Patents

Literature

99results about How to "Improve color display" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

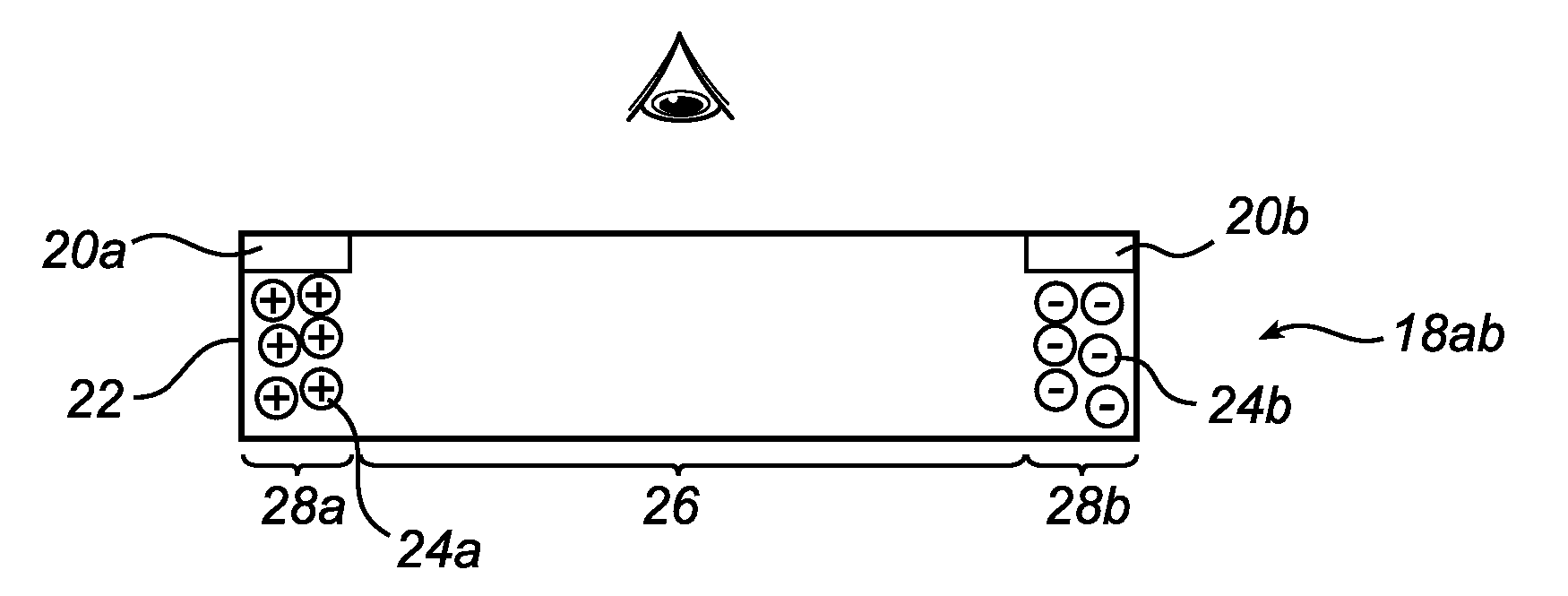

