Gas storage bottle with electric temperature control system and preparation method of gas storage bottle

A gas storage cylinder and electronic control technology, which is applied in the field of gas storage cylinders or hydrogen storage cylinders, can solve the problems of reducing hydrogen use efficiency, unstable hydrogen temperature, and inability to control hydrogen temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

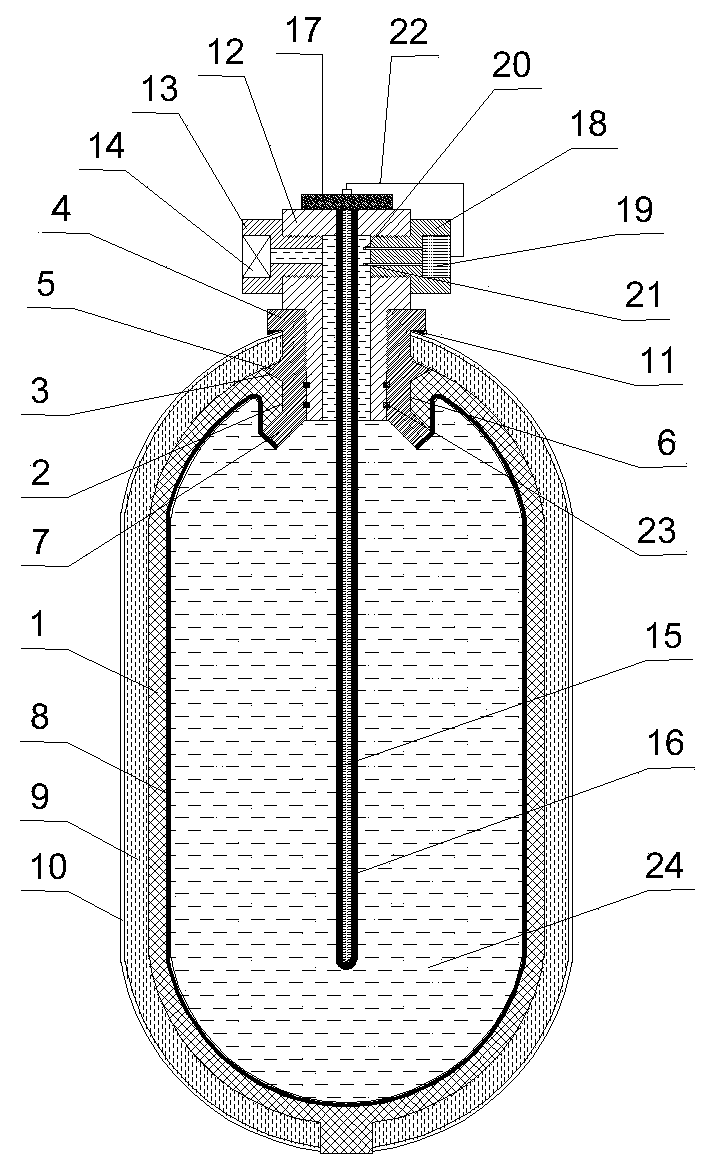

Embodiment 1

[0022] A hydrogen storage bottle with an electric temperature control system such as figure 1 As shown, where: 1 is a metal hydrogen storage bottle, 2 is a metal hydrogen storage bottle mouth, 3 is a metal hydrogen storage bottle positioning oblique groove, 4 is a shape memory alloy sleeve, 5 is a shape memory alloy oblique shoulder, 6 is a shape Memory alloy sleeve, 7 is the shape memory alloy end protrusion, 8 is the inner resin bottle, 9 is the rubberized carbon fiber, 10 is the outer protective layer, 11 is the sealant, 12 is the outer valve of the hydrogen storage bottle, and 13 is the hydrogen storage bottle Valve seat, 14 is the air inlet and outlet valve, 15 is the bimetallic hot and cold temperature control rod, 16 is the metal protective cover of the temperature control rod, 17 is the heat dissipation block of the temperature control rod, 18 is the control valve seat, 19 is the controller, 20 is the gas For the pressure sensor, 21 is a gas temperature sensor, 22 is a d...

