Patents

Literature

34results about How to "Strong resistance to yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low driving voltage dimming film and preparation method thereof

ActiveCN106353911AStrong resistance to yellowingStrong service lifeNon-linear opticsLiquid-crystal displayLow voltage

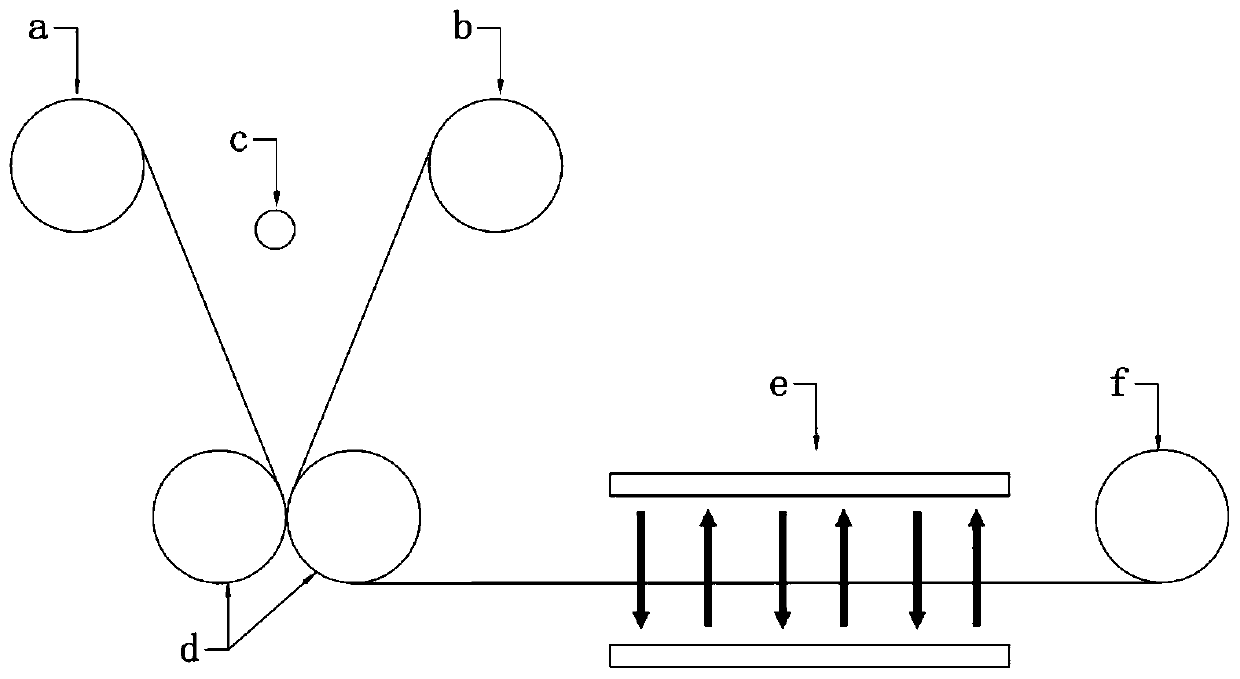

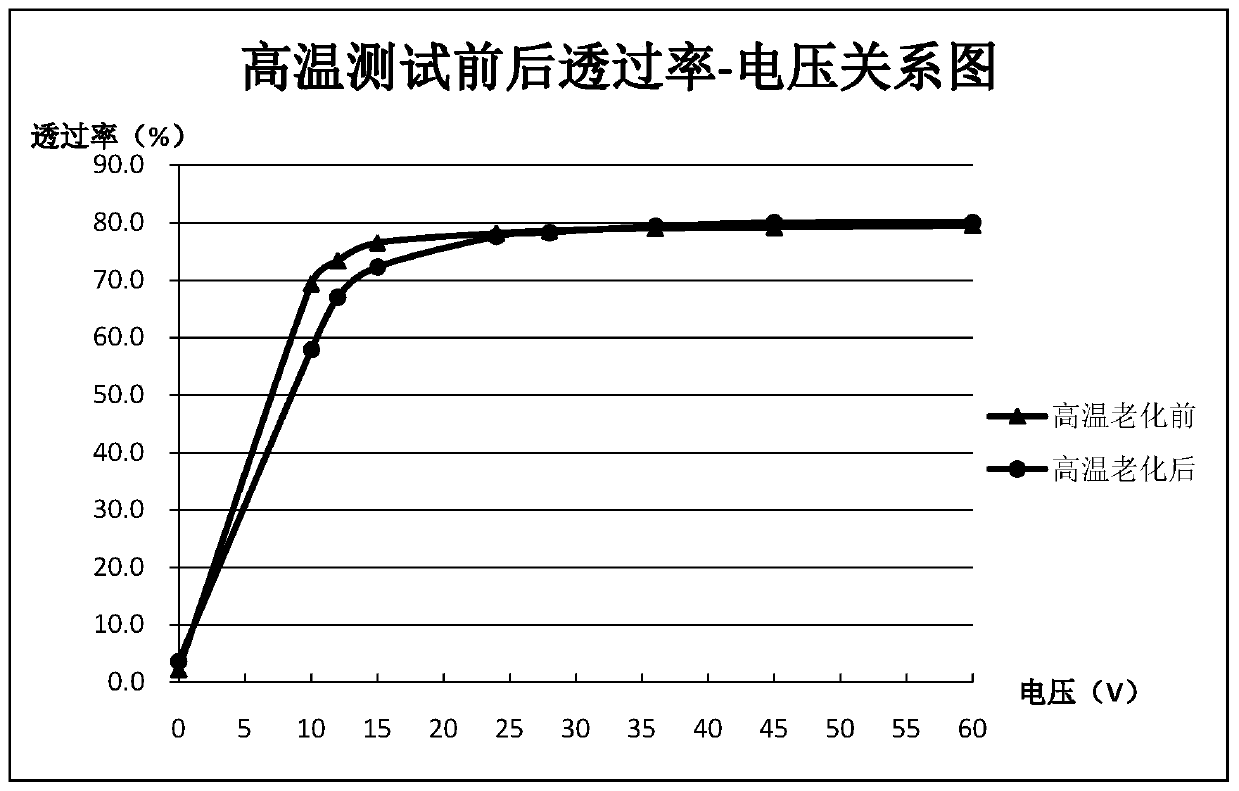

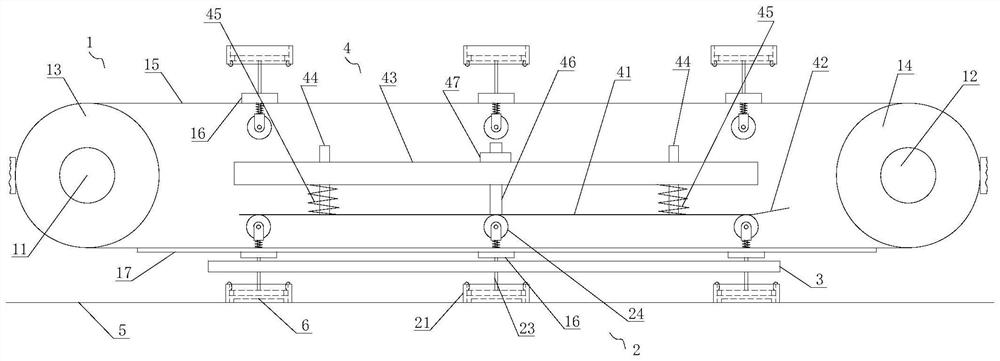

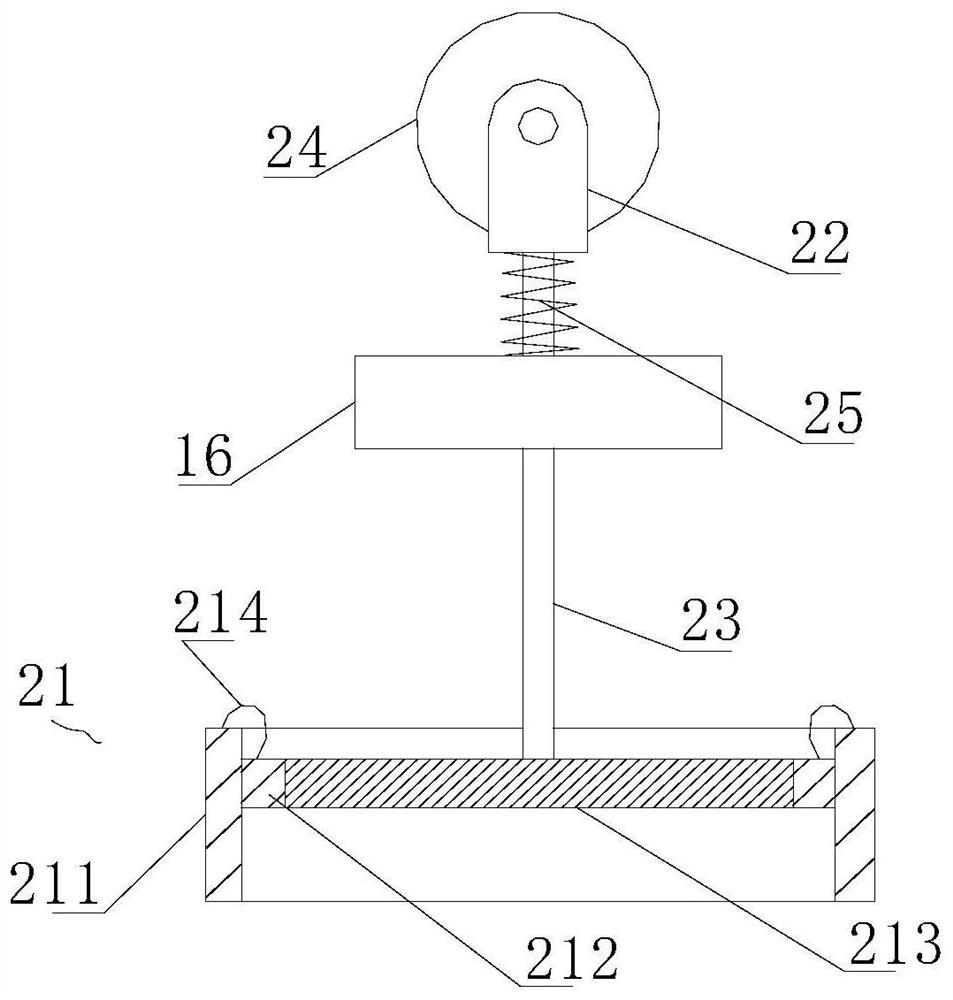

The invention relates to a low driving voltage dimming film and a preparation method thereof. The preparation method comprises the steps of mixing acrylate, an acrylic monomer, a surfactant and a photoinitiator in a ratio to prepare UV (Ultraviolet) optical cement, mixing the UV optical cement with liquid crystal uniformly, adding 0.1-0.8% of spacer and mixing to prepare PDLC (Polymer Dispersed Liquid Crystal); and sandwiching the PDLC between two transparent conductive films, rolling to form a liquid crystal film, and curing the liquid crystal film by heating or with ultraviolet light, thus forming the dimming film. The obtained low voltage dimming film has the working voltage of 24 / 36 V and the lower power consumption of 0.5-1.5 W / m<2>, simultaneously has excellent photoelectric performance, and is suitable for metro shielding doors, bathroom partitions, bank partitions and the like.

Owner:XIANGTAN UNIV +1

Synthesis method of organosilicon-modified aqueous polyurethane acrylate

The invention provides a synthesis method of organosilicon-modified aqueous polyurethane acrylate, which takes different aliphatic diisocyanates, alcoholic hydroxyl-terminated polysiloxane and acrylic acid monomer as main raw materials, and utilizes a stepwise synthesis method. The stepwise synthesis method comprises the following steps of: synthesizing organosilicon-modified polyurethane, introducing a hydrophilic group, and introducing the acrylic acid monomer, wherein a mixed solution of dibutyl tin laurate and organic carboxylic acid rare earth is taken as a catalyst for reflowing at the certain temperature so as to optimize the reaction condition; therefore, the invention provides a synthesis method of photo-cured aqueous polyurethane acrylate with great performances of yellowing resistance, high hardness and the like. The invention has the characteristics of high yield, easy operation and control and the like.

Owner:东莞市贝特利新材料有限公司

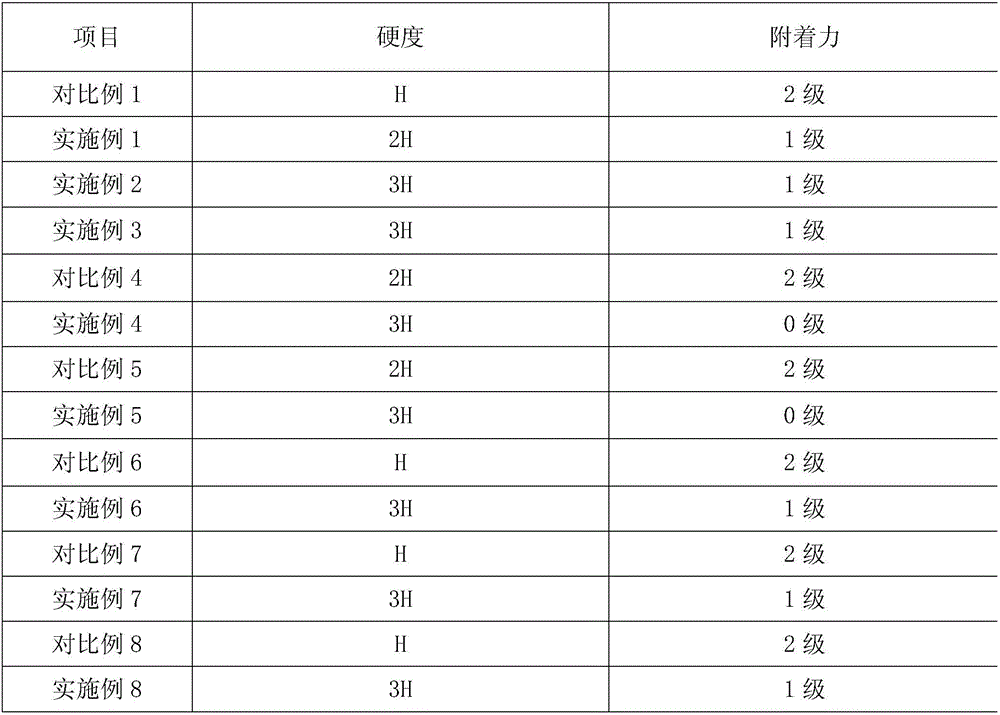

Anti-yellowing waterborne polyurethane emulsion with high glue film hardness and preparation method of anti-yellowing waterborne polyurethane emulsion

ActiveCN105885666APrevent crystallizationIncrease drying speedPolyurea/polyurethane coatingsEmulsionPolyol

