Method and device utilizing kiln waste heat for rapidly drying electrotechnical porcelain

A rapid drying and kiln technology, applied in the direction of drying gas arrangement, drying chamber/container, local agitation dryer, etc., can solve the problems of high energy consumption, environmental pollution, long drying process time, etc., to achieve large energy waste and reduce The effect of burning costs and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

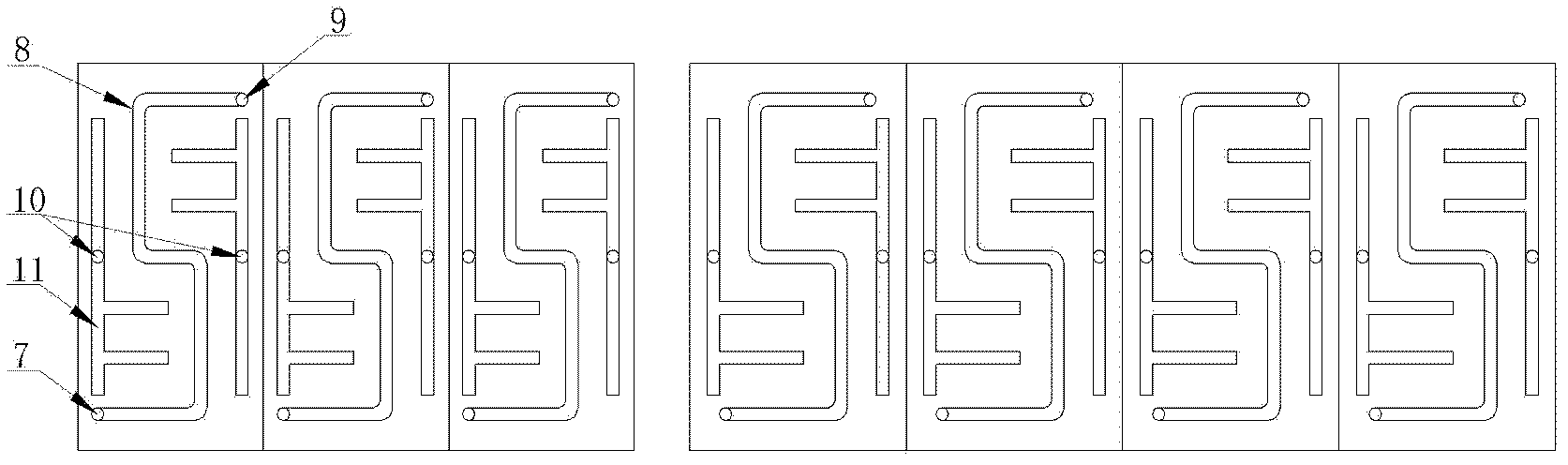

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

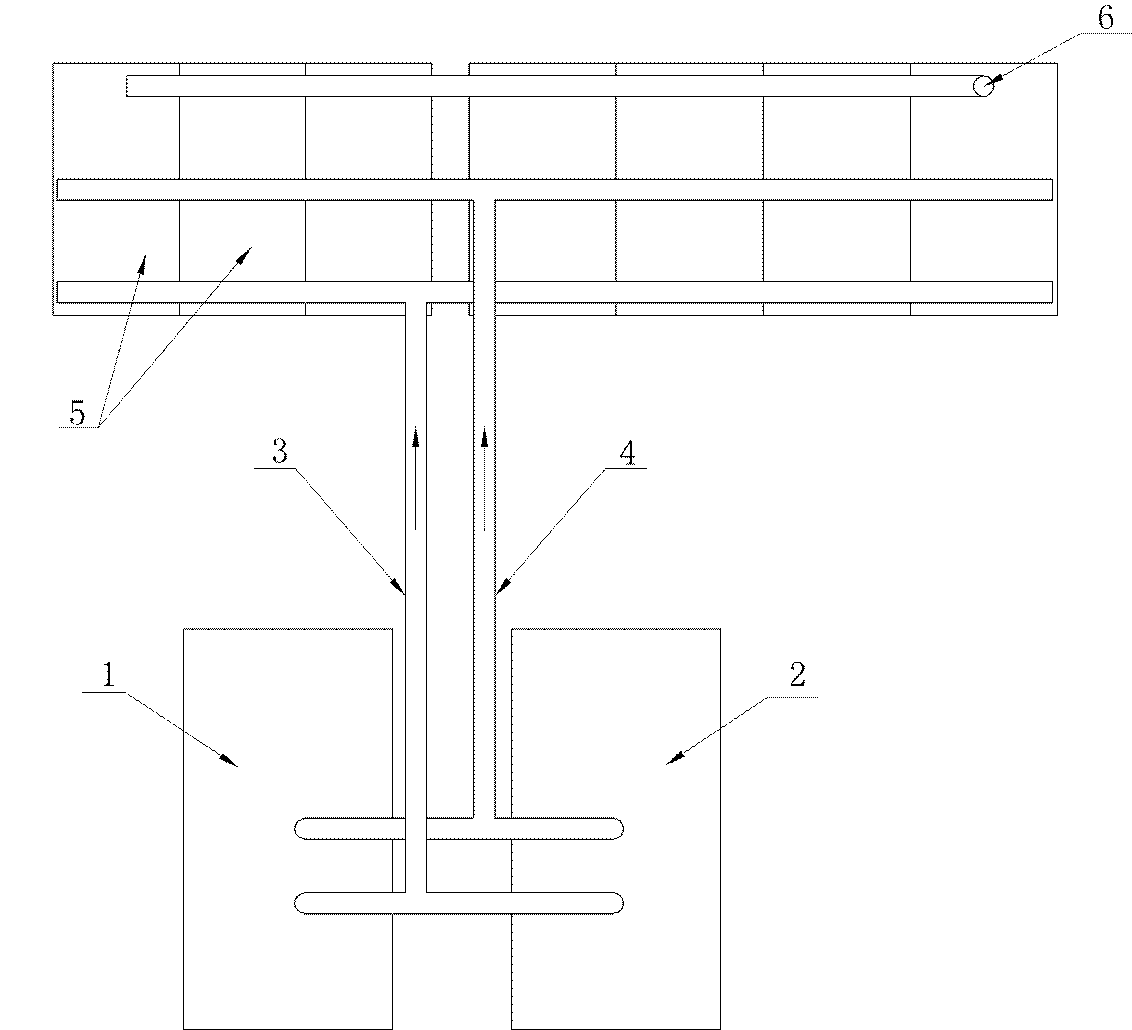

[0015] The invention makes full use of the waste heat of the kiln, supplemented by a hot blast stove as a heat source, and transports it to the underground pipe network