Patents

Literature

40results about How to "Increase translucency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

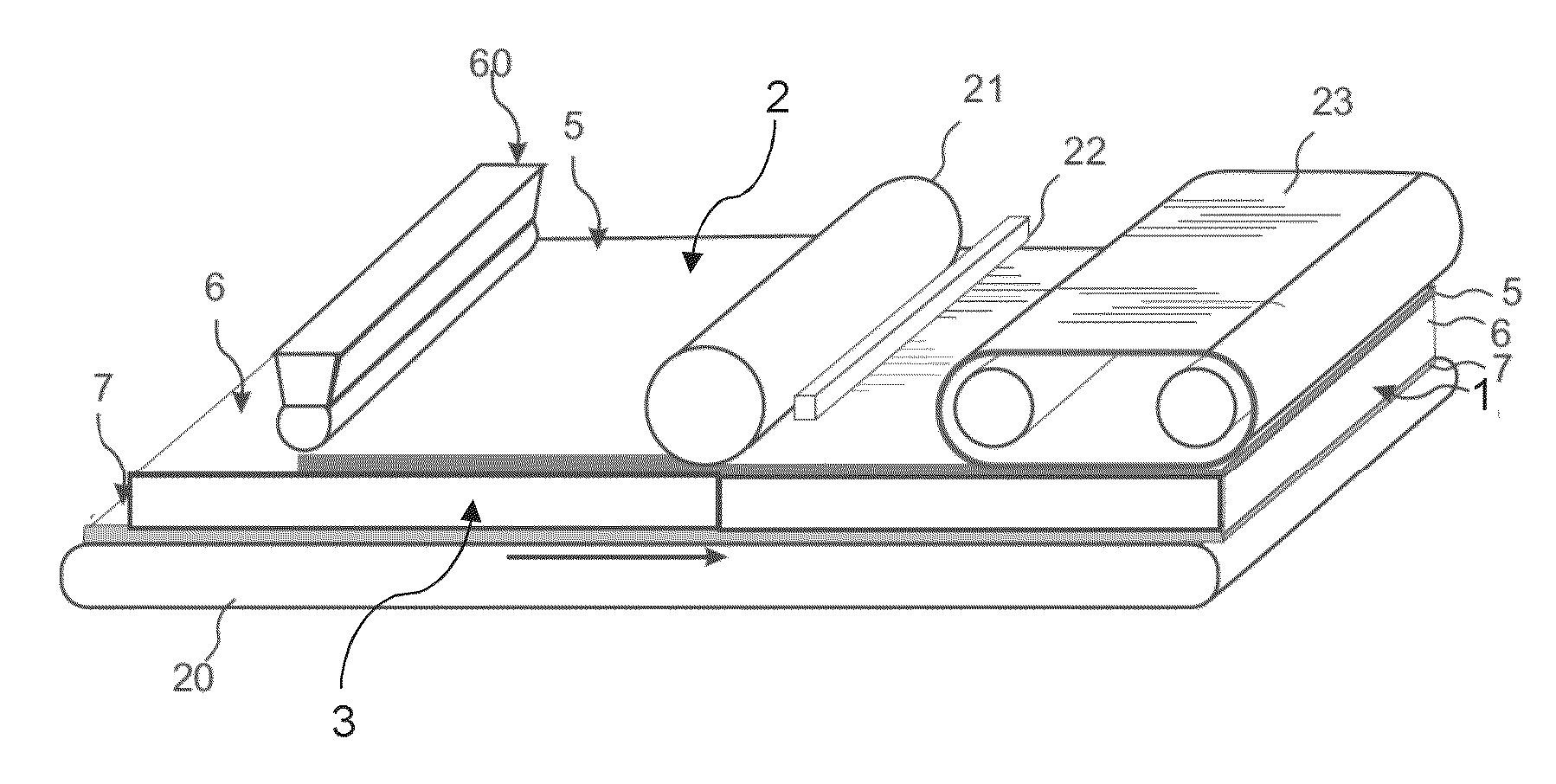

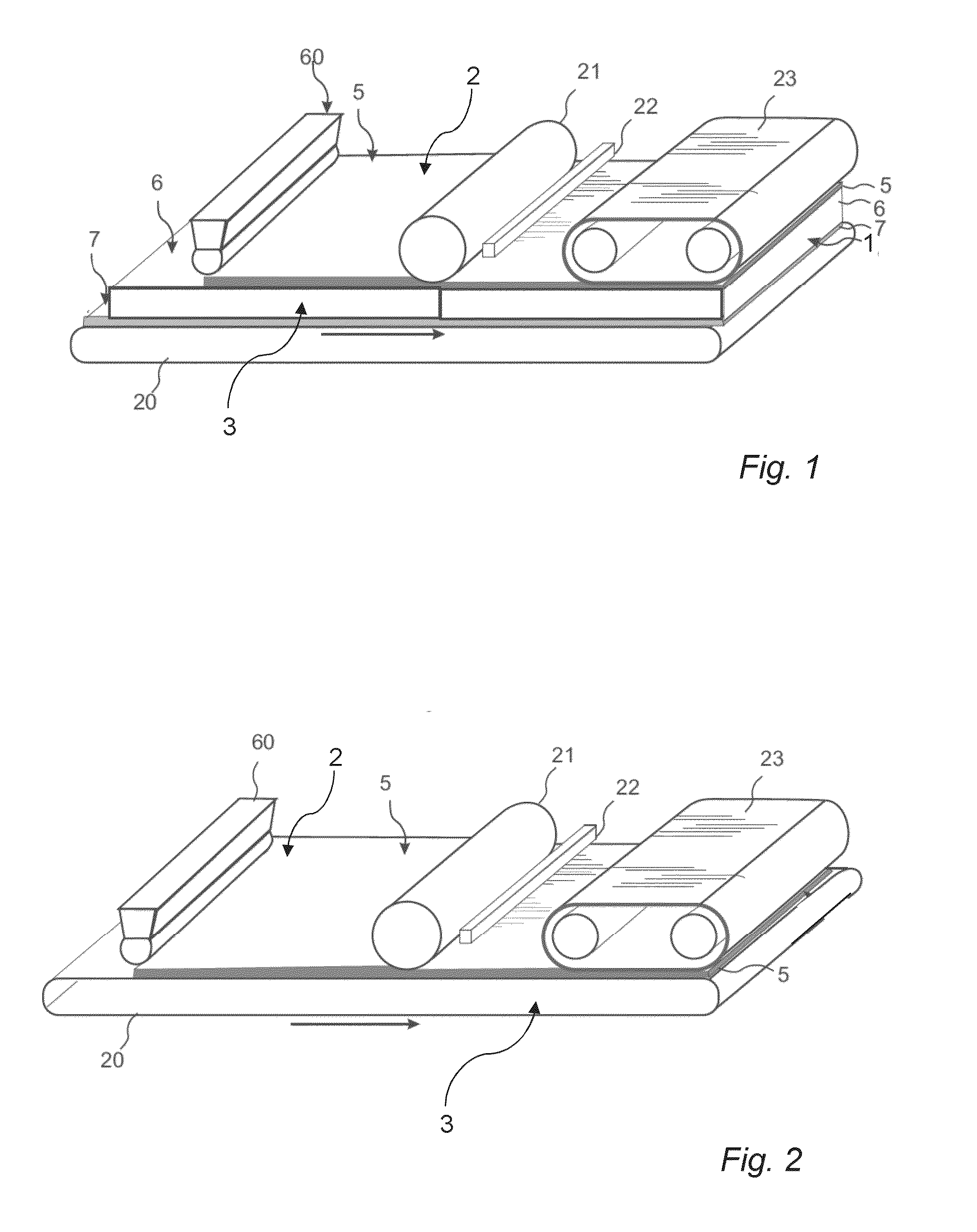

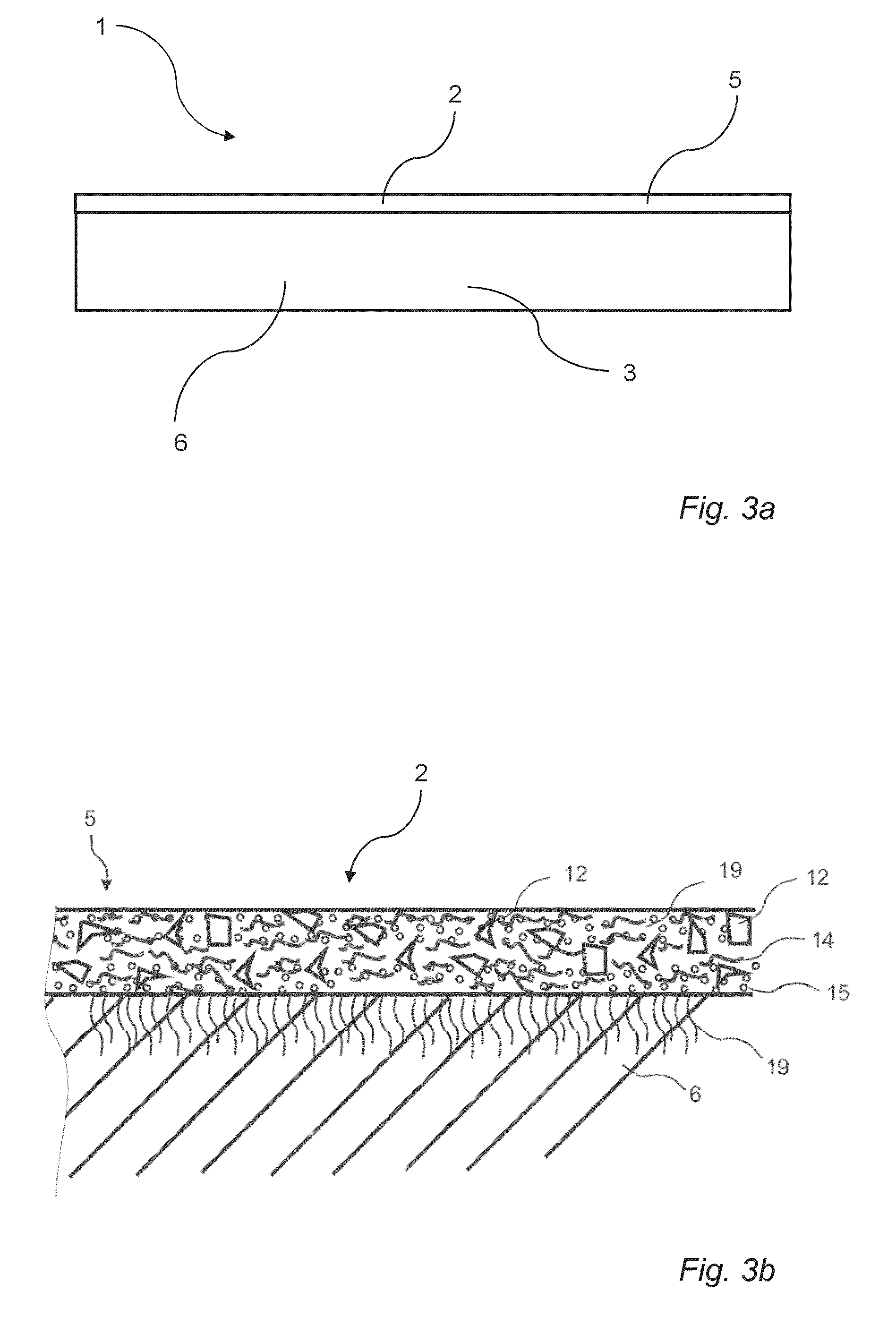

Method for producing a building panel

ActiveUS20130273244A1Simple technologyImprove the immunityLiquid surface applicatorsWood working apparatusMaterials science

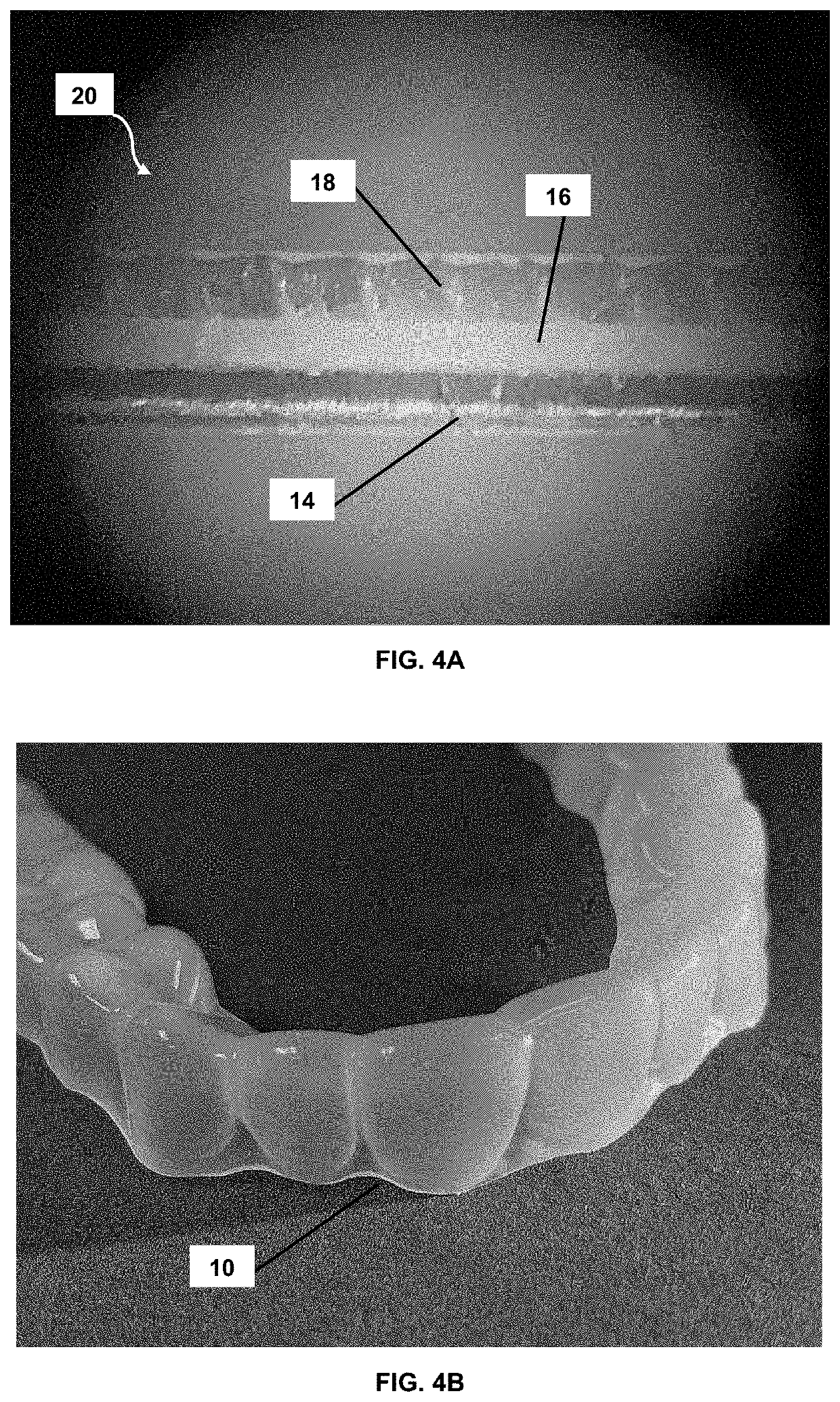

A method for producing a building panel. The method includes forming a mix (2) including wood particles (14), a solvent, a binder (19) and optionally at least one additive (15), wherein the binder (19) and optionally said at least one additive (15) are homogenously distributed in the mix (2) by means of the solvent and wherein the binder (19) impregnates the wood particles (14), drying the mix (2), applying the mix (2) on a substrate (3), and forming a layer (5) by applying heat and pressure to the mix (2).

Owner:VÄLINGE INNOVATION AB

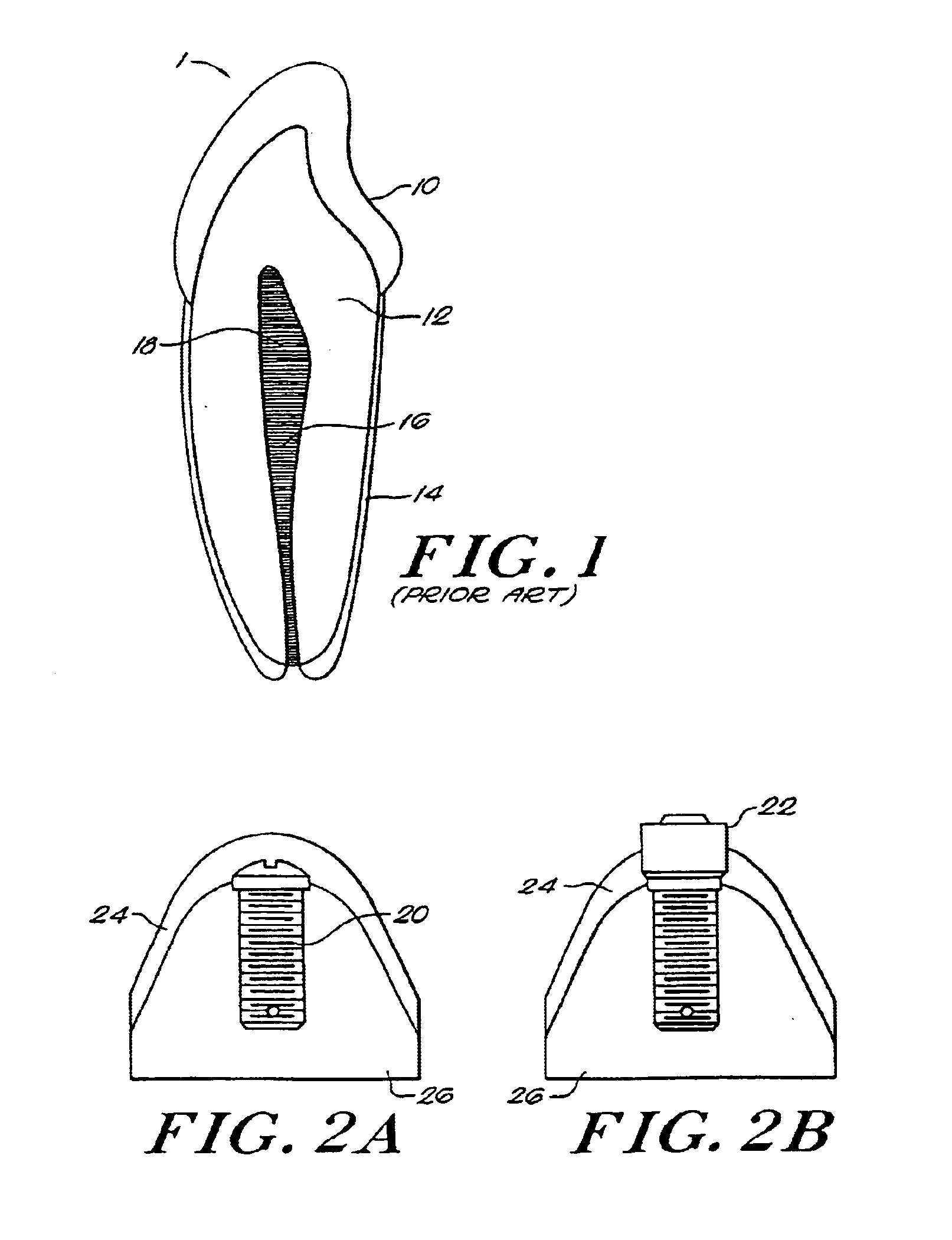

Method for fabricating endodontic, orthodontic, and direct restorations having infused ceramic network

InactiveUS6881488B2High strengthIncrease translucencyImpression capsOther chemical processesPliabilityMetal alloy

A ceramic network for endodontic, orthodontic or restorative materials infused with a monomer, glass or metal alloy. After infusion of the monomer, glass or metal alloy, the monomer, glass or metal alloy is treated to form with the ceramic network an interpenetrating network of improved wear, resistance and flexibility.

