Fluid motion device for accelerating and energy-saving

A fluid and fluid layer technology, applied in transportation and packaging, hydrodynamic characteristics/hydrostatic characteristics, affecting the air flow flowing through the surface of the aircraft, etc., to achieve the effect of saving energy and simplifying the structure of the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

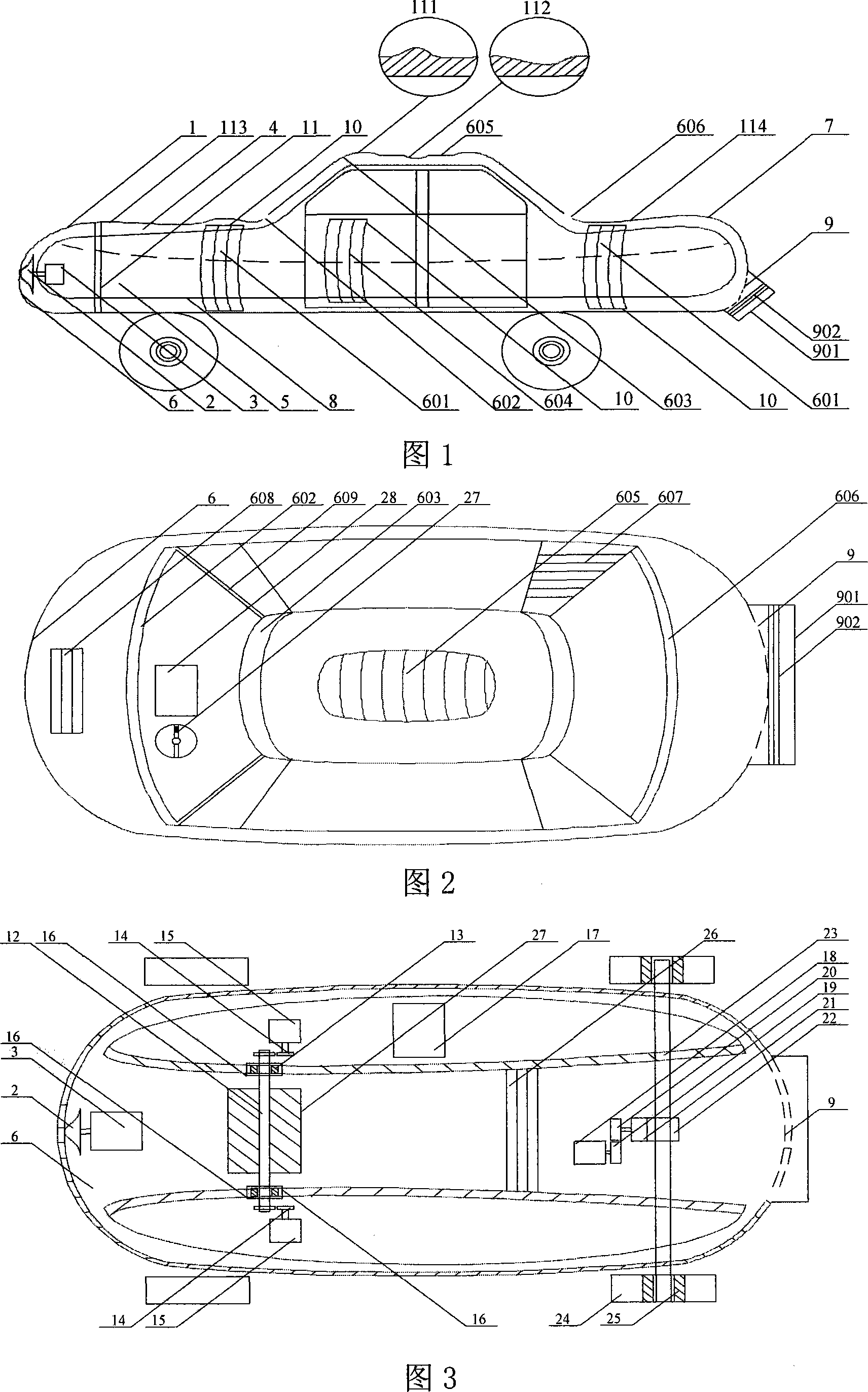

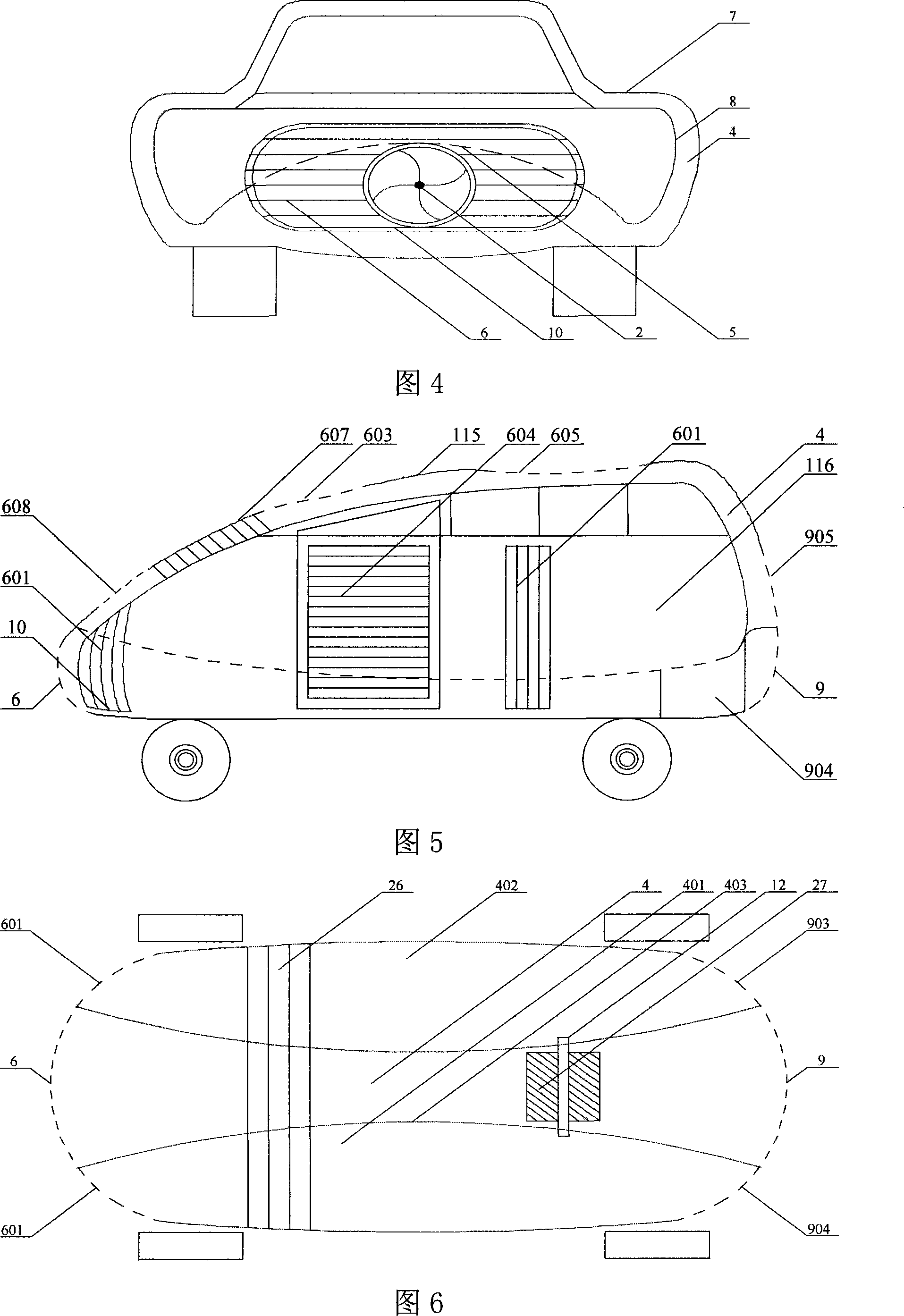

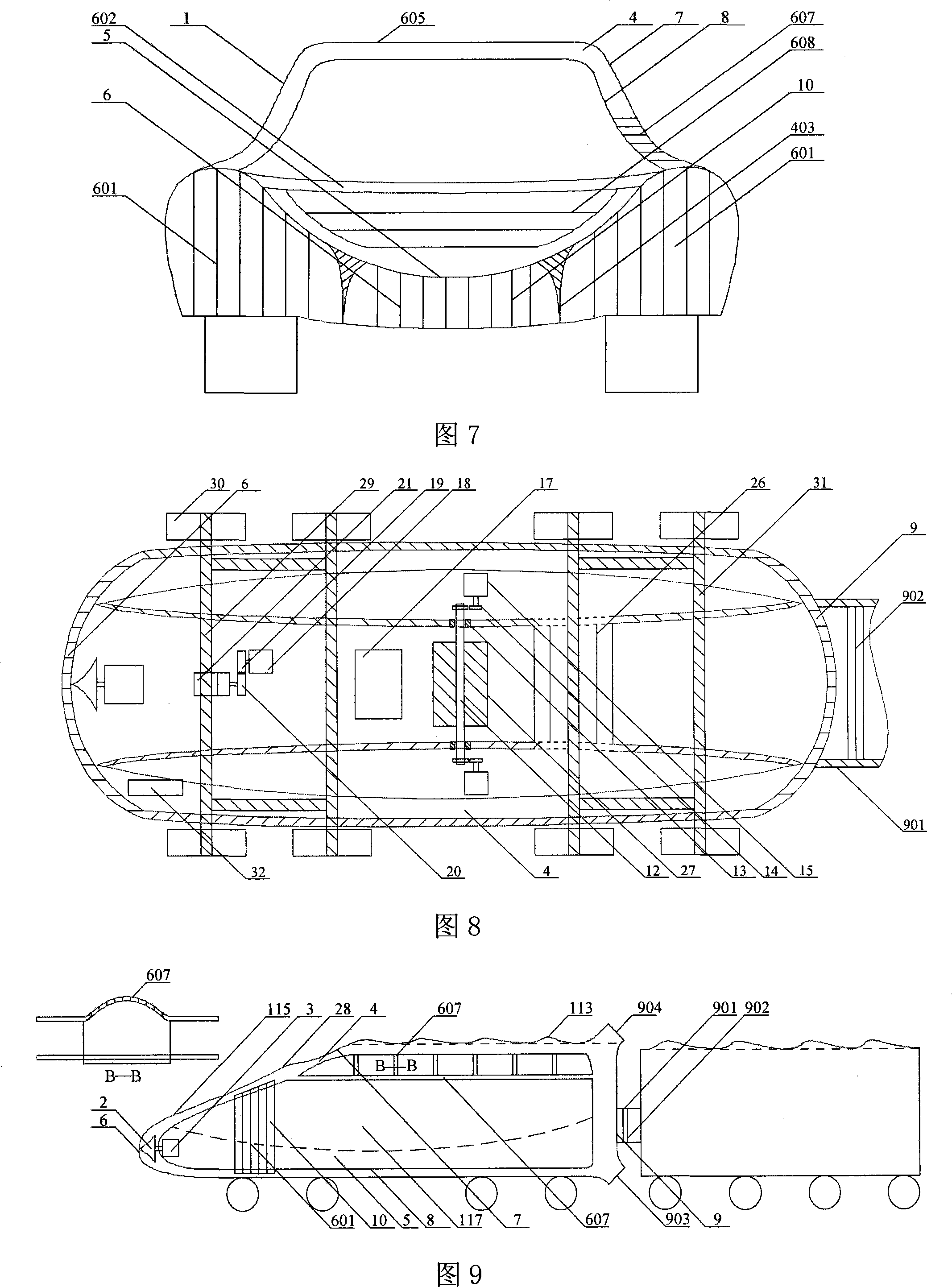

[0036] As shown in Figure 1-4: the outer shell 7 of the moving body 1 has an inner shell 8, and there is a fluid layer 4 between the inner shell 8 and the outer shell 7, and the inner shell 8 and the outer shell 7 are separated into fluid layers with a certain distance 4. Open a large hole at the front end of the shell 7 to connect the inlet 6 with the fluid layer 4 and the concave hole 5 in the fluid layer 4, open the outlet 9 at the rear end of the shell, and let the fluid introduced by the inlet 6 pass through the fluid layer 4 After passing through smoothly without hindrance, it is discharged from the exhaust port 901 of the outlet 9.

[0037] There is a flying saucer-shaped rotating head 2 in the middle of the inlet 6 for forming the fluid wall with the greatest resistance. There are four concave triangle lines on the contact surface between the rotating head and the fluid, which is convenient to cut the air flow. The rotating head 2 is driven by the motor 3 to rotate at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com