Addition-type molded silicone rubber for LED bracket material and preparation method and application of addition-type molded silicone rubber

An LED bracket and addition molding technology, applied in the field of silicone rubber, can solve the problems of unsatisfactory product performance, high tensile strength, poor light transmittance, etc., and achieve excellent optical performance and elasticity, good air tightness, and yellow resistance. Strong denaturation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

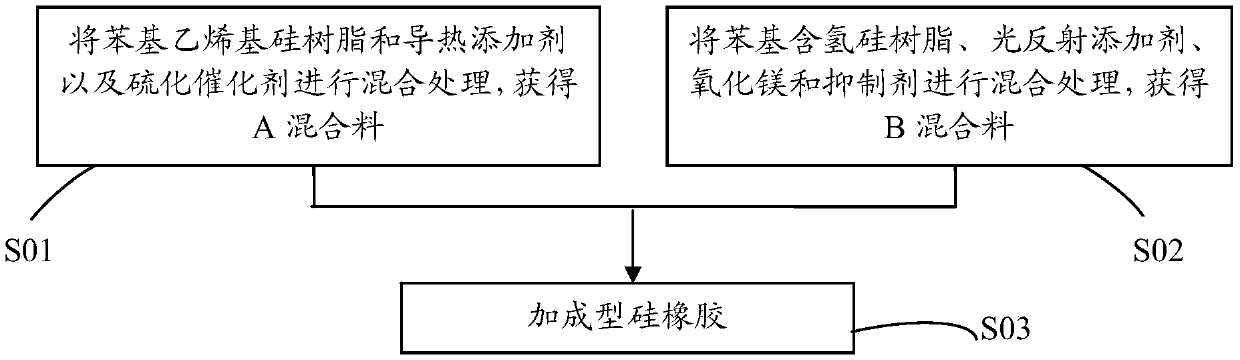

[0051] On the other hand, the embodiment of the present invention also provides the preparation method of the above-mentioned addition-type silicone rubber. The preparation method technological process of described addition type silicone rubber is as figure 1 As shown, it includes the following steps:

[0052] S01. Preparation of compound A: Mix phenyl vinyl silicone resin, thermal conductivity additive and vulcanization catalyst to obtain compound A;

[0053] S02. Preparation of B mixture: Mix phenyl hydrogen-containing silicone resin, light reflection additive, magnesium oxide and inhibitor to obtain B mixture;

[0054] S03. Mixing treatment of glue A and glue B: mixing the A compound and the B compound.

[0055] Wherein, the mixing process in the steps S01 to S03 is to make each component fully mixed uniformly, therefore, as long as it is a mixing method that can make each component fully mixed uniformly, it is within the scope of the disclosure of the present invention. ...

Embodiment 1

[0063] This embodiment provides an addition-type silicone rubber and a preparation method thereof. The addition type silicone rubber comprises the following components by mass:

[0064] Phenyl silicone resin: the refractive index is 1.50, the vinyl content is 6.3%, the viscosity is 25000mpa·s, 60 parts;

[0065] Phenyl hydrogen-containing silicone resin: the refractive index is 1.50, the hydrogen content is 0.24%, the viscosity is 7000mpa·s, 65 parts;

[0066] Platinum catalyst: 10PPM;

[0067] Alumina: spherical, 40 parts;

[0068] Titanium dioxide: 30 parts

[0069] Magnesium oxide: 5 parts

[0070] Inhibitor: 10PPM.

[0071] The preparation method of the addition type silicone rubber comprises the steps:

[0072] S11: 60 parts of phenyl silicone resin with a refractive index of 1.50, a vinyl mass fraction of 6.3%, and a viscosity of 25000mpa·s, 40 parts of spherical alumina and 10PPM platinum catalyst were mixed and ground evenly, and used as component A for later use...

Embodiment 2

[0076] This embodiment provides an addition-type silicone rubber and a preparation method thereof. The addition type silicone rubber comprises the following components by mass:

[0077] Phenyl silicone resin: the refractive index is 1.45, the mass fraction of vinyl is 6.3%, the viscosity is 25000mpa·s, 60 parts;

[0078] Phenyl hydrogen-containing silicone resin: the refractive index is 1.45, the mass fraction of hydrogen is 0.24%, the viscosity is 7000mpa·s, 65 parts;

[0079] Platinum catalyst: 10PPM;

[0080] Alumina: spherical, 40 parts;

[0081] Titanium dioxide: 30 parts

[0082] Magnesium oxide: 5 parts

[0083] Inhibitor: 10PPM.

[0084] The preparation method of the addition type silicone rubber comprises the steps:

[0085] S21: 60 parts of phenyl silicone resin with a refractive index of 1.45, a vinyl mass fraction of 6.3%, and a viscosity of 25000mpa·s, 40 parts of spherical alumina and 10PPM platinum catalyst were mixed and ground evenly, and used as compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com