Owner:TRUSTEES OF BOSTON UNIV

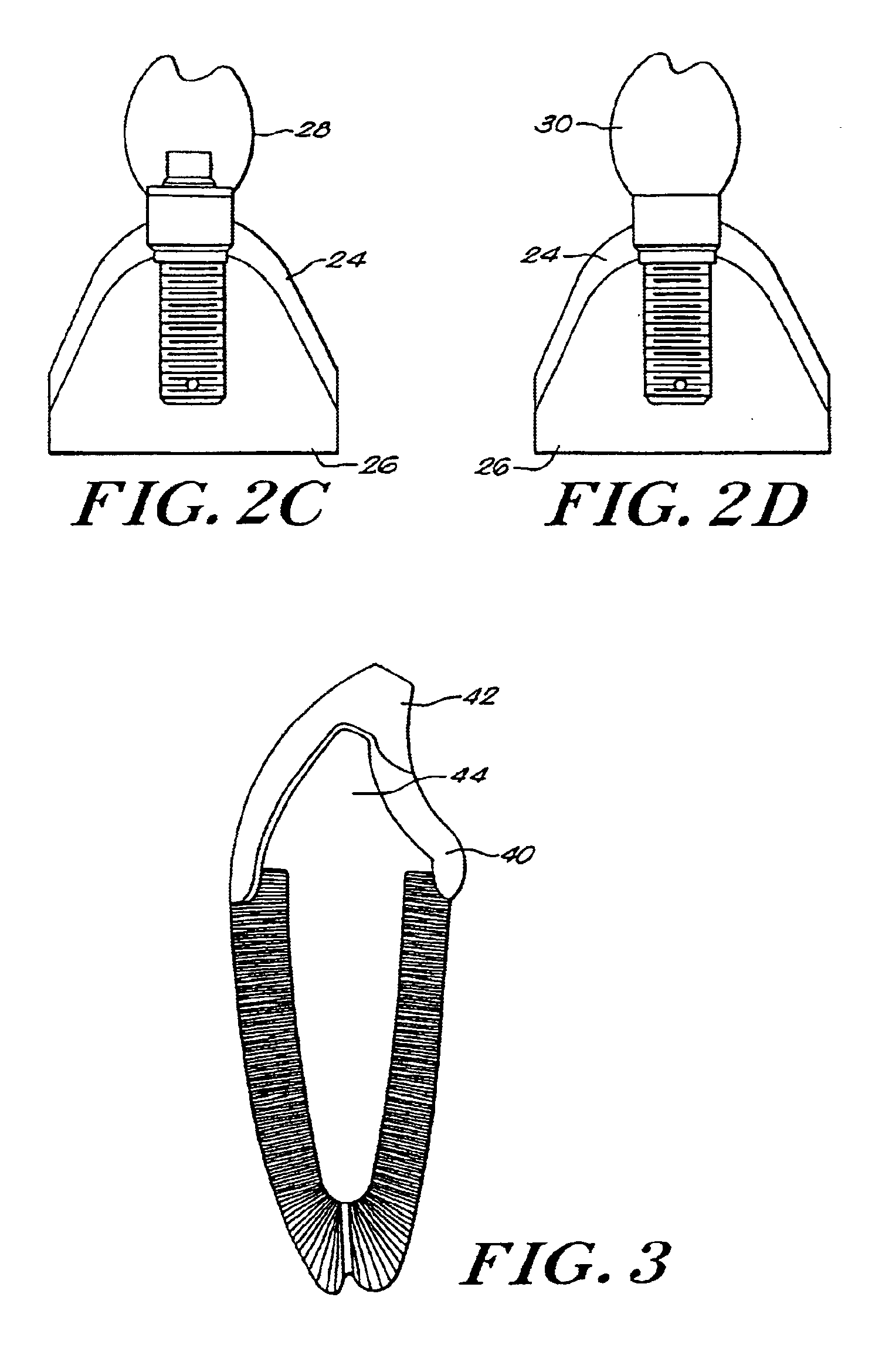

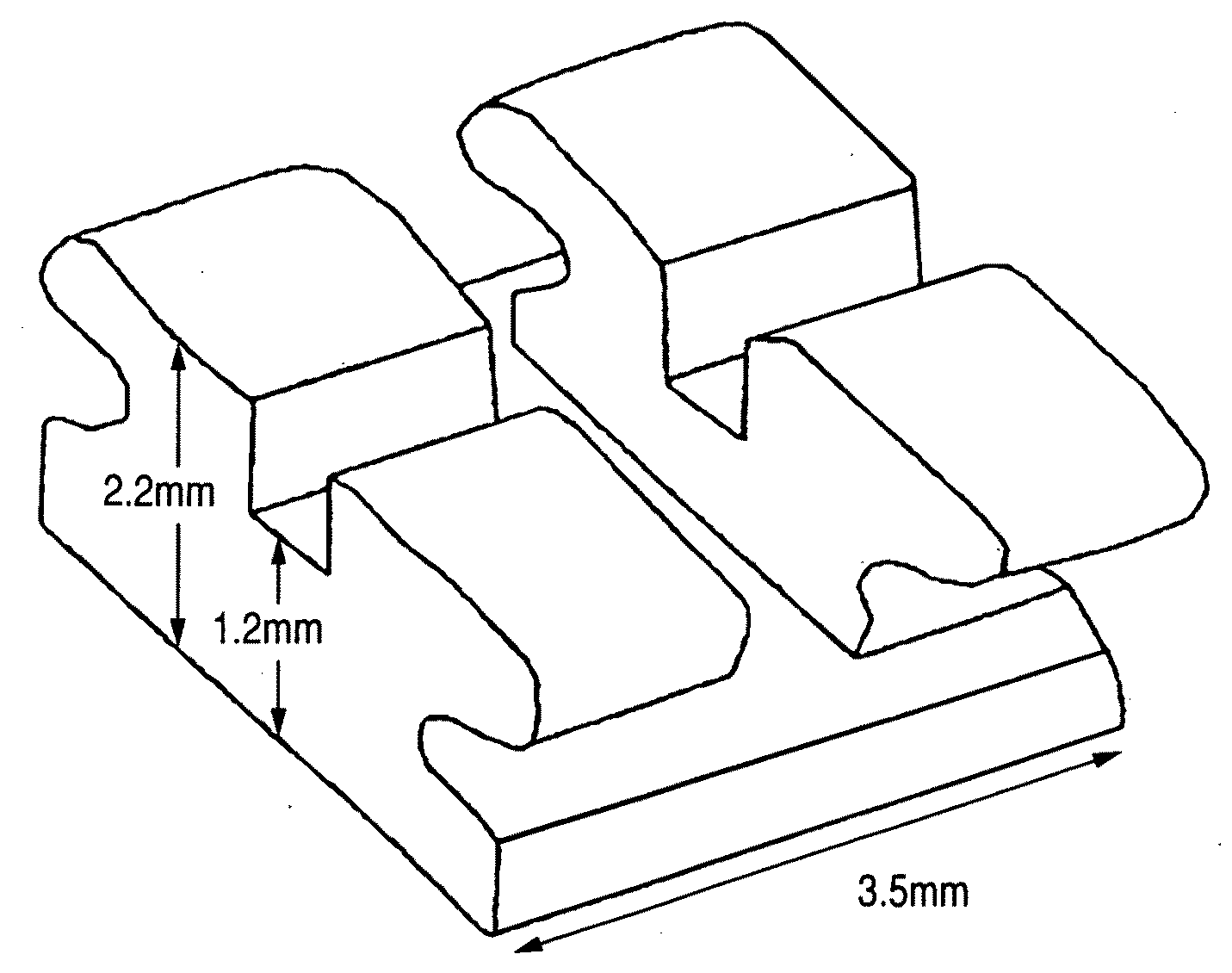

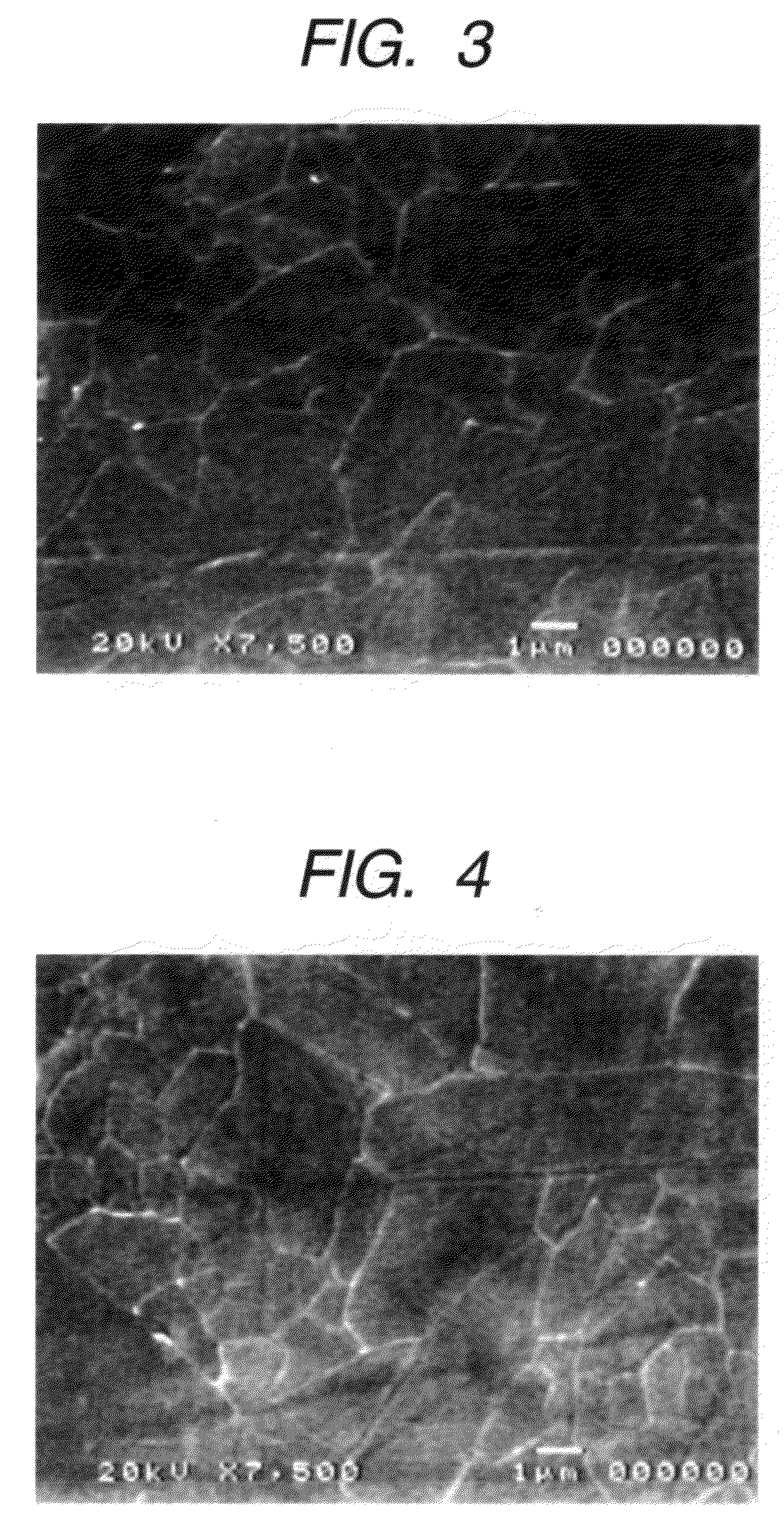

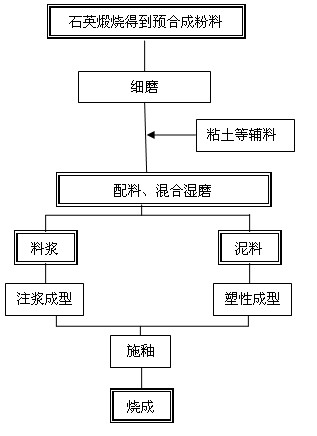

High toughness translucent alumina sintered body, method for producing the same, and its uses

ActiveUS20090111067A1Improve toughnessHigh strengthBracketsCeramic shaping apparatusLong axisFlexural strength

In the conventional alumina sintered bodies, a sintered body having high flexural strength, high toughness and high translucency in combination is not obtained, and a translucent alumina sintered body suitable for a dental material requiring both strength and sensuousness was not obtained. A translucent alumina sintered body having fracture toughness of 4.5 MPa·m0.5 or more, flexural strength of 350 MPa or more, and all light transmittance (sample thickness: 1 mm) to a visible light having a wavelength of 600 nm, of 60% or more is provided. The sintered body wherein sintered crystal grains are slender plate-like and / or columnar shape having an average aspect ratio of 1.5 or more and an average long axis length of 15 μm or less is preferred.

Owner:TOSOH CORP

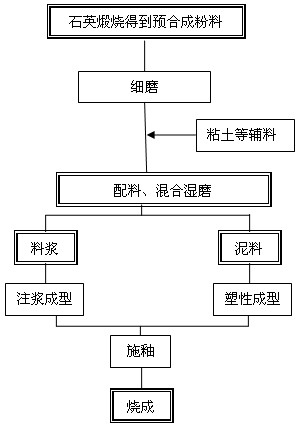

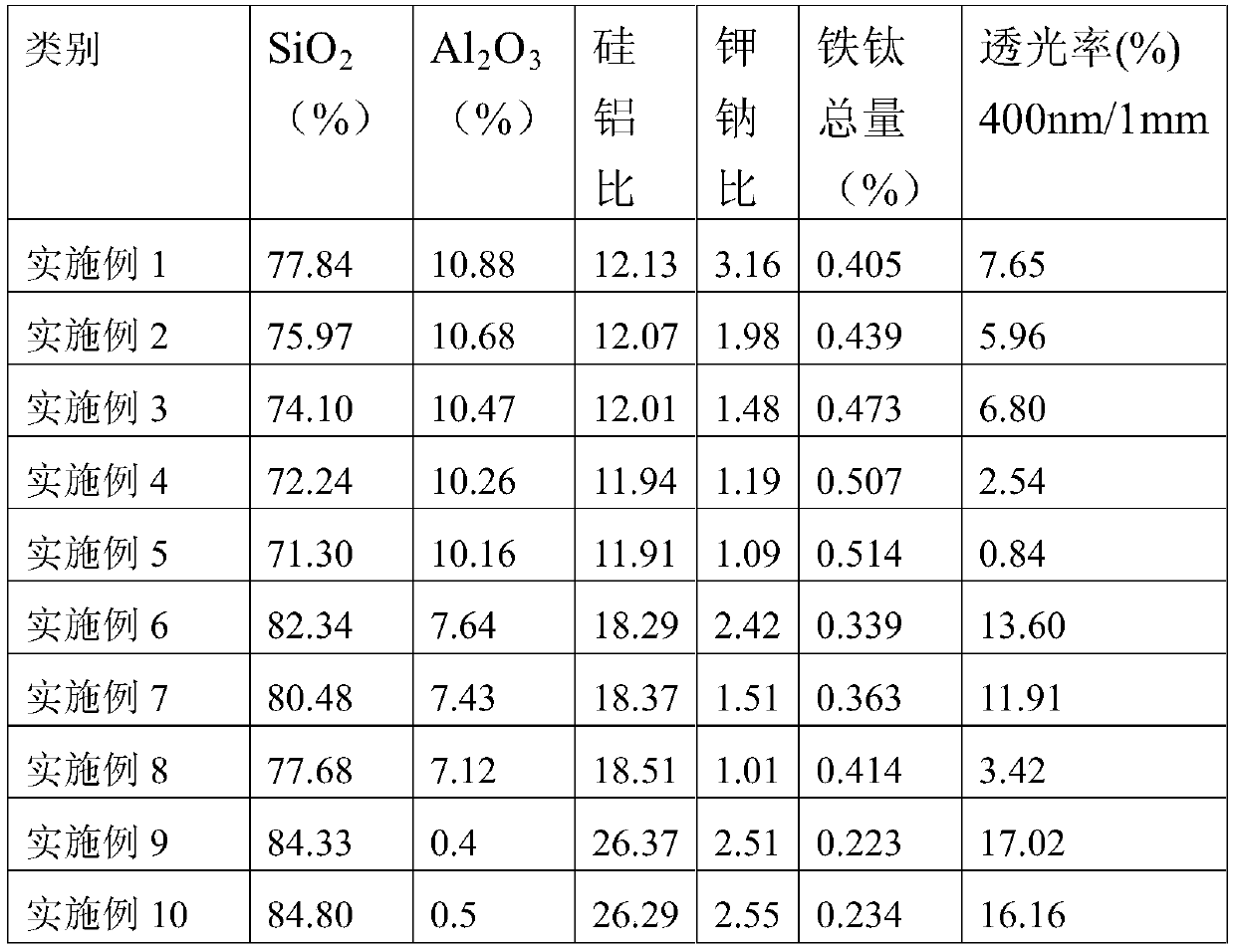

Ceramic manufacturing method using quartz as matrix material and product

The invention discloses a ceramic manufacturing method using quartz as a matrix material and a product. Silicon dioxide is used as the matrix material; aluminum oxide, basic oxide and magnesium oxide are used as auxiliary materials; and the ceramic comprises the following materials in part by weight: 90 to 94 percent of silicon dioxide, 3 to 6 percent of aluminum oxide, 0.5 to 1.5 percent of basic oxide, 0.2 to 1 percent of magnesium oxide and the balance of impurities. The method comprises the following steps of: calcining the silicon dioxide serving as the matrix material to obtain pre-synthesized powder, wherein the beta-quartz is converted into alpha-quartz by crystal transfer in the calcining process; grinding the obtained pre-synthesized powder, wherein the granularity distribution of the ground pre-synthesized powder meets certain requirements; weighing and proportioning the ground pre-synthesized powder and auxiliary materials in a ratio, performing wet milling in a ball mill to obtain slurry, and molding the slurry to obtain a daily ceramic blank; and preparing a ceramic product by the processes of drying, glazing, temperature controlled sintering and the like.

Owner:HUNAN HUALIAN CHINA IND

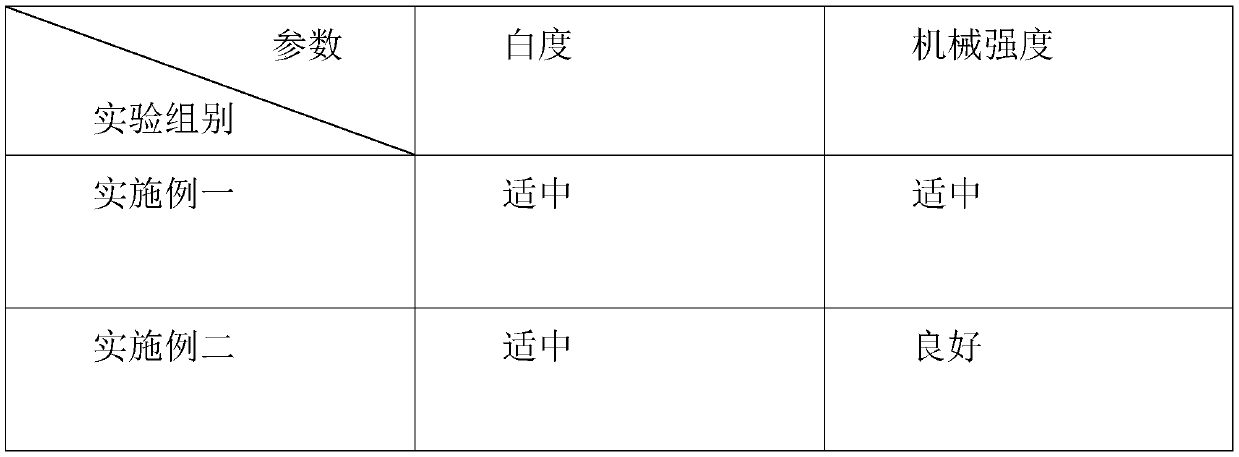

Ordinary fine procelain

ActiveCN101928132ALower firing temperatureHigh whitenessSolid waste disposalClaywaresBall millBone china

The invention relates to procelain production and aims to provide an ordinary fine procelain featuring low firing temperature and reduced production cost. The ordinary fine procelain of the invention comprises the following components in percentage by weight: 9-12% of Guangxi soil, 5-10% of Jingxing soil, 2-6% of Shanyin soil, 2-7% of Yusi soil, 2-8% of Tang county soil, 8-14% of Longyan soil, 22-28% of quartz, 24-30% of Datong soil, 8-14% of feldspar and 6-8% of fine bone china waste powder. Blank is crushed, processed into fine powder of 100 meshes and ball-milled in a wet-type ball mill while being added with water, blank: ball: water=1:2.5:1; the mixture is levigated for 18-20 hours; the mixture passes through a sieve of 250 meshes, the fineness of the mixture is 0.8%, the mixture is dehydrated by a mud press to have a water content of 21% and then vacuum pugging is carried out on the mixture for twice at a vacuum degree more than or equal to 0.09MPa.In the invention, the fine bone china waste powder is added to the production of the ordinary fine procelain, therefore the firing temperature of the ordinary fine porcelain in the invention is reduced by about 30 DEG C compared with the firing temperature of the traditional ordinary fine porcelain.

Owner:PINGDING YINGYU PORCELAIN

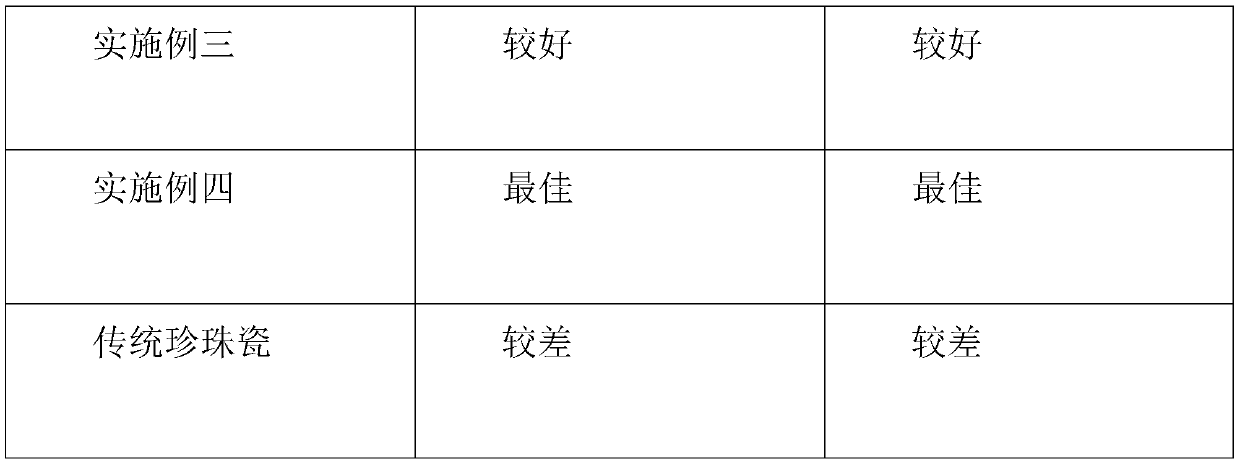

Pearl white ceramic product and preparation method thereof

The invention relates to the technical field of ceramic production, and discloses a pearl white ceramic product, which comprises a green body and a glaze layer, the glaze layer is coated on the outersurface of the green body, the green body comprises, by mass, 3-12 parts of titanium dioxide, 10-30 parts of kaolin, 5-15 parts of neodymium ore, 8-16 parts of dysprosium ore, 10-30 parts of rare earth, 10-30 parts of aluminum oxide, 10-18 parts of zirconium oxide, 12-18 parts of bentonite, 15-25 parts of quartz and 12-18 parts of feldspar. The invention also provides a preparation method of the pearl white ceramic product. The preparation method comprises the following steps: S1, ball-milling, and weighing the raw materials; and S2, stirring and mixing. The whiteness and the semitransparent degree of the pearl ceramic prepared in the invention are greatly improved, the pearls are added into the raw materials, the ceramic prepared by calcining is better in texture and strong in antibacterial ability, subsequent ligands can be prevented from chapping during drying, and refined mud cakes are convenient to transport and store.

