Full-automatic oil pressing system and oil pressing method

A fully automatic oil press technology, applied in the direction of combustion method, shaking grate, fat oil/fat production, etc., can solve the problems of smoke pollution, trouble, discharge out of the furnace, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

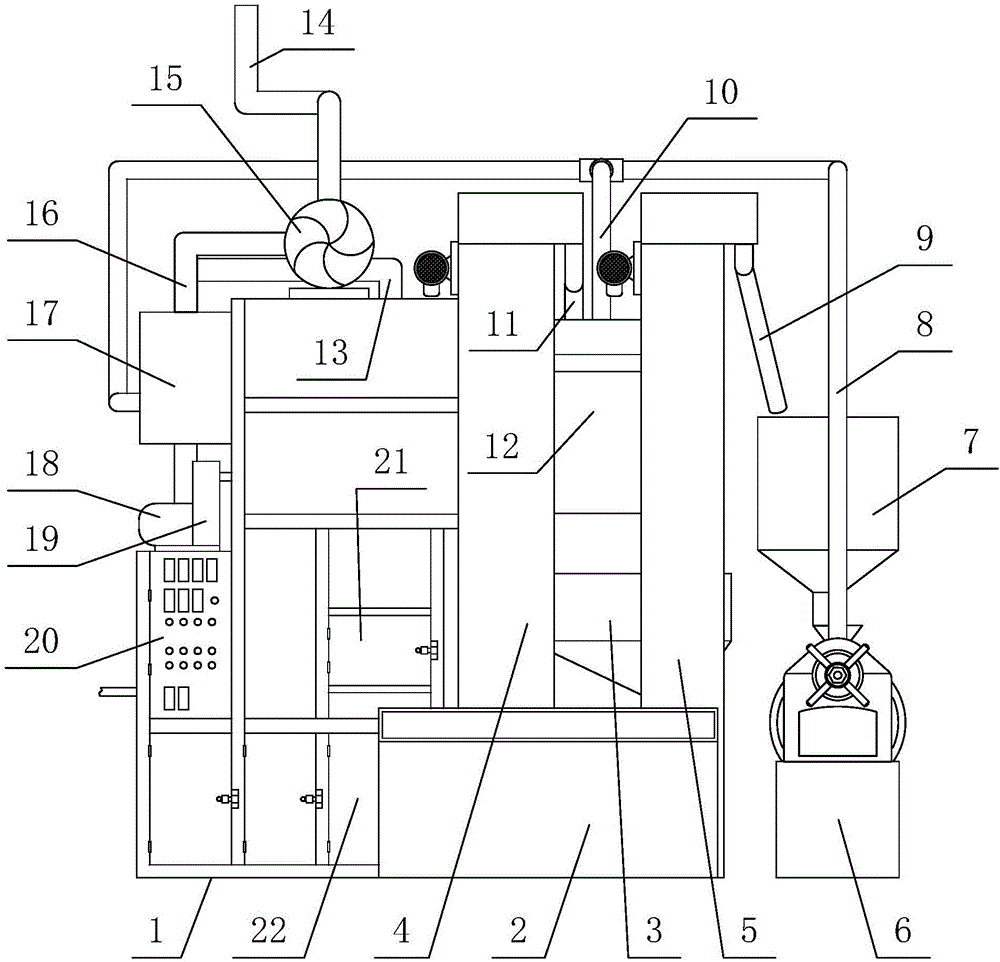

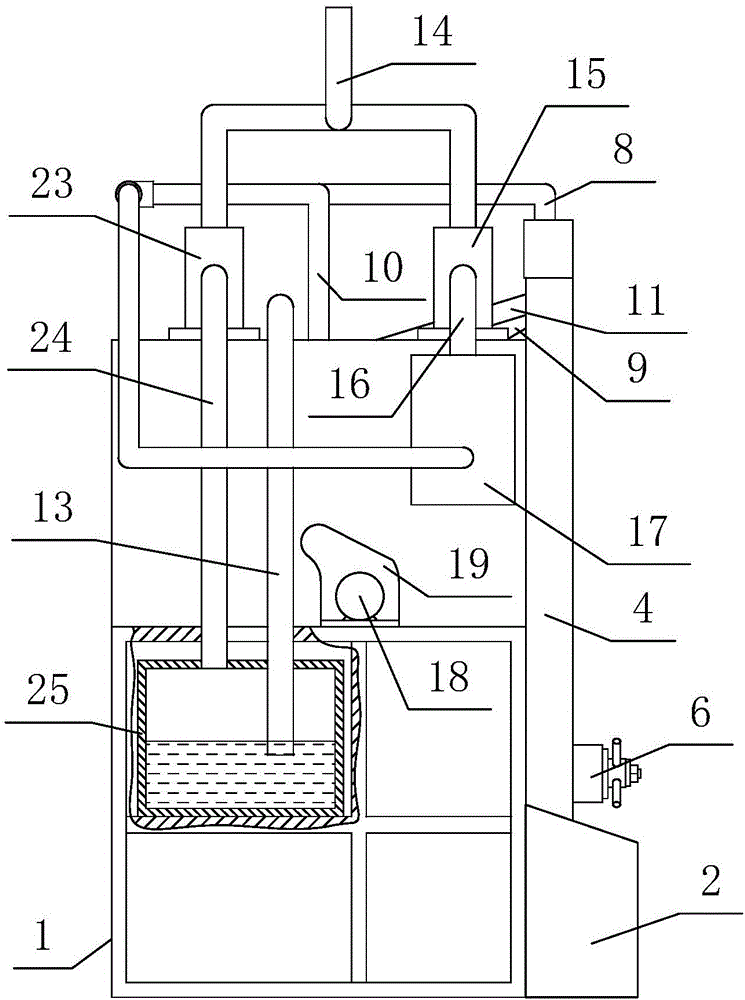

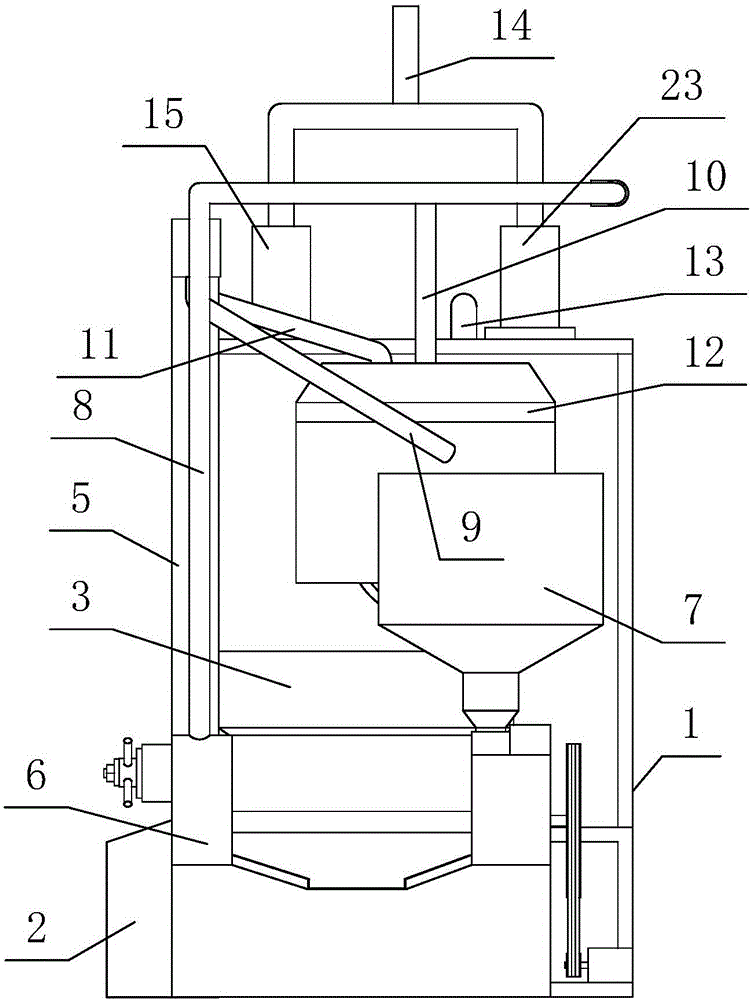

[0080] Such as Figure 1 to Figure 6 As shown, a fully automatic oil extraction system includes a casing 1, a frying device 28, a first power unit, a second power unit, a raw material container 2, a first elevator 4, a clinker container 3, and an oil press 6 , the second hoist 5, the first exhaust fan 23, the external exhaust flue 14, the combustion flue gas purification device, the dust and oil fume treatment system, the temperature sensor, the position sensor, the processor, the control panel 20,

[0081] The casing 1 is fixedly installed on the ground of the workplace, and is formed by welding steel structure skeletons and steel plates or connecting them by bolts and screws. The casing 1 has a front and a back oppositely arranged. In order to arrange a reasonable layout of the workplace, generally at least one side of the casing 1 is installed against a wall, and the side of one side against the wall is the back of the casing 1. The side opposite to the back is the front. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com