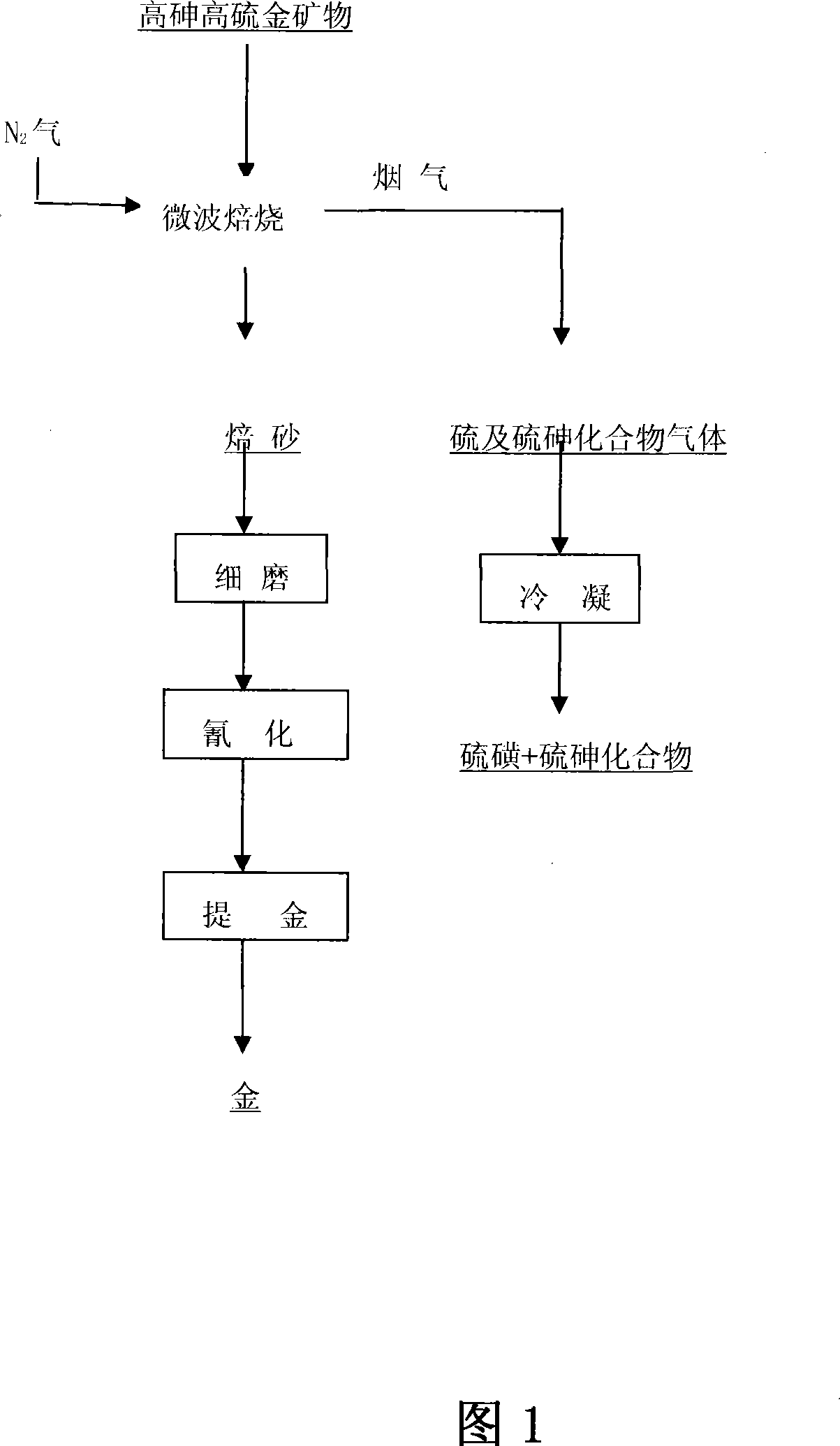

Method for pretreating refractory gold ore by employing microwave calcining

A microwave roasting and pretreatment technology, applied in the direction of improving process efficiency, can solve the problems of unsuitable ore, long process flow, low slurry concentration, etc., and achieve the effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A gold mineral is a flotation gold concentrate containing arsenic, sulfur and carbon. The gold concentrate contains minerals such as pyrite, marcasite, arsenopyrite, graphite and organic carbon that affect gold leaching, and the embedded gold particle size is fine. The multi-element analysis of minerals is shown in Table 1.

[0029] the element

Au(g / t)

Ag(g / t)

As

Fe

S

C

Sb

Content (%)

the element

Content (%)

39.63

Cu

0.02

23.84

Pb

0.03

0.70

Zn

0.05

15.55

CaO

6.02

15.11

MgO

3.25

3.97

SiO 2

39.17

1.49

Al 2 o 3

7.02

[0030] The occurrence state analysis of gold minerals is shown in Table 2.

[0031]

Occurrence status

bare gold

Package gold

Package gold

Package gold

total

...

Embodiment 2

[0035] A gold concentrate is composed of gold-arsenic concentrate and pyrite-containing concentrate. The chemical composition is shown in Table 3.

[0036] the element

[0037] Microwave roasting test conditions: raw ore 100g, roasting temperature 485°C, roasting time 12min, power 5kw. The contents of S and As in the calcined sand after microwave roasting were 2.23% and 0.52%, respectively. The calcined sand is finely ground and then cyanide leached. The gold leaching rate is 96.69%. The recovery rate of sulfur is 92%, and the sulfur dioxide content in the flue gas is 850mg / m 3 . After conventional roasting, the gold leaching rate is 59.03%.

Embodiment 3

[0039] A gold mine is a refractory metallurgical mine containing arsenic, sulfur and carbon. The gold ore contains pyrite, orthorhombite, arsenopyrite, graphite and amorphous carbon and other minerals that affect gold leaching, and the gold embedded particle size is fine, containing 23% wrapped gold. The main chemical composition of I flotation gold concentrate is shown in Table 4.

[0040] the element

[0041] Microwave roasting test conditions: 100g of the above-mentioned refractory metallurgical ore was roasted in a nitrogen atmosphere, the roasting temperature was 500°C, the roasting time was 10min, and the power was 4kw. The calcined sand is finely ground first, and then cyanide leaching is carried out. After microwave roasting pretreatment, the gold leaching rate was 97.89%. The recovery rate of sulfur is 94.5%, and the content of sulfur dioxide in the flue gas is 860mg / m 3 . After conventional roasting, the gold leaching rate is 62.33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com