Owner:福建省德化县晖德陶瓷有限公司

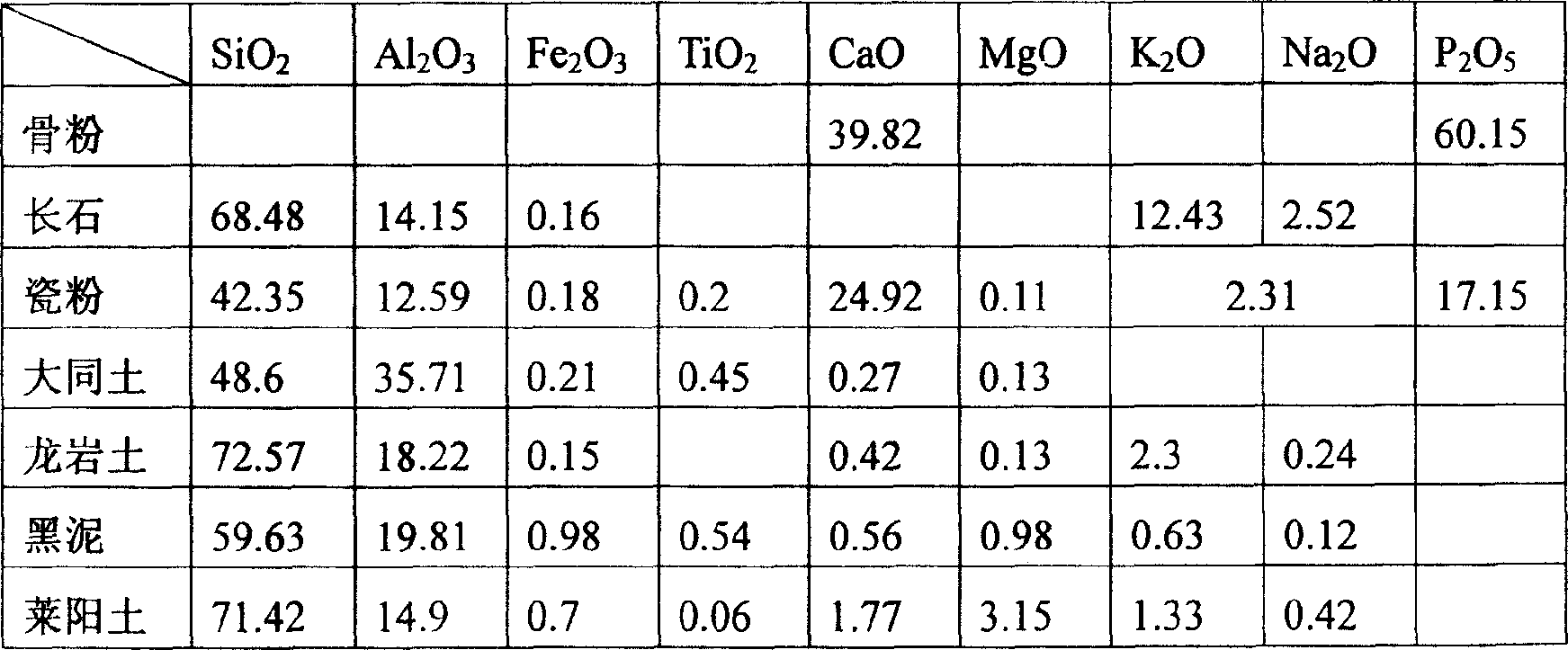

Bone-green porcelain

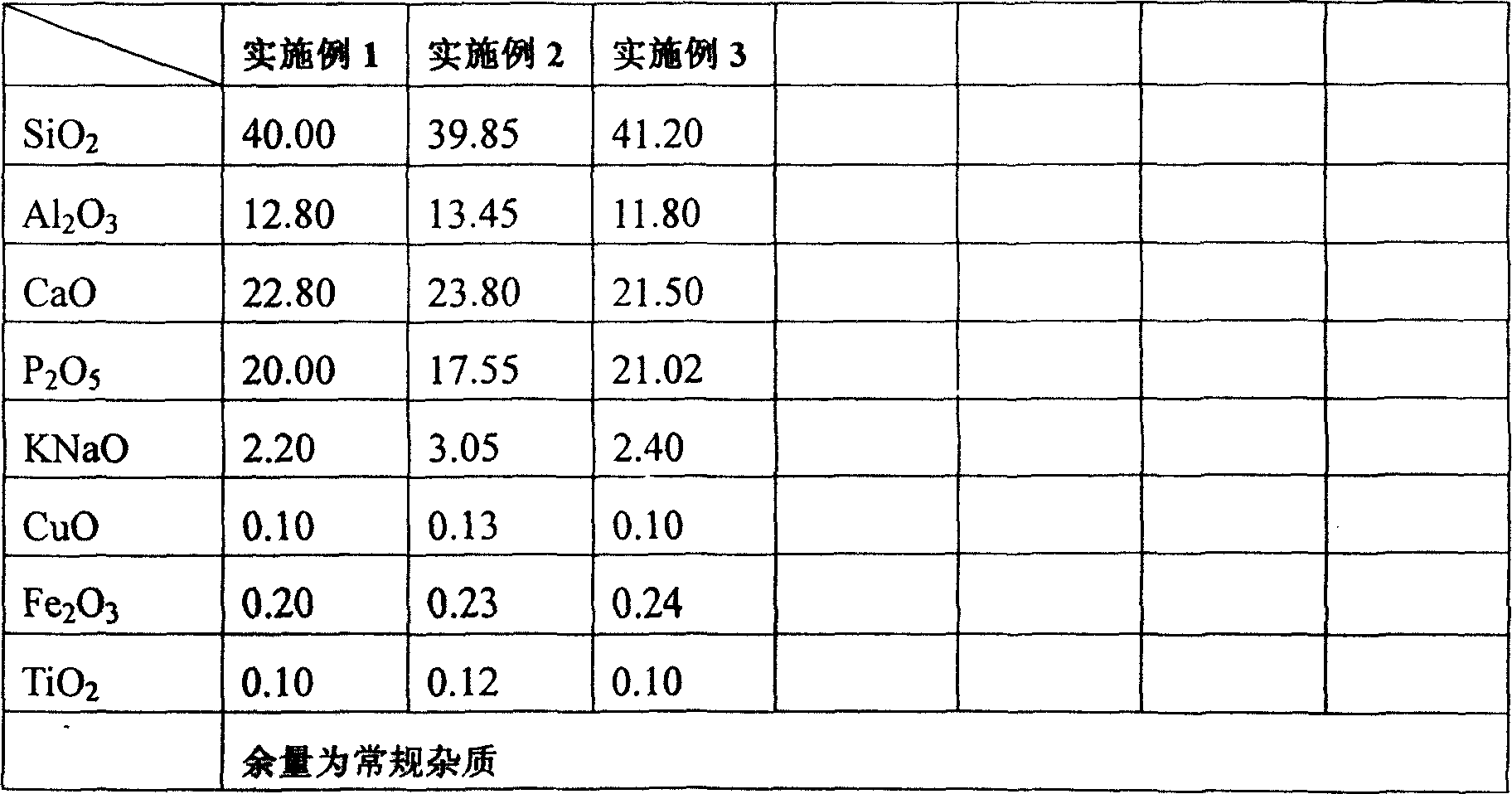

The invention relates to a bone jade green ceramic, comprising SiO2 39-45wt%, Al2O3 11-16ey%, CaO2 1-26wt%, P2O5 17-22wt%, KNaO 2-4wt%, TiO2 0.1-0.2wt%, Fe2O3 0.3-0.5wt%, CuO 0.05-0.3wt%, and routine impurities the rest. And its raw materials comprise: bone powder 32-36wt%, feldspar 7-10wt%, ceramic powder 16-20wt%, Datong earth 20-24wt%, Longyan earth 8-10wt%, black earth 2-6wt% and Laiyang earth 1-5wt%, as well as CuO 0.05-0.3wt% and Fe2O3 0.1-0.2wt%. And its blank bodies have absinthe-green brilliance, characters of bone ceramtics, good light transmitting property, high translucency, etc. Especially, it is fired by normal oxidizing flame, beneficial to scale production.

Owner:淄博华光瓷业有限公司

Ceramic green body and preparation method of bright-convex-glaze ceramic

InactiveCN107352968AHigh tinting strengthHigh hiding powerClaywaresScreen printingManufacturing technology

The invention relates to the technical field of the manufacturing of ceramics, and provides a ceramic green body and a preparation method of a bright-convex-glaze ceramic. The ceramic green body is prepared from the following raw materials: potash feldspar, soda feldspar, quartz sand, porcelain clay, calcite, calcined talc, a brightener, aluminum oxide and zinc oxide. The ceramic green body has excellent mechanical performance. The preparation method comprises the following steps of mixing and grinding the raw materials for the ceramic green body into slurry, oven-drying, controlling humidity to form a ceramic green body basal powder, and then pressing to form the ceramic green body; carrying out first-time sintering; successively coating basal glaze and surface glaze on the surface of the ceramic green body; jetting ink towards the surface glaze by adopting an ink jet printing technique to carry out printing, so as to form a first decorative pattern design; oven-drying the first decorative pattern design; spraying bright-convex-glaze glaze towards the first decorative pattern design by adopting a screen printing technique, so as to form a second decorative pattern design; afterwards, carrying out second-time sintering. The bright-convex-glaze ceramic prepared and obtained by the preparation method can reach the visual effects of from the front, a whole range, and from the side, a single peak; far, near, high, low, no two parts alike.

Owner:四川汇丰陶瓷有限公司

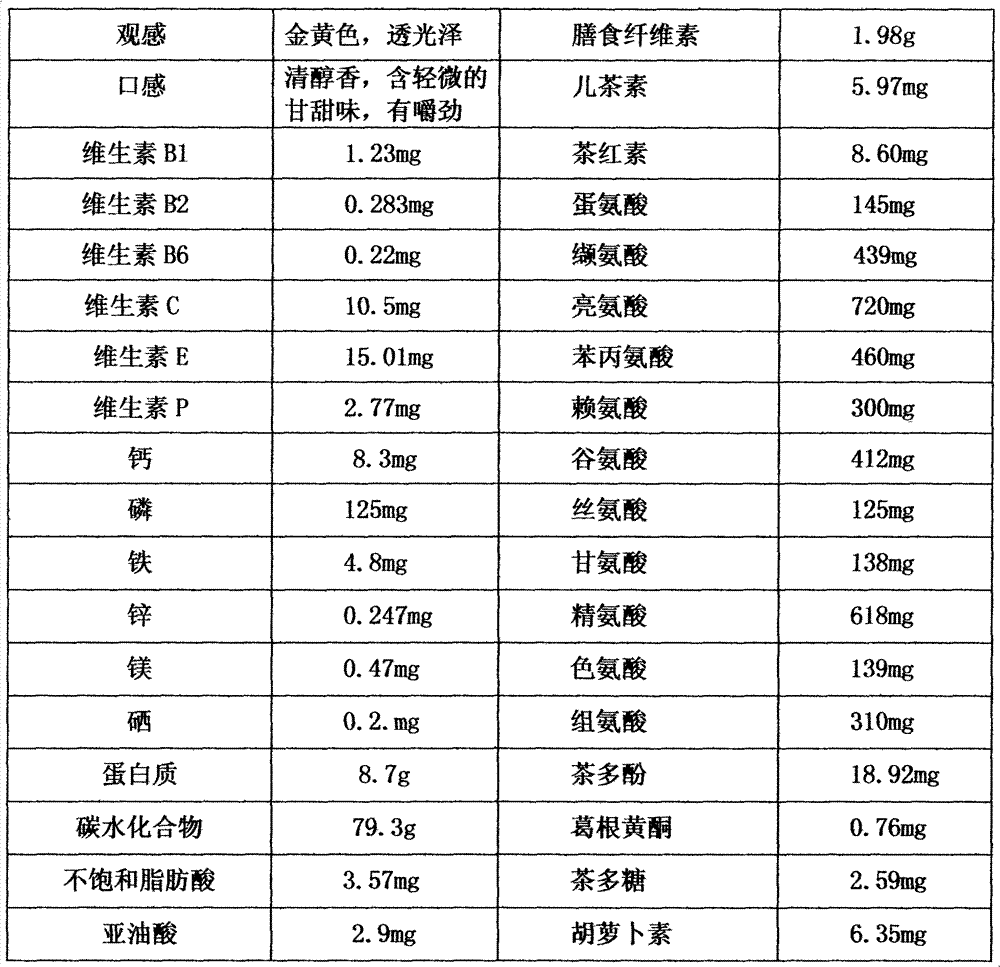

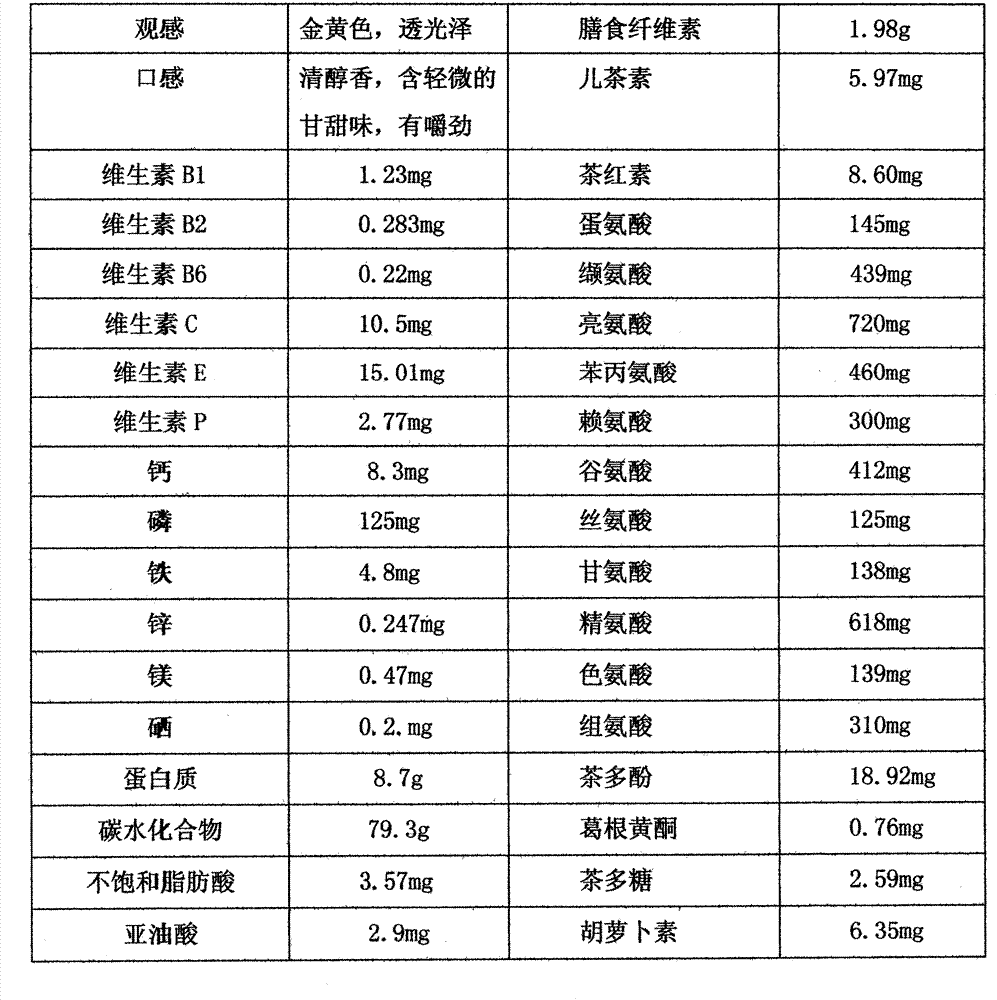

Preparation technology of black tea pearl rice

The invention discloses a preparation technology of black tea pearl rice. The preparation method comprises the following steps of: extracting concentrated solutions of black tea, green tea, corn stigma, poria cocos and radix puerariae respectively, and uniformly mixing the concentrated solutions with the prepared oyster mushroom slurry, tremella slurry, ramie oil and hippophae rhamnoides powder; stirring the mixture with corn powder, millet powder and polished round-grained rice powder to obtain granules; performing the puffing and extrusion processes with granulation equipment, and forming with a die to obtain golden yellow and bright black tea pearl rice the same as rice grains; and drying, finishing, sterilizing and packing to obtain a finished product.

Owner:王跃进

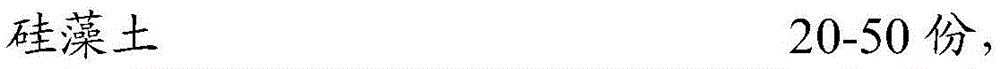

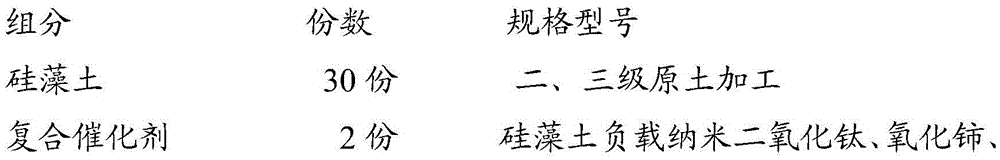

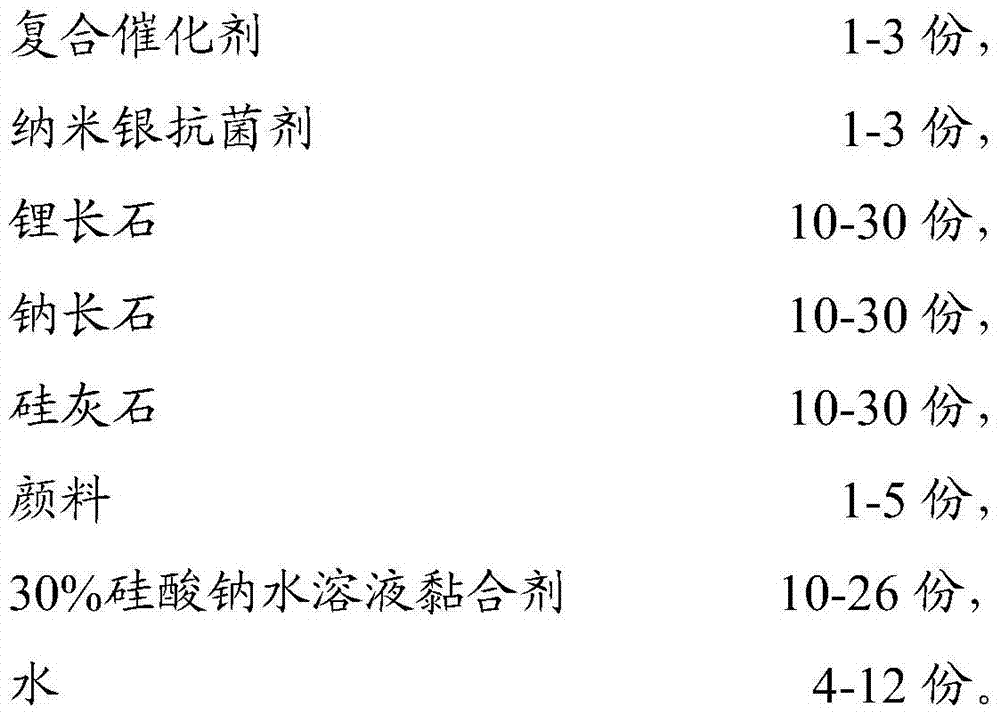

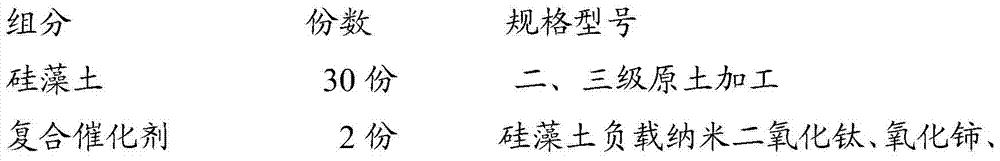

Diatom-containing ecological brick and production method thereof

The invention discloses a diatom-containing ecological brick and a production method thereof. The diatom-containing ecological brick is prepared from the following raw materials in parts by weight: 20-50 parts of diatomaceous earth, 1-3 parts of composite catalyst, 1-3 parts of nano-silver antibacterial agent, 10-30 parts of lithium feldspar, 10-30 parts of albite, 10-30 parts of wollastonite, 1-5 parts of pigment, 10-26 parts of 30% sodium silicate water solution adhesive and 4-12 parts of water. The raw materials are prepared into a finished product by the processes of dry-mixing, wet-mixing, pelleting, drying, compression moulding, drying, firing, cooling, checking and the like. The product provided by the invention is made from pure inorganic materials, and does not easily mold; the diatom-containing ecological brick is laid onto a wall by a dry method during construction, thus being convenient in construction, short in period, high in efficiency and low in cost; compared with a diatom ooze-containing decoration wall material, the strength and water resistance of the diatom-containing ecological brick are remarkably improved, and the service life of the diatom-containing ecological brick is remarkably prolonged.

