Packaging paper card UV ink printing curing and drying device

A technology of curing and drying, ink printing, applied in the direction of ink, printing, printing machines, etc., can solve the problems of high energy consumption, low drying and curing efficiency, etc., and achieve the effects of excellent performance, improved drying and curing efficiency, good strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

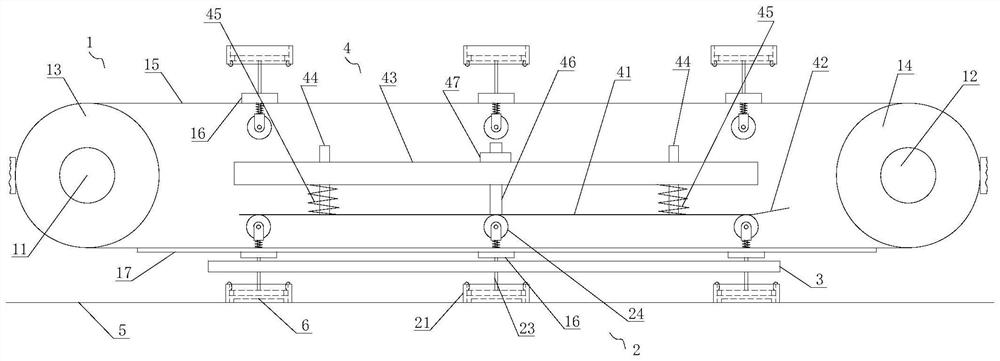

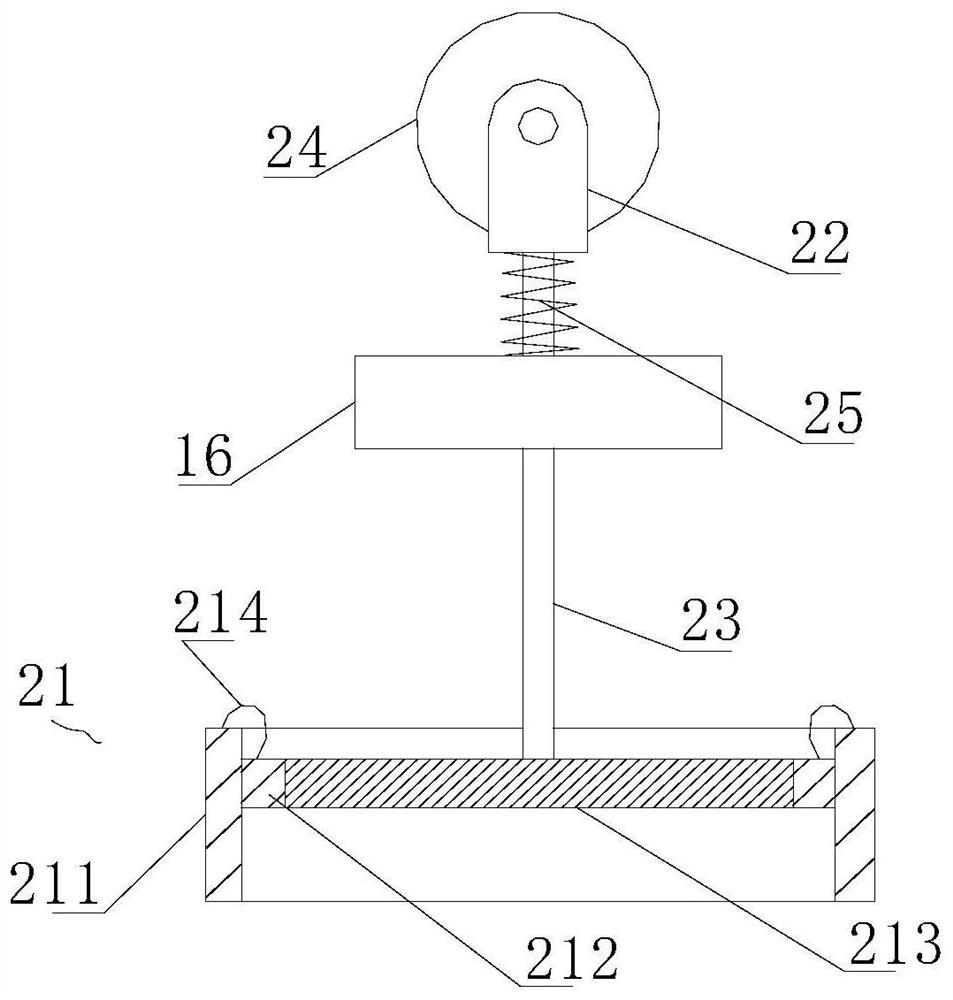

[0021] refer to figure 1 , 2 , a UV ink printing, curing and drying device for wrapping paper cards of the present invention, comprising a driving device 1, several cover mechanisms 2, UV lamps 3 and an adjustment device 4, the driving device 1 is provided with a cover mechanism 2, and the driving The device 1 drives the cover mechanism 2 to pass under the UV lamp 3 and the adjustment device 4, and when the cover mechanism 2 passes under the adjustment device 4, the adjustment device 4 forces the cover mechanism 2 to move downward for printing. The wrapping paper card to be cured and dried by the ink is covered, and the driving device 1 includes a driving shaft 11, a driven shaft 12, two driving sprockets 13, two driven sprockets 14, two chains 15 and several mounting plates 16. The driving shaft 11 is provided with two driving sprockets 13, the driven shaft 12 is provided with two driven sprockets 14, and the front and rear corresponding driving sprockets 13 and driven sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com