Preparation method of modified polytetrafluoroethylene dispersion concentrated solution

A technology of polytetrafluoroethylene and tetrafluoroethylene, which is applied in the field of preparation of modified polytetrafluoroethylene dispersion concentrate, to achieve the effects of strong yellowing resistance, improved application performance, and improved gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

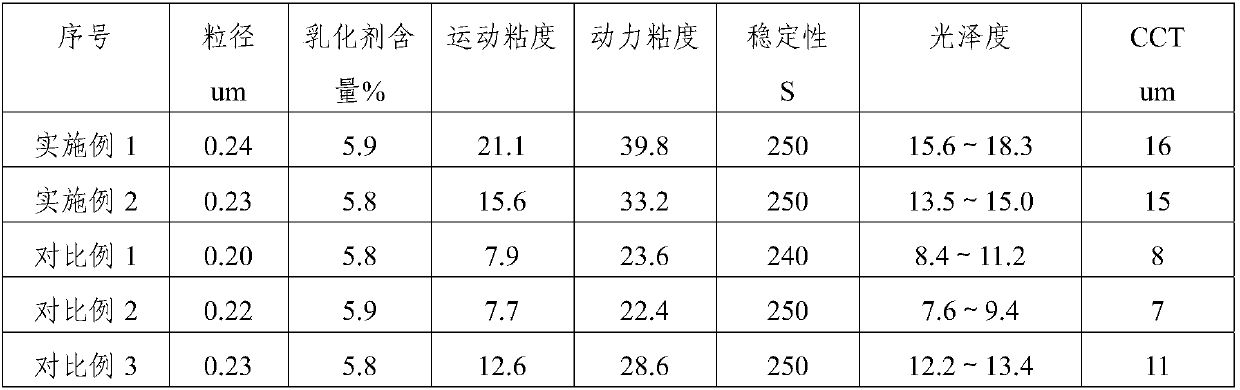

Examples

Embodiment 1

[0029] This embodiment relates to a method for preparing a modified polytetrafluoroethylene dispersion concentrate, comprising the following steps:

[0030] 1) Clean the 50L stainless steel autoclave, add 32L of deionized water, 8g of ammonium perfluorooctanoate, 8g of succinic acid, and 2kg of paraffin, seal the autoclave, evacuate and replace with nitrogen, and analyze the oxygen content until the oxygen content is ≤30ppm;

[0031] 2) Add 15g of modified monomer A (PPVE), raise the temperature of the reaction kettle to 78±1°C, put in the gas phase monomer tetrafluoroethylene, and add 0.15g of ammonium persulfate to the pressure of 1.6MPa in the kettle. During the reaction, the pressure in the kettle was maintained at 1.6MPa, and the temperature was 80-90°C. According to the change of the polymerization speed, the initiator can be added appropriately, and the number of additions depends on the reaction speed. When the tetrafluoroethylene feeding amount reaches 5.5Kg, stop st...

Embodiment 2

[0037] This embodiment relates to a method for preparing a modified polytetrafluoroethylene dispersion concentrate, comprising the following steps:

[0038] 1) Clean the 50L stainless steel autoclave, add 32L of deionized water, 8g of ammonium perfluorooctanoate, 8g of succinic acid, 2kg of paraffin, seal the autoclave, evacuate and replace with nitrogen, analyze the oxygen content until the oxygen content is ≤30ppm;

[0039] 2) Add 15 g of modified monomer A (HFP). The temperature of the reaction kettle was raised to 78±1°C, the gas-phase monomer tetrafluoroethylene was put in, and the pressure inside the kettle was 1.6MPa, and 0.15g of ammonium persulfate was added. During the reaction, the pressure in the kettle was maintained at 1.6MPa, and the temperature was 80-90°C. According to the change of the polymerization speed, the initiator can be added appropriately, and the number of additions depends on the reaction speed. When the tetrafluoroethylene feeding amount reaches...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com