Owner:营口盼盼硅藻材料集团有限公司

Method for producing zircon oxide blank

PendingCN111233469AExcellent optical propertiesIncrease translucencyImpression capsCeramic shaping apparatusMetallurgyPhysical chemistry

Owner:IVOCLAR VIVADENT AG

Halodendron cake

InactiveCN102919679AIncrease health functionWith hypolipidemicFood preparationCholesterolBlood pressure

The invention discloses a halodendron cake. The halodendron cake is characterized by comprising the following materials in parts by mass: 60-65 parts of rice powder, 10-20 parts of halodendron vegetable powder, 8-15 parts of oat powder, 5-10 parts of lotus powder and 5-10 parts of white granulated sugar. The halodendron cake has healthcare functions of reducing blood fat, reducing blood pressure, assimilating cholesterol, assisting to relieve pressure, and promoting physical and mental health; green halodendron vegetable powder particles are adorned on a semitransparent cake body, and the lotus powder is added to increase translucence of the cake body, so that an ornamental value of food is increased; the halodendron cake is fragrant and sweet in mouthfeel, and distinctive is color, fragrance and taste. According to the halodendron cake, a novel application field for additionally developing and processing halodendron is developed. The halodendron cake can be produced by a traditional rice cake production device, and is easy to achieve industrial production.

Owner:蒋亚飞

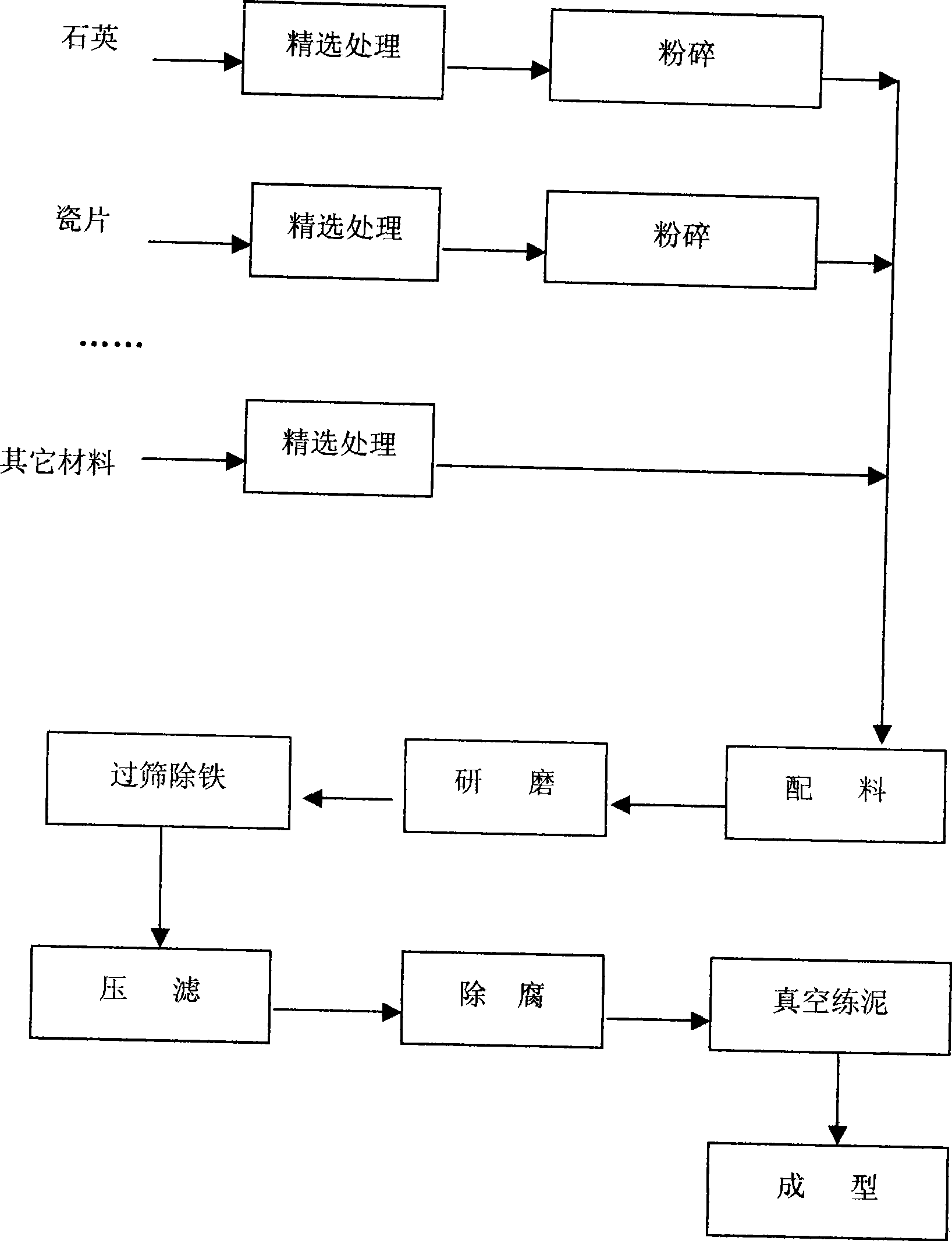

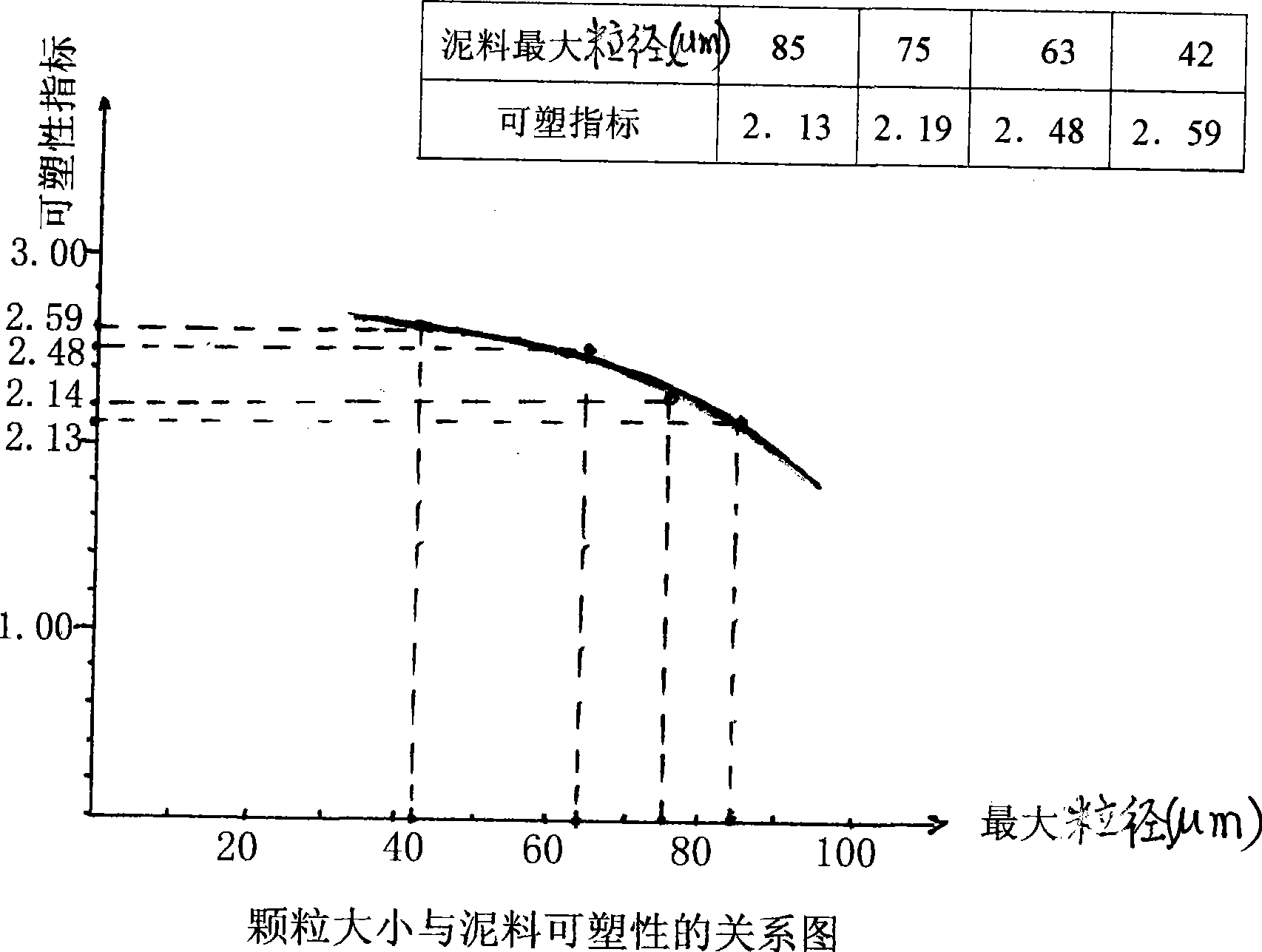

Plasticization process of bone porcelain pug

The invention relates to a method for improving the pug plasticity in the production process of a bone china. The invention provides a process for plasticizing a bone china pug, which comprises the following process steps: hard raw materials crushing, material blending, grinding, iron removal through sieving, pressure filtration, mustiness, vacuum pugging and the like. The method is characterized in that the raw materials are crushed to grains with the maximum grain size of less than 42 mu m in the process step of crushing the raw materials, and the materials are ground to grains with the maximum grain size of less than 42 mu m in the grinding process step. The method has the following substantive characteristics and marked improvements: 1. the method reveals the corresponding relation between the grain size and the plasticity of the pug, and achieves the aim of improving the plasticity by a method of controlling the fineness of the pug; 2. the production formula of the bone china is designed not to use bentonite or plasticizer at all so as to thoroughly eliminate the negative effects brought by harmful impurities contained in the bentonite and the plasticizer, improves the product quality obviously and reduces the production cost effectively; and 3. the adoption of the process for crushing hard materials such as quartz, ceramic chips and the like in advance can improve grinding efficiency, shorten grinding time, and reduce energy consumption.

Owner:广东文化长城集团股份有限公司

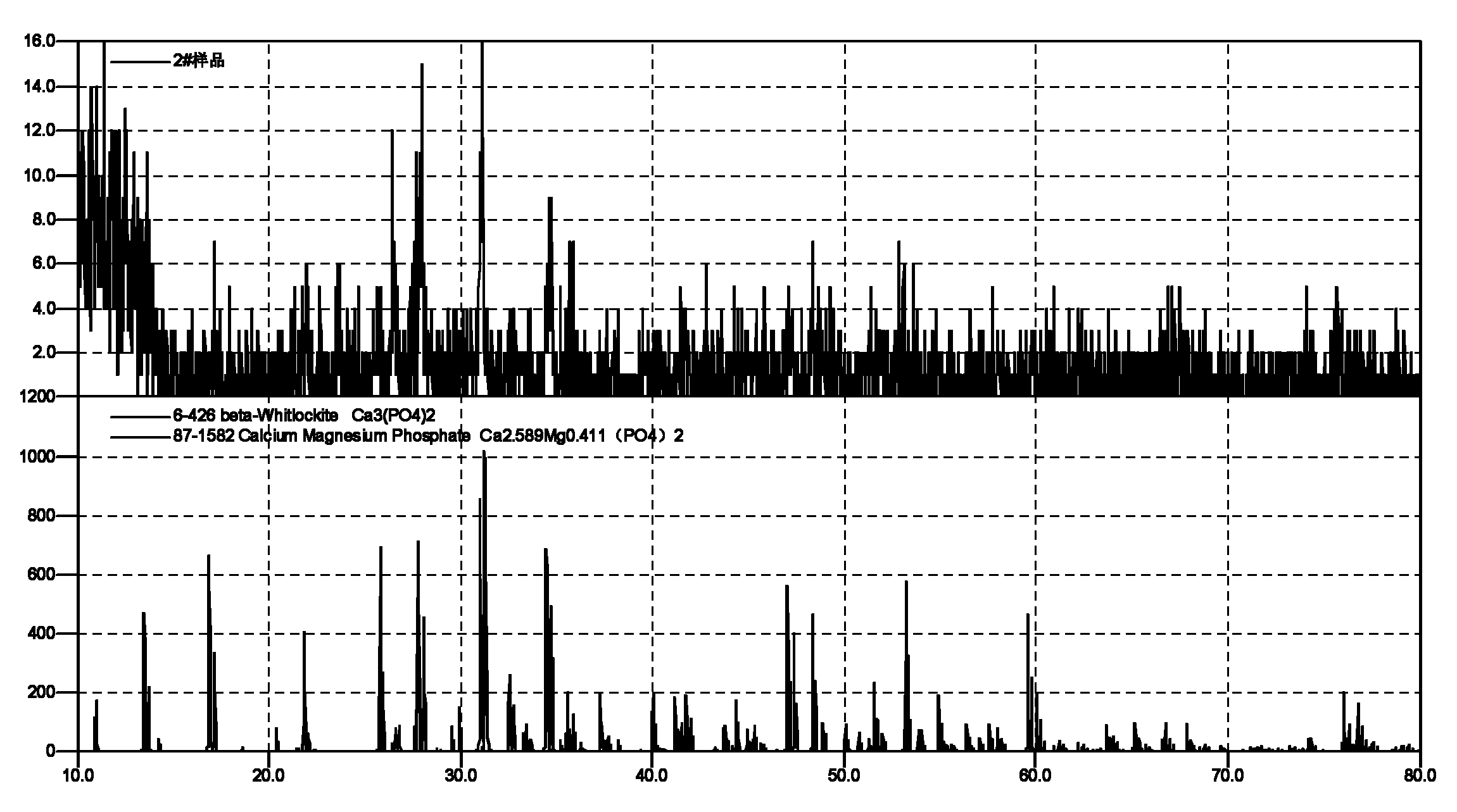

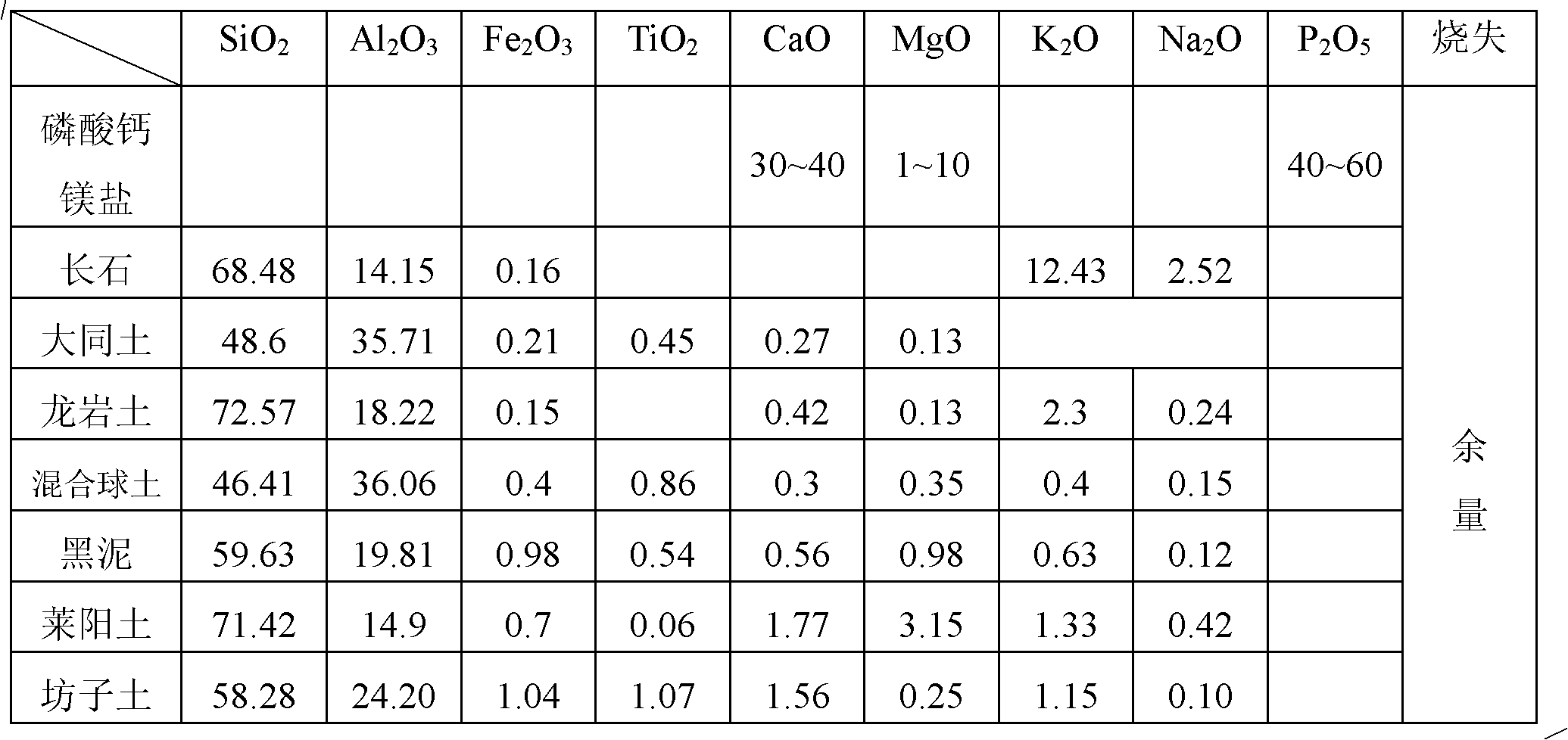

Calcium magnesium phosphate for ceramic and preparation method thereof

ActiveCN102530909AFine and smooth surface of enamelGlaze stablePhosphorus compoundsCeramic glazeCalcium hydroxide

The invention relates to a preparation method of calcium magnesium phosphate for ceramic, belonging to the field of ceramic glass materials. The calcium magnesium phosphate for ceramic is characterized in that the calcium magnesium phosphate for ceramic is synthesized by using phosphoric acid, calcium hydroxide and magnesium carbonate through chemical reaction, and the chemical compositions of the calcium magnesium phosphate comprise MgCa2(PO4) and CaMg(HPO4)2, wherein the weight ratio of Ca<2> to Mg<2> is (6-9): (1-4). A ceramic product made of the calcium magnesium phosphate for ceramic which is used as a main material has the advantages that the ceramic glaze surface is fine and smooth, the glazing color is stable, nontoxic and environmental-friendly and the application scope is wide. By introducing a large quantity of magnesium oxide to replace partial calcium oxide, the produced ceramic product has the advantages that the entire body has light-blue gloss, the semi-transparency is higher, the refraction principle of light can be fully utilized, and the ceramic product is enabled to have attractive gloss with white in blue and blue in white.

Owner:淄博华光国瓷科技文化有限公司

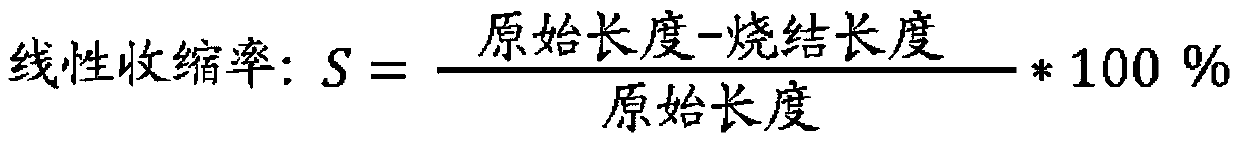

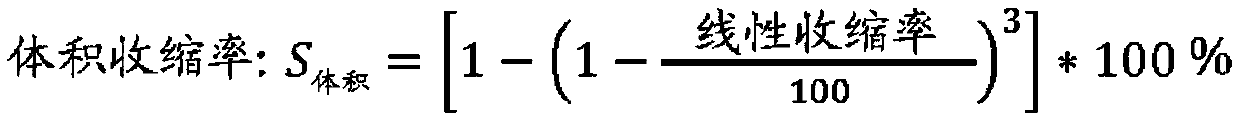

Production method of ceramic with engobe decoration

ActiveCN114149246AUniform coverageImprove shrinkage ratioCeramic materials productionClaywaresAluminium hydroxideFrit

The invention discloses a production method of ceramic with engobe decoration. The production method comprises the following steps: (1) preparing a blank; (2) mixing 65-70 parts by mass of clay, 15-20 parts by mass of low-temperature frit, 2-5 parts by mass of sinking beads, 5-10 parts by mass of feldspar, 2-5 parts by mass of aluminum hydroxide micro powder and 1-2 parts by mass of an expanding agent to obtain an engobe raw material, grinding and sieving the engobe raw material, and grinding the engobe raw material into slurry according to the ratio of the material to the balls to water being (1-1.1): (2-2.1): (1-1.1); (3) covering the slurry obtained in the step (2) on the blank prepared in the step (1), naturally air-drying, and carving a preset pattern on the blank coated with engobe; and (4) firing: firing the blank decorated in the step (3) in an oxidizing atmosphere at the firing temperature of 1240-1300 DEG C for 12-14 hours to obtain a product. According to the production method, the engobe is more uniformly covered on the blank, and the problems of discontinuity and spacing lines between the engobe and the blank in the firing process are solved.