The invention provides an anti-yellowing waterborne polyurethane emulsion with high glue film hardness. The anti-yellowing waterborne polyurethane emulsion is prepared from raw materials in parts by weight as follows: 60 parts of carbon dioxide copolymer polyols, 1-10 parts of a hydrophilic chain extender, 20-60 parts of aliphatic diisocyanate, 0.01-1 part of a catalyst, 0-10 parts of a non-hydrophilic chain extender, 100-300 parts of deionized water, 0.1-5 parts of a chain-extending crosslinking agent and 5-40 parts of a polyacrylate emulsion. The invention further provides a preparation method of the anti-yellowing waterborne polyurethane emulsion with high glue film hardness. The waterborne polyurethane emulsion is prepared from basic raw materials including carbon dioxide copolymer polyols and aliphatic diisocyanate through composite modification under the action of the polyacrylate emulsion and has higher glue film hardness and a higher anti-yellowing property.

Owner:GUANGDONG UNIV OF TECH

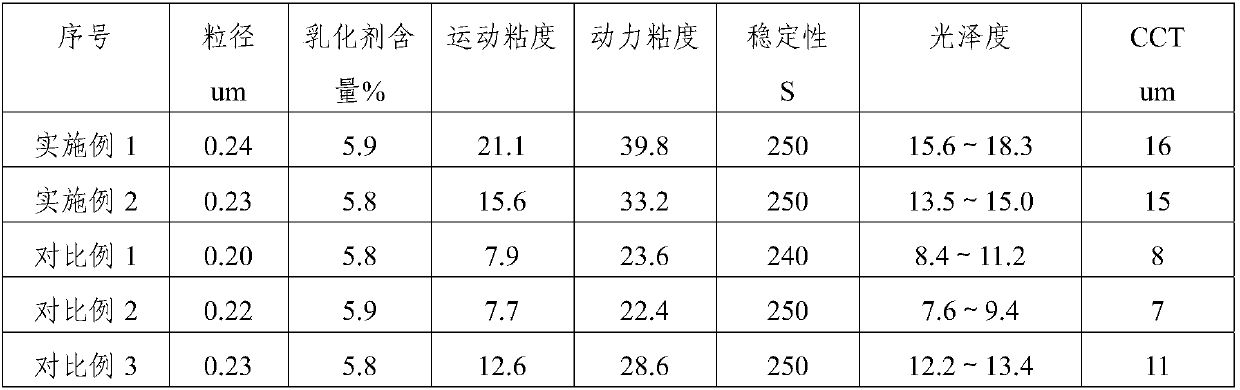

Preparation method of modified polytetrafluoroethylene dispersion concentrated solution

InactiveCN107652386AHigh Limit Membrane ThicknessImprove application processabilityTetrafluoroethylenePolymer science

The invention relates to a preparation method of a modified polytetrafluoroethylene dispersion concentrated solution. The polymerization reaction is carried out in three stages: in the first stage, controlling a reaction pressure to be in a range of 1.0-1.8 MPa and adding 20-30% of tetrafluoroethylene monomers and 40-60% of modified monomers; in the second stage, controlling the reaction pressureto be in a range of 2.0-3.0 MPa and adding 60-70% of tetrafluoroethylene monomers; and in the third stage, controlling the reaction pressure to be in a range of 2.0-3.0 MPa and adding residual tetrafluoroethylene monomers and residual modified monomers. According to the method disclosed by the invention, the pressure is operated in a variable pressure mode in the polymerization process, and recycling is performed twice in an intermediate process for realize a soft-hard-soft three-layer molecular structure of particles, so that the application processing performance of the dispersed concentrated solution is improved fundamentally, and the obtained polytetrafluoroethylene dispersion concentrated solution has the characteristics of extremely high yellowing resistance, good surface glossiness,high limit film-crack thickness, high smoothness, high cracking resistance, excellent non-viscosity and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Anti-yellowing water-based coating agent and preparation method and coating technology thereof

The invention discloses an anti-yellowing water based coating agent. The anti-yellowing water based coating agent is prepared by the matching of the following components by weight: 90-97 parts of an acrylic ester modified polyurethane water solution, 0.5-1 part of a nanometer ZnO, 0.5-1 part of a flatting agent, 0.5-2 part(s) of a cross-linking agent, and 0.5-2 part(s) of a thickening agent. The anti-yellowing water based coating agent has the advantages of aquosity and environmental protection, non-pollution and the like, belongs to a resource-saving product, is low in cost, meanwhile can be mixed with other raw materials, and is an ideal coating adhesive product.

