Preparation process for improving reflectivity of Mini-LED lamp panel

A preparation process, mini-led technology, applied in the printing process, the printing and printing of special varieties of printed matter, to achieve the effects of high surface hardness, high brightness and contrast values, and not easy to blacken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

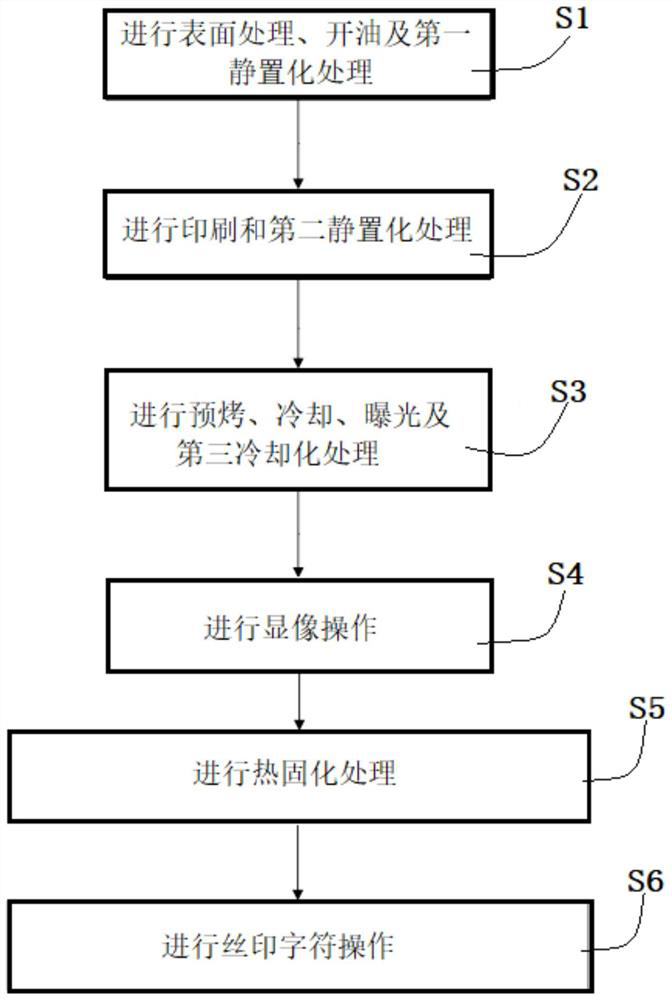

[0029] Such as figure 1 As shown, a preparation process for improving the reflectivity of Mini-LED lamp panels includes the following steps:

[0030] S1. Carry out the surface treatment process on the substrate of the Mini-LED light board, and then carry out oiling and first static treatment;

[0031] The surface treatment process in the above step S1 is a process of cleaning and deoxidizing the copper foil surface of the substrate by using a brushing operation; the purpose of the surface treatment is to clean and deoxidize the copper foil surface of the substrate before printing ink, thereby Increase the roughness of the copper foil surface to achieve higher ink adhesion; the specific implementation method of oil opening is: mix the main agent and curing agent in a ratio of 3:1, stir or shake for 10 minutes, or according to the mixing requirements Add a certain amount of diluent to dilute, diluent such as water, etc. can be.

[0032] The above-mentioned main agent is photos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com