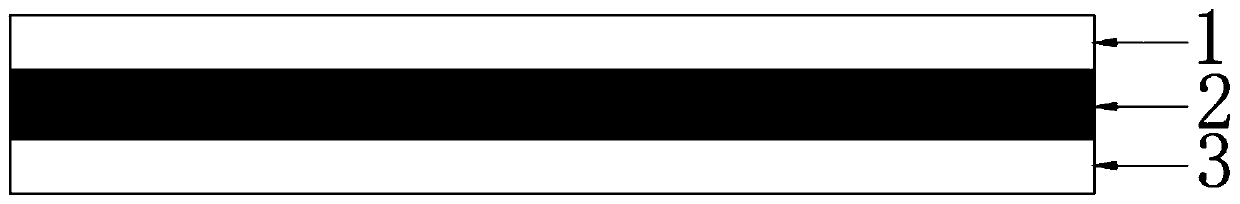

A kind of wide temperature dimming film and preparation method thereof

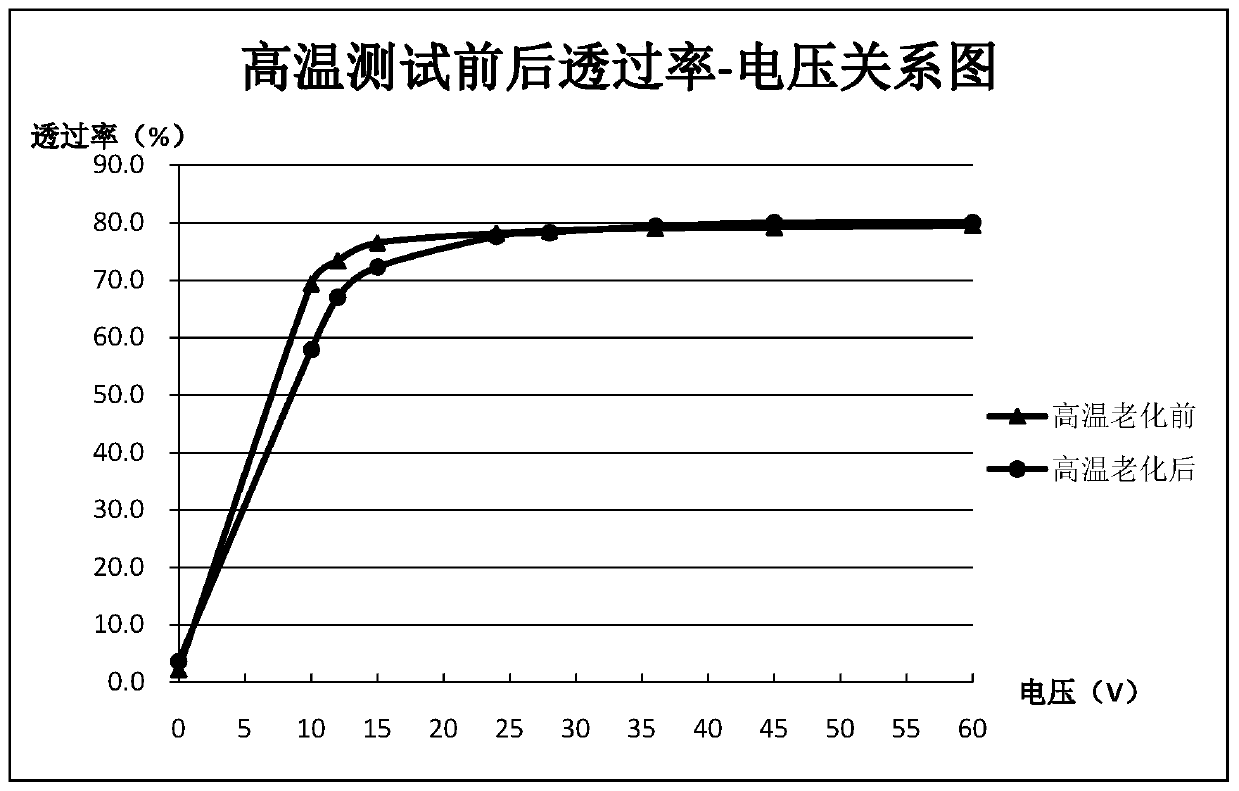

A technology of light film and temperature adjustment, which is applied in the field of light control film, can solve the problems of high temperature of 80-90 ℃, can not be used, etc., and achieve the effect of long service life, strong shielding and good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