Owner:DRAGON CLAN CHINA

Novel two-component joint beautifying agent

InactiveCN106811166AIncrease elasticityStrong resistance to yellowingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySolvent free

The invention relates to a novel two-component joint beautifying agent composed of components A and B. The component A comprises, by mass, 70-80 parts of polyaspartic acid ester, 5-15 parts of propylene carbonate, 5-10 parts of fumed silica and 2-5 parts of titanium dioxide, and the component B comprises, by mass, 70-85 parts of polyol and aromatic / aliphatic isocyanate polymer, 8-15 parts of 2, 2, 4-trimethyl-1, 3-pentanediol diisobutyrate and 1-15 parts of diethyl fumarate. The novel two-component joint beautifying agent is composed of polyaspartic acid ester resin and a high-elasticity prepolymer curing agent formed by polymerizing polyol and aromatic / aliphatic isocyanate and has the advantages of being high in yellowing resistance, elastic and solvent-free, the problem that an epoxy resin type joint beautifying agent is not resistant to yellowing and water, is subject to influence of air temperature during construction and cannot be used outdoors is solved, and a gap in domestic joint beautifying industry is filled in.

Owner:DONGGUAN COHUI IND MATERIALS

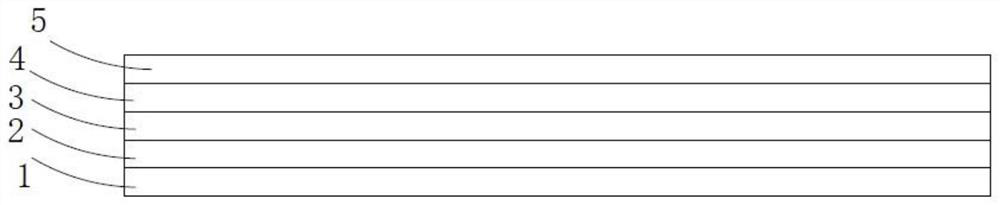

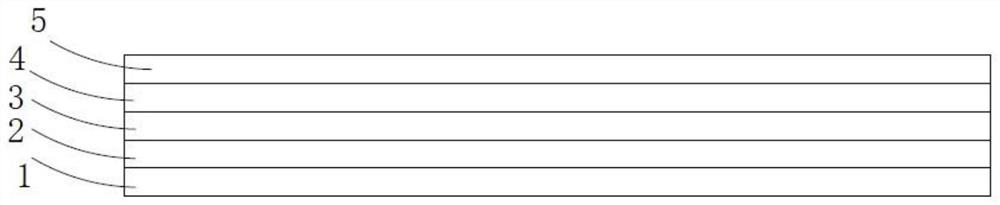

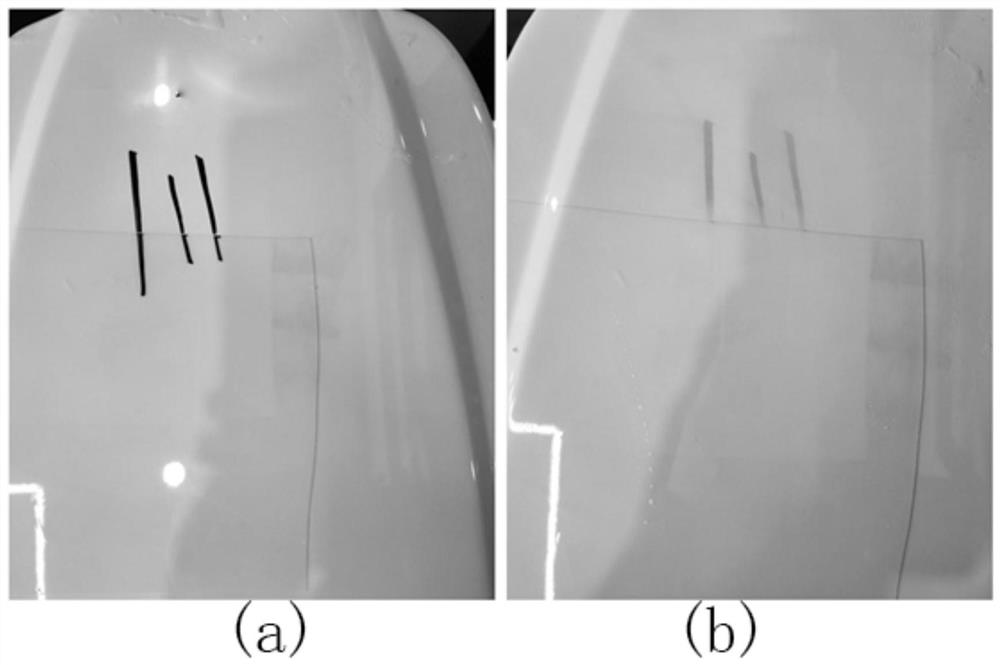

Self-repairing yellowing-resistant paint surface protective film and preparation method thereof

InactiveCN113072890AIncrease stickinessImprove protectionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceFunctional monomer

The invention discloses a self-repairing yellowing-resistant paint surface protective film and a preparation method thereof. The paint surface protective film is sequentially composed of a release film layer I, a pressure-sensitive adhesive layer, a TPU base material, a self-repairing coating and a release film layer II from bottom to top. The self-repairing coating is made of thermocuring functional polyurethane acrylate resin and comprises 20-50% of functional monomer modified acrylic resin, 10-30% of polymer polyol, 40-60% of a diluting solvent, 10-20% of a curing agent, 0.2-0.5% of a catalyst and 0.5-2% of an auxiliary agent, the TPU base material is optical-grade aliphatic TPU, the pressure-sensitive adhesive is an acrylate adhesive, and the release film layer is a PET silicone oil release film. The paint surface protective film prepared by the invention not only has excellent yellowing resistance and self-repairing performance, but also has high transparency, high glossiness, excellent scratch resistance, acid and alkali resistance, rain spot resistance and the like, so that the self-repairing yellowing-resistant paint surface protective film is suitable for the fields of automobile, furniture films and the like.

Owner:南阳金牛彩印集团有限公司 +1

High gloss white UV (Ultra Violet) coating application technology

ActiveCN104209249AStrong resistance to yellowingUniform colorPretreated surfacesCoatingsPolymer scienceSpray coating

The invention relates to the coating application technology, in particular to a high gloss white UV (Ultra Violet) coating application technology. The gloss white UV coating application technology comprises the following steps of hair sanding; roller coating UV priming paint; roller coating pure white UV priming paint; roller coating sanding UV priming paint; sanding and dedusting; shower coating transparent UV priming paint; moistening before shower coating; shower coating pure white highlight UV finishing paint; coating a film after drying. The application technology is dispense with spray coating, has no paint mists and is in batch production; since UV white paint is utilized for shower coating the surface of a plate, the color is very uniform, and the adhesive force is strong; most important is that transparent gloss paint is not used on the surface, so that the coating has strong resistance to yellowing, is non-discolouring basically, and has the grade of fifth level.

