Tunnel kiln waste heat boiler

A waste heat boiler and tunnel kiln technology, applied in the field of waste heat boilers, can solve the problem of how to heat when there is no waste heat or insufficient waste heat, and achieve the effects of reducing combustion costs, simplifying production processes, and reducing fuel varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

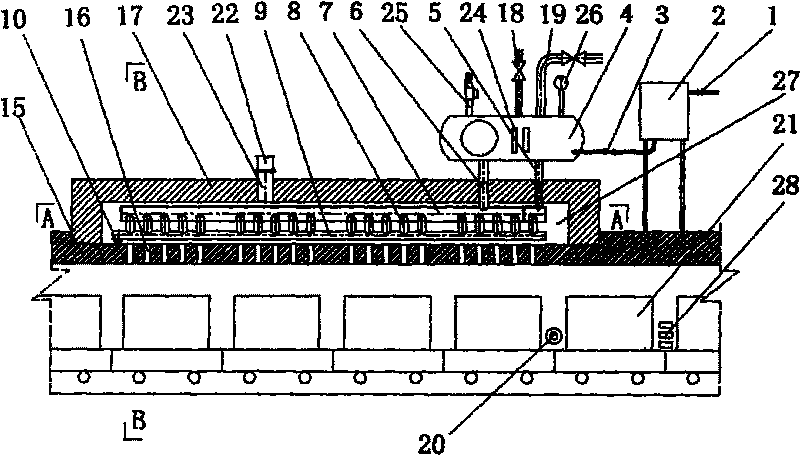

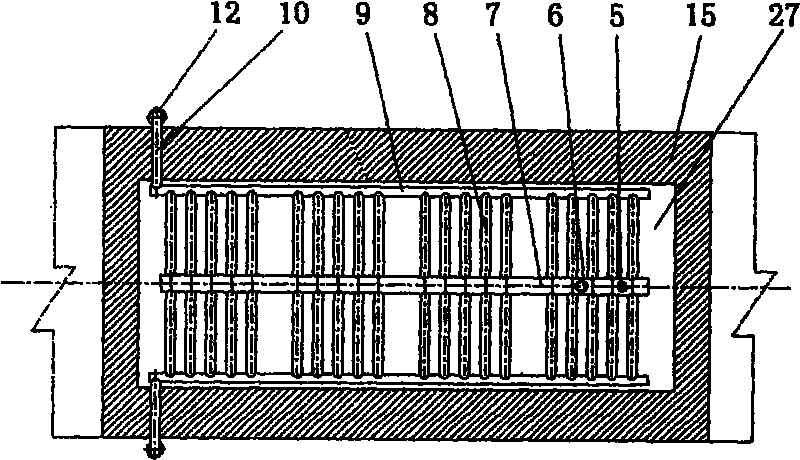

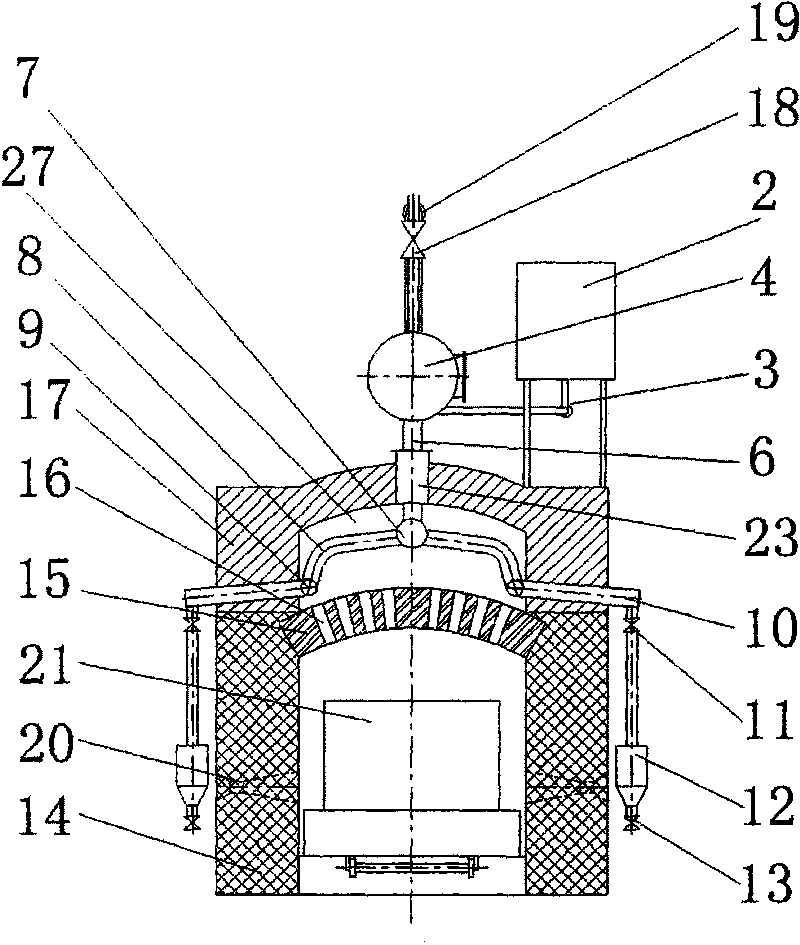

[0013] The tunnel kiln waste heat boiler of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. In the present invention, a multi-tube vaporization pot and a masonry hot air furnace are arranged on the kiln roof of the tunnel kiln cooling zone, and a pair of temporary burner burners are added to the walls on both sides of the tunnel kiln cooling zone between the blast hole at the kiln tail and the hot air hole. . See figure 1 , figure 2 , set the water supply pipeline to the roof of the tunnel kiln cooling zone kiln, the water supply valve 1 connected to the water supply pipeline is connected to the water valve 2 with a pipeline, and the bottom of the water valve 2 is connected to the valve 3 and the steam storage tank 4 in turn through the pipeline, and at the bottom of the steam storage tank 4 The steam output pipe 19 with a valve and the steam discharge pipe 18 with a valve are connected on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com