Method for producing a semiconductor device

一种半导体、氮化物半导体的技术,应用在半导体器件、半导体/固态器件制造、电气元件等方向,能够解决透明电极没有充分结晶等问题,达到减少光吸收、减少应变、提高半透明性和导电性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

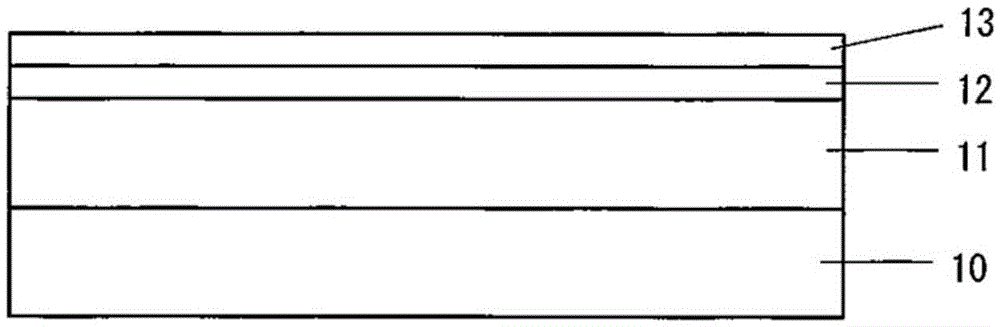

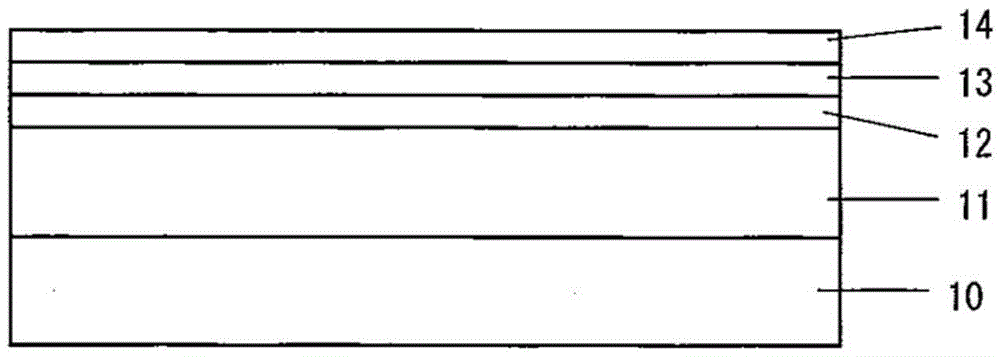

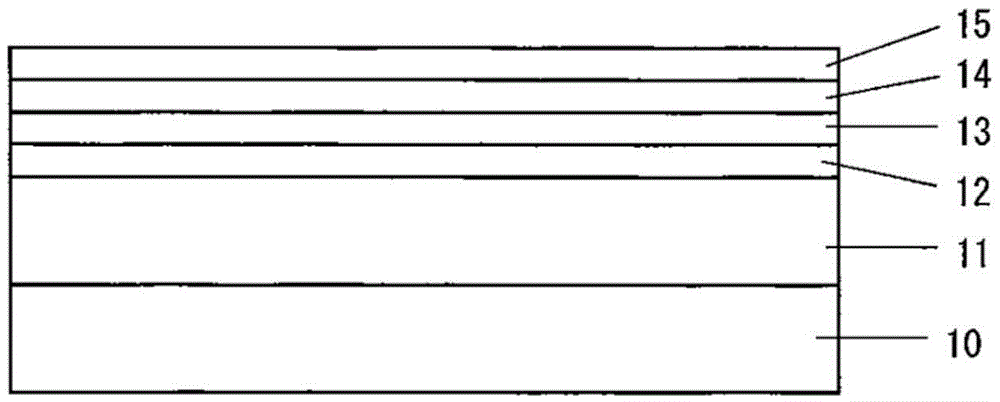

[0024] Figure 1A to Figure 1D is a schematic diagram showing a process for forming a light emitting device according to Embodiment Mode 1. FIG. figure 2 is a flowchart showing a part of the process for manufacturing the light emitting device according to Embodiment Mode 1 (before and after forming the transparent electrode 15 ). Next will refer to Figure 1A to Figure 1D with figure 2 A process for manufacturing a Group III nitride semiconductor light emitting device according to Embodiment Mode 1 will be described.

[0025] First, a sapphire substrate 10 is prepared, and heat-treated in a hydrogen atmosphere to remove impurities adhering to the surface. Next, an AlN buffer layer (not shown) is formed on the sapphire substrate 10, and an n-type layer 11, a light-emitting layer 12 and a p-type cladding layer 13 are sequentially deposited on the buffer layer by MOCVD ( Figure 1A ).

[0026] Each of n-type layer 11, light-emitting layer 12, and p-type cladding layer 13 may...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com