Pearl porcelain and preparation method thereof

A pearl porcelain and pearl technology, applied in clay products, other household utensils, applications, etc., can solve the problems of difficult firing control, small firing temperature range, high whiteness, translucency, mechanical strength, thermal stability, etc., to achieve Improved translucency, mechanical strength and thermal stability, improved wear resistance, and better body texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

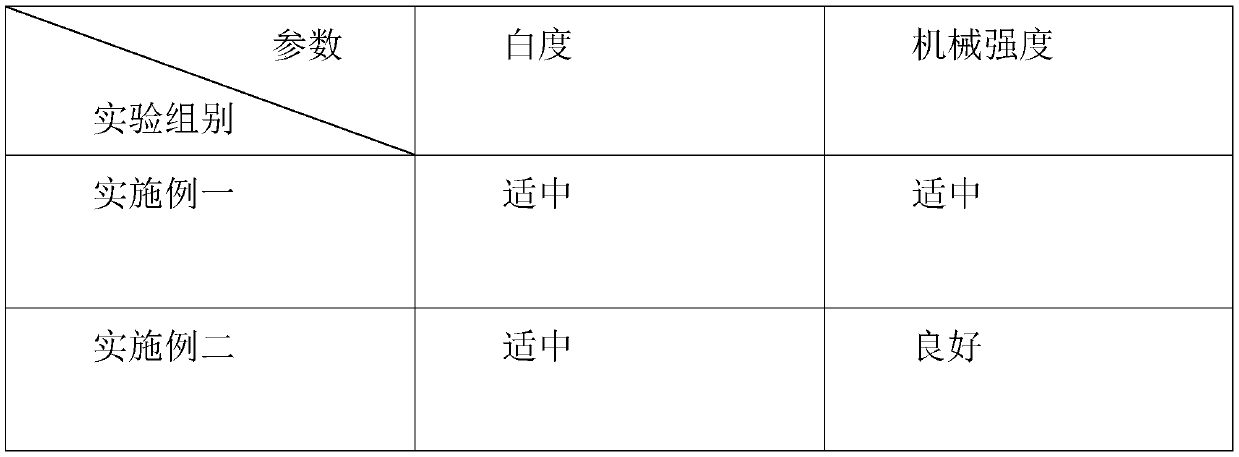

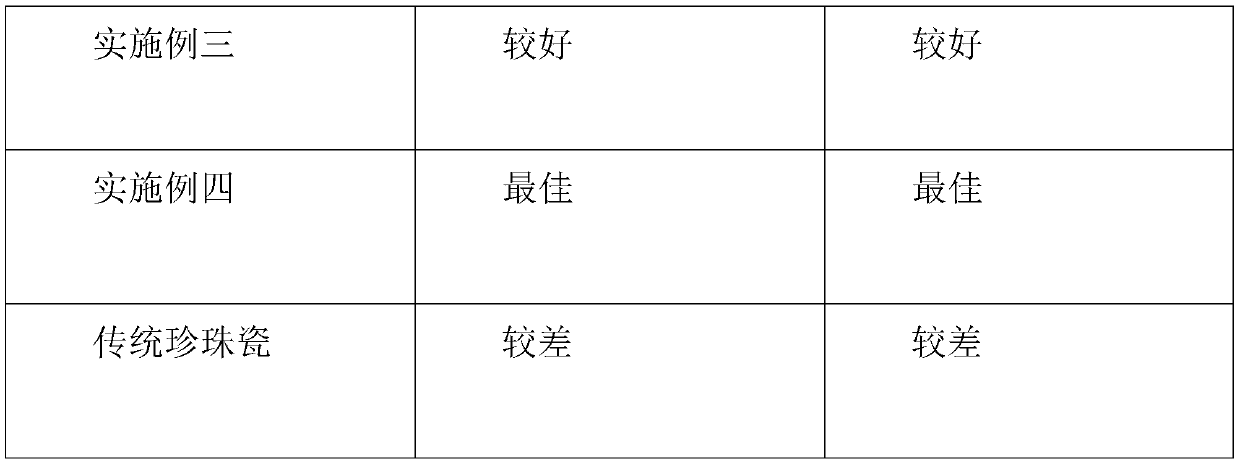

Embodiment 1

[0022] The invention provides a technical solution: pearl porcelain, the polypropylene formula includes the following components: 23% of pearl powder, 13% of feldspar, 12% of quartz, 7% of dolomite, 1% of kaolin, and 4% of lithium fluoride , 3% talc, 3% zinc oxide, 3% low-temperature frit, 5% barium carbonate, and the rest are rare earths.

[0023] A kind of preparation method of pearl porcelain as above, this preparation method comprises the following steps:

[0024] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0025] S2: drying, drying pearl powder, feldspar, quartz, dolomite, kaolin, lithium fluoride, talc, zinc oxide, low-temperature frit, barium carbonate and rare earth for use;

[0026] S3: crushing, according to the particle size required for decoration, the material obtained by crushing the dried material of S2 is made into a porcelain sand body by means of traditional production work;

[0027] S4: setting the shape, p...

Embodiment 2

[0033] The invention provides a technical solution: pearl porcelain, the polypropylene formula includes the following components: 30% of pearl powder, 8% of feldspar, 16% of quartz, 3% of dolomite, 4% of kaolin, and 1% of lithium fluoride , talc 8%, zinc oxide 0.5%, low-temperature frit 5%, barium carbonate 2%, and the rest are rare earths.

[0034] A kind of preparation method of pearl porcelain as above, this preparation method comprises the following steps:

[0035] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0036] S2: drying, drying pearl powder, feldspar, quartz, dolomite, kaolin, lithium fluoride, talc, zinc oxide, low-temperature frit, barium carbonate and rare earth for use;

[0037] S3: crushing, according to the particle size required for decoration, the material obtained by crushing the dried material of S2 is made into a porcelain sand body by means of traditional production work;

[0038] S4: setting the shape, ...

Embodiment 3

[0044] The invention provides a technical solution: pearl porcelain, the polypropylene formula includes the following components: 25% of pearl powder, 10% of feldspar, 13% of quartz, 5% of dolomite, 2% of kaolin, and 2% of lithium fluoride , talc 5%, zinc oxide 1%, low-temperature frit 3.6%, barium carbonate 3%, and the rest are rare earths.

[0045] A kind of preparation method of pearl porcelain as above, this preparation method comprises the following steps:

[0046] S1: Quantitative weighing, all raw materials are weighed according to the above components;

[0047] S2: drying, drying pearl powder, feldspar, quartz, dolomite, kaolin, lithium fluoride, talc, zinc oxide, low-temperature frit, barium carbonate and rare earth for use;

[0048] S3: crushing, according to the particle size required for decoration, the material obtained by crushing the dried material of S2 is made into a porcelain sand body by means of traditional production work;

[0049] S4: setting the shape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com