Owner:SICHUAN FINE ARTS INST

Synthetic stone of high translucence, method of its production and use

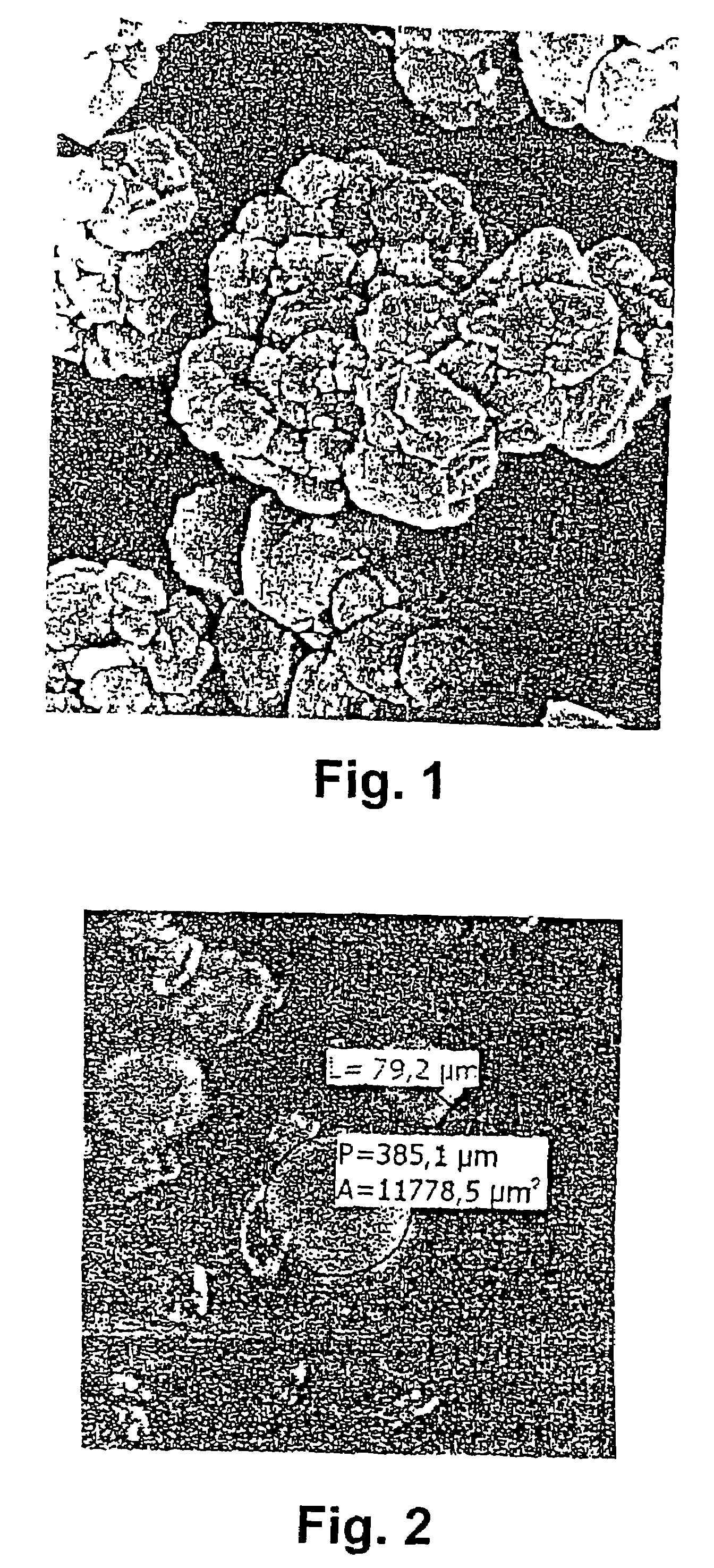

ActiveUS8362111B2Wettability deterioratesHigh light transmittanceIrregular area designCovering/liningsParticulatesMineral particles

Stone is formed from 5 to 60% by weight of polymerised, low-viscosity, transparent or low-colour-resin, 20 to 90% by weight of spherical alumina trihidrate Al2O3.3H2O containing less regular particles containing, advantageously 0 to 100% by weight of a transparent or translucent substitute of alumina trihydrate, and / or with 0 to 20% or pre-prepared particulate, filled resin of a chosen colour, and / or mineral particles and less than 2% by weight of luminophor. These individual components are mixed intensely whilst extracting included gaseous parts. Extraction is carried out whilst mixing, and / or after mixing, and / or before mixing. The mixture is initiated by introducing a starter and intensely mixing it into the mixture. The mixture is poured into a mould or onto a moving endless belt. The cured synthetic stone is removed from the mould or the hardened composite is taken off the the belt. Synthetic stone can be used in products as a light carrier.

Owner:POLJAKOV MICHAL

Secret-color porcelain glaze and preparation method thereof

The invention belongs to the technical field of glaze preparation, and particularly relates to secret-color porcelain glaze which is prepared from the following raw materials in parts by weight: 45-60parts of potassium feldspar, 12-20 parts of quartz, 7-15 parts of fluorite, 12-20 parts of plant ash, 1-3 parts of titanium oxide, 1-3 parts of ferric oxide, 1-3 parts of gold ore and 1-3 parts of marble. The invention also discloses a preparation method of the secret-color porcelain glaze. The preparation method comprises the following steps: (1) weighing the raw materials according to the proportion,(2) fully crushing the raw materials, and uniformly mixing to obtain a mixed glaze material, (3) adding the mixed glaze into a ball mill, and adding water for ball milling to obtain glaze slip,(4) uniformly applying the glaze slip to a biscuiting blank, drying the glazed blank, putting the dried glazed blank into a kiln for firing, heating to 1260-1300 DEG C in an oxidizing atmosphere in astepped heating manner, keeping the temperature for 60-80 minutes, and naturally cooling to room temperature, thereby obtaining the secret-color ceramic glaze. The secret-color porcelain prepared by the raw material ratio and the preparation method disclosed by the invention is good in coloring effect, uniform in glaze color, high in glossiness, high in hardness, free of cracks and high in yield.

Owner:禹州大唐钧瓷文化有限公司

Pearl porcelain and preparation method thereof

The invention discloses pearl porcelain. The formula of the pearl porcelain comprises the following components: 23%-30% of pearl powder, 8%-13% of feldspar, 12%-16% of quartz, 3%-7% of dolomite, 1%-4%of kaolin, 1%-4% of lithium fluoride, 3%-8% of talc, 0.5%-3% of zinc oxide, 3%-5% of low-temperature frit, 2%-5% of barium carbonate and the balance rare earth. The invention also discloses a preparation method of the pearl porcelain. The preparation method comprises the following steps: quantitatively weighing, drying, crushing, forming, adhering, firing and forming, applying an outer protectivelayer, and naturally cooling. The beneficial effects of the invention are that: the transparent glaze is additionally arranged on the outermost side of the ceramic product so that the wear resistanceis improved, the Baume meter concentration is 43-48 and the glazing thickness is 0.5-0.8 mm when the transparent shaft is glazed so that the prepared transparent shaft protective layer is good in wall-hanging property, the phenomenon of uneven upper and lower thicknesses caused by local agglomeration or low density is not easy to occur, and the thickness of the transparent glaze is strictly controlled and thus the color of the pearl porcelain is better displayed.

Owner:淄博泰山瓷业有限公司

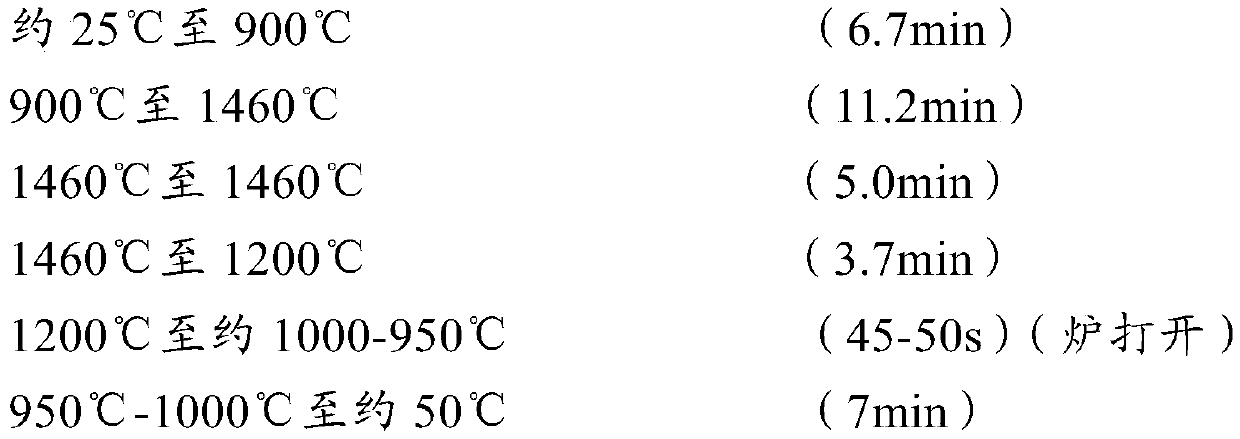

Rapid coloring process of lithium disilicate microcrystalline glass

InactiveCN111908795AUniform colorNo color differenceGlass shaping apparatusPhysical chemistryCrystallization temperature

The invention discloses a rapid coloring process of lithium disilicate microcrystalline glass. Therapid coloring process comprises the following steps: proportioning and melting, forming, annealing, nucleation and crystallization, repeated vacuum heat treatment and the like. According to the process, melting, annealing and crystallization temperature and time are reasonably selected, so the colored lithium disilicate microcrystalline glass has the advantages of uniform color, no chromatic aberration and favorable semi-permeability and accords with bioesthetics; process flow is simple, and coloring is rapid; the usage of facing porcelain is avoided, so cost is low; a crystal phase in the lithium disilicate glass can be effectively improved through proper repeated heat treatment steps; mechanical strength is improved; and the semitransparent degree and the surface gloss of the glass are effectively improved on the basis of color stabilization.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