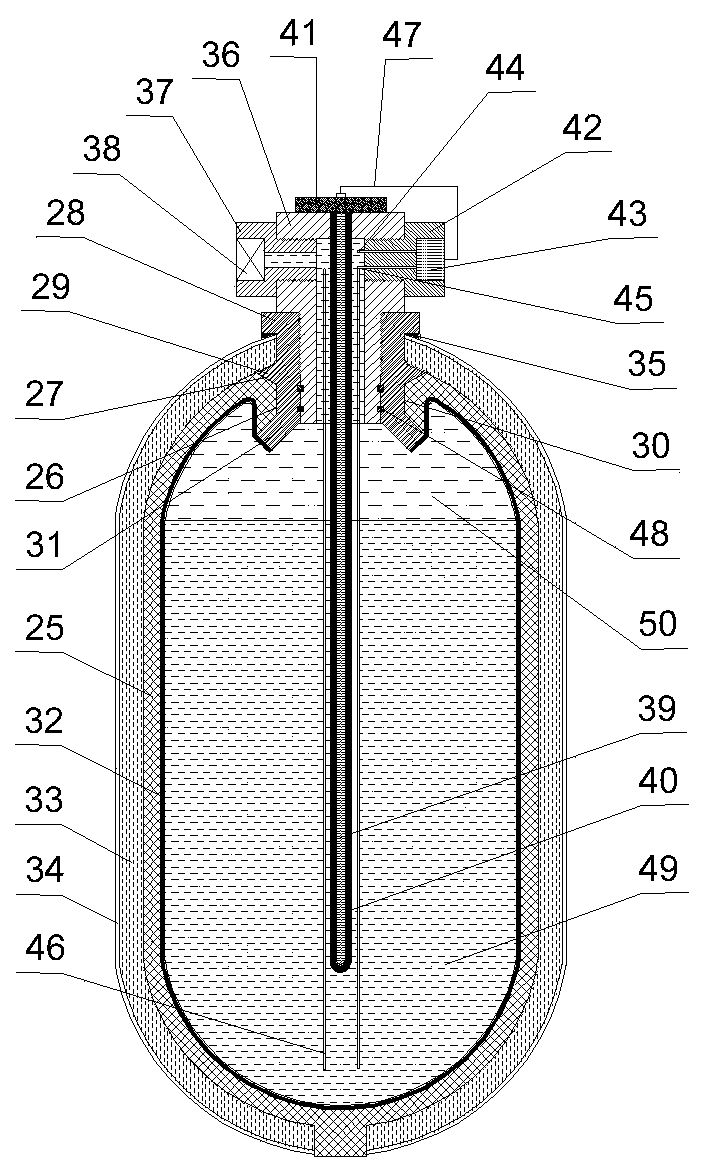

Embodiment 2

[0030] A liquid storage bottle with an electric temperature control system such as figure 2 As shown, where: 25 is a metal hydrogen storage bottle, 26 is a metal hydrogen storage bottle mouth, 27 is a metal hydrogen storage bottle positioning oblique groove, 28 is a shape memory alloy sleeve, 29 is a shape memory alloy oblique shoulder, and 30 is a shape Memory alloy sleeve, 31 is the shape memory alloy end protrusion, 32 is the inner resin bottle, 33 is the rubberized carbon fiber, 34 is the outer protective layer, 35 is the sealant, 36 is the outer valve of the hydrogen storage bottle, and 37 is the hydrogen storage bottle Valve seat, 38 is the air inlet and outlet valve, 39 is the bimetallic hot and cold temperature control rod, 40 is the metal protective cover of the temperature control rod, 41 is the heat dissipation block of the temperature control rod, 42 is the control valve seat, 43 is the controller, 44 is the gas For the pressure sensor, 45 is a liquid temperature se...