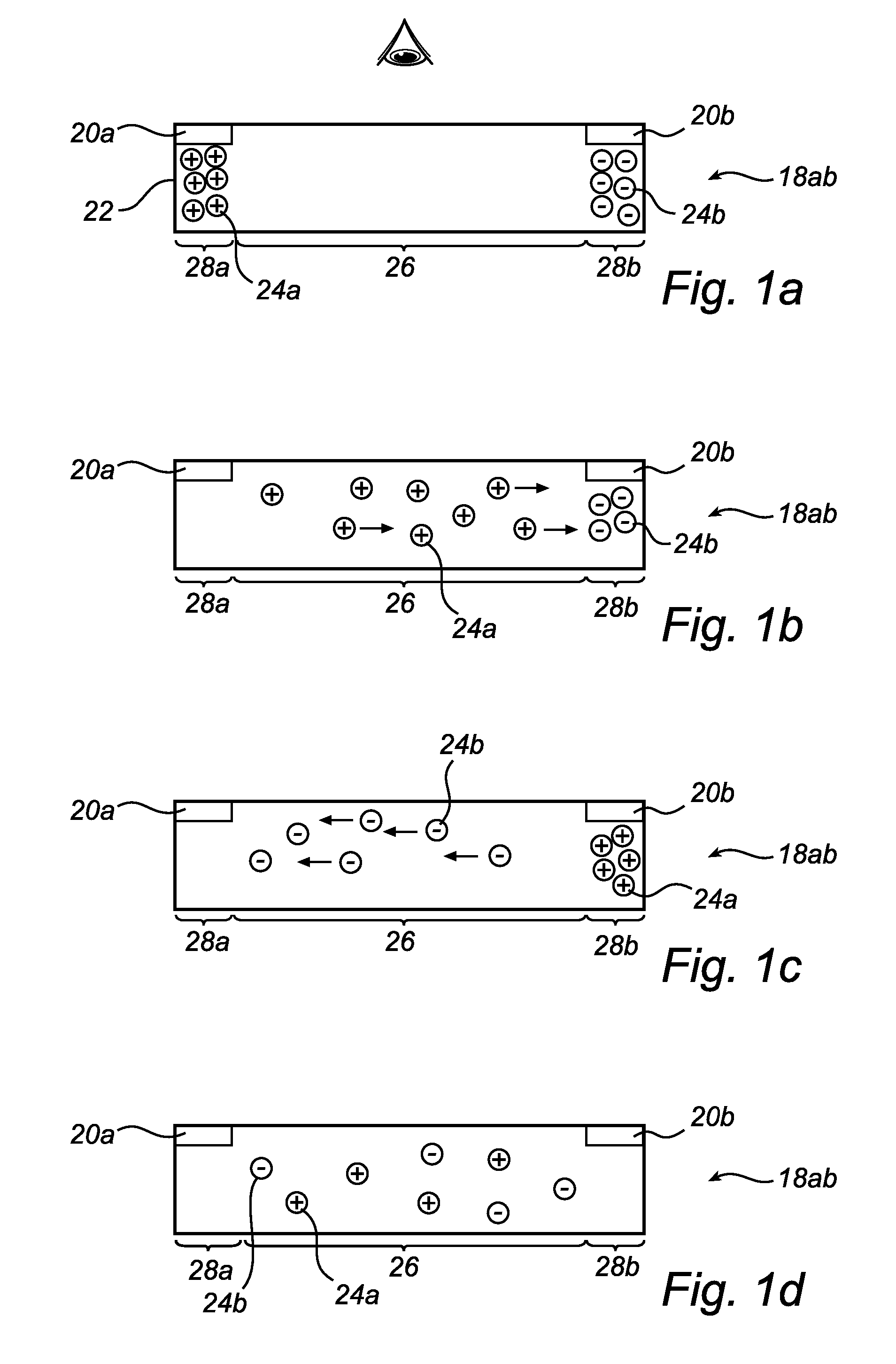

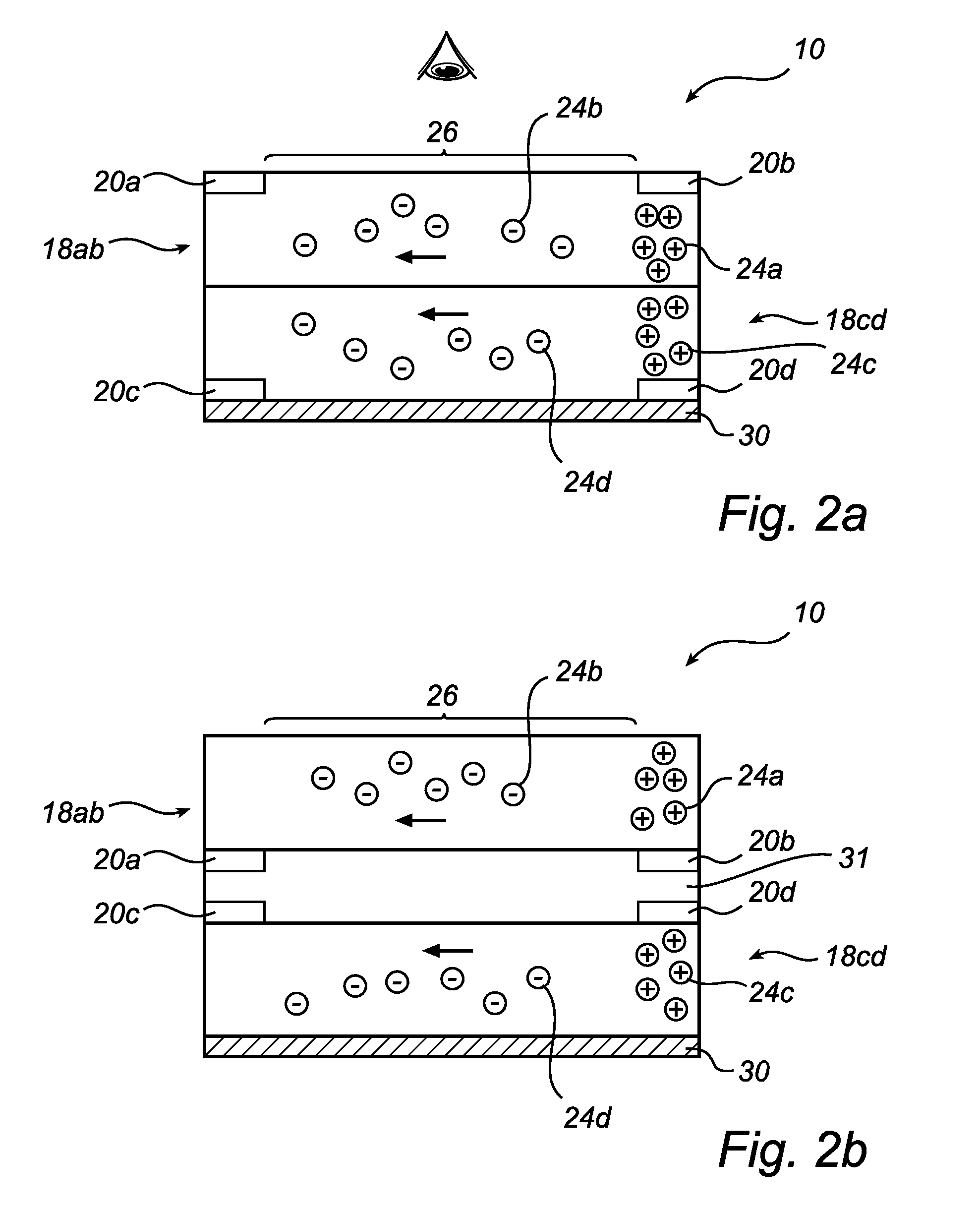

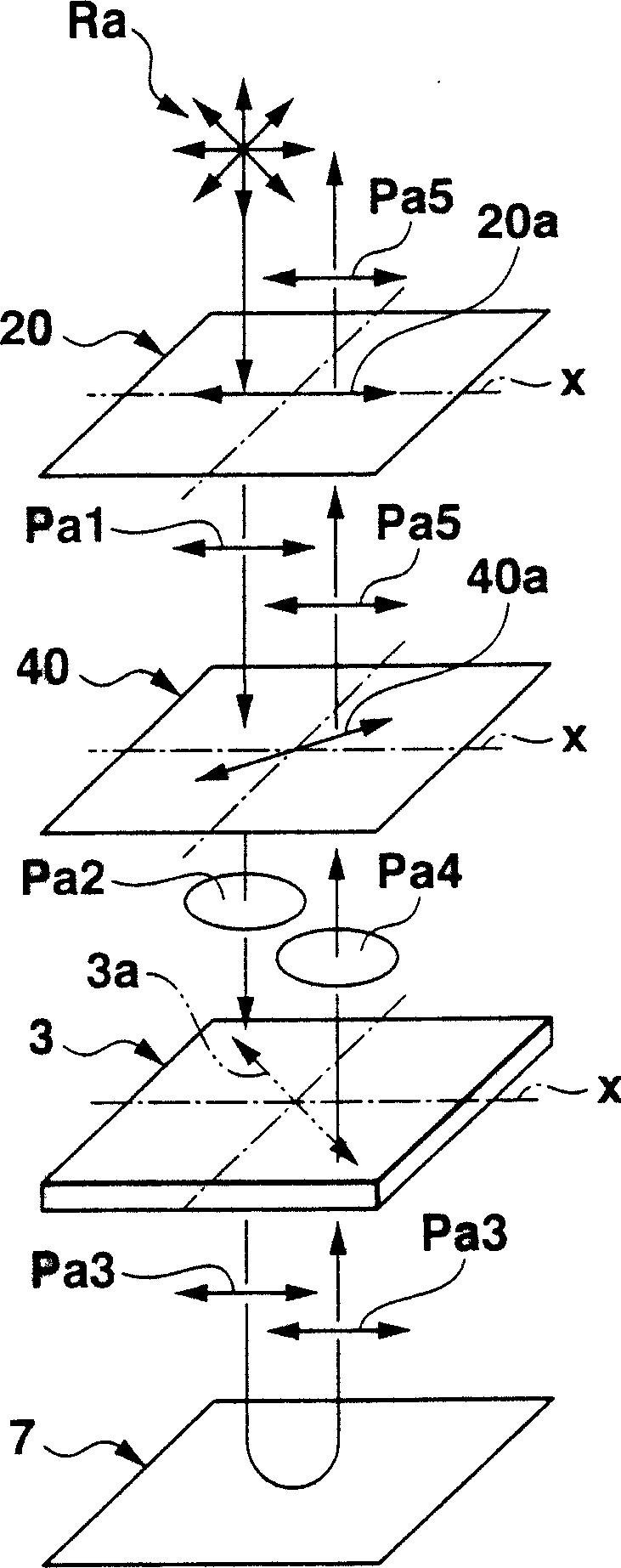

In-plane switching electrophoretic colour display

InactiveUS20100060628A1Improved electrophoreticImprove color displayCathode-ray tube indicatorsNon-linear opticsIn planeOptical property