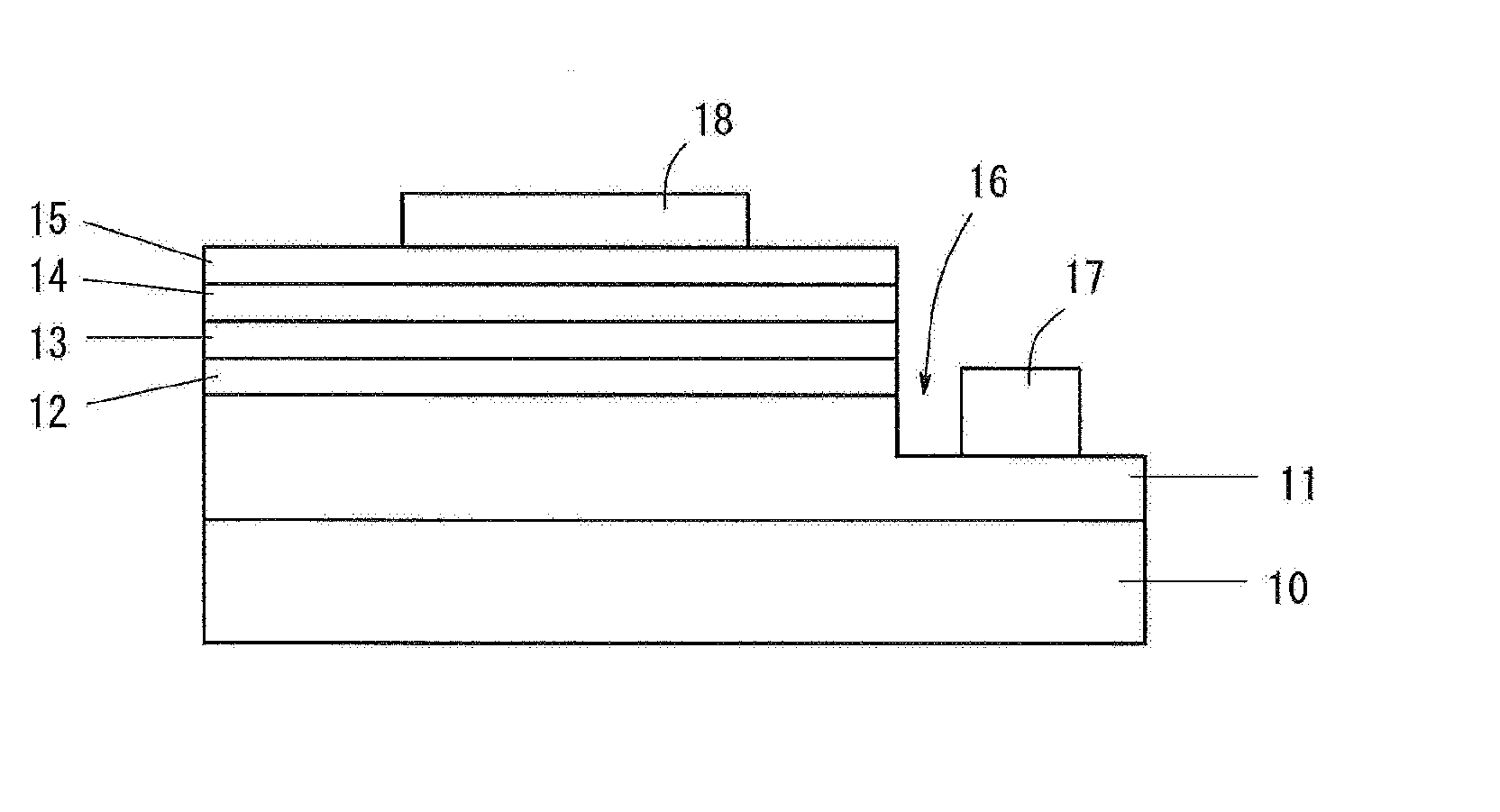

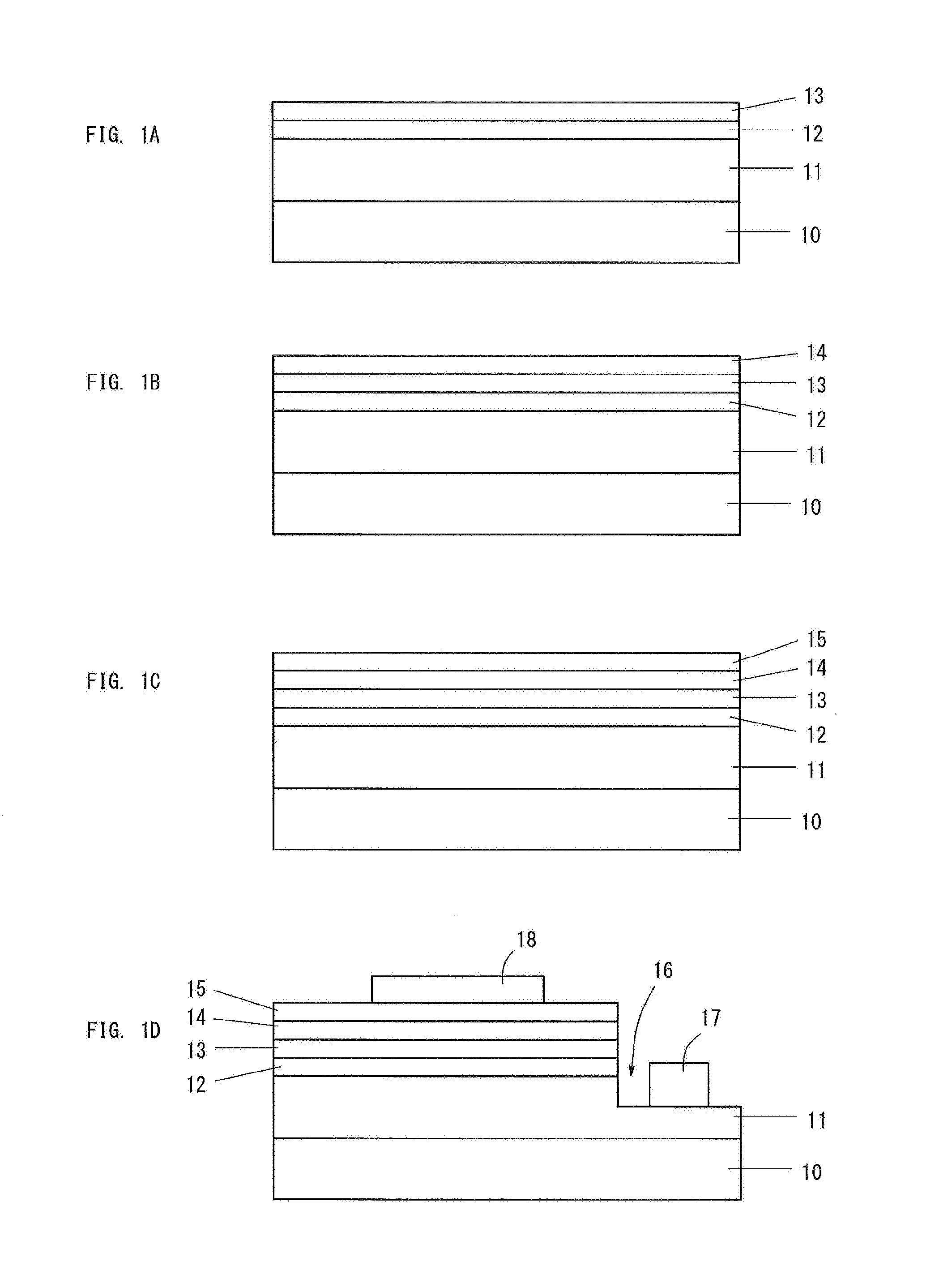

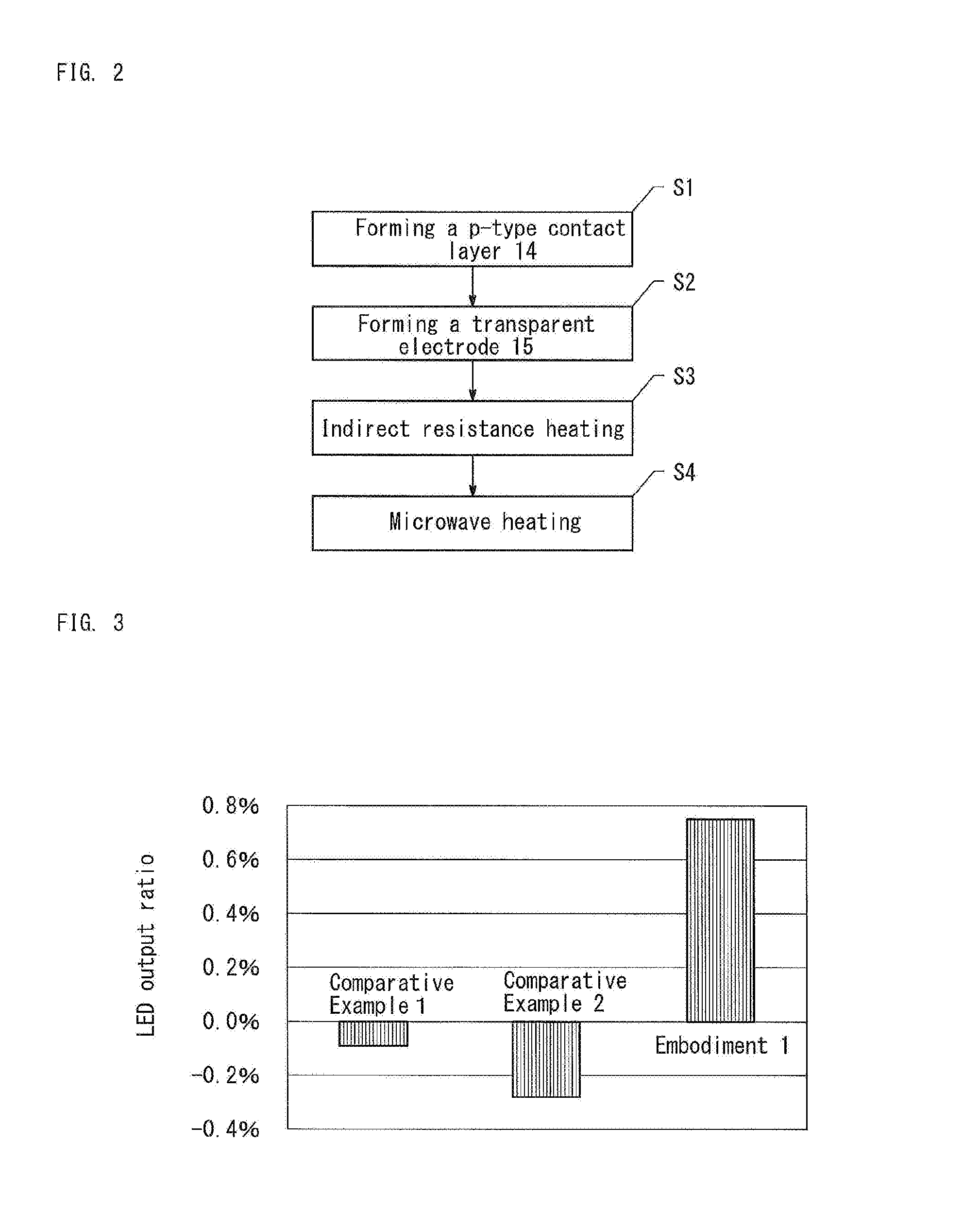

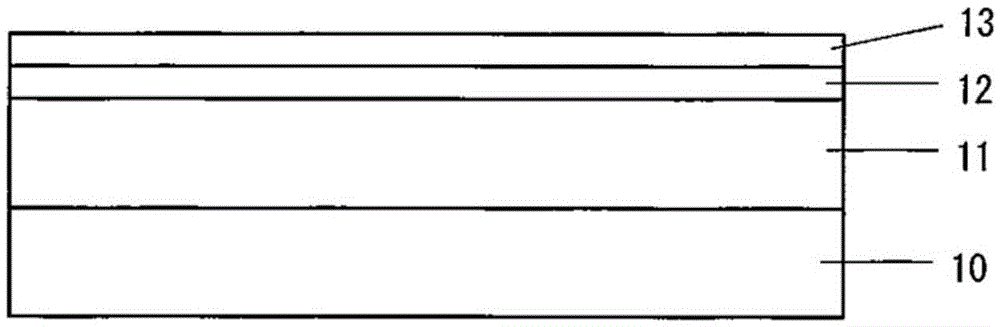

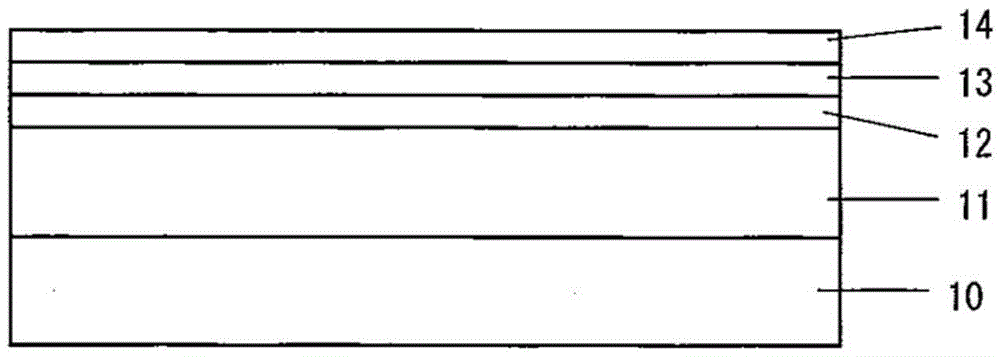

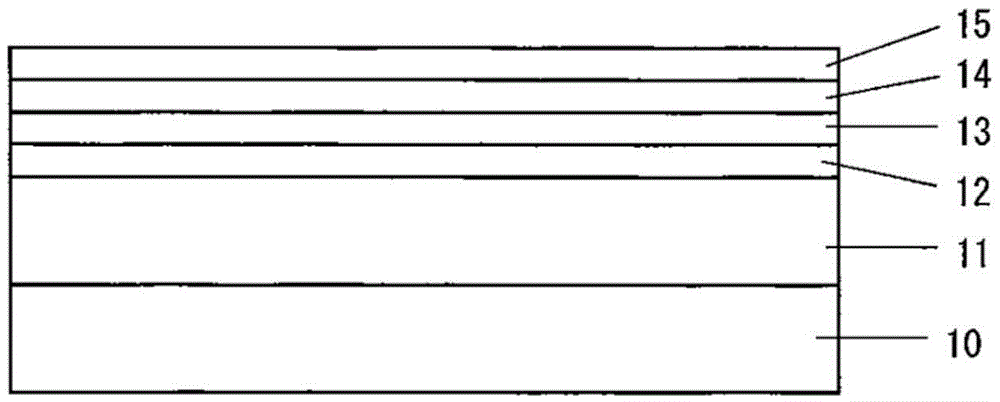

Method for producing a semiconductor device

ActiveUS20160211418A1StrainReduce light absorptionSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumGas phase

The present invention provides a method for producing a semiconductor device exhibiting the improved emission efficiency by reducing a strain between a p-contact layer and a transparent electrode. A transparent electrode made of IZO (Zinc-doped Indium Oxide) was formed on a p-type contact layer by vapor deposition or sputtering. Subsequently, a p-type cladding layer and a p-type contact layer were p-type activated and a transparent electrode was crystallized by indirect resistance heating. This heat treatment was performed under a reduced pressure at a temperature of 700° C. Next, microwave heating was performed for three to thirty minutes at a temperature of 100° C. to 350° C. by microwave irradiation with a frequency of 5.8 GHz in a nitrogen atmosphere. This reduced a strain of the transparent electrode, and improved the conductivity or translucency of the transparent electrode.

Owner:TOYODA GOSEI CO LTD

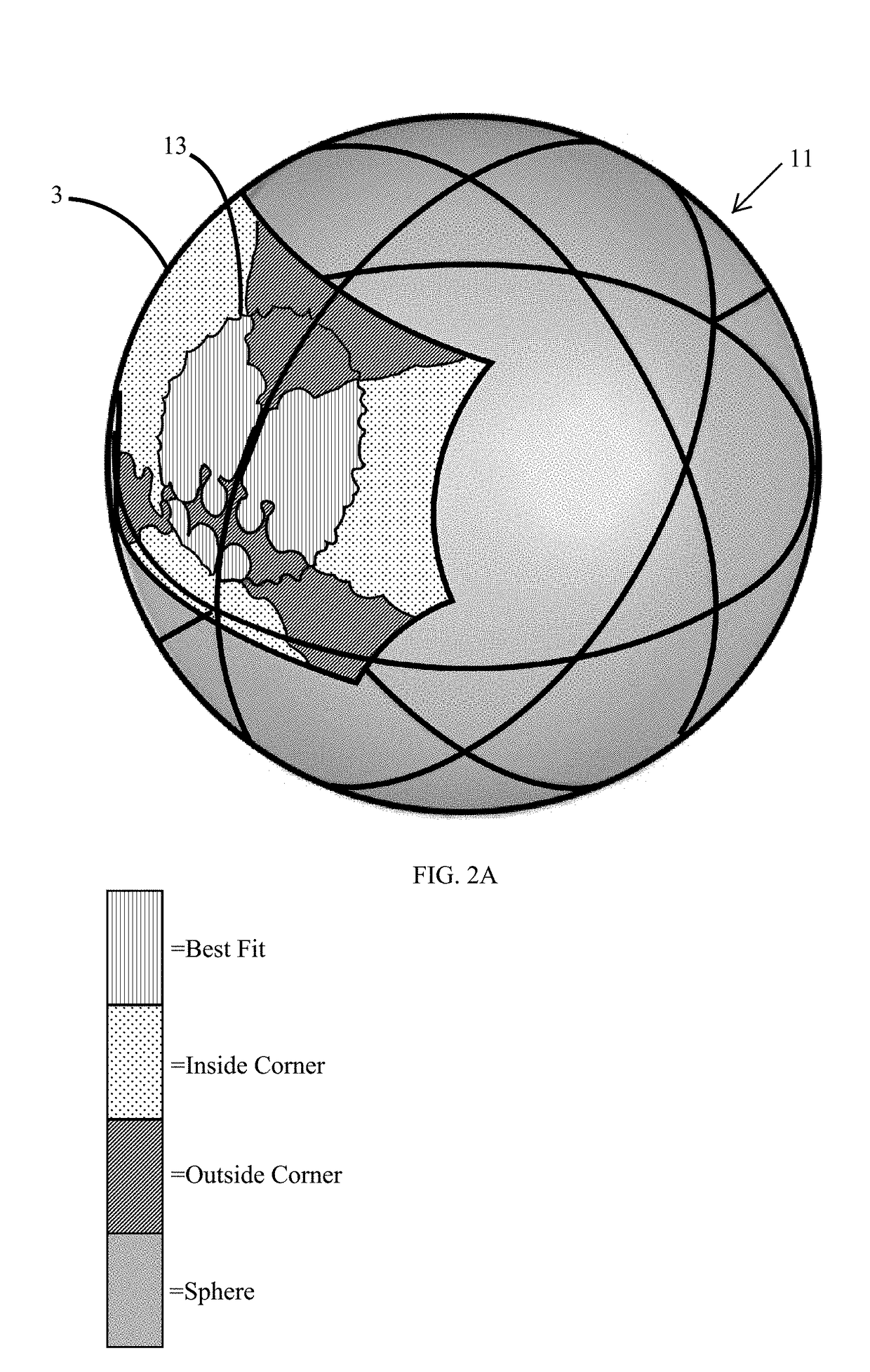

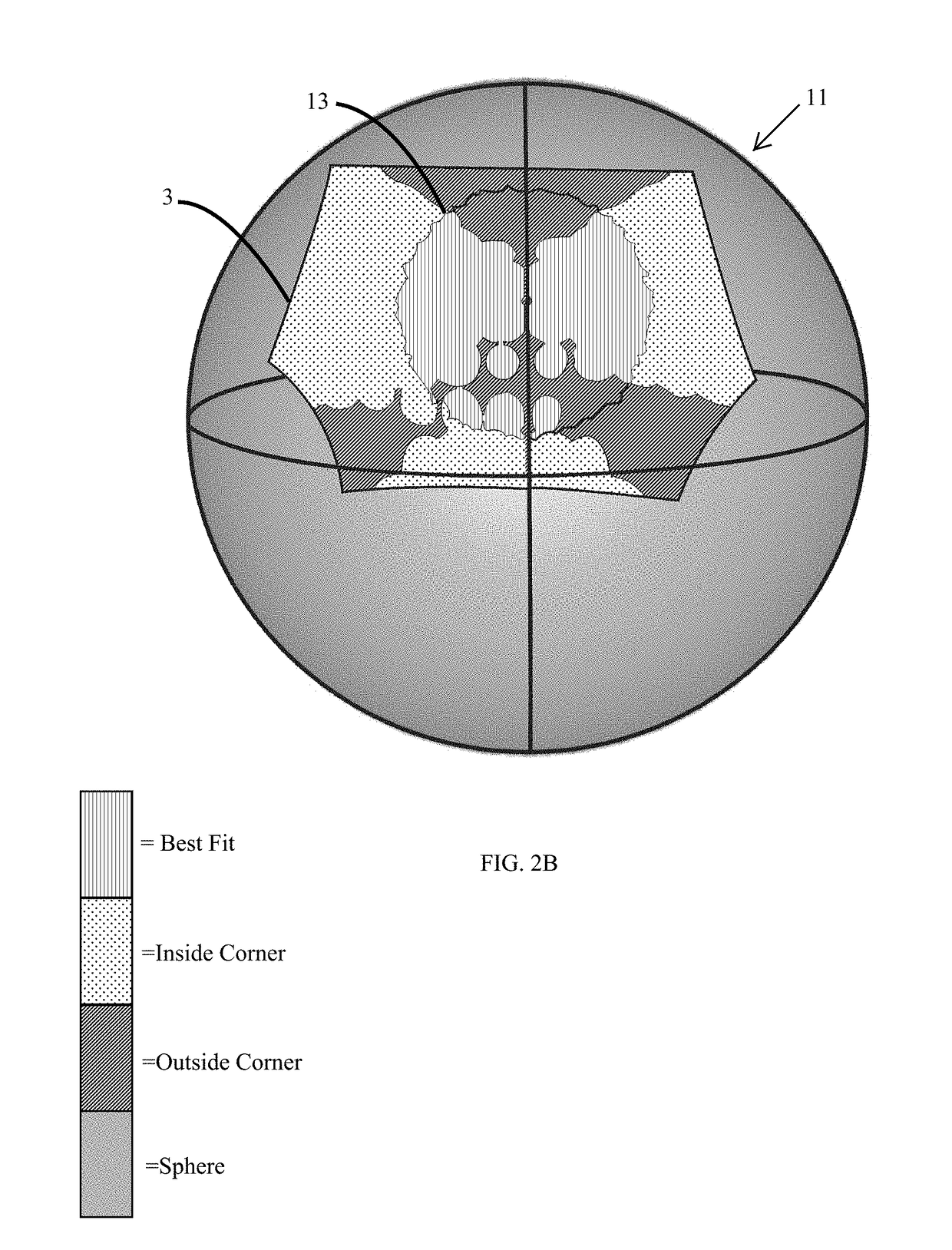

Rigid articles having a well-defined corner

ActiveUS20190061983A1Achieve recyclabilityReduced formulation complexityBottlesDomestic articlesEngineeringMechanical engineering

Owner:THE PROCTER & GAMBLE COMPANY

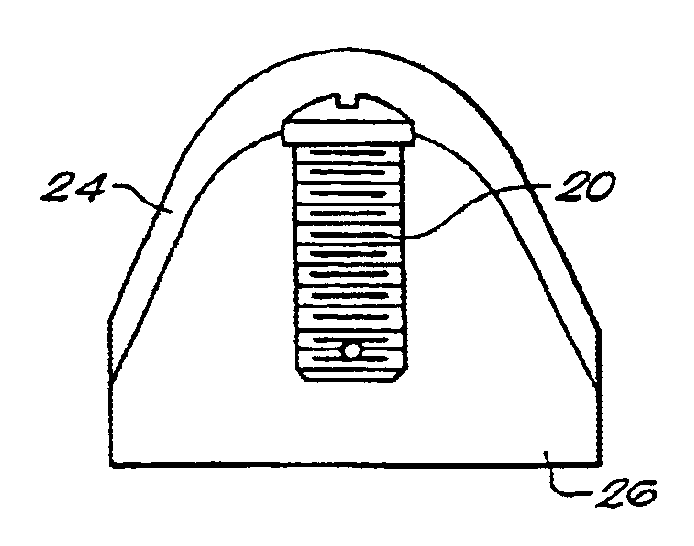

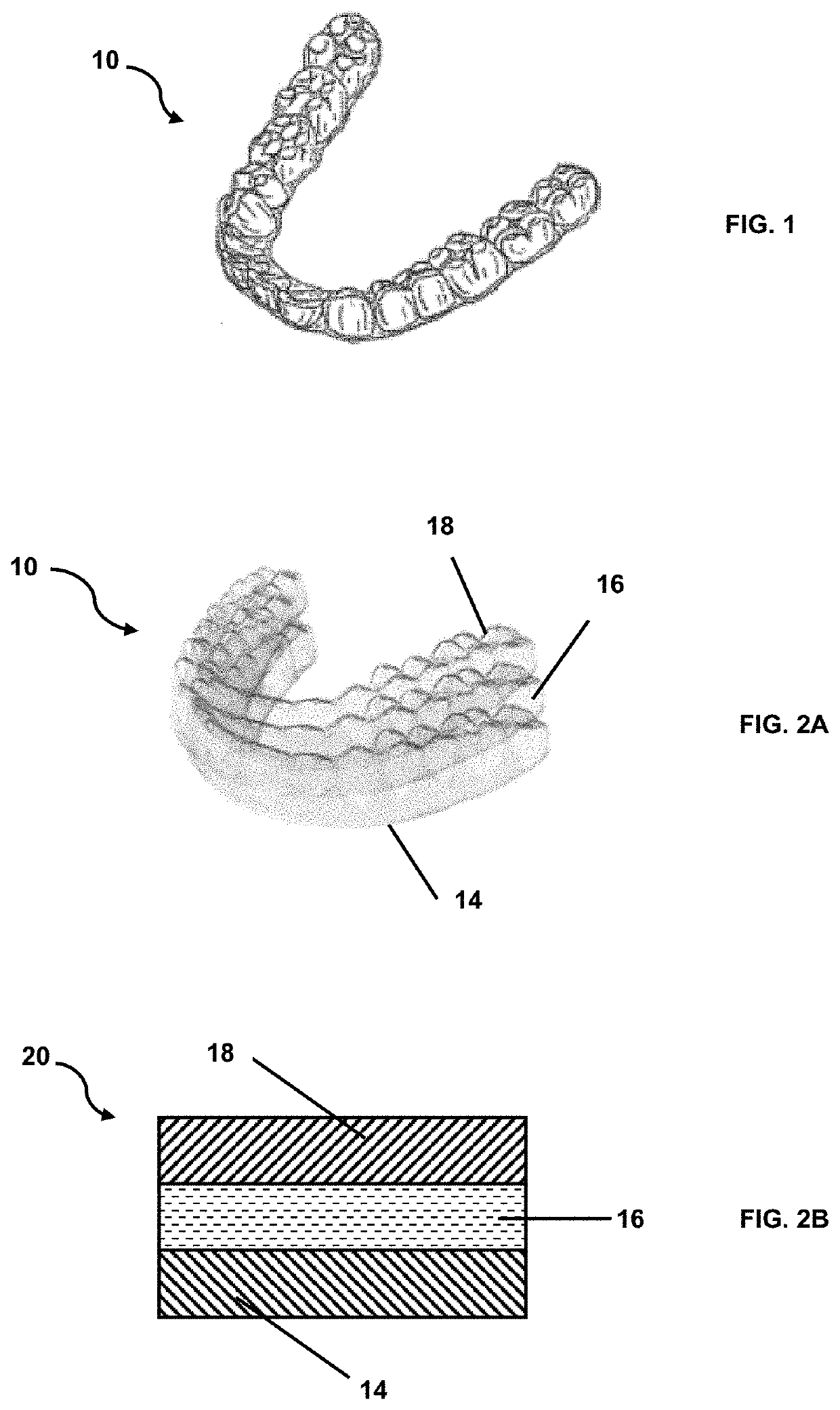

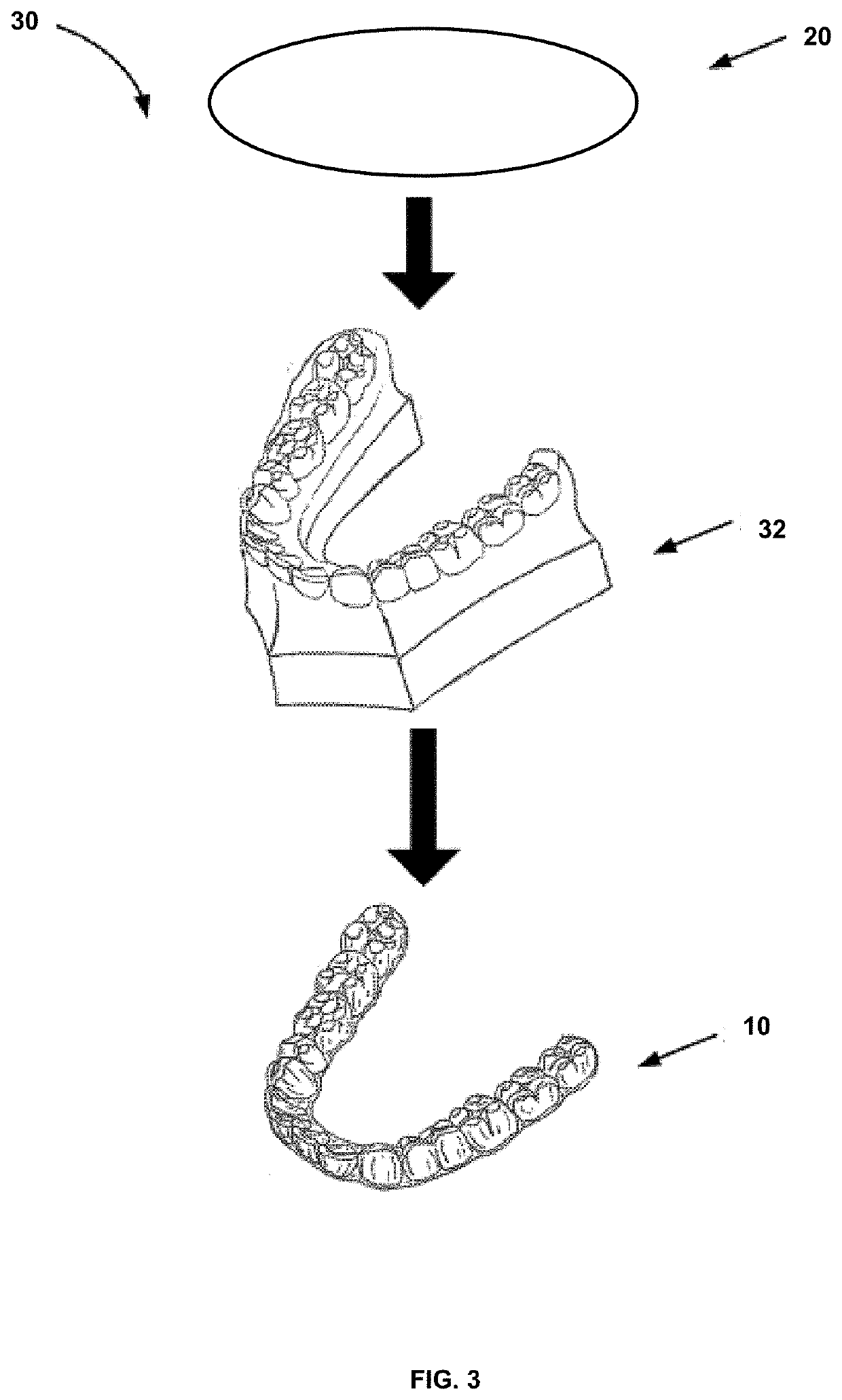

Orthodontic appliances and materials

PendingUS20210137642A1Increase translucencyIncrease heatOthrodonticsSynthetic resin layered productsHuman eyeBiomedical engineering