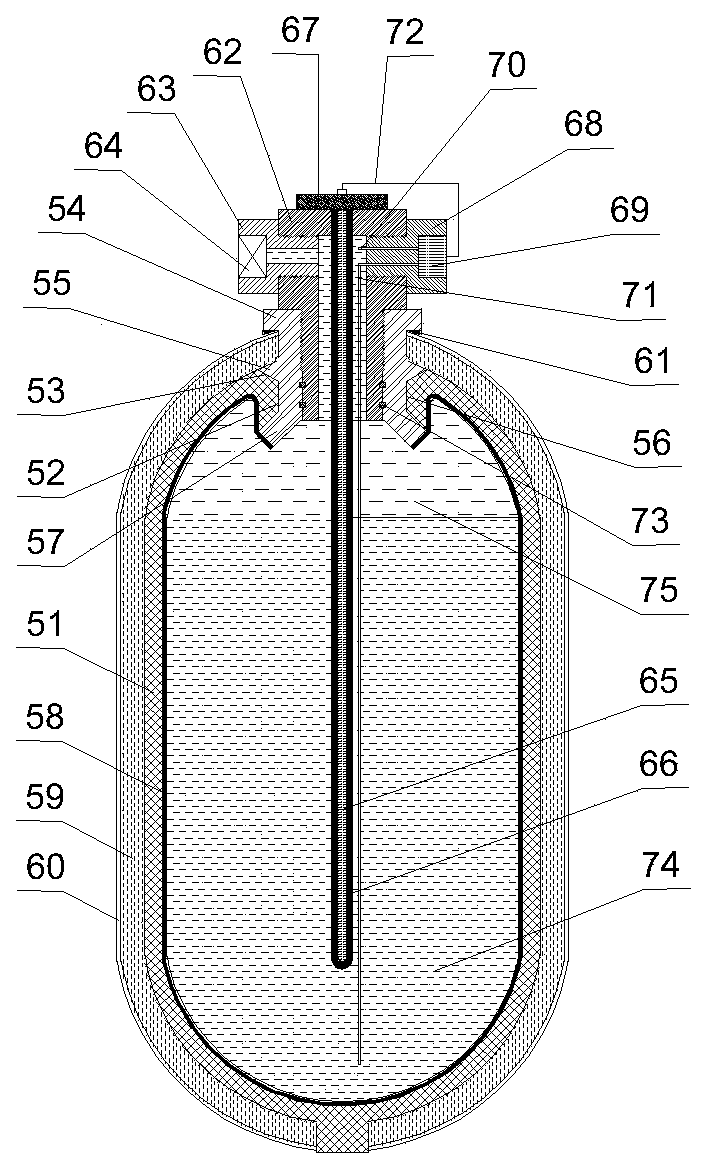

Embodiment 3

[0038] A hydrogen storage bottle containing hydrogen storage particles with an electric temperature control system such as image 3 As shown, where: 51 is a metal hydrogen storage bottle, 52 is a metal hydrogen storage bottle mouth, 53 is a metal hydrogen storage bottle positioning inclined groove, 54 is a shape memory alloy sleeve, 55 is a shape memory alloy inclined shoulder, and 56 is a shape Memory alloy sleeve, 57 is the shape memory alloy end protrusion, 58 is the inner resin bottle, 59 is the rubberized carbon fiber, 60 is the outer protective layer, 61 is the sealant, 62 is the outer valve of the hydrogen storage bottle, and 63 is the hydrogen storage bottle Valve seat, 64 is the air inlet and outlet valve, 65 is the bimetallic hot and cold temperature control rod, 66 is the metal protective cover of the temperature control rod, 67 is the heat sink block of the temperature control rod, 68 is the control valve seat, 69 is the controller, 70 is the gas For the pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com