Double-component polyurea sealant

A kind of beautifying agent, two-component technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of being easily affected by the construction environment, intolerance to yellow edges, poor gloss, etc. To achieve the effect of reducing heat volatilization deformation, strong adhesion and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

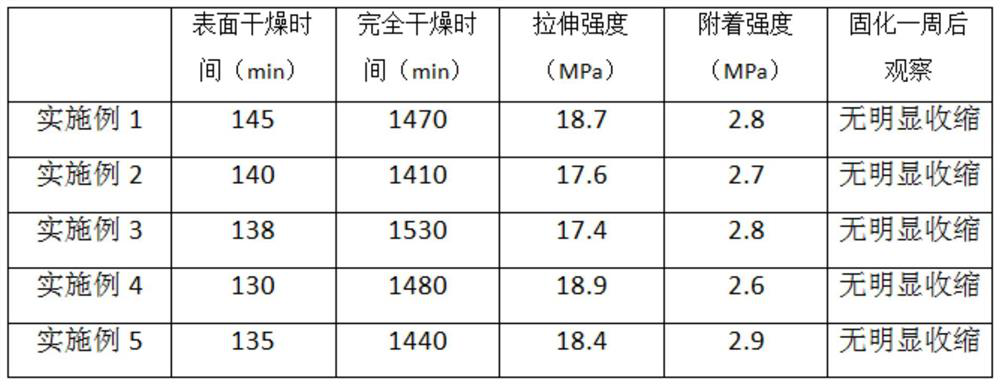

Examples

Embodiment 1

[0014] Such as figure 1 As shown, a two-component polyurea beautifying agent according to the present invention is composed of component A and component B. The component A includes polyaspartate polyurea, fumed silica, Lime powder, leveling agent, dispersant, accelerator, matte powder; component B includes curing agent isocyanate, epoxy resin, defoamer, wetting agent, pigment.

[0015] The said A component includes 60% aspartate polyurea, 5% fumed silica, 2% lime powder, 0.5% leveling agent, 1.2% dispersant, 2% accelerator, 1% by mass. % matte powder.

[0016] The said component B includes 35% curing agent isocyanate, 30% epoxy resin, 0.1% defoamer, 0.8% wetting agent and 2% pigment by mass.

[0017] The dispersant is triethylhexyl phosphoric acid.

[0018] The defoamer is trialkylmelamine.

[0019] The epoxy resin is novolac polyepoxy resin.

Embodiment 2

[0021] Such as figure 1 As shown, a two-component polyurea beautifying agent according to the present invention is composed of component A and component B. The component A includes polyaspartate polyurea, fumed silica, Lime powder, leveling agent, dispersant, accelerator, matte powder; component B includes curing agent isocyanate, epoxy resin, defoamer, wetting agent, pigment.

[0022] The said A component comprises 85% aspartate polyurea, 10% fumed silica, 3% lime powder, 0.8% leveling agent, 1.8% dispersant, 3% accelerator, 2% by mass. % matte powder.

[0023] The B component includes 45% curing agent isocyanate, 40% epoxy resin, 0.3% defoamer, 1% wetting agent, and 8% pigment by mass.

[0024] The dispersant is sodium lauryl sulfate.

[0025] The defoamer is cyanuric chloride melamine.

[0026] The epoxy resin is novolac polyepoxy resin.

Embodiment 3

[0028] Such as figure 1 As shown, a two-component polyurea beautifying agent according to the present invention is composed of component A and component B. The component A includes polyaspartate polyurea, fumed silica, Lime powder, leveling agent, dispersant, accelerator, matte powder; component B includes curing agent isocyanate, epoxy resin, defoamer, wetting agent, pigment.

[0029] The said A component includes 60% aspartate polyurea, 10% fumed silica, 2% lime powder, 0.8% leveling agent, 1.2% dispersant, 3% accelerator, 1% by mass. % matte powder.

[0030] The B component includes 45% curing agent isocyanate, 40% epoxy resin, 0.1% defoamer, 1% wetting agent, and 2% pigment by mass.

[0031] The dispersant is triethylhexyl phosphoric acid.

[0032] The defoamer is cyanuric chloride melamine.

[0033] The epoxy resin is novolac polyepoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com