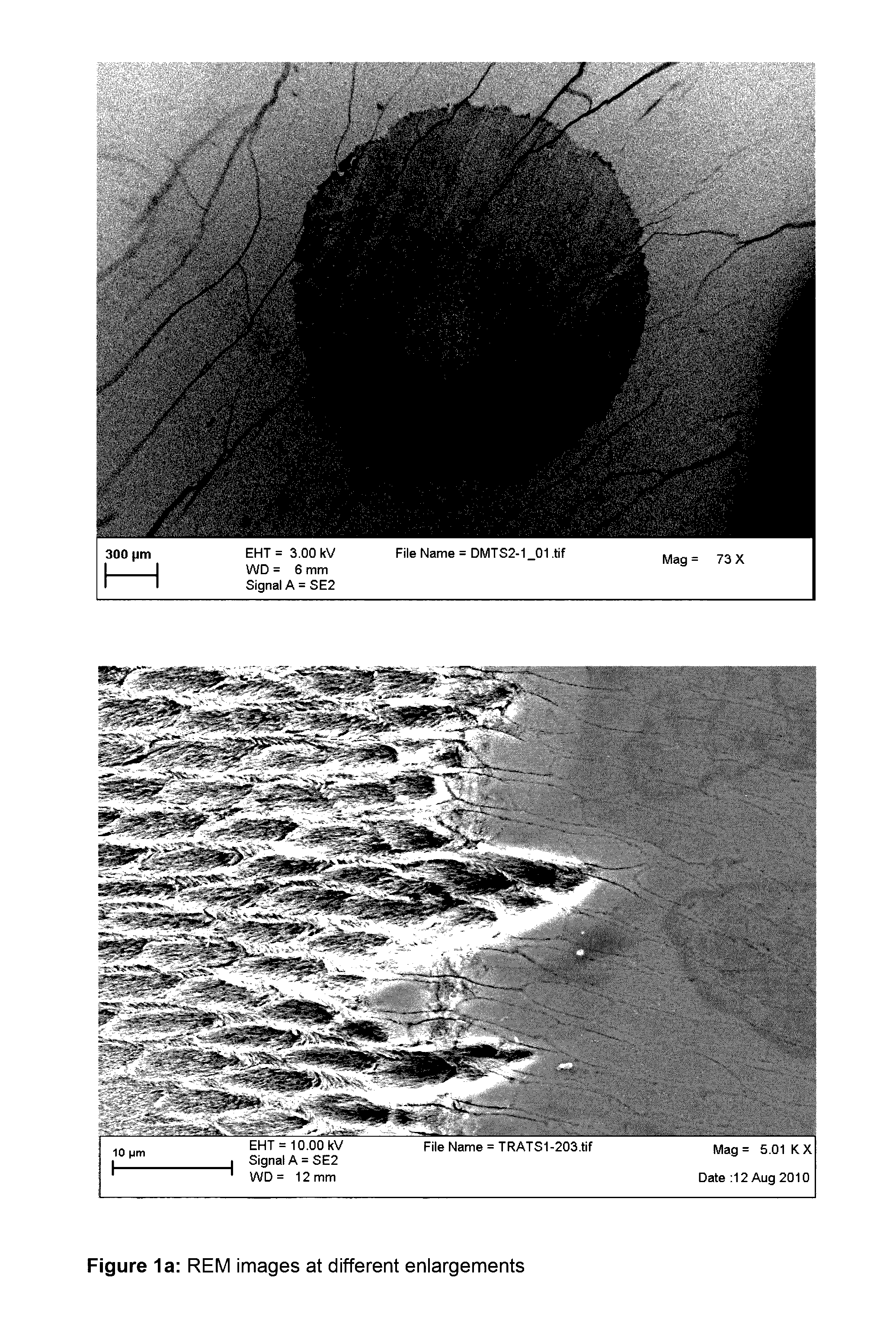

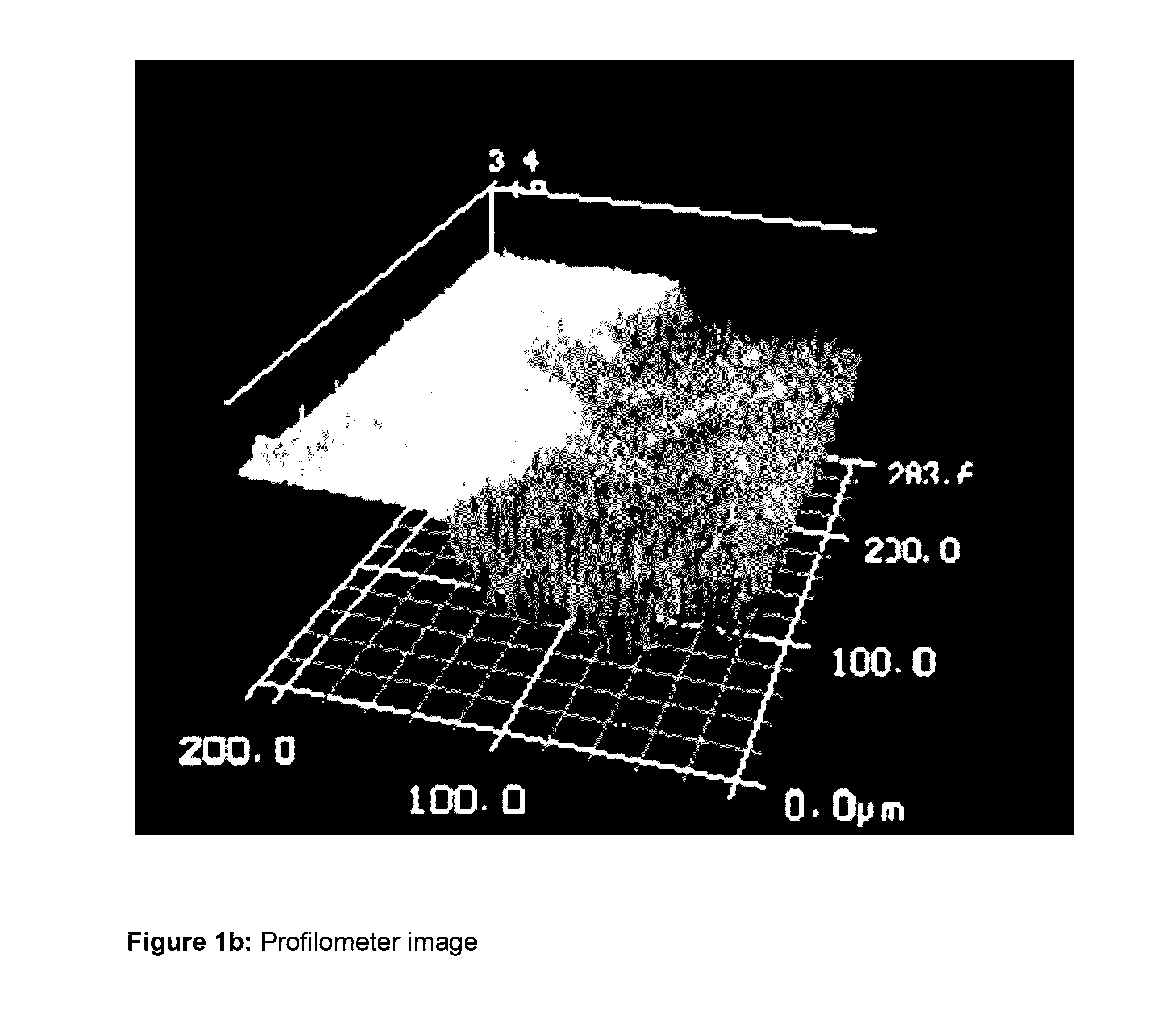

An orthodontic appliance shaped to receive teeth. The orthodontic appliance can be constructed from a laminate structure with a outer transparent layer and an inner translucent layer. The translucent layer can scatter light to decrease a relative degree or perceived gloss to the human eye, and hence provide a more natural appearance to the orthodontic appliance.

Owner:SMYLIO INC

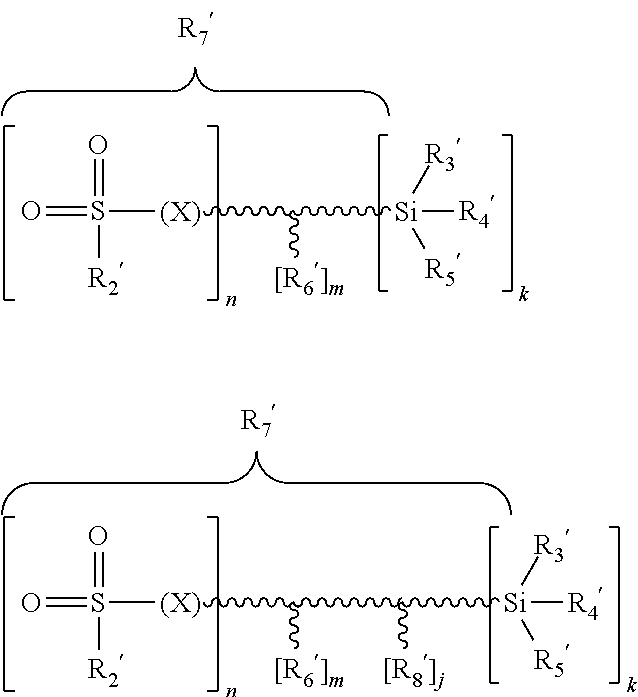

Compounds containing (meth)acrylate groups and sulfonate or sulfate groups, polymers and condensates therefrom and use of the polymers and condensates

ActiveUS20160297901A1Improve etching effectEasy to mergeGroup 4/14 element organic compoundsImpression capsMeth-Carboxylic acid

A compound has at least three functionalities, including a first functionality (a) that is a sulfonate group or a sulfate group of the formula —(O)d—SO3M with d=0 or 1 and with M=hydrogen or a monovalent metal cation or a corresponding portion of a multivalent metal cation; a second functionality (b) that is a (meth)acryl residue; and a third functionality (c) that is a carboxylic acid function and / or a thioether group. When the compound is free of silicon, the sulfonate or sulfate group and the (meth)acryl residue are separated from each other by a hydrocarbon-containing residue having a carbon chain. The carbon chain is interrupted by S or NH, or the carbon chain contains a linking group, selected from C(O)NH, NHC(O), NR8C(O), NHC(O)O, NR8C(O)O, NHC(O)NH, C(O)NHC(O) and —C(O)S—, wherein R8 is alkyl or alkenyl or a (meth)acryl group.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Compounds containing (meth)acrylate groups and sulfonate or sulfate groups, polymers and condensates therefrom and use of the polymers and condensates

ActiveUS9745391B2Improve etching effectEasy to mergeGroup 4/14 element organic compoundsImpression capsMeth-Carboxylic acid

A compound has at least three functionalities, including a first functionality (a) that is a sulfonate group or a sulfate group of the formula —(O)d—SO3M with d=0 or 1 and with M=hydrogen or a monovalent metal cation or a corresponding portion of a multivalent metal cation; a second functionality (b) that is a (meth)acryl residue; and a third functionality (c) that is a carboxylic acid function and / or a thioether group. When the compound is free of silicon, the sulfonate or sulfate group and the (meth)acryl residue are separated from each other by a hydrocarbon-containing residue having a carbon chain. The carbon chain is interrupted by S or NH, or the carbon chain contains a linking group, selected from C(O)NH, NHC(O), NR8C(O), NHC(O)O, NR8C(O)O, NHC(O)NH, C(O)NHC(O) and —C(O)S—, wherein R8 is alkyl or alkenyl or a (meth)acryl group.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

