Copper silicon alloy sputtering target material and copper silicon alloy recording layer

A technology for copper-silicon alloy and recording layer, which is applied in the fields of copper-silicon alloy sputtering targets and copper-silicon alloy recording layers, can solve the problems that copper metal is prone to spontaneous reaction and oxidation, decrease, poor recording quality, etc. Effects of spontaneous reaction and oxidation, improved stability, and improved recording quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Cu 0.75 Si 0.08 Cr 0.17 Alloy sputtering target

[0048] Mix 1195.76 grams of copper powder, 56.37 grams of silicon powder, and 221.78 grams of chromium powder evenly, and continue hot pressing for 3 hours at a temperature of 600 ° C to 800 ° C and a pressure of 500 bar (bar) to obtain Cu 0.75 Si 0.08 Cr 0.17 Alloy sputtering target.

[0049] In the prepared copper-silicon alloy sputtering target, copper accounts for about 75 atomic percent of the overall copper-silicon alloy sputtering target; silicon accounts for about 8 atomic percent of the overall copper-silicon alloy sputtering target; chromium accounts for about 8 atomic percent of the overall copper-silicon alloy The sputtering target is about 17 atomic percent.

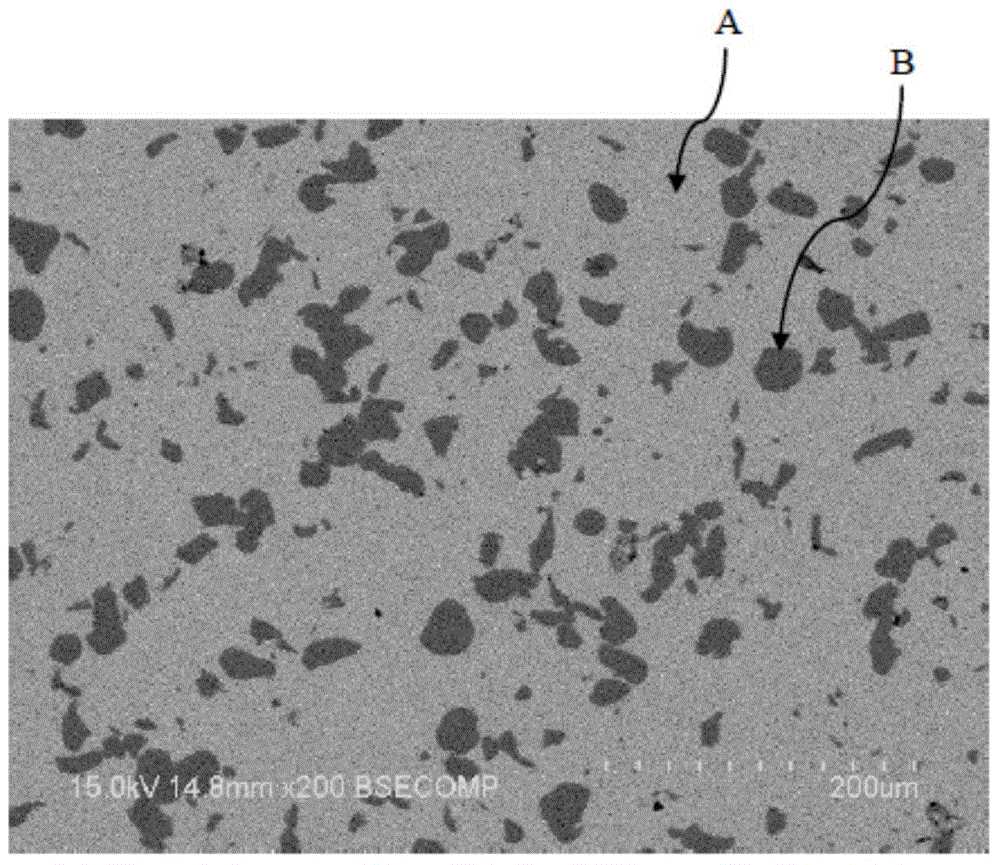

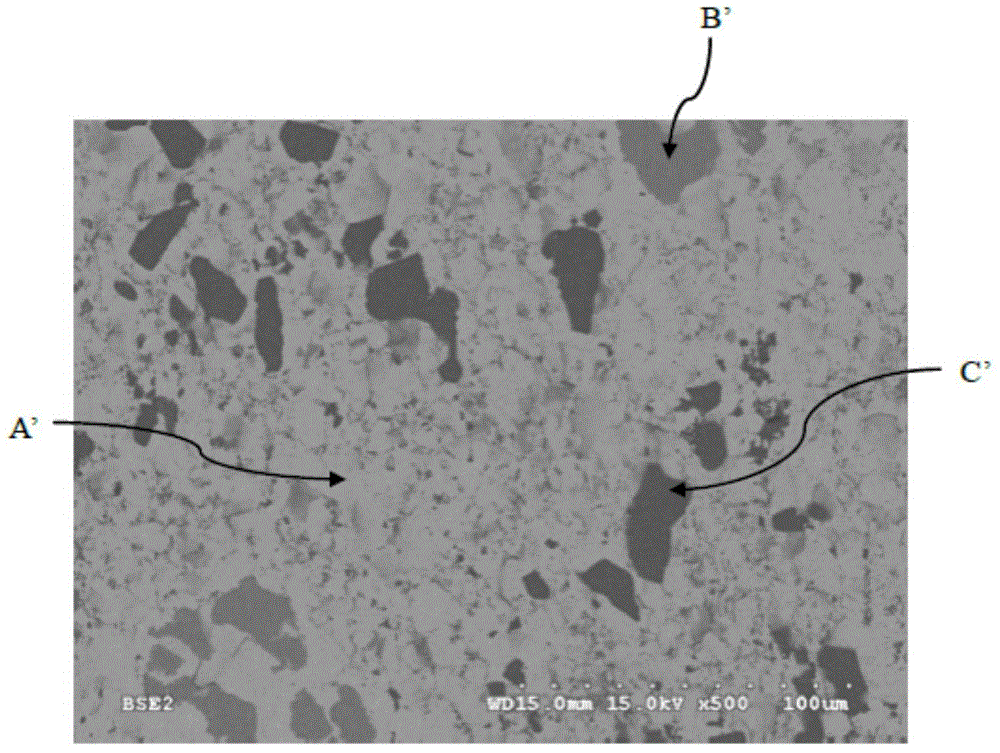

[0050] see figure 1 As shown, the Cu 0.75 Si 0.08 Cr 0.17 Scanning electron microscope image of the alloy sputtering target; figure 1 Among them, the light gray phase A (base phase) of Example 1 is a CuSi alloy; the dark gray phase ...