of the drying room through two sets of kiln waste heat utilization systems; The system radiates heat through the underground pipe network of the drying room; when the kiln ceases fire, another set of heat source delivery system is used to transfer heat directly through the underground pipe network of the drying room.

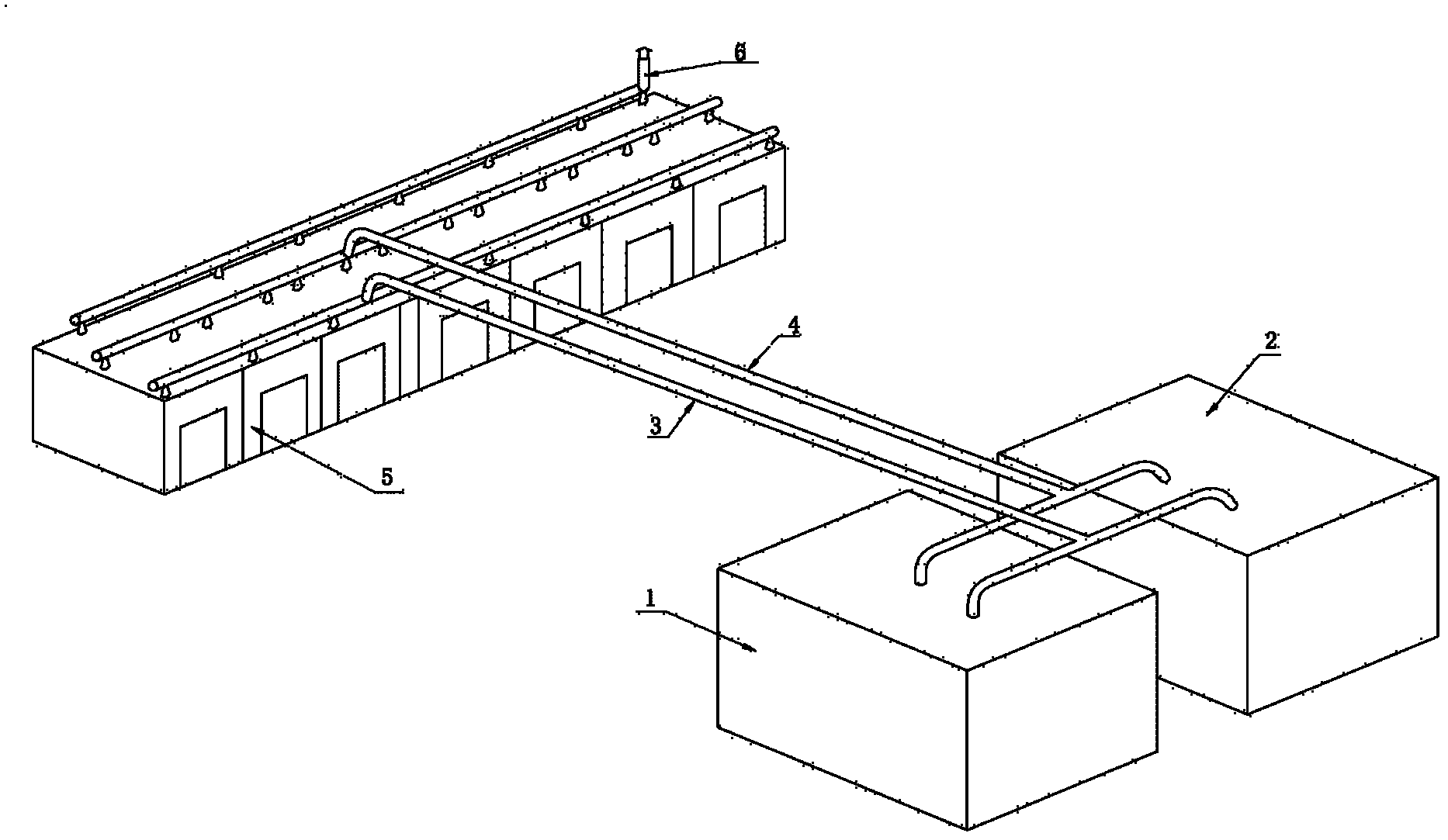

[0016] The present invention includes No. 3 kiln 1, No. 4 kiln 2 and drying room 5; No. 3 kiln 1 and No. 4 kiln 2 communicate with the drying room 5 through the hot air duct 3 before the cease-fire and the waste heat duct 4 after the cease-fire The drying room is built with high-alumina refractory bricks, the top is covered with prefabricated cement board, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com