Exhausting and pressure stabilizing system of ternary battery anode material sintering atmosphere kiln

A technology of cathode material and sintering atmosphere, which is applied in the field of ternary battery cathode material sintering atmosphere kiln exhaust and voltage stabilization system, can solve the problems of large oxygen consumption, reduction of oxygen partial pressure of kiln, and change of kiln temperature field, etc. Achieve the effects of strong self-control, quality assurance, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

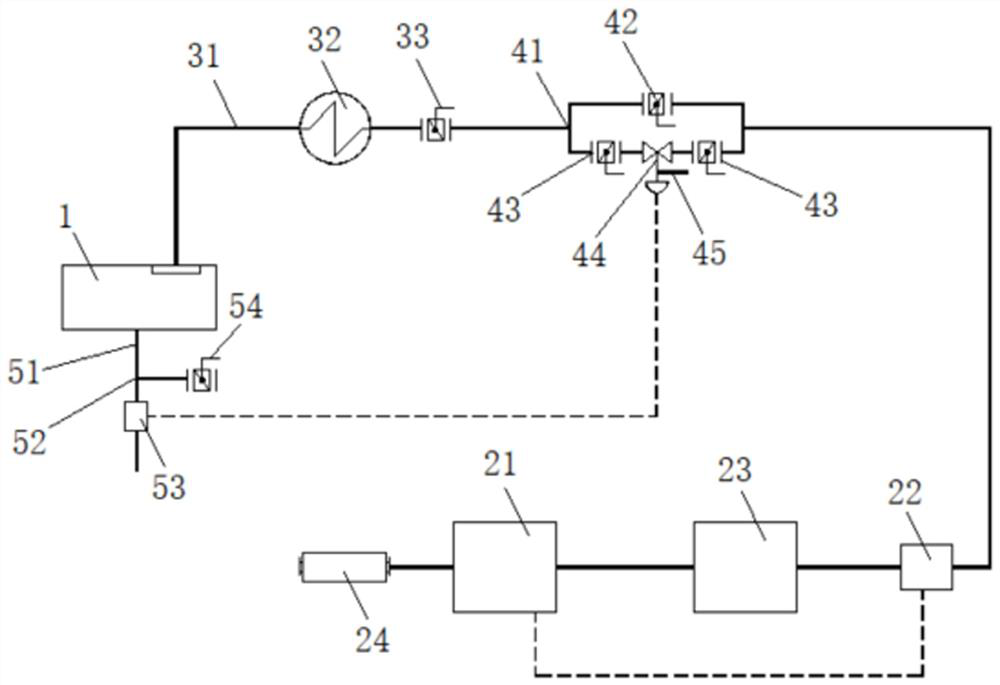

[0020] An atmosphere kiln exhaust and voltage stabilization system for sintering positive electrode materials of ternary batteries, mainly aimed at the sintering of nickel-cobalt-manganese ternary precursors and lithium source mixed materials in an atmosphere kiln, which includes sequentially connected exhaust devices, flue gas The automatic adjustment device and the flue gas extraction device, the exhaust device is connected to the atmosphere kiln 1, and the pressure detection device is also connected to the atmosphere kiln. Furnace internal pressure and provide flue gas overflow adjustment guidance to the flue gas automatic regulating device.

[0021] The flue gas extraction device includes an exhaust fan 21 and a first pressure detector 22 for detecting the pressure of the flue gas discharged through the automatic flue gas adjustment device. The first pressure detector 22 is arranged between the exhaust fan 21 and the automatic flue gas adjustment device , the first pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com