Owner:惠州市摩彩装饰材料有限公司

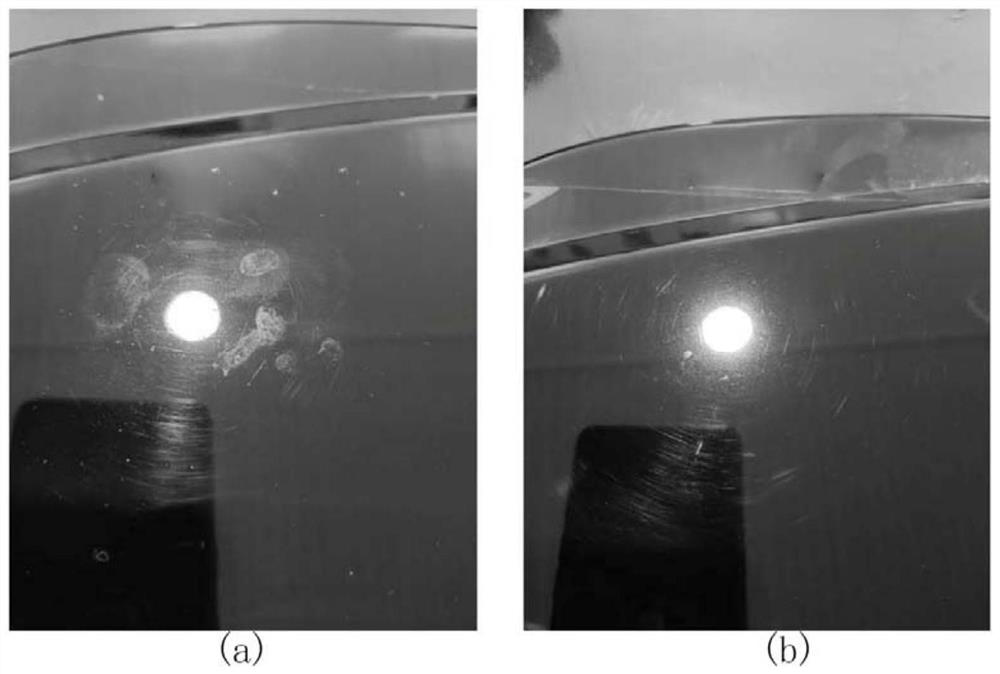

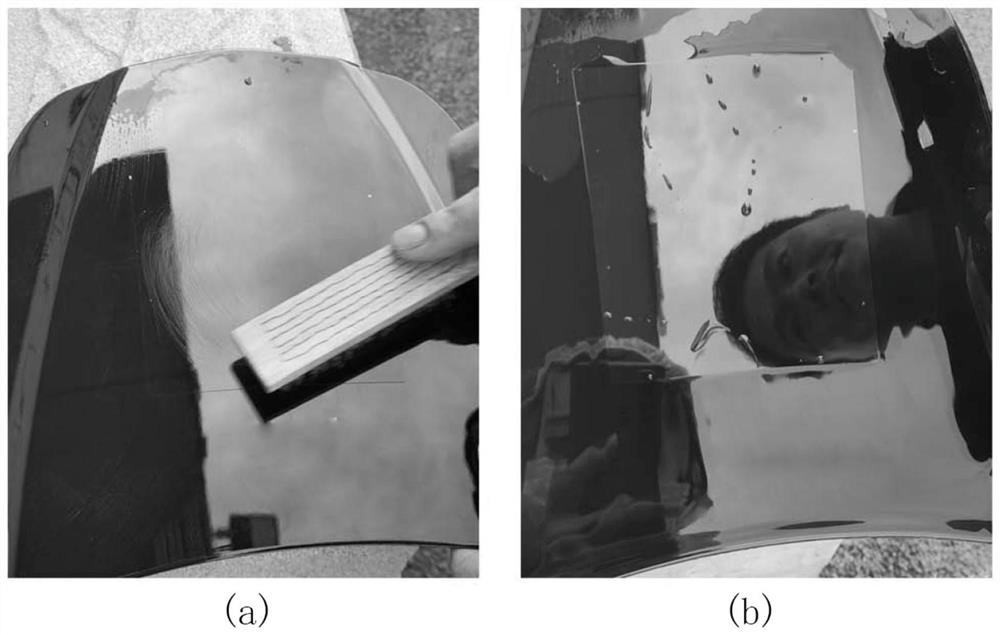

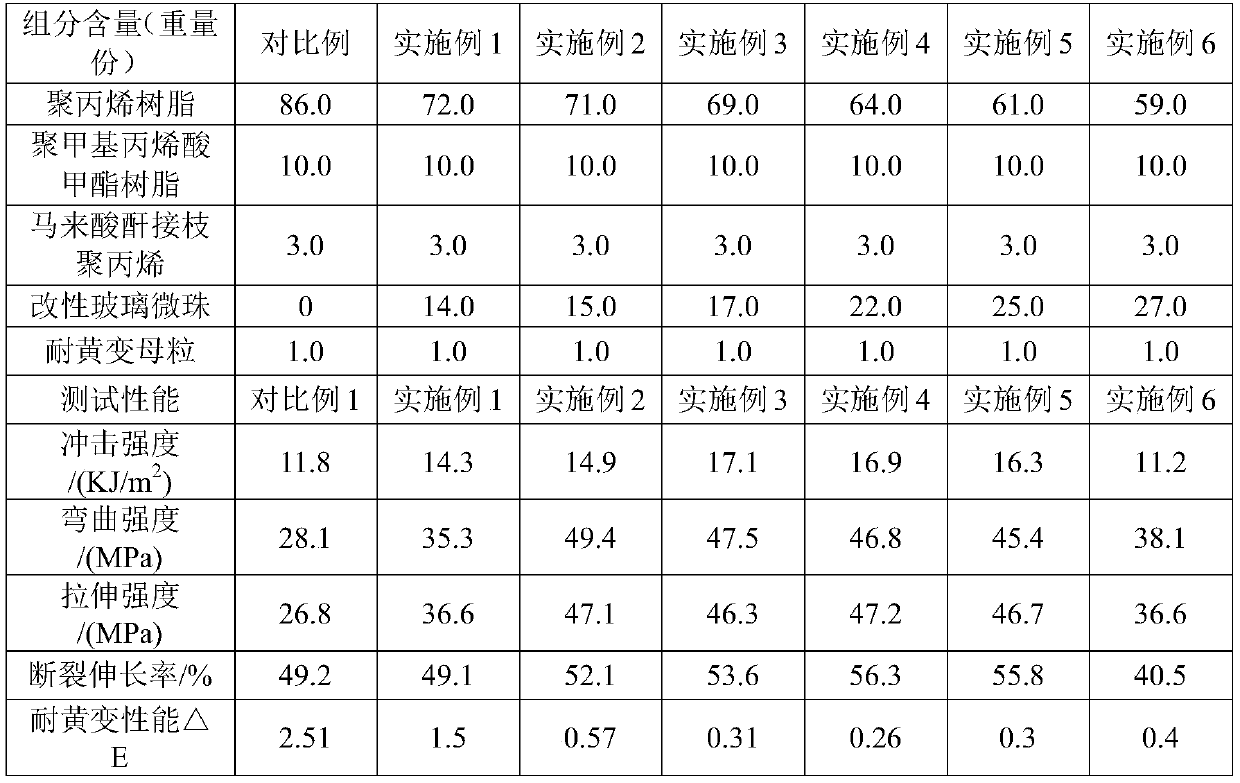

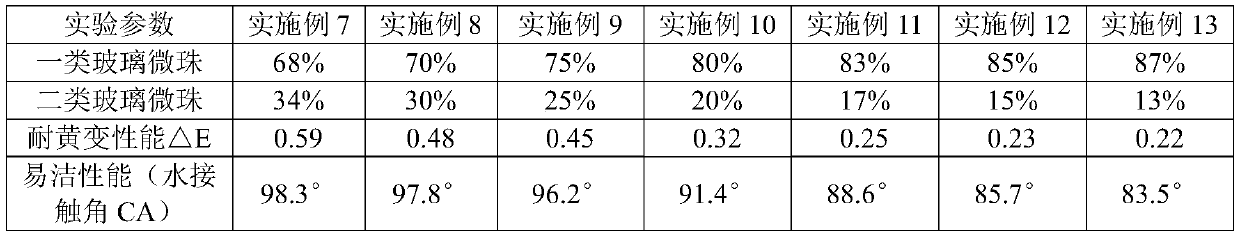

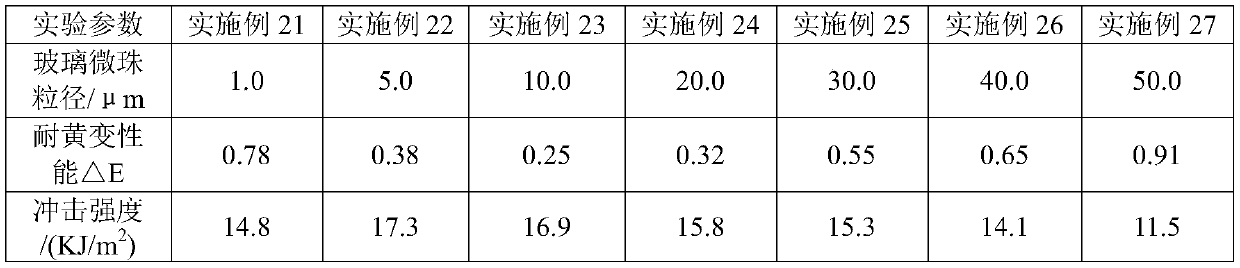

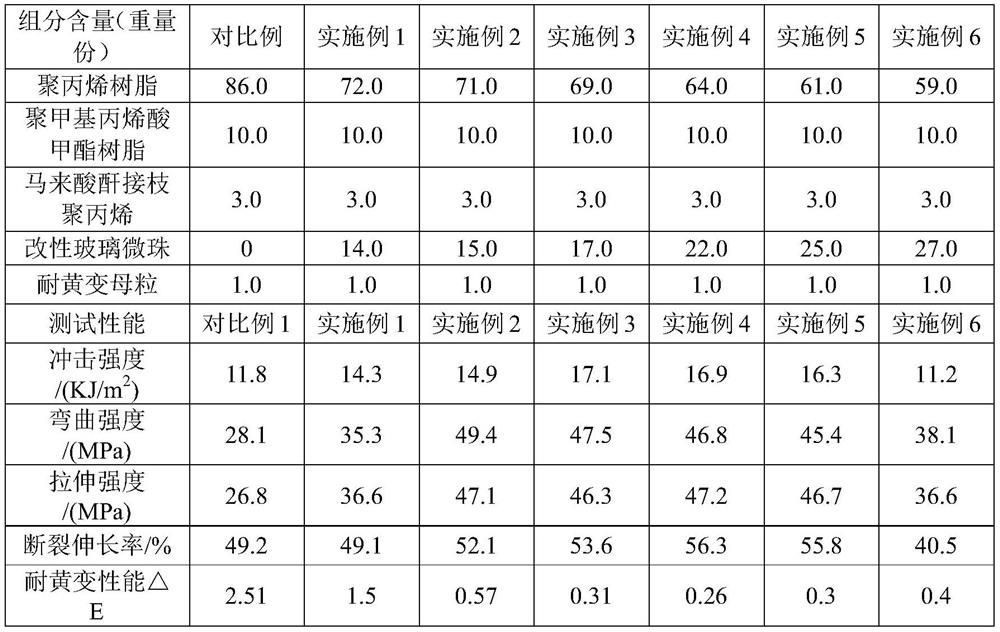

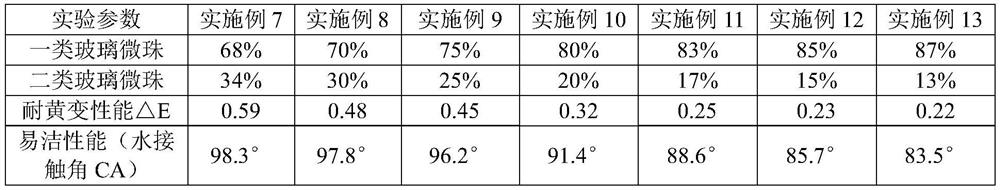

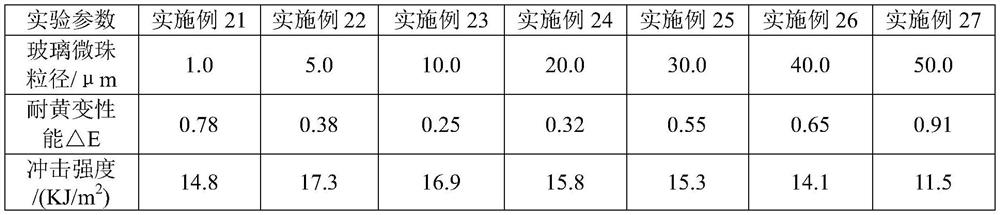

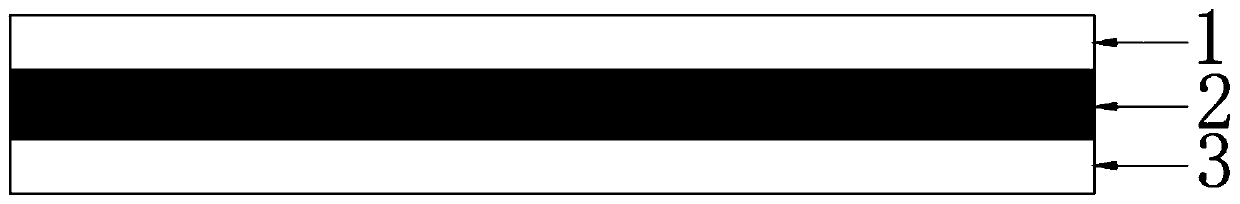

Modified glass microsphere and preparation method thereof and method for preparing composite resin product by using modified glass microsphere

