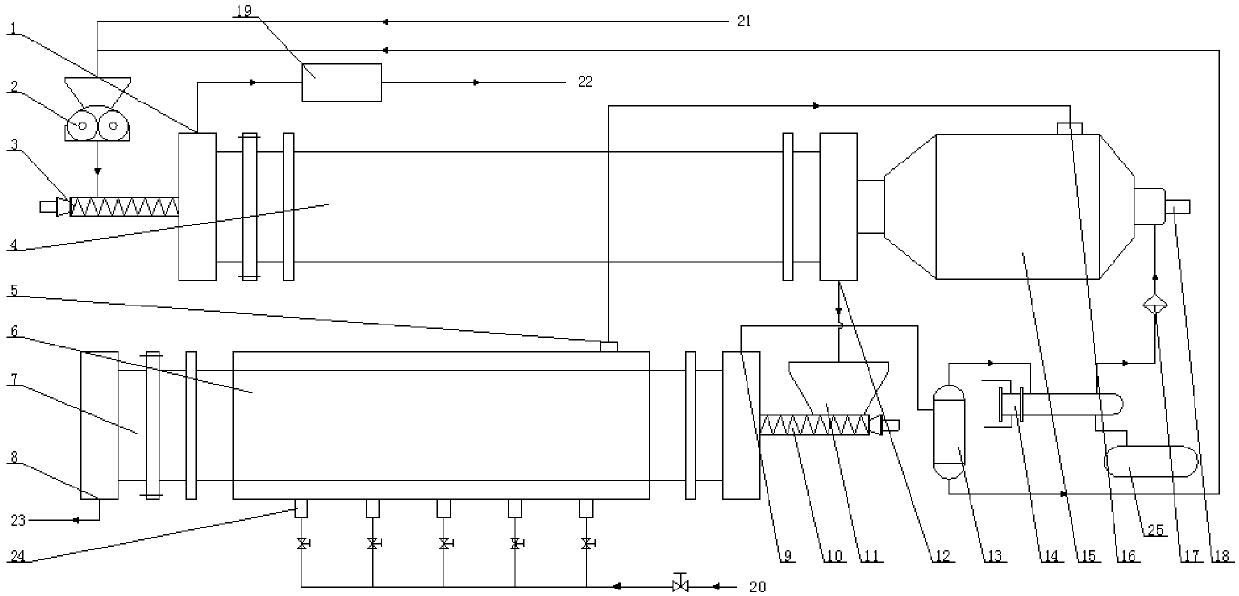

[0069] The pulverizer model used in this embodiment is SDF300-2, the screw conveyor I model is SL280-2, the screw conveyor II model SL250-3, the screw conveyor model is SL200 / 3-3, and the heating furnace model is SRL6, the model of the internal heating rotary kiln dryer is SG1200-11, the model of the external heating pyrolysis furnace is SR800 / 1200-8, the model of the storage bin is SC12, the model of the hot blast furnace is SRL12000, and the model of the tar washing separator is SX10 -2, the burner model is STAR-500.

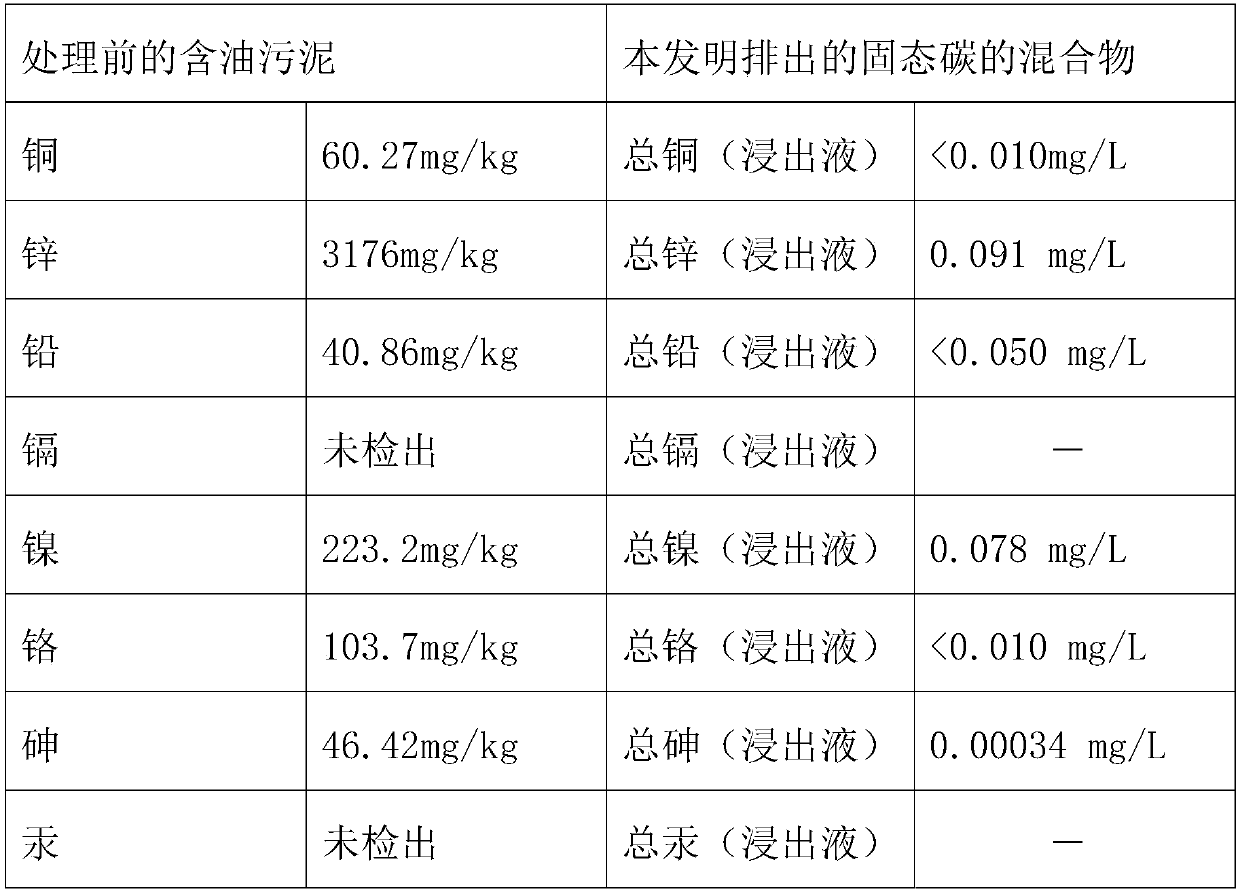

[0070] The oily sludge treated is 1t / h, which is the oily sludge formed in Shengli Oilfield. The content of toxic heavy metals copper, zinc, lead, cadmium, nickel, chromium, arsenic, and mercury in the oily sludge is 60.27mg / kg respectively , 3176mg / kg, 40.86mg / kg, not detected, 223.2mg / kg, 103.7mg / kg, 46.42mg / kg, not detected. (as shown in table 1) process through following method of the present invention:

[0071] (1) Pulverization: transport the oily slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com