Preparation method of anti-yellowing polyurethane artificial flower

A technology of polyurethane and artificial flowers, applied in the field of polyurethane artificial flowers, to achieve strong yellowing resistance, improve tensile strength and impact strength, and improve hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

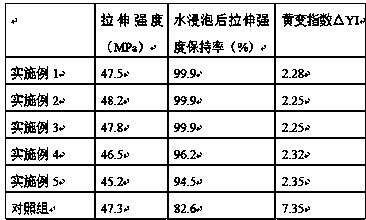

Examples

Embodiment 1

[0020] A preparation method of anti-yellowing polyurethane artificial flowers, comprising the following contents:

[0021] (1) Raw material preparation

[0022] The raw material components of the component A include, in parts by weight, 78 parts of composite polyester polyols containing benzene rings, 4.5 parts of white masterbatch, 0.9 parts of water, 3.5 parts of German BASF chain extender ADR-4368CS, organic bismuth 1.5 parts of catalyst, 0.5 part of 2-hydroxyl-4-dodecyloxybenzophenone;

[0023] The polyester polyol containing benzene ring is obtained by mixing PD-56LV and PS-2412 in a weight ratio of 1:1; the organic bismuth catalyst is bismuth neodecanoate;

[0024] The component B is obtained by mixing dicyclohexylmethane diisocyanate and hydrogenated xylylene diisocyanate with an NCO content of 34.2-36.8% in a weight ratio of 14:1;

[0025] (2) Dehydrate the composite polyester polyol containing benzene rings under a vacuum of 0.12kPa until the water content is lower ...

Embodiment 2

[0028] A preparation method of anti-yellowing polyurethane artificial flowers, comprising the following contents:

[0029] (1) Raw material preparation

[0030] The raw material components of the component A include, in parts by weight, 75 parts of composite polyester polyols containing benzene rings, 3 parts of white masterbatch, 0.6 parts of water, 4 parts of German BASF chain extender ADR-4368CS, organic bismuth 1.8 parts of catalyst, 0.4 part of 2-hydroxyl-4-dodecyloxybenzophenone;

[0031] The polyester polyol containing benzene ring is obtained by mixing PD-70LV and PS-2502A at a weight ratio of 1:1; the organic bismuth catalyst is mixed with bismuth laurate and bismuth isooctanoate at a weight ratio of 3:1;

[0032] The component B is obtained by mixing dicyclohexylmethane diisocyanate and hydrogenated xylylene diisocyanate with an NCO content of 34.2-36.8% in a weight ratio of 16:1;

[0033] (2) Dehydrate the composite polyester polyol containing benzene rings under ...

Embodiment 3

[0036] A preparation method of anti-yellowing polyurethane artificial flowers, comprising the following contents:

[0037] (1) Raw material preparation

[0038] The raw material components of the component A include, in parts by weight, 80 parts of composite polyester polyols containing benzene rings, 6 parts of white masterbatch, 1.2 parts of water, 3 parts of German BASF chain extender ADR-4368CS, organic bismuth 1.2 parts of catalyst, 0.6 part of 2-hydroxyl-4-dodecyloxybenzophenone;

[0039] The polyester polyol containing benzene ring is obtained by mixing PHN-56 and PS-2412 in a weight ratio of 1:1; the organic bismuth catalyst is obtained by mixing bismuth neodecanoate and bismuth isooctanoate in a weight ratio of 2:1;

[0040] The component B is obtained by mixing dicyclohexylmethane diisocyanate and hydrogenated xylylene diisocyanate with an NCO content of 34.2-36.8% in a weight ratio of 12:1;

[0041](2) Dehydrate the composite polyester polyol containing benzene ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com