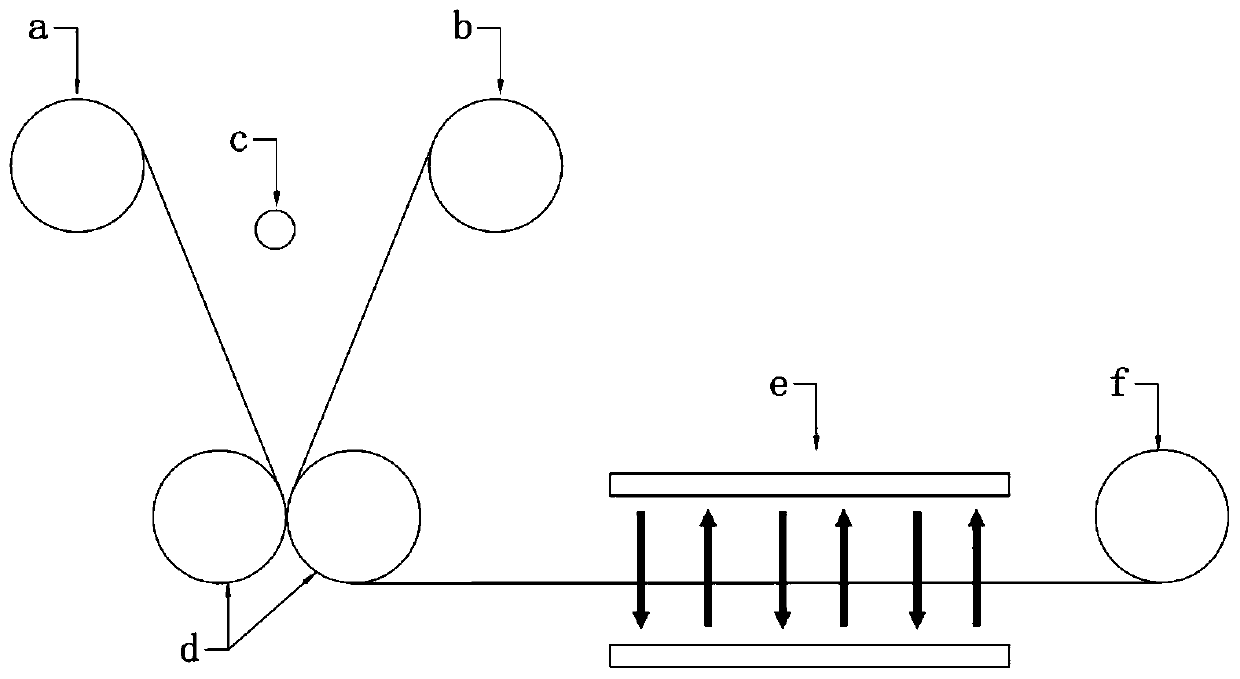

Method used

Image

Examples

Embodiment 1

[0045] Step a, under light-shielding or yellow light environment, add 7% hydroxyethyl methacrylate, 6% methacrylate, 7% polyalkylated bornyl acrylate, 23% polyolefin acrylate, acrylic acrylate oligomer 52%, diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide 3%, 1-hydroxycyclohexyl phenyl ketone 2%, mix in proportion, stir well after mixing, and get wide temperature LCD UV glue A;

[0046] Step b, mix the liquid crystal with a clearing point of 108°C and a freezing point <-30°C with the wide-temperature liquid crystal UV glue A in a ratio of 6:4, set the stirring temperature to 50°C, and stir well to obtain a mixture B; 3‰ of the total weight of the 15μm spacer, fully stirred and evenly degassed to obtain a wide-temperature polymer-dispersed liquid crystal mixture, waiting for coating construction;

[0047] In step c, drop the wide-temperature polymer-dispersed liquid crystal mixture into two transparent nano-silver conductive films, set the rolling temperature to 50°C, and rol...

Embodiment 2

[0051] Step a, under light-shielding or yellow light environment, mix 60% acrylate oligomer, 12% isobornyl acrylate, 8% hydroxyalkyl methacrylate, 8% β-hydroxyethyl methacrylate, silane Coupling agent 9%, 2,4,6-(trimethylbenzoyl) diphenylphosphine oxide 2%, 2-hydroxy-2-methyl-1-phenyl-1-propanone 1%, proportional Mix, and stir well after mixing to obtain wide temperature liquid crystal UV glue B;

[0052] Step b, after mixing the liquid crystal with a clearing point of 97°C and a freezing point of <-40°C with the wide-temperature liquid crystal UV glue B at a ratio of 5.5:4.5, set the stirring temperature to 30°C, and stir well to obtain a mixture B; 5‰ of the total weight of the 12μm spacer, fully stirred and evenly degassed to obtain a wide-temperature polymer-dispersed liquid crystal mixture, waiting for coating construction;

[0053] Step c, drop the wide-temperature polymer-dispersed liquid crystal mixture into two transparent ITO conductive films, set the rolling temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| isotropization temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com