Inorganic silicate imitation fair-faced concrete coating and its preparation method and application

A technology of imitating fair-faced concrete and inorganic silicate, applied in the direction of alkali metal silicate paint, coating, etc., can solve the problems of unsatisfactory prevention effect, efflorescence, and inability to see close-up, and achieve realistic imitation of fair-faced concrete effect, Improve cohesion and crack resistance, good effect of yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

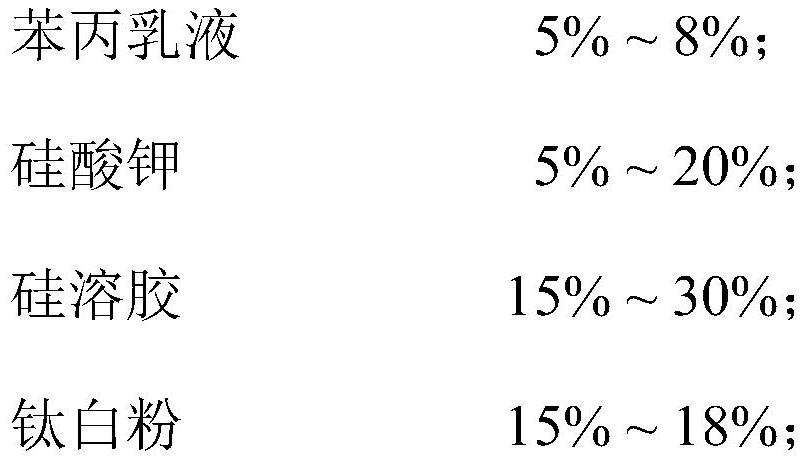

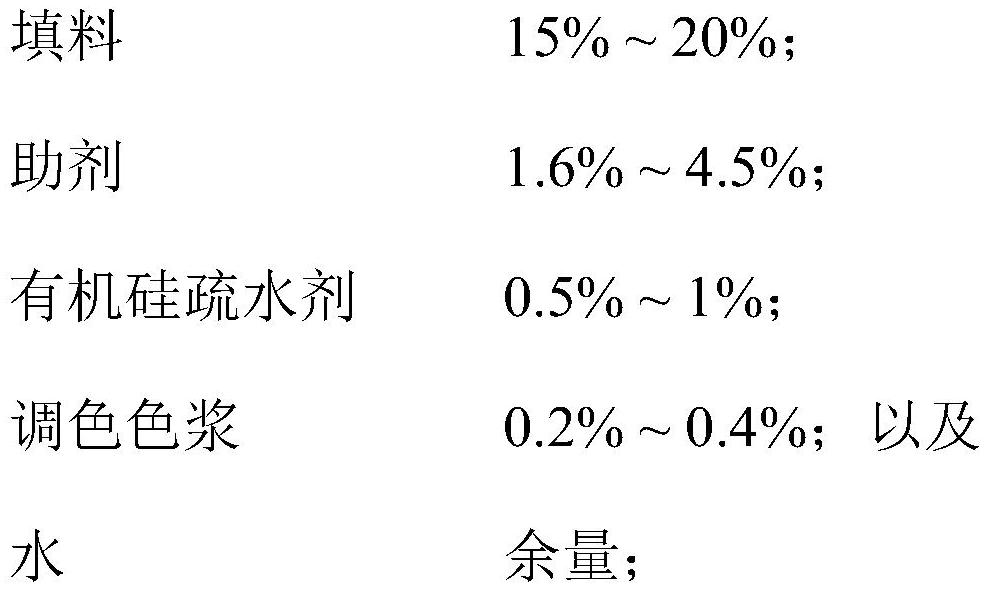

[0060] Another embodiment of the present invention also provides a preparation method of an inorganic silicate imitating fair-faced concrete coating, comprising the following steps S1-S6.

[0061] Step S1: Take each component of the above-mentioned inorganic silicate imitation fair-faced concrete coating for subsequent use.

[0062] Step S2: Stir and mix an appropriate amount of water and additives to form a colloidal substance.

[0063] Step S3: adding titanium dioxide and fillers to the colloidal substance, and grinding.

[0064] Step S4: Continue to add the styrene-acrylic emulsion, and mix well.

[0065] Step S5: continue to sequentially add potassium silicate, silica sol, organosilicon hydrophobic agent and remaining water, and mix well.

[0066] Step S6: Continue adding toning color paste to obtain inorganic silicate imitation fair-faced concrete paint.

[0067] The preparation method of the above-mentioned inorganic silicate imitating fair-faced concrete coating has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com