The invention discloses a modified glass microsphere and a preparation method thereof and a method for preparing a composite resin product by using the modified glass microsphere. The modified glass microsphere includes a first class glass microsphere and a second class glass microsphere, a discontinuous metal layer and an ultraviolet absorbent wrap the surface of the first class glass microsphere, a hydrophobic material wraps the surface of the second class glass microphere, the coverage rate of the metal layer on the surface of the first glass microsphere is 45.0%-85.0%, and the modified glass microbead is added into the component of a common anti-yellowing product to improve the anti-yellowing property and the mechanical property of the product.

Owner:JOMOO KITCHEN & BATHROOM

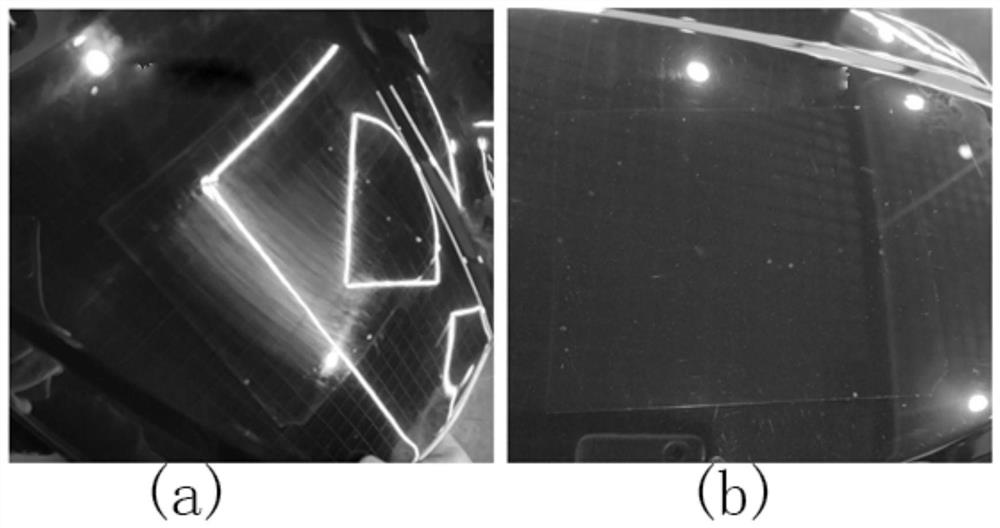

Thermocuring self-repairing paint surface protective film and preparation method thereof

PendingCN113072891AGood optical performanceStrong weather resistanceEster polymer adhesivesAnti-corrosive paintsPolymer sciencePtru catalyst

The invention provides a thermocuring self-repairing type paint surface protective film and a preparation method thereof. The paint surface protective film is sequentially composed of a release film layer A, a pressure-sensitive adhesive layer, a base material layer, a self-repairing coating and a release film layer B from bottom to top. The self-repairing coating is made of self-repairing thermocuring type modified polyurethane acrylate resin and comprises 10-18% of functionalized acrylic resin I, 10-18% of functionalized acrylic resin II, 12-35% of polymer polyol, 30-50% of a solvent, 15-30% of a curing agent, 0.05-0.2% of a catalyst and 0.3-1.0% of auxiliaries, and the base material is made of optical-grade aliphatic TPU, the pressure-sensitive adhesive is an acrylate adhesive, and the release film layer is a PET silicone oil release film. The paint surface protective film is simple in preparation process and easy for industrial batch production, the self-repairing coating has excellent scratch resistance, self-repairing performance, aging resistance, corrosion resistance, pollution resistance and the like after being thermally cured, and the self-repairing paint surface protective film can be widely applied to the fields of automobile and furniture paint surface protection, electronic equipment screen protection and the like.

Owner:南阳金牛彩印集团有限公司

Double-component polyurea sealant

PendingCN114045141AStrong resistance to yellowingStrong adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyaspartic acid

The invention relates to a double-component polyurea sealant. The double-component polyurea sealant comprises a component A and a component B. The component A comprises polyaspartic acid ester polyurea, fumed silica, lime powder, a leveling agent, a dispersing agent, an accelerant and matte powder. The component B comprises curing agent isocyanate, epoxy resin, a defoaming agent, a wetting agent and pigment. The invention has the following beneficial effects: the sealant is formed by compounding polyaspartic acid ester polyurea, a curing agent isocyanate, epoxy resin and a plurality of reinforcing agents, has strong yellowing resistance, reduces heated volatilization deformation, is firm in connection, strong in adhesive force, water-resistant and high in adhesive force, and is not easily influenced by construction conditions.

