Vascular bypass grafting instrument and method

a vascular bypass and grafting technology, applied in the field of fasteners and delivery instruments, can solve the problems of localized death of living tissue, eventual failure of repair, and generally faster stapling, so as to reduce heart strain, reduce force requirements, and reduce blood loss. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

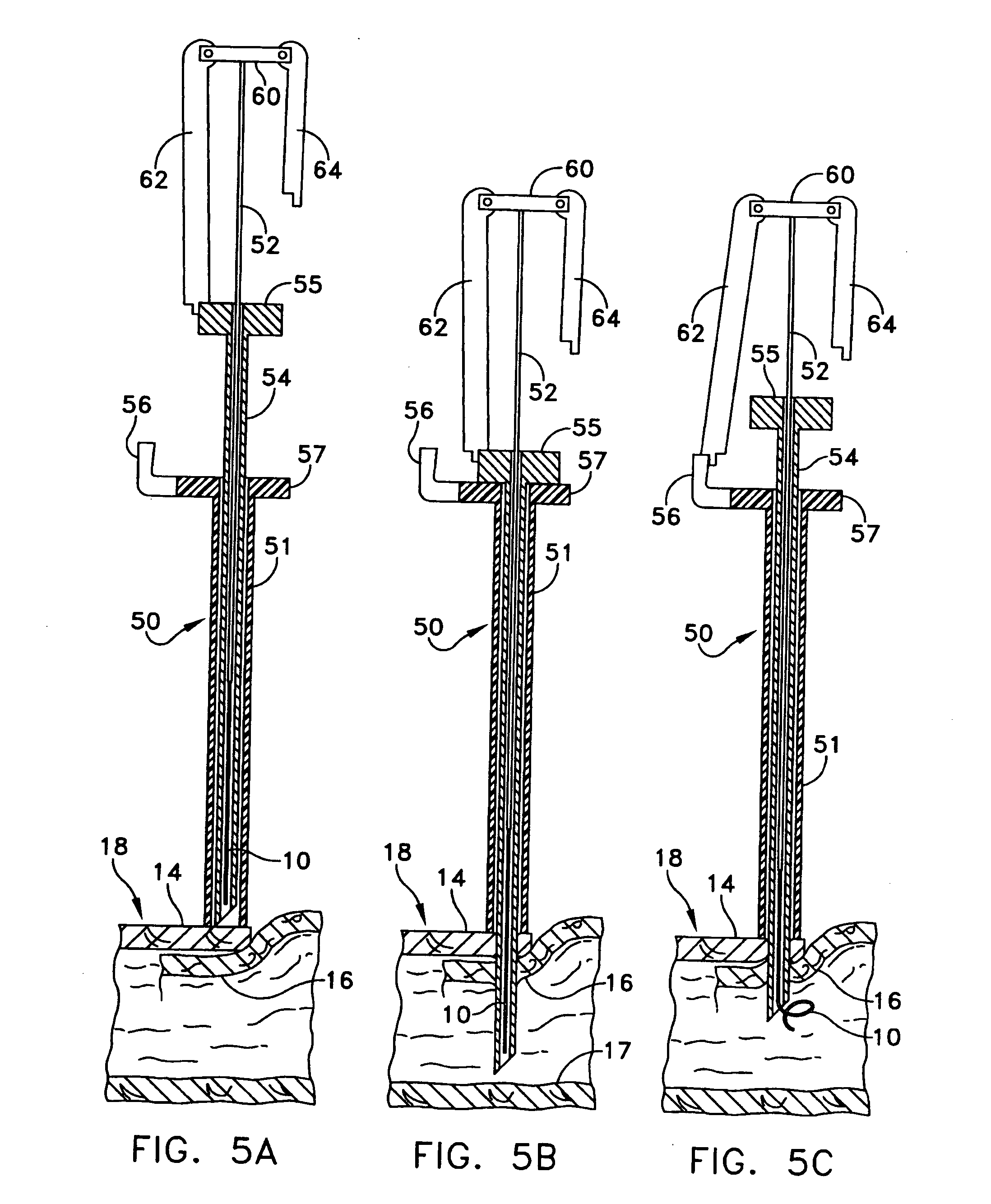

[0054]FIGS. 5A-5F show a delivery instrument 50 and the method for inserting the fastener. The delivery instrument 50 consists of a plunger 52 having a head portion 60, a needle 54 having a head portion 55, and a sleeve 51 having a head portion 57 and a stop 56. The plunger 52 fits slidingly inside a lumen of the needle 54, which fits slidingly inside of the sleeve 51. FIGS. 5A-5F show the fastener 10 being used to attach a graft (tissue; lower membrane) 16 to a blood vessel having a first layer of tissue 14 and an opposite wall 17. The fasteners described herein, however, can be used for any layers of material or tissue. Furthermore, the delivery instrument 50 can deliver any of the fasteners described herein.

[0055] Depending on the situation, support for the lower membrane 16 will be required in order to insert the fastener 10. This normally will be the rigidity of the body tissue itself or a mechanical support which is provided separately, often as an integral part of the instrum...

second embodiment

[0062]FIGS. 6A through 6F show the delivery instrument 100 which can deliver any of the fasteners described herein. The plunger 102 has a head portion 110 having both a short stop 114 and a long stop 112 attached to it. The head portion 105 of the needle 104 has two slots 116 and 118 to accept the long 112 and short 114 stops, respectively, at different times of the process. The needle 104 is slidingly accepted by sleeve 101 having a head portion 107. The tip of the delivery instrument 100, fastener 10 and needle 104 for FIGS. 6A-6F appear the same as in FIGS. 5A-5F, respectively, and are not shown for the sake of clarity.

[0063] First, as shown in FIG. 6A, the long stop 112 is brought into contact with the head portion 105 of the needle 104. The plunger 102 and needle 104 are then inserted into the tissue in unison by pushing down in the direction of arrow 120 until the needle's head portion 105 comes into contact with the sleeve's head portion 107, as shown in FIG. 6B. The needle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com