Self-repairing yellowing-resistant paint surface protective film and preparation method thereof

A self-healing and protective film technology, applied in the direction of pressure-sensitive film/sheet, film/sheet adhesive, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Functionalized polyurethane acrylate self-repairing coating composition includes: polyhydroxya hyaloside alone modified acrylate resin (hydroxyl) 25%, polytetrahydrofuran (BASF POLYTHF2000) 20%, butyl acetate 40%, isophorone diisocyanate (Corsicon DESMODUR I) 15%, Dikutikyl Tin catalyst (US Gas DABCO T-12), silicon-containing current plane (Silok-353) 0.5%.

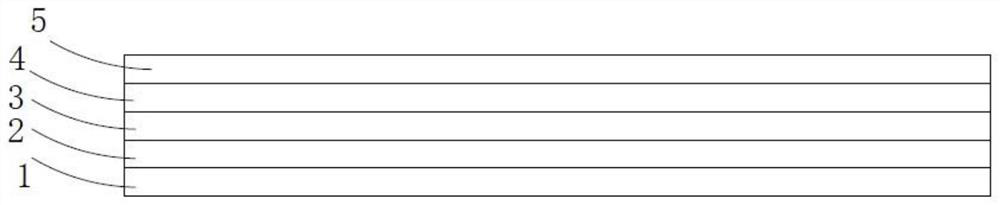

[0038] The preparation method of the self-repair resistance of the yellow-modified painted surface protective film is as follows:

[0039] Using a slit coating method, Ashilan AROSET 9510H acrylate pressure-senso water is applied to 50 μm PET release film layer I, drying and optical grade argotc aliphatic TPU base at 80-110 ° C temperature The film is covered with a thickness of 35 μm acrylic pressure sensitive gel layer; the functionalized polyurethane acrylate prepared above is applied to the other surface of the TPU base film, and the coating means is applied using a microidal roll. During the five sections of "80 ° ...

Embodiment 2

[0041] Functionalized polyurethane acrylate self-repairing coating composition includes: polyhydroxya hyalopyridone modified acrylate resin (hydroxyl) 20%, polycaprolactone diol (BASF PCL2000) 25%, acetate 40% of the ester, six methylene diisocyanate trim (Cousca Children DESMODUR N3300) 15%, Dikutikini catalyst (US Gas DABCO T-12), silicon-containing flow flat agent (SILOK-353) 0.5%.

[0042] The preparation method of the self-repair resistance of the yellow-modified painted surface protective film is as follows:

[0043] Using a slit coating method, Ashilan AROSET 9510H acrylate pressure-senso water is applied to 50 μm PET release film layer I, drying and optical grade argotc aliphatic TPU base at 80-110 ° C temperature The film is covered with a thickness of 30 μm acrylic pressure sensitive gel layer; the functionalized polyurethane acrylate prepared above is applied to the other surface of the TPU base film, and the coating method is coated with a microidal roll, followed by D...

Embodiment 3

[0045] Functionalized polyurethane acrylate self-repairing coating composition includes: polyhydroxylastic modified acrylate resin (hydroxyl) 25%, polytetrahydrofuran etheriol (BASF POLYTHF2000) 10%, propylene glycol methyl ether acetate 45 %, Six methylene diisocyanate trimer (Cischeon DESMODUR N3300) 20%, Dikutikatin catalyst (US gas DABCO T-12), benzole (Tinuvin234, BASF) is stable 0.5% of the agent, affinitive phenol (IRGANOX1076, BASF) antioxidant 0.5%.

[0046] The preparation method of the self-repair resistance of the yellow-modified painted surface protective film is as follows:

[0047] Using a slit coating method, Ashilan AROSET 9510H acrylate pressure-senso water is applied to 50 μm PET release film layer I, drying and optical grade argotc aliphatic TPU base at 80-110 ° C temperature The film is covered with a thickness of 35 μm acrylic pressure sensitive gel layer; the functionalized polyurethane acrylate prepared above is applied to the other surface of the TPU base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com