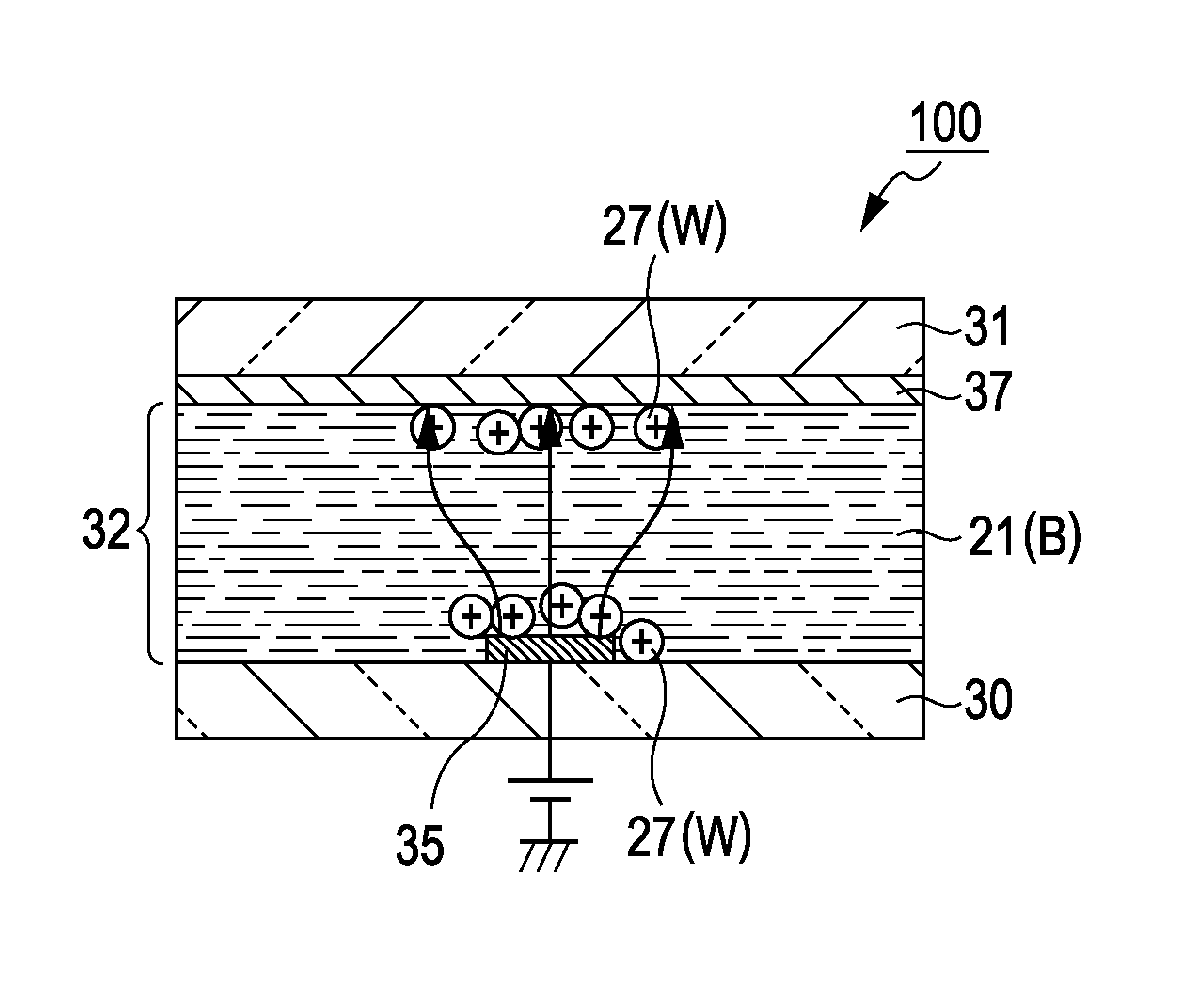

