Small-sized biomass chopped-material direct-fired water boiler

A hot water boiler and biomass technology, applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve the problems of high boiler fuel cost, difficulty in popularization and application, and rapid equipment wear, so as to achieve low combustion cost, save labor, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

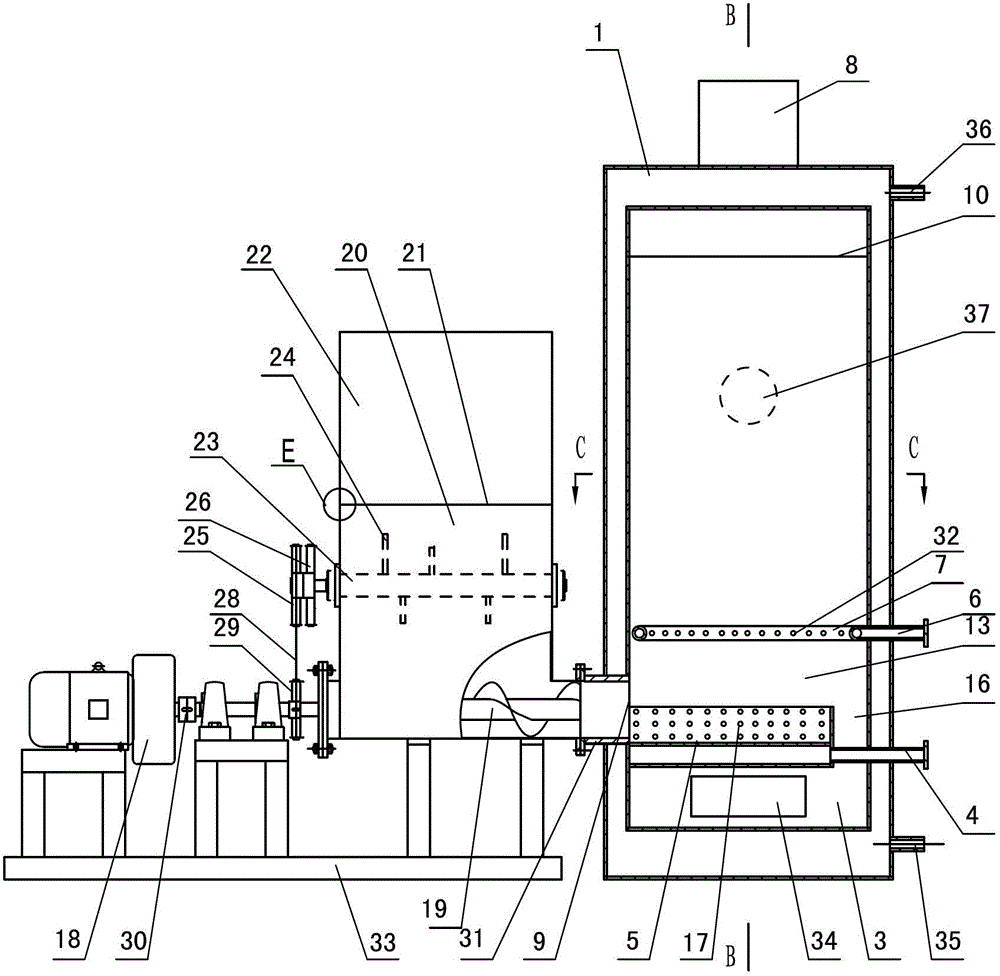

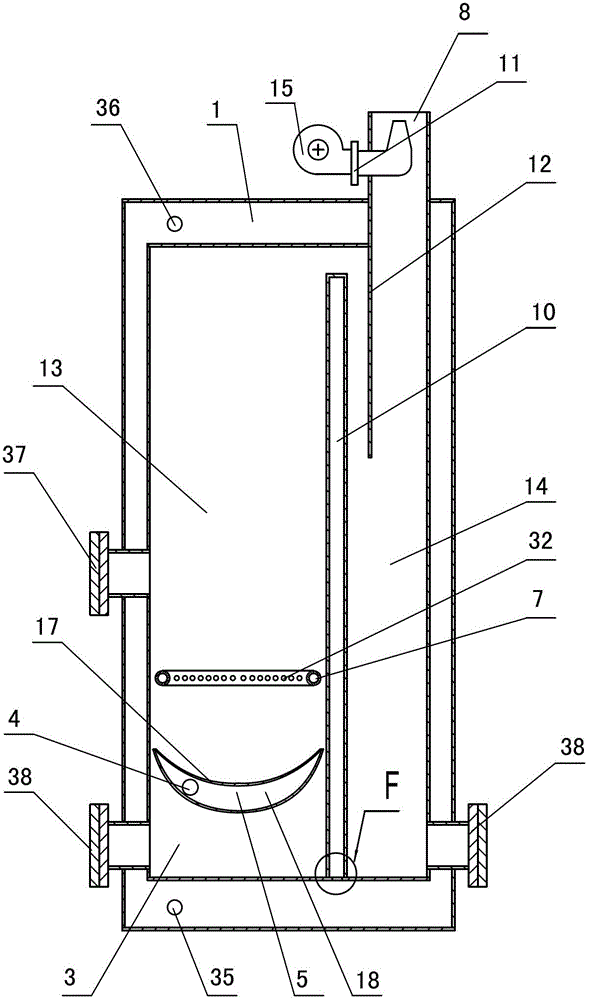

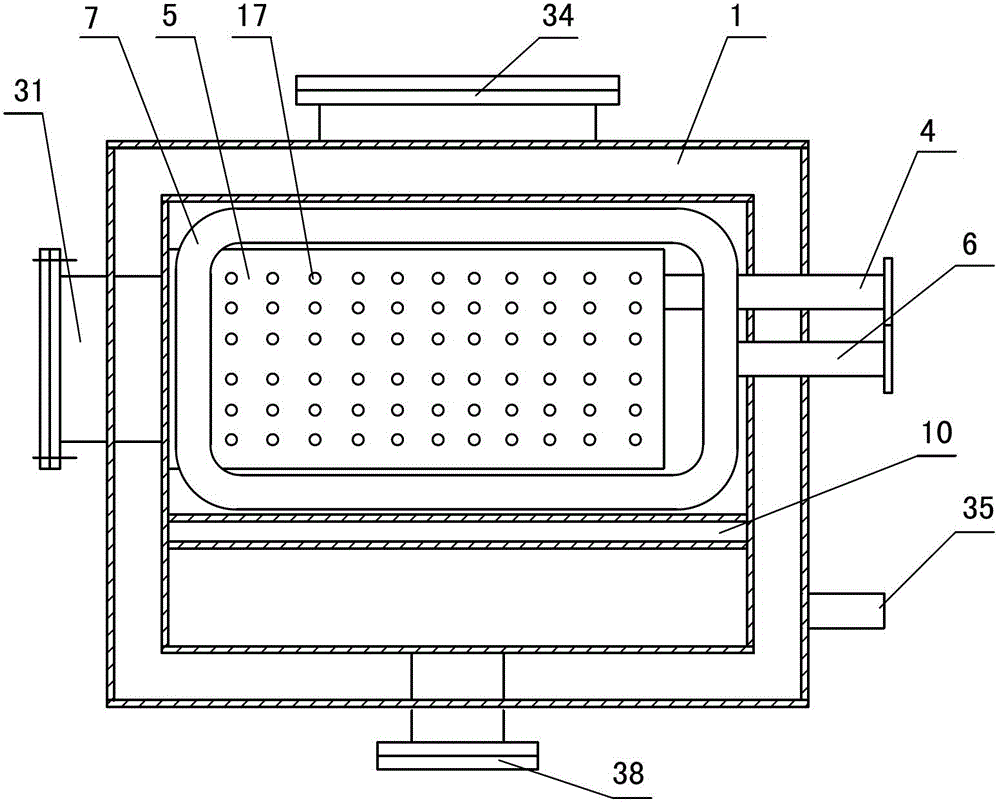

[0030] exist Figure 1-6 In the shown embodiment: the furnace body includes an ash collection chamber 3 arranged at the bottom of the furnace, a primary air intake pipe 4, a primary air chamber 5 located above the ash collection chamber 3 and in communication with the primary air intake pipe 4, a secondary air intake Pipe 6, the secondary air distribution pipe 7 located above the primary air chamber 5 and connected with the secondary air inlet pipe 6, the smoke exhaust pipe 8 arranged on the top of the furnace, and the furnace is located between the primary air chamber 5 and the secondary air distribution pipe The side wall between 7 has feed opening 9; Automatic feeding mechanism comprises reduction motor 18, screw auger 19 and feed box 20, and wherein screw auger 19 is horizontally installed in the bottom in feed box 20, and screw auger The power input end of 19 is connected with the output end of reduction motor 18 through coupling 30;

[0031] The flue gas diverting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com