A modified glass microsphere, its preparation method and its method for preparing composite resin products

A technology of glass microspheres and composite resins, which is applied in its preparation method and the field of preparing composite resin products and modified glass microspheres, to achieve good mechanical properties, improve yellowing resistance, and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

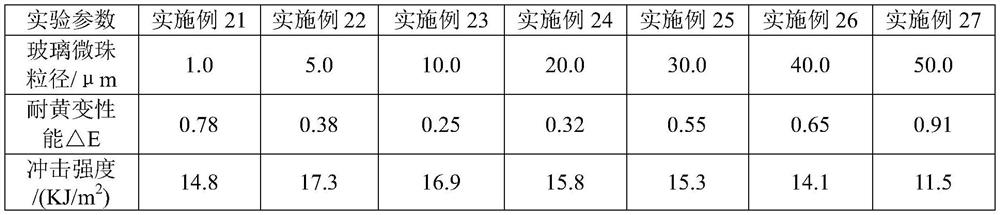

Examples

Embodiment 1

[0035] The preparation of the anti-yellowing product comprises the following steps:

[0036] (1) Preparation of modified glass beads

[0037] 1) Preparation of a class of glass microbeads

[0038] The mixed glass microbeads obtained by mixing solid glass microbeads and hollow glass microbeads with particle diameters of both 10.0 μm were subjected to surface pretreatment. Among them, the solid glass microspheres account for 50.0% of the mixed glass microspheres, and the hollow glass microspheres account for 50.0%. 4 F) coarsening, washing with water, tin chloride (SnCl) in the mixed solution of hydrofluoric acid (HF) 2 ) and hydrochloric acid (HCl) mixed solution sensitized, washed with water, ammonia solution containing silver nitrate (AgNO 3 +NH 3 ·H 2 O) in the activation step for treatment.

[0039] The glass microspheres after surface pretreatment have improved the chemical activity of their surface, and then the pretreated glass microspheres are coated with metal al...

Embodiment 2 to Embodiment 6

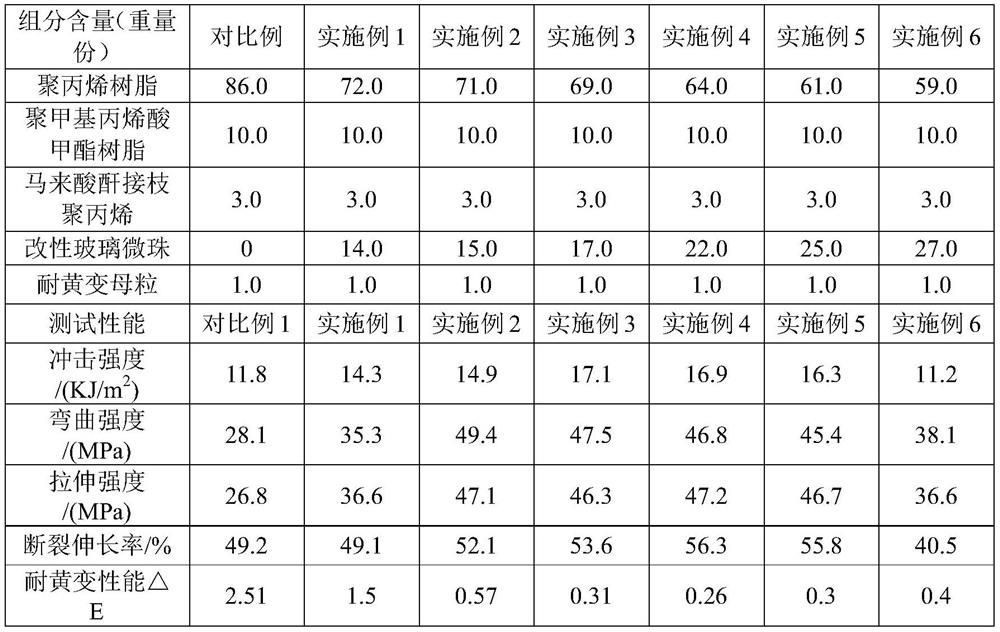

[0055] According to the components specified in Table 1, the weight ratio of the modified glass beads was appropriately adjusted, and the preparation method in Example 1 was repeated. Table 1 lists the corresponding test results.

Embodiment 7-13

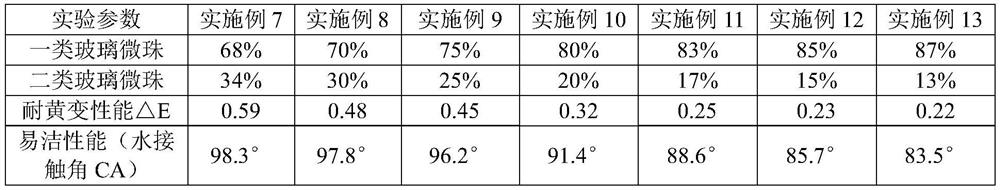

[0065] Under the condition that the content of each component in Example 4 in Table 1 is unchanged, only the weight ratio of the first-class glass microbeads and the second-class glass microbeads is changed, and the preparation method in Example 4 is repeated for other steps. Table 2 lists corresponding test results.

[0066] Table 2 Effects of content of first-class glass microbeads and second-class glass microbeads on yellowing resistance and easy-to-clean performance

[0067]

[0068] It can be seen that within a certain range, the more content of the first-class glass microbeads, the better the yellowing resistance, and the more the content of the second-class glass microbeads, the better the easy-to-clean performance. However, considering the acceptable range of yellowing resistance and easy-to-clean performance of the product, the content of Class I glass microbeads is 70%-85%, the content of Class II glass microbeads is 15%-30%, and the content of Class I glass micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com