Owner:北京吉时吉兴贸易有限公司

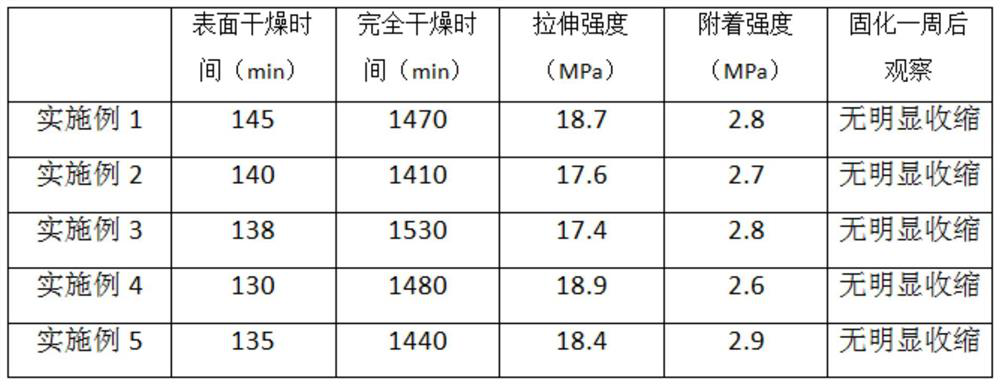

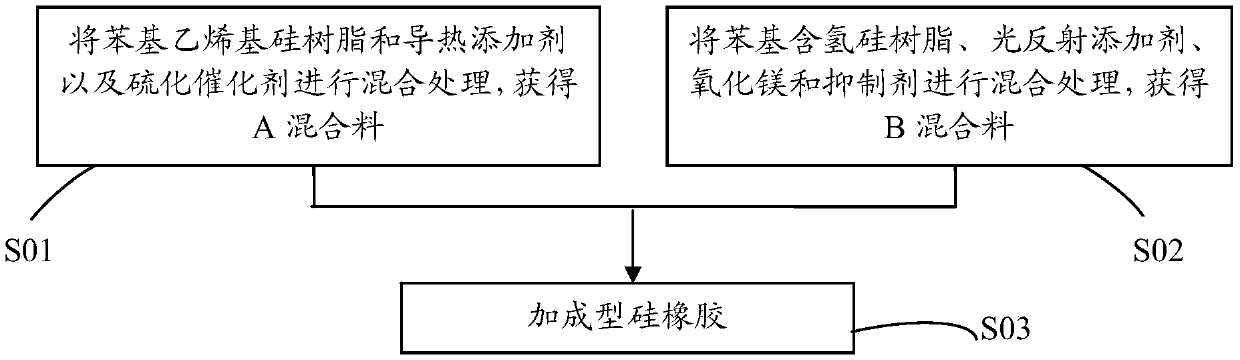

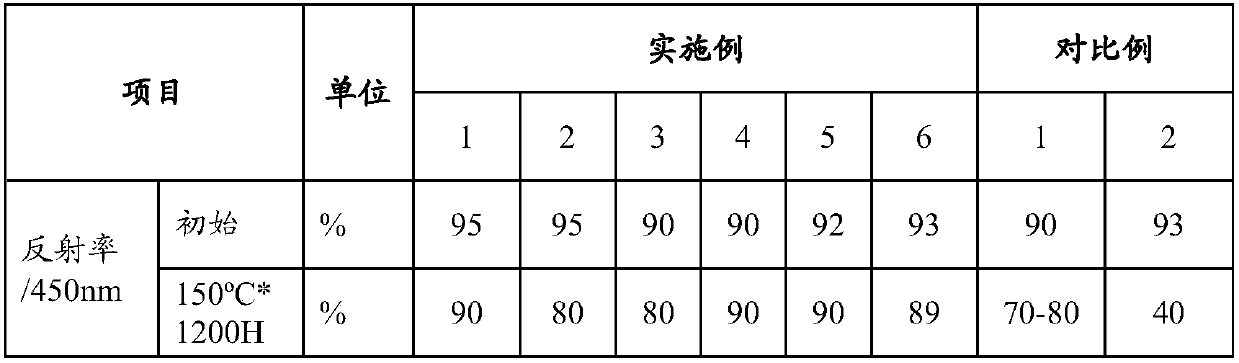

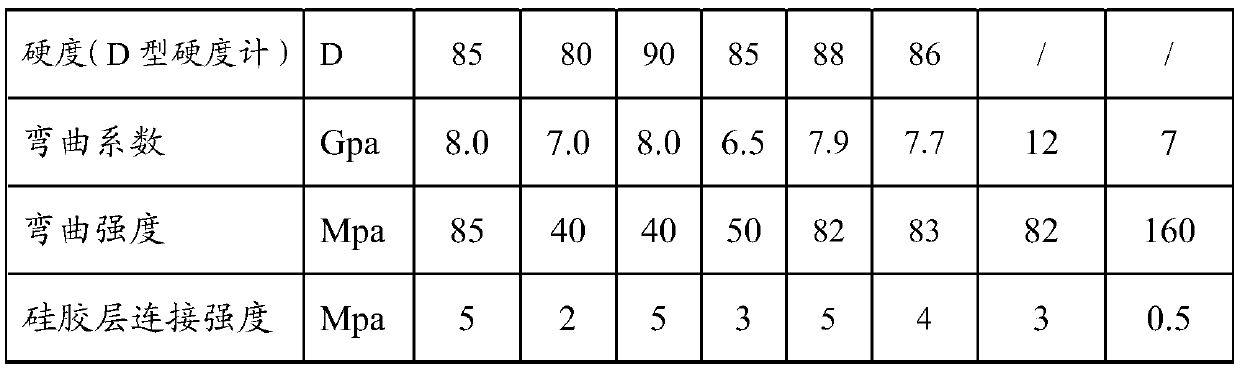

Addition-type molded silicone rubber for LED bracket material and preparation method and application of addition-type molded silicone rubber

The invention discloses addition-type molded silicone rubber for an LED bracket material and a preparation method and application of the addition-type molded silicone rubber. The addition-type moldedsilicone rubber is prepared from, by mass, 10-90 parts of phenylvinyl silicone resin, 10-80 parts of phenyl hydrogen-containing silicone resin, 5-30 PPM of a sulfurization catalyst, 10-80 parts of a thermal conductive additive, 1-60 parts of a light reflection additive, 0-10 parts of magnesium oxide and 5-30 PPM of an inhibitor. The components of the addition-type molded silicone rubber are uniformly dispersed, the addition-type molded silicone rubber has excellent optical properties and elasticity after solidification molding, the structure is stable, the airtightness is good, the rubber doesnot absorb water, the yellowing resistance is high, the preparation method of the rubber can effectively ensure the stability of the related performance of the prepared addition-type molded siliconerubber and the stability of the working performance of devices packaged by the addition-type molded silicone rubber, and the service life of the corresponding device is prolonged.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

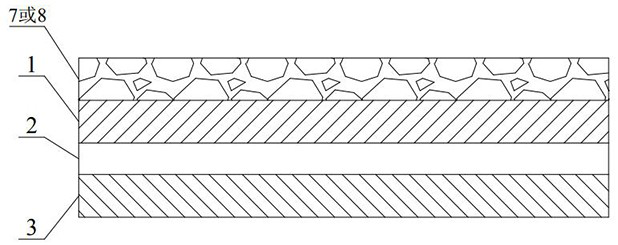

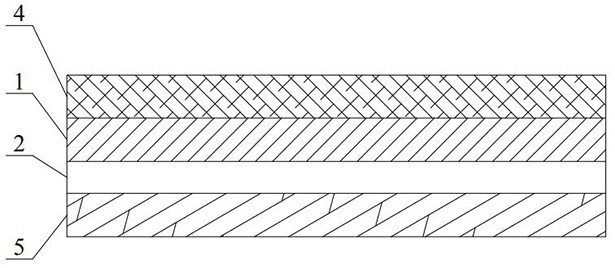

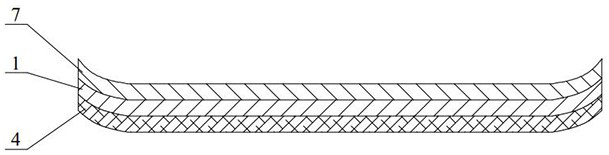

Low driving voltage dimming film and preparation method thereof

ActiveCN106353911BStrong resistance to yellowingStrong service lifeNon-linear opticsEngineeringAcrylate ester

The invention relates to a low driving voltage dimming film and a preparation method thereof. The preparation method comprises mixing acrylate, acrylic acid monomers, surfactants and photoinitiators in proportion to prepare UV optical glue, and mixing the UV optical glue with liquid crystal After uniformity, add 1‰~8‰ spacers and mix to prepare PDLC; then PDLC is sandwiched between two transparent conductive films, and rolled to form a liquid crystal film, and the liquid crystal film is heat-cured or UV-cured, that is Can be made into dimming film. The low-voltage dimming film obtained by the present invention has a working voltage of 24 / 36V, a power consumption as low as 0.5-1.5W / ㎡, and excellent photoelectric performance, and is suitable for subway screen doors, bathroom partitions, bank partitions and other occasions.

Owner:XIANGTAN UNIV +1

Anti-yellowing UV (ultraviolet) varnish

The invention belongs to the technical field of anti-wear and anti-scratching processing of the surface of a plastic product and particularly relates to an anti-yellowing UV (ultraviolet) varnish. The anti-yellowing UV varnish is characterized in that the anti-yellowing UV varnish comprises the following components in percentage by weight: 50-80% of aliphatic polyurethane hex-acrylate, 15-30% of butyl acrylate, 0-15% of dipropylene glycol diacrylate, 1-4% of 2-hydroxyl-2-methyl-1-phenylacetone and 1-4% of 1-hydroxycyclohexyl phenyl ketone. The anti-yellowing UV varnish has good anti-yellowing performance and coating flexibility and is particularly suitable for use in anti-wear and anti-scratching processing of a plastic hose.

Owner:浙江三荣塑胶有限公司

PVC composite material for decorative plate and manufacturing method of material

The invention provides a PVC composite material for a decorative plate and a manufacturing method of the material. The method mainly includes the following steps that firstly, mangosteen shells are cleaned, dried, smashed and screened to obtain mangosteen shell powder, and the mangosteen shell powder is processed by a diluted hydrochloric acid solution to obtain acidified mangosteen shell powder; secondly, the acidified mangosteen shell powder is processed by a potassium permanganate solution to obtain modified mangosteen shell powder; thirdly, europium oxide reacts with nitric acid to prepare an europium nitrate solution, and the europium nitrate solution, a urea solution, sodium dodecyl benzene sulfonate and the modified mangosteen shell powder are mixed, stirred, filtered, washed, dried, roasted and ball-milled to obtain composite powder; fourthly, PVC, the composite powder and other auxiliaries are mixed, melted, extruded, subjected to water cooling, granulated and dried, and the PVC composite material for the decorative plate is obtained. The manufactured PVC composite material for the decorative plate has high yellowing resistance.

Owner:叶剑

Anti-oxidation heat-dissipation paint and preparation method therefor

InactiveCN105111843AImprove impact resistanceImprove corrosion resistanceAnti-corrosive paintsOxidation resistantTetrahydrofuran

The present invention discloses anti-oxidation heat-dissipation paint. The anti-oxidation heat-dissipation paint consists of the following raw materials in parts by weight: 0.3-1 part of 2,6-di-t-butyl-4-methylphenol, 2-3 parts of aluminum sulfate ammonium, 4-6 parts of butyl benzyl phthalate, 12-15 parts of styrene-maleic anhydride copolymer, 6-10 parts of propargyl alcohol, 90-100 parts of tetrahydrofuran, 4-7 parts of graphene, 16-20 parts of nano silica dioxide, 0.2-0.3 part of a silane coupling agent KH560, 700-800 parts of dimethyl formamide, 4-5 parts of sodium nitride, 0.04-0.05 parts of aluminium trichloride, 1.6-2 parts of a 2-3% sodium ascorbate solution, 1.8-2 parts of a 2-3% copper sulphate solution, 120-130 parts of high-density polyethylene, 2-3 parts of calcium lactate, 0.3-1 part of sodium diacetate, 3-5 parts of sodium potassium silicate, and 0.8-1 part of glyceryl monostearate. The paint provided by the present invention is excellent in oxidation resistance, high in yellowing resistance, not liable to aging, high in peeling resistance, and superior in comprehensive performance.

Owner:BENGBU NANZI INSTR

Anti-yellowing priming paint

InactiveCN105295609AStrong resistance to yellowingGood yellowing resistanceCoatingsAcrylic resinSolvent

The invention discloses an anti-yellowing priming paint which consists of the following components in parts by weight: 40-50 parts of acrylic resin, 10-15 parts of pentachlorodiphenyl, 10-15 parts of flax oil, 5-10 parts of titanium dioxide, 20-25 parts of a filling material, 1-2 parts of bentonite, 1-5 parts of an auxiliary and 1-15 parts of a solvent. The provided anti-yellowing priming paint has extremely strong anti-yellowing capability, and the anti-yellowing performance is obviously superior to that of the conventional priming paint product, so that the quality of the product using the provided priming paint is improved, and the provided priming paint has a wide market prospect.

Owner:李晓念

Preparation method of anti-yellowing polyurethane artificial flower

InactiveCN110713587AEasy to processGuaranteed mechanical strengthArtificial flowers and garlandsPolyesterPolymer science

The invention belongs to the technical field of polyurethane artificial flowers and particularly relates to a preparation method of anti-yellowing polyurethane artificial flowers. The preparation method comprises the following steps: stirring and mixing a component B and a component A according to an isocyanate index of 1.3 at the temperature of 75-80 DEG C, pouring the mixture into a preheated mold, demolding the shaped flowers after 12-15 minutes, and performing standing treatment for 7 days after demolding, thereby obtaining the yellowing-resistant polyurethane artificial flower. Compared with the prior art, the method is simple; by reasonably selecting an isocyanate raw material and a polyol raw material, reasonably controlling the isocyanate index and increasing free-NCO groups underthe condition of ensuring the mechanical strength, urea bonds are generated by cross-linking with water in the reaction process, so that the content of the urea bonds in chain segments is increased, and then the hydrophobicity of the composite material is improved; in addition, the benzene ring-containing polyester polyol is reasonably compounded, so that the mechanical properties of polyurethanecan be ensured, the influence of moisture in air on the prepared simulation flower is avoided, and the yellowing resistance is high.

Owner:界首市希捷仿真花卉有限公司

A kind of water-based polyurethane emulsion with yellowing resistance and high film hardness and preparation method thereof

ActiveCN105885666BPrevent crystallizationIncrease drying speedPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention provides an anti-yellowing waterborne polyurethane emulsion with high glue film hardness. The anti-yellowing waterborne polyurethane emulsion is prepared from raw materials in parts by weight as follows: 60 parts of carbon dioxide copolymer polyols, 1-10 parts of a hydrophilic chain extender, 20-60 parts of aliphatic diisocyanate, 0.01-1 part of a catalyst, 0-10 parts of a non-hydrophilic chain extender, 100-300 parts of deionized water, 0.1-5 parts of a chain-extending crosslinking agent and 5-40 parts of a polyacrylate emulsion. The invention further provides a preparation method of the anti-yellowing waterborne polyurethane emulsion with high glue film hardness. The waterborne polyurethane emulsion is prepared from basic raw materials including carbon dioxide copolymer polyols and aliphatic diisocyanate through composite modification under the action of the polyacrylate emulsion and has higher glue film hardness and a higher anti-yellowing property.

Owner:GUANGDONG UNIV OF TECH

A modified glass microsphere, its preparation method and its method for preparing composite resin products

ActiveCN110372912BGood yellowing resistanceImprove mechanical propertiesUv absorbancePolymer science

The invention discloses a modified glass microsphere, a preparation method thereof and a method for preparing composite resin products using the same. Modified glass microspheres include Type I glass microspheres and Type II glass microspheres. The surface of Type I glass microspheres is coated with discontinuous metal layers and UV absorbers. The surface of Type II glass microspheres is coated with hydrophobic materials, and The coverage rate of the layer on the surface of a class of glass microspheres is 45.0-85.0%, and the above-mentioned modified glass microspheres are added to the components of ordinary anti-yellowing products to improve the anti-yellowing performance and mechanical properties of the products.

Owner:JOMOO KITCHEN & BATHROOM

Coating material of silicone rubber magnetic core and coating method thereof

InactiveCN111863426AGood chemical stabilityStrong toughnessOrganic/organic-metallic materials magnetismPermanent magnet manufactureEpoxyPolymer science

The invention discloses a coating material of a silicone rubber magnetic core and a coating method thereof. A ferrite magnetic core is used in coils and transformers of various electronic devices. Traditionally, a surface of a magnetic core needs to be coated with an insulating coating made of an epoxy resin material, compared with the prior art, the coating material is advantaged in that the magnetic core made of silica gel is good in chemical stability, free of influence of cold and hot impact, high in toughness, high in insulativity, resistant to corrosion, simple in production process, high in yellowing resistance and environmentally friendly, automatic large-batch production can be realized, the voltage resistance, corrosion resistance and aging resistance of electronic equipment andtransformers are greatly improved, reliability and stability of products in severe environments such as high temperature, high pressure, high and low temperature impact, salt mist and high temperatureand high humidity are particularly improved, meanwhile, the process has large-batch automatic production capacity, and consistency of products is greatly improved.

Owner:东莞市华芯联科技有限公司

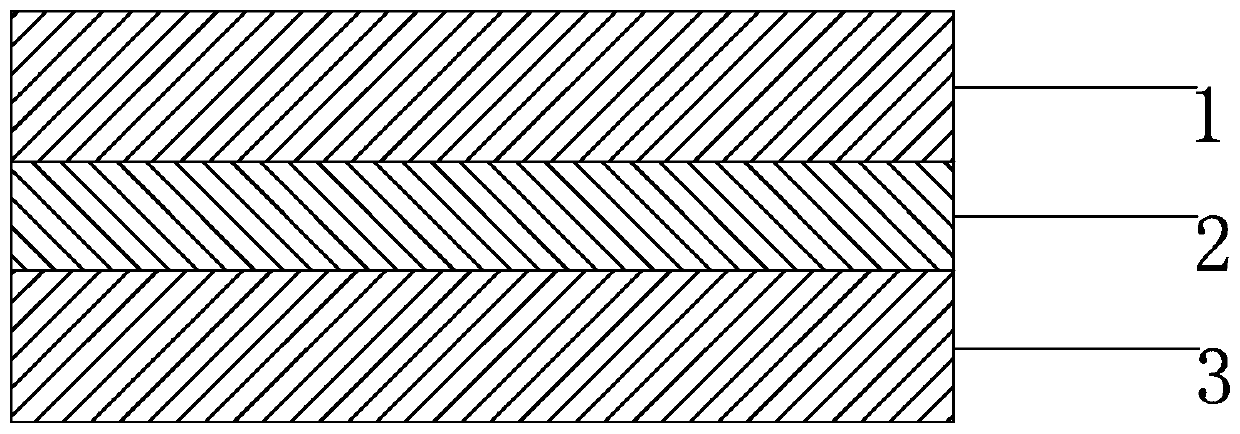

A kind of wide temperature dimming film and preparation method thereof

ActiveCN108594509BGood high and low temperature resistanceGood optical performanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceLiquid-crystal display

The invention relates to a wide temperature polymer dispersed liquid crystal which comprises a wide temperature polymer dispersed liquid crystal layer. Transparent conductive film layers are arrangedon the upper surface and the lower surface of the wide temperature polymer dispersed liquid crystal layer, and a sandwich structure is formed; the wide temperature polymer dispersed liquid crystal layer is made from wide temperature liquid crystals, wide temperature liquid crystal UV glue and introns. The clearing point of the wide temperature liquid crystals ranges from 95 DEG C to 119 DEG C, thefreezing point is lower than -30 DEG C or lower than -40 DEG C; the wide temperature liquid crystals are of a multiphenyls structure. The invention further provides a preparation method of the wide temperature polymer dispersed liquid crystal and the wide temperature liquid crystal UV glue applied to the same. The developed wide temperature polymer dispersed liquid crystal not only can keep normal on-state transparent under the low-temperature environment at -30--40 DEG C, but also has switch response under the high-temperature hostile environment at 80-100 DEG C, the excellent high and low temperature resistant property is achieved, the product can be selected for use according to different areas and special environments, and the polymer dispersed liquid crystal product application market is effectively expanded.

Owner:ZHUHAI SINGYES NEW MATERIALS TECH CO LTD

Ceramic tile seam beautifying curing agent low-cost system seam beautifying agent

InactiveCN110964443AReduce construction difficultyStrong yellowing resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesComposite materialFirming agent

The invention discloses a ceramic tile seam beautifying curing agent low-cost system seam beautifying agent which comprises a component A and a component B, and the ratio of the component A to the component B is 1:1. The component A comprises resin, silicate, carbon nanospheres, glyceryl acrylate and an auxiliary agent; the component B comprises a modified curing agent, an accelerant, a thixotropic agent, a pigment and a coupling agent; the component A comprises the following raw materials in parts by weight: 20-30 parts of resin, 20-30 parts of silicate, 10-15 parts of the carbon nanospheres,2-10 parts of glyceryl acrylate and 5-20 parts of the auxiliary agent; the component B comprises the following raw materials in parts by weight: 30-40 parts of the modified curing agent, 2-10 parts of the accelerant, 3-8 parts of the thixotropic agent, 6-10 parts of the pigment and 0-10 parts of the coupling agent. The ceramic tile seam beautifying curing agent low-cost system seam beautifying agent has the advantages of various types, water resistance, oil resistance, easiness in cleaning, friction resistance, high strength, high brightness, difficulty in mildewing and the like.

Owner:山东齐辰新型建材有限公司

Synthesis method of organosilicon-modified aqueous polyurethane acrylate

The invention provides a synthesis method of organosilicon-modified aqueous polyurethane acrylate, which takes different aliphatic diisocyanates, alcoholic hydroxyl-terminated polysiloxane and acrylic acid monomer as main raw materials, and utilizes a stepwise synthesis method. The stepwise synthesis method comprises the following steps of: synthesizing organosilicon-modified polyurethane, introducing a hydrophilic group, and introducing the acrylic acid monomer, wherein a mixed solution of dibutyl tin laurate and organic carboxylic acid rare earth is taken as a catalyst for reflowing at the certain temperature so as to optimize the reaction condition; therefore, the invention provides a synthesis method of photo-cured aqueous polyurethane acrylate with great performances of yellowing resistance, high hardness and the like. The invention has the characteristics of high yield, easy operation and control and the like.

Owner:东莞市贝特利新材料有限公司

A high-gloss white uv coating construction technology

ActiveCN104209249BStrong resistance to yellowingUniform colorPretreated surfacesCoatingsWetting frontUV coating

Owner:惠州市摩彩装饰材料有限公司

Packaging paper card UV ink printing curing and drying device

ActiveCN113334925ATo achieve the purpose of energy savingKeep dryInksPrinting press partsMechanical engineeringElectrical and Electronics engineering

The invention discloses a packaging paper card UV ink printing curing and drying device. The device comprises a driving device, a plurality of cover mechanisms, a UV lamp and an adjusting device, the driving device is provided with the cover mechanisms, the driving device drives the cover mechanisms to pass through the positions below the UV lamp and the adjusting device, and when the cover mechanisms pass through the position below the adjusting device, the cover mechanisms are forced by the adjusting device to move downwards to cover printed packaging paper cards on which ink is to be cured and dried; and compared with the prior art, the drying and curing efficiency can be improved, and the energy consumption is reduced.

Owner:HAIYAN XIMEI PRINTING

Production process of color-changeable stain-resistant leather mobile phone rear cover

ActiveCN113083635AImprove aestheticsGain functionalityClimate change adaptationCoatingsColloidal silicaPolymer science

The invention relates to a production process of a color-changeable stain-resistant leather mobile phone rear cover and relates to the technical field of mobile phone decoration and explosion prevention. The production process comprises the following steps that 1, embossed paper or an embossed film with leather texture is coated with a coating, a thermochromic material or a photochromic material or color sizing or color paste which is different in color and is fused with each other is added into the coating, then drying, curing and shaping are carried out, and a leather layer with the embossed paper or the embossed film is obtained; 2, the surface of the leather layer is coated with acrylic adhesive or silica gel or pressure-sensitive adhesive so as to form an adhesive layer on the leather layer; 3, a layer of a release film is attached to the adhesive layer; 4, the embossed paper or the embossed film is torn off, and the other surface of the leather layer is coated with a stain-resistant coating so as to form a stain-resistant layer on the other surface of the leather layer; and 5, the release film is stripped, and the adhesive layer is attached to the mobile phone rear cover layer to obtain the color-changeable stain-resistant leather mobile phone rear cover. By means of the production process, the functionality and aesthetic property of the mobile phone rear cover can be improved.

Owner:HENGSHAN JIACHENG NEW MATERIAL

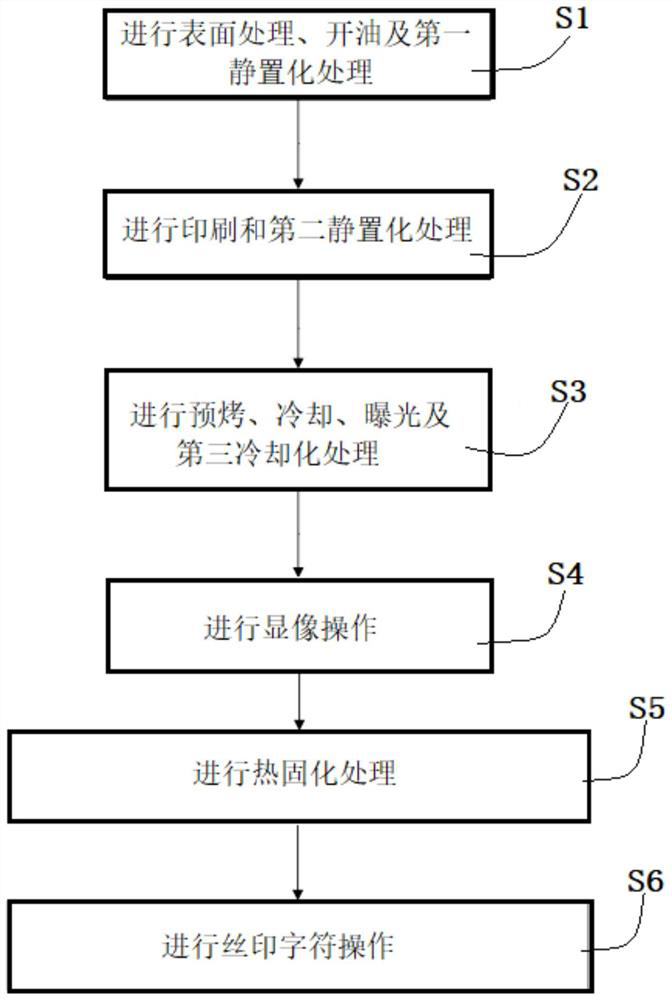

Preparation process for improving reflectivity of Mini-LED lamp panel

ActiveCN114211893AImprove reflectivityIncrease brightnessPattern printingOther printing apparatusEngineeringLED lamp

The preparation process for improving the reflectivity of the Mini-LED lamp panel comprises the following steps: carrying out a surface treatment process on a substrate of the Mini-LED lamp panel, and then carrying out oil boiling and first standing treatment; s2, printing the substrate formed in the step S1, and continuing to perform second standing treatment after the printing treatment is finished; s2, performing pre-baking treatment on the substrate formed in the step S2, sequentially performing cooling and exposure after the pre-baking is finished, and continuing third standing treatment after the exposure is finished; performing development operation on the substrate formed in the step S3; performing thermocuring treatment on the substrate formed in the step S4; carrying out character silk-screen operation on the substrate formed in the step S5; according to the technology, the lateral erosion rate is smaller than 40%, the reflectivity reaches 88% or above, the manufactured backlight face can evenly reflect the luminosity of a backlight source, the reflectivity of light emitted by the reflecting lamp beads is higher, and the brightness value and the contrast value of the whole screen can be higher.

Owner:广东合通建业科技股份有限公司

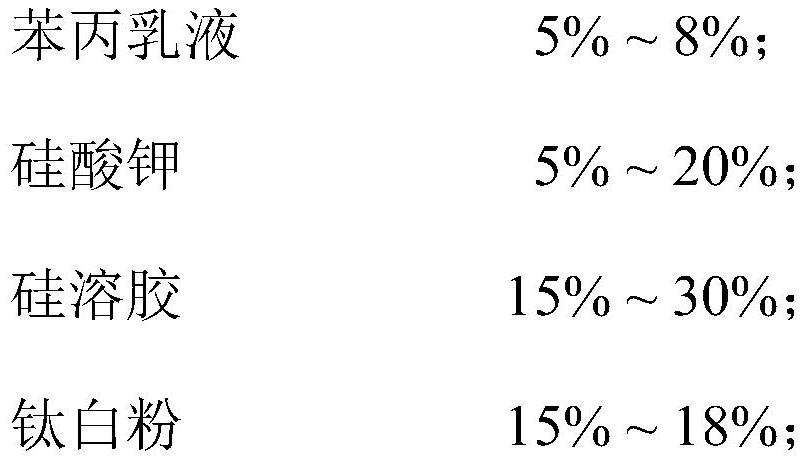

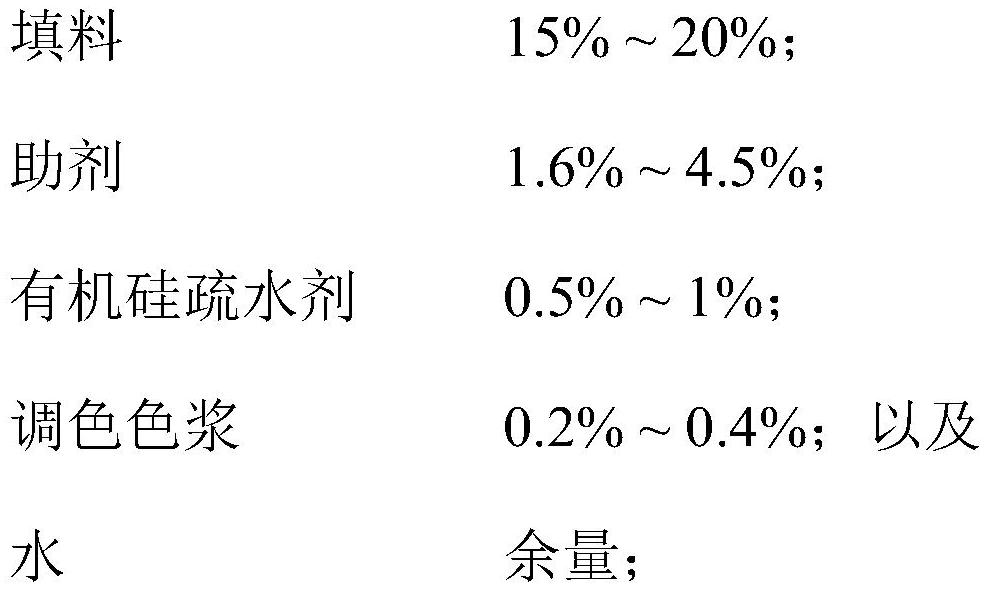

Inorganic silicate imitation fair-faced concrete coating and its preparation method and application

ActiveCN112961514BImprove permeabilityImprove stabilityAlkali metal silicate coatingsCrack resistanceSilicic acid

The invention relates to a paint and its preparation method and application. In terms of mass percentage, the coating includes 5%-8% of styrene-acrylic emulsion, 5%-20% of potassium silicate, 15%-30% of silica sol, 15%-18% of titanium dioxide, 15%-20% of filler, 1.6% to 4.5% of agent, 0.5% to 1% of organic silicon hydrophobic agent, 0.2% to 0.4% of color paste and the rest of water; among them, potassium silicate is silane modified potassium silicate with a modulus of 3.5 to 4.0; Silica sol is stabilized. Adhesive system composed of specific content of styrene-acrylic emulsion, potassium silicate and silica sol. Silicate has good permeability, reacts with cement wall, and can penetrate into the wall substrate, so the bonding force is strong. Styrene-acrylic emulsion It improves the encapsulation of the coating on the powder, and the synergistic effect of potassium silicate and silica sol improves the cohesion and crack resistance of the coating film. The paint has good stability, the prepared paint film has weak luster, and has a good and realistic imitation fair-faced concrete effect; and the paint film has strong bonding force with the base material, is not easy to peel off, and has good yellowing resistance.

Owner:广东嘉宝莉科技材料有限公司 +1

Ultrariolet rag solidifying printing lustering oil and its preparation method

ActiveCN100432161CHigh glossStrong resistance to yellowingInksEpoxy resin coatingsEpoxyHigh resistance

An ultraviolet solidified polishing oil for print is prepared from epoxy prepolymer, polyol, polyaryl thionium salt and assistant through proportionally and sequentially mixing at the temp lower than 50 deg.C. Its advantages are no volume shrinking, high adhesion and toughness, and high resistance to yellowing.

Owner:SHANTOU DONGFENG PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com