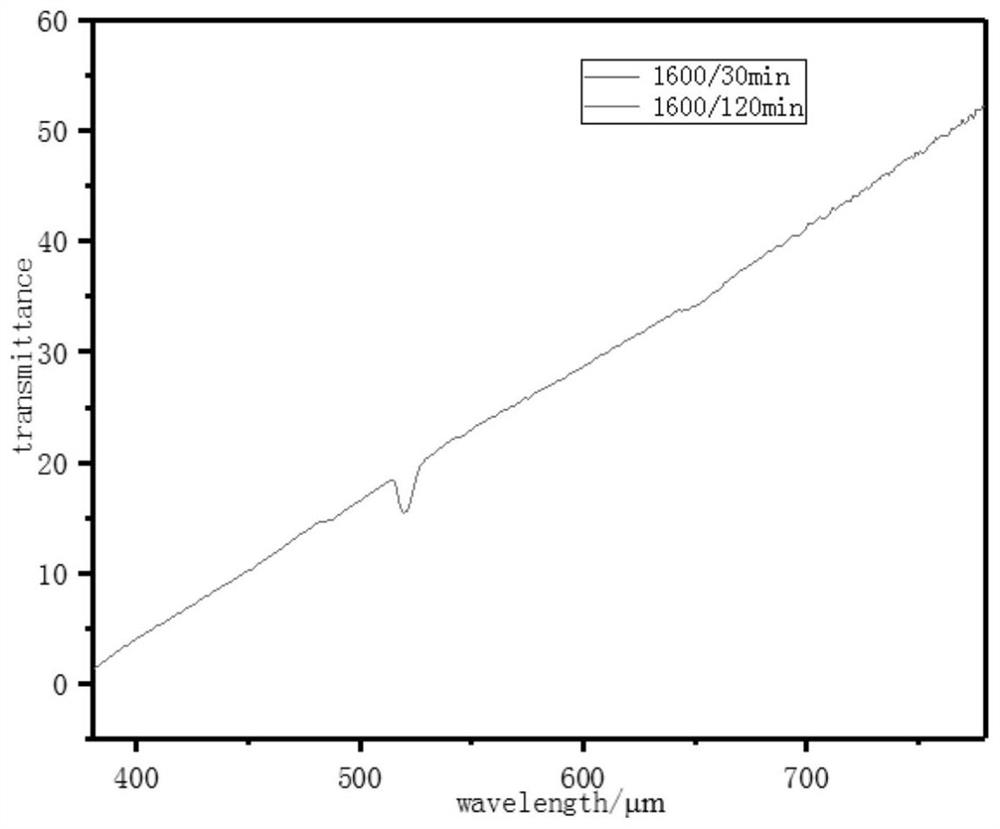

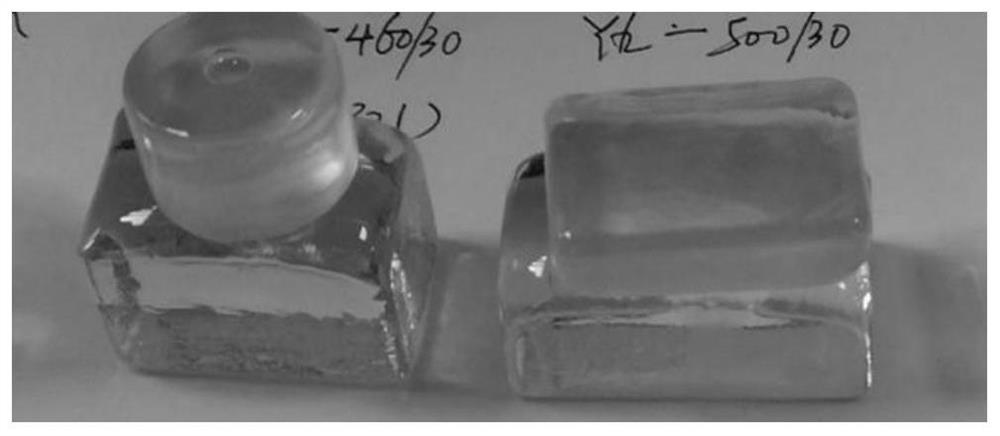

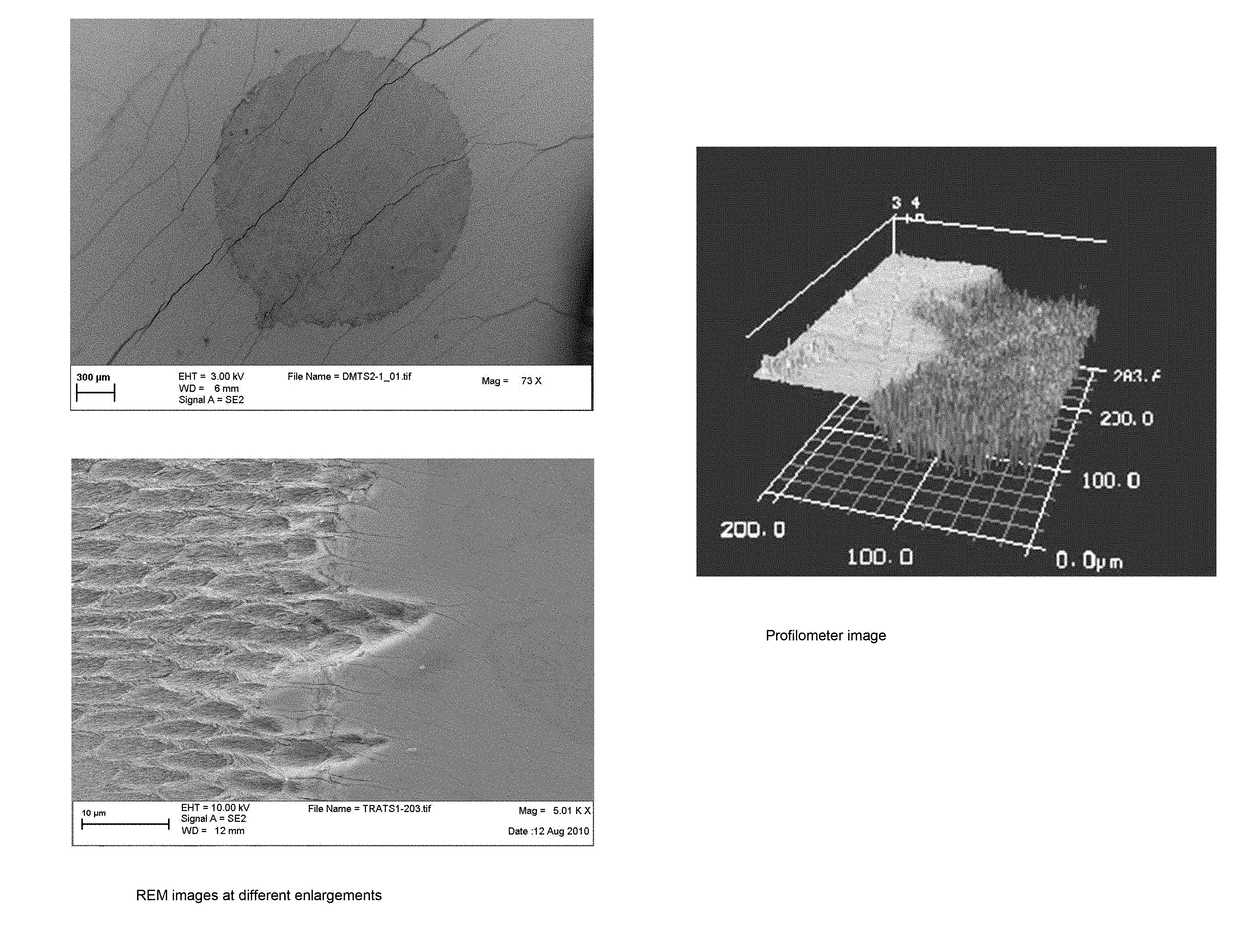

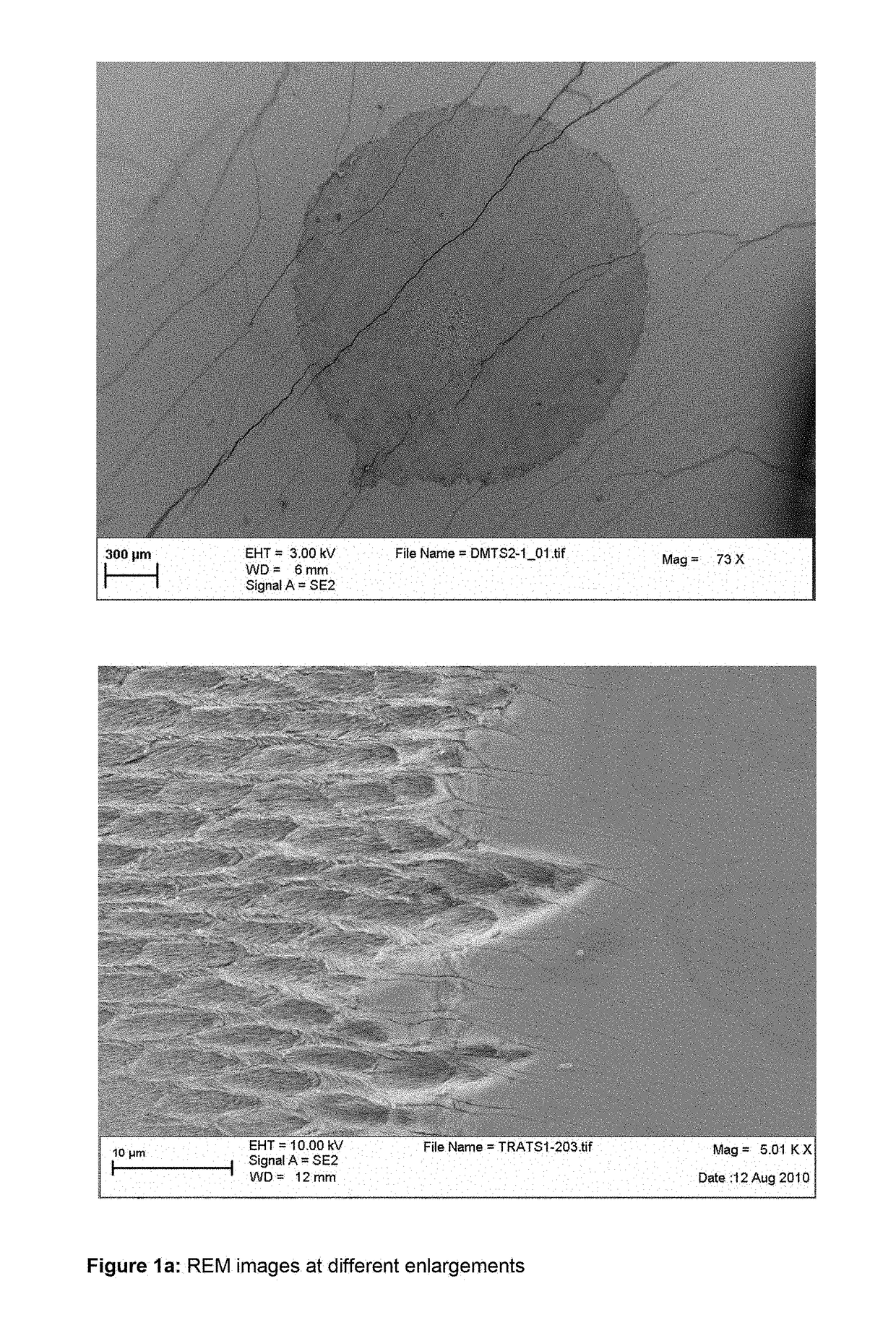

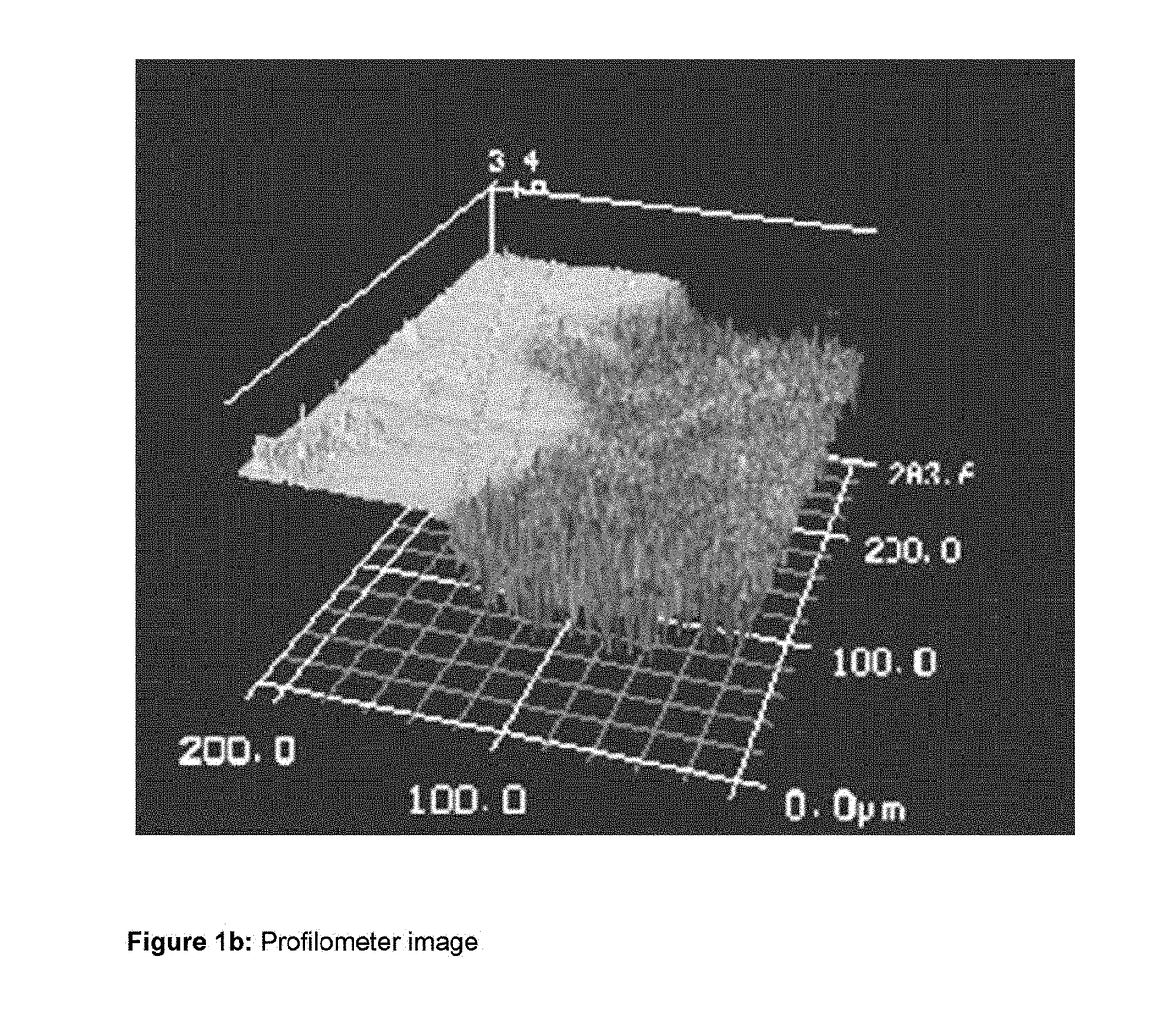

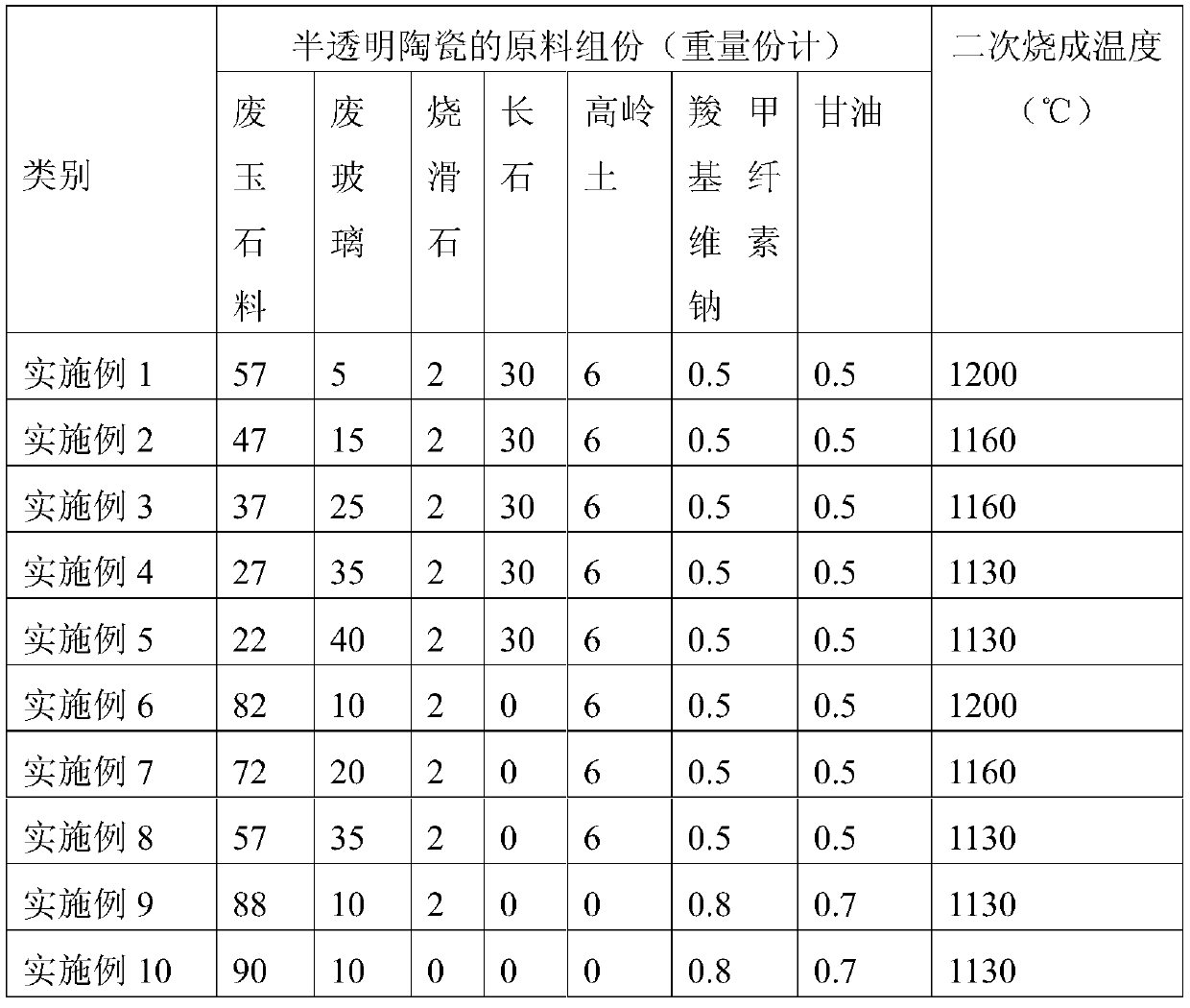

Translucent ceramics and methods of making the same

The invention provides semitransparent ceramic and a production method thereof. The semitransparent ceramic comprises, by weight, 22-100 parts of waste jade material, 0-40 parts of waste glass, 0-2 parts of calcined talcum, 0-30 parts of feldspar, 0-6 parts of kaolin, 0.2-0.8 part of sodium carboxymethyl cellulose and 0-0.7 part of glycerin. The production method includes: processing and evenly mixing the needed raw materials to obtain a mud material; repeatedly kneading the mud material until even mixing is achieved, then wrapping the mud material with wet cloth for standby, sufficiently drying bases according to the different required shapes of the bases, and performing secondary calcining under 1130 DEG C, 1160 DEG C or 1200 DEG C. The semitransparent ceramic and the production method have the advantages that the waste jade material is used as the main raw material, the glass-phase content in the bases is increased by the waste glass to increase the transparency of the bases, and the production method is simple in process, easy to operate, low in raw material cost, high in practicality and capable of achieving industrial production.

Owner:HENAN POLYTECHNIC UNIV

Diatom ecological brick and production method thereof

The invention discloses a diatom-containing ecological brick and a production method thereof. The diatom-containing ecological brick is prepared from the following raw materials in parts by weight: 20-50 parts of diatomaceous earth, 1-3 parts of composite catalyst, 1-3 parts of nano-silver antibacterial agent, 10-30 parts of lithium feldspar, 10-30 parts of albite, 10-30 parts of wollastonite, 1-5 parts of pigment, 10-26 parts of 30% sodium silicate water solution adhesive and 4-12 parts of water. The raw materials are prepared into a finished product by the processes of dry-mixing, wet-mixing, pelleting, drying, compression moulding, drying, firing, cooling, checking and the like. The product provided by the invention is made from pure inorganic materials, and does not easily mold; the diatom-containing ecological brick is laid onto a wall by a dry method during construction, thus being convenient in construction, short in period, high in efficiency and low in cost; compared with a diatom ooze-containing decoration wall material, the strength and water resistance of the diatom-containing ecological brick are remarkably improved, and the service life of the diatom-containing ecological brick is remarkably prolonged.

Owner:营口盼盼硅藻材料集团有限公司

Preparation technology of black tea pearl rice

The invention discloses a preparation technology of black tea pearl rice. The preparation method comprises the following steps of: extracting concentrated solutions of black tea, green tea, corn stigma, poria cocos and radix puerariae respectively, and uniformly mixing the concentrated solutions with the prepared oyster mushroom slurry, tremella slurry, ramie oil and hippophae rhamnoides powder; stirring the mixture with corn powder, millet powder and polished round-grained rice powder to obtain granules; performing the puffing and extrusion processes with granulation equipment, and forming with a die to obtain golden yellow and bright black tea pearl rice the same as rice grains; and drying, finishing, sterilizing and packing to obtain a finished product.

Owner:王跃进

Method for producing a semiconductor device

ActiveCN105810782AReduce strainReduce light absorptionSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumGas phase

The present invention provides a method for producing a semiconductor device exhibiting the improved emission efficiency by reducing a strain between a p-contact layer and a transparent electrode. A transparent electrode made of IZO (Zinc-doped Indium Oxide) was formed on a p-type contact layer by vapor deposition or sputtering. Subsequently, a p-type cladding layer and a p-type contact layer were p-type activated and a transparent electrode was crystallized by indirect resistance heating. This heat treatment was performed under a reduced pressure at a temperature of 700 degrees centigrade. Next, microwave heating was performed for three to thirty minutes at a temperature of 100 degrees centigrade to 350 degrees centigrade by microwave irradiation with a frequency of 5.8 GHz in a nitrogen atmosphere. This reduces a strain of the transparent electrode, and improves the conductivity or translucency of the transparent electrode.

Owner:TOYODA GOSEI CO LTD

Hua celadon and preparation method thereof

Owner:淄博华光国瓷科技文化有限公司

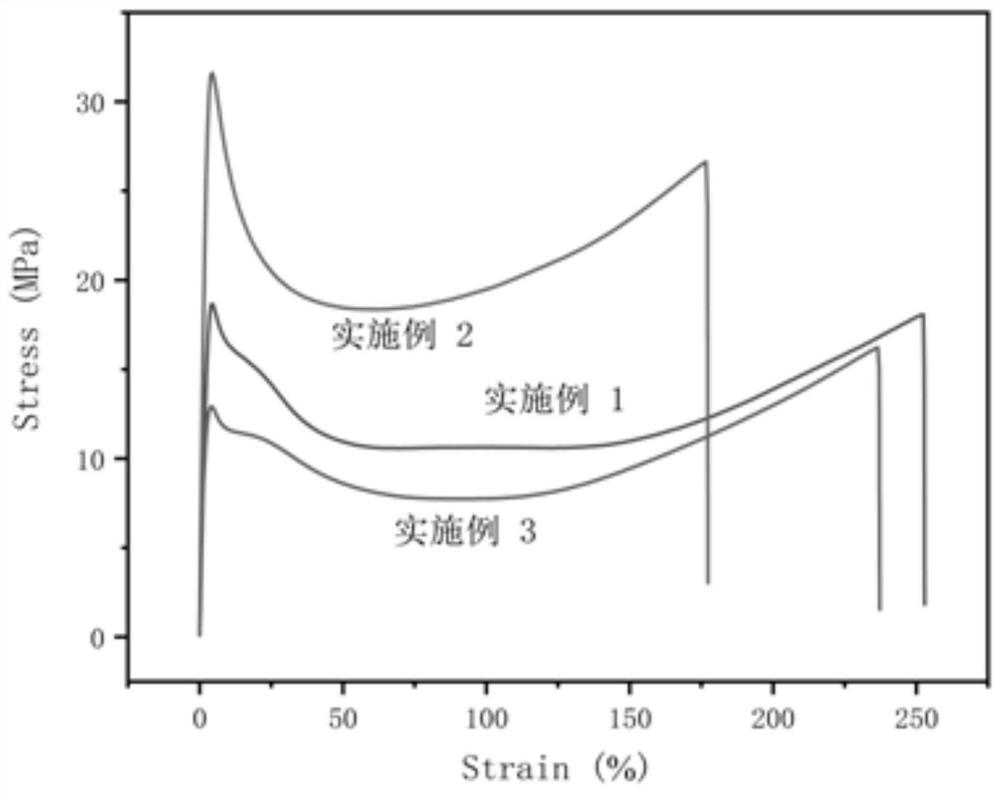

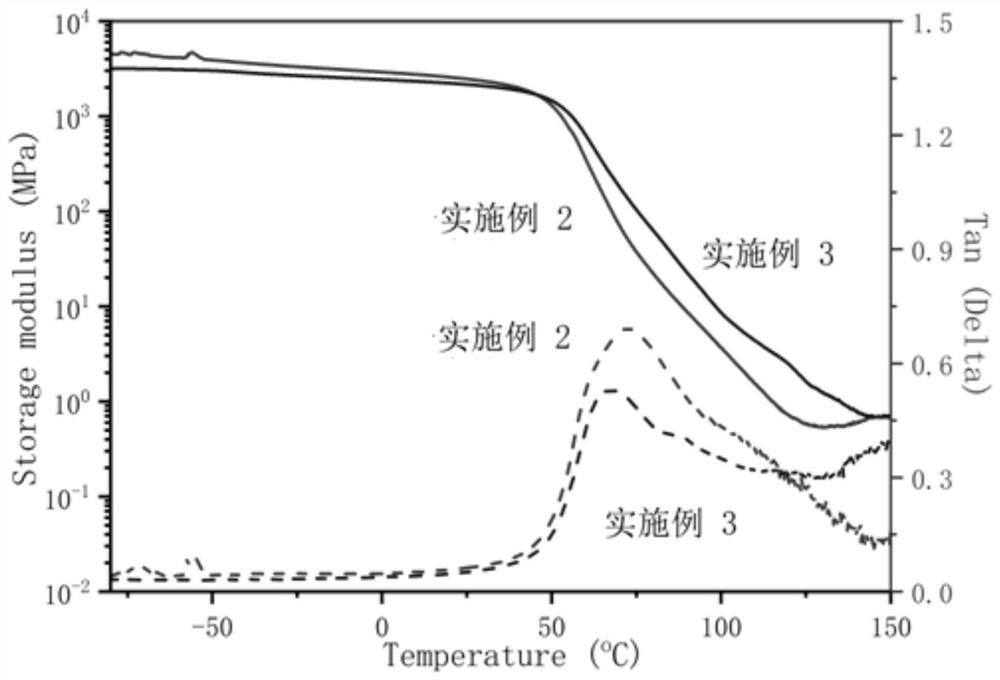

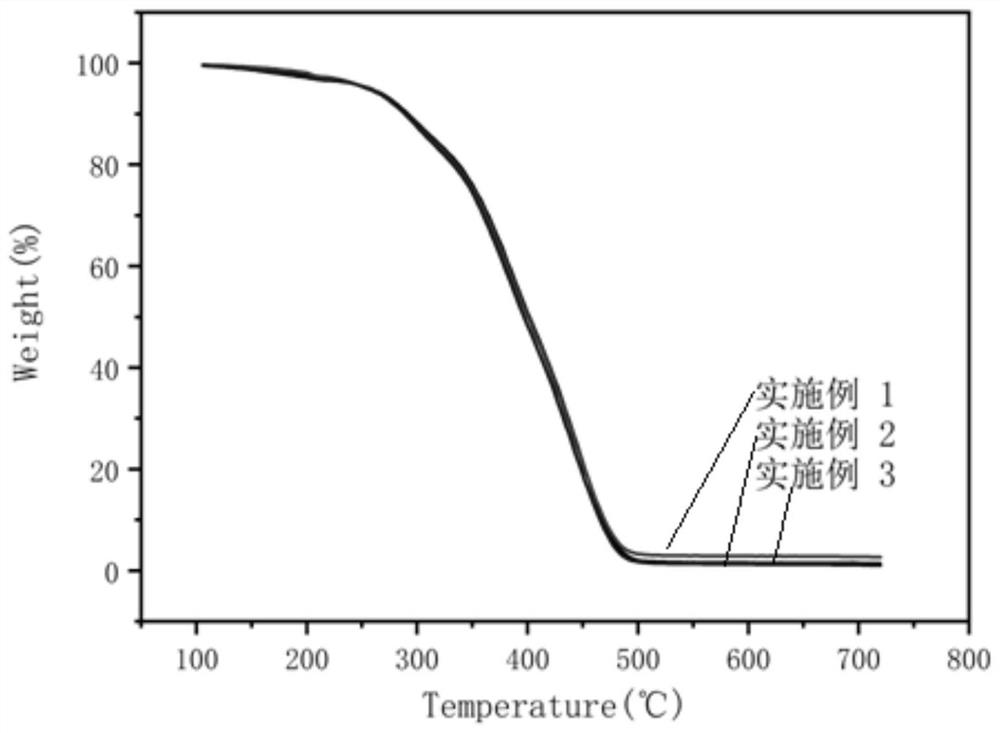

High-performance dynamic cross-linked polymer based on vinyl hydrazide bond and preparation method

The invention relates to the field of polymer materials, and relates to a high-performance dynamic crosslinked polymer based on vinyl hydrazide bonds and a preparation method thereof. The ratio of raw materials is: 5-50 parts of diacetoacetate-based monomers, two 5-50 parts of hydrazide monomer, 10-80 parts of acetoacetated polyester or acetoacetated polyether polyol monomer or amino-terminated polyether monomer, and 0.1-50 parts of crosslinking agent. The raw material monomer involved in the present invention has a simple structure, is easy to obtain, and has an easy synthesis process and is extremely easy to prepare in batches. The material has excellent mechanical properties, self-healing properties as well as recyclability and thermal stability.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com