Embodiment 2

[0051] Example 2: Cu 0.75 Si 0.08 Ni 0.17 Alloy sputtering target

[0052] Mix 1213.20 grams of copper powder, 57.20 grams of silicon powder, and 254.06 grams of nickel powder evenly, and continue hot pressing for 3 hours at a temperature of 600 ° C to 800 ° C and a pressure of 500 bar to obtain Cu 0.75 Si 0.08 Ni 0.17 Alloy sputtering target.

[0053] In the prepared copper-silicon alloy sputtering target, copper accounts for about 75 atomic percent of the overall copper-silicon alloy sputtering target; silicon accounts for about 8 atomic percent of the overall copper-silicon alloy sputtering target; nickel accounts for about The sputtering target is about 17 atomic percent.

Embodiment 3

[0054] Example 3: Cu 0.75 Si 0.08 Ti 0.17 Alloy sputtering target

[0055] Mix 1110.59 grams of copper powder, 52.36 grams of silicon powder, and 189.75 grams of titanium powder evenly, and continue hot pressing for 3 hours at a temperature of 600 ° C to 800 ° C and a pressure of 500 bar to obtain Cu 0.75 Si 0.08 Ti 0.17 Alloy sputtering target.

[0056] In the prepared copper-silicon alloy sputtering target, copper accounts for about 75 atomic percent of the overall copper-silicon alloy sputtering target; silicon accounts for about 8 atomic percent of the overall copper-silicon alloy sputtering target; titanium accounts for about The sputtering target is about 17 atomic percent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com