Thermocuring self-repairing paint surface protective film and preparation method thereof

A self-healing, heat-curing technology for adhesive types, pressure-sensitive films/sheets, film/sheet-like adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

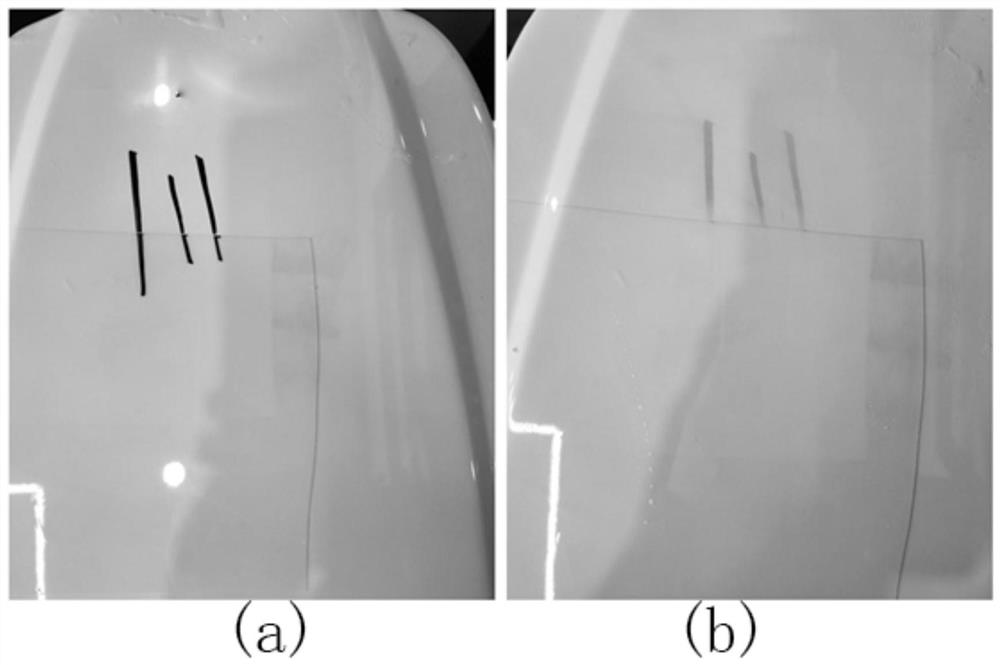

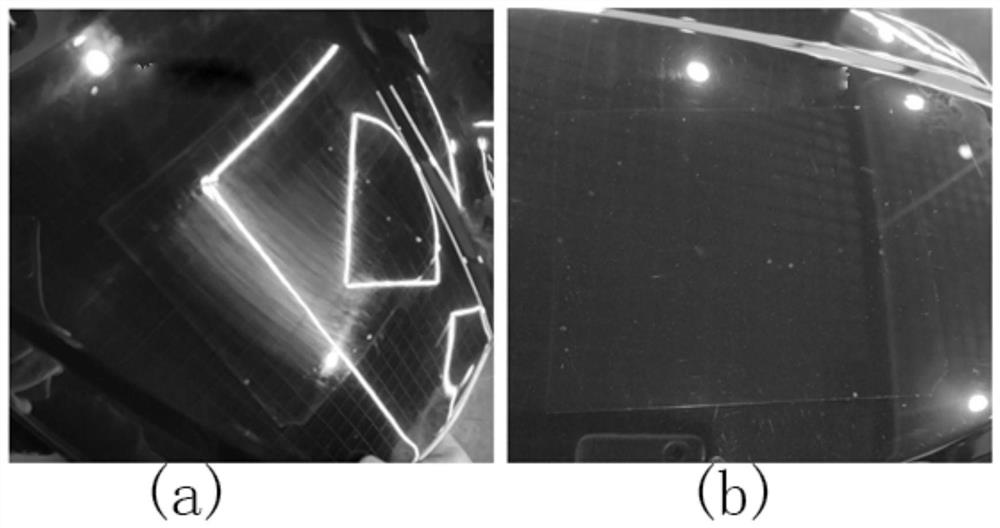

Examples

Embodiment 1

[0043] The composition of the self-healing coating includes: furfuryl alcohol modified polyhydroxy acrylate resin I (hydroxyl value ~ 90mg KOH / g) 12%, maleimide modified polyhydroxy acrylate resin II (hydroxyl value ~ 90mg KOH / g) 12% %, polycaprolactone diol (BASF PCL2000) 28%, propylene glycol methyl ether acetate 32%, 1,6-hexamethylene diisocyanate trimer (Covestro DesmodurN3300) 15%, dibutyltin dilaurate catalyst ( American gas Dabco T-12) 0.1%, silicon-containing leveling agent (Silok-354) 0.9%.

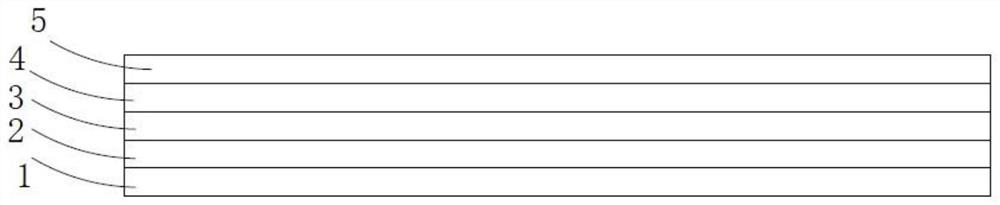

[0044] The preparation method of this thermosetting self-healing paint surface protective film is as follows:

[0045] Using the slit coating method, first coat Ashland AROSET 9510H acrylic pressure-sensitive adhesive on a 50μm PET release film A, dry it at 80-110°C, and coat it with optical grade Argotec aliphatic TPU Film lamination to form an acrylic pressure-sensitive adhesive layer with a thickness of 38 μm; apply the self-healing coating prepared above to the other side of...

Embodiment 2

[0047] The composition of the self-healing coating includes: furfurylamine modified polyhydroxy acrylate resin I (hydroxyl value ~ 95mg KOH / g) 10%, maleimide modified polyhydroxy acrylate resin II (hydroxyl value ~ 95mg KOH / g) 10%, polytetrahydrofuran ether diol (BASF PolyTHF2000) 19%, propylene glycol methyl ether acetate / butyl acetate (4:1) 35%, isophorone diisocyanate (Covestro Desmodur I) 25%, octanoic acid Sn catalyst (American gas Dabco T-9) 0.08%, silicon-containing leveling agent (Silok-354) 1.0%.

[0048] The preparation method of this thermosetting self-healing paint surface protective film is as follows:

[0049] Using the slit coating method, first coat Ashland AROSET 9510H acrylic pressure-sensitive adhesive on a 50μm PET release film A, dry it at 80-110°C, and coat it with optical grade Argotec aliphatic TPU Film lamination to form an acrylic pressure-sensitive adhesive layer with a thickness of 35 μm; apply the self-healing coating prepared above to the other s...

Embodiment 3

[0051] The composition of the self-healing coating includes: furfuryl alcohol modified polyhydroxy acrylate resin I (hydroxyl value ~ 90mg KOH / g) 15%, maleimide modified polyhydroxy acrylate resin II (hydroxyl value ~ 90mg KOH / g) 15% %, polytetrahydrofuran ether diol (BASF PolyTHF2000) 12%, butyl acetate / cyclohexanone (3:1) 35%, 1,6-hexamethylene diisocyanate trimer (Covestro Desmodur N3300) 22%, Stannous octoate catalyst (American gas Dabco T-9) 0.1%, antioxidant (BASF TINUVIN B97) 0.9%.

[0052] The preparation method of this thermosetting self-healing paint surface protective film is as follows:

[0053] Using the slit coating method, first coat Ashland AROSET 9510H acrylic pressure-sensitive adhesive on a 50μm PET release film A, dry it at 80-110°C, and coat it with optical grade Argotec aliphatic TPU Film lamination to form an acrylic pressure-sensitive adhesive layer with a thickness of 35 μm; apply the self-healing coating prepared above to the other side of the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com