Production process of color-changeable stain-resistant leather mobile phone rear cover

A mobile phone back cover and production process technology, applied to special surfaces, devices for coating liquid on surfaces, coatings, etc., can solve problems such as insufficient functionality and aesthetics, and achieve improved aesthetics, strong stability, and tactile sensation comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The production process of the color-changing anti-fouling leather mobile phone back cover comprises the following steps:

[0030] 1. Coating paint on embossed paper or embossed film with leather texture, adding thermochromic material or photochromic material or color paste or color paste of different colors and blending in the paint, and then drying and curing Shaping to obtain a leather layer 1 with embossed paper or embossed film.

[0031] 2. Coating acrylic glue or silica gel or pressure-sensitive adhesive on the surface of the leather layer 1 to form an adhesive layer 2 on the leather layer 1 .

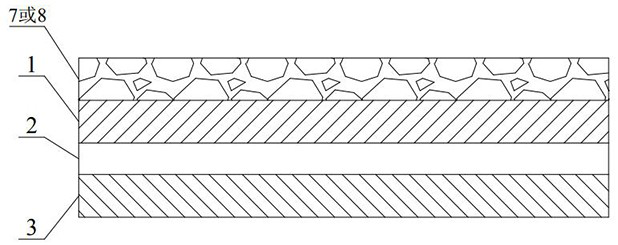

[0032] 3. Paste a layer of release film 3 on the adhesive layer 2 (obtained as figure 1 structure shown).

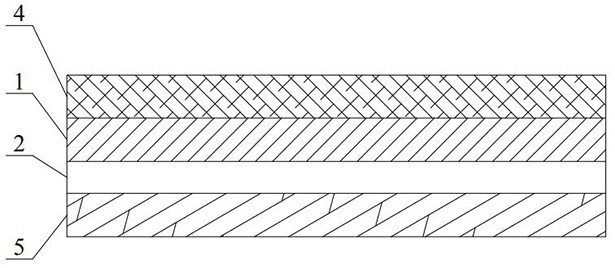

[0033] 4. Tear off the embossed paper or embossed film, and apply an antifouling paint on the other surface of the leather layer 1 to form an antifouling layer 4 on the other surface of the leather layer 1 .

[0034] 5. Peel off the release film 3, and stick the ad...

Embodiment 2

[0038] The production process of the color-changing anti-fouling leather mobile phone back cover comprises the following steps:

[0039] 1. Coating paint on the surface of the substrate layer 6 , and adding thermochromic material or photochromic material or colorants or pastes of different colors that blend together in the paint.

[0040] 2. Curing the paint, and pressing out the texture on the paint surface through a textured roller during the curing process, so that the paint forms a leather layer 1; The texture is pressed out on the surface of the paint, so that the paint forms a leather layer 1, and then the embossed paper or embossed film is torn off.

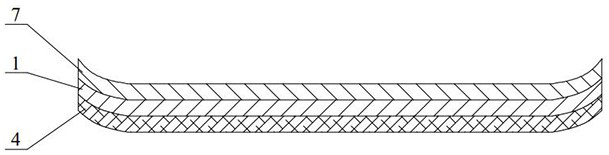

[0041] 3. The substrate layer 6 and the leather layer 1 are taken as a whole and subjected to hot bending or injection molding process to shape it into a color-changing anti-fouling leather mobile phone back cover (such as image 3 shown).

[0042] Preferably, an antifouling layer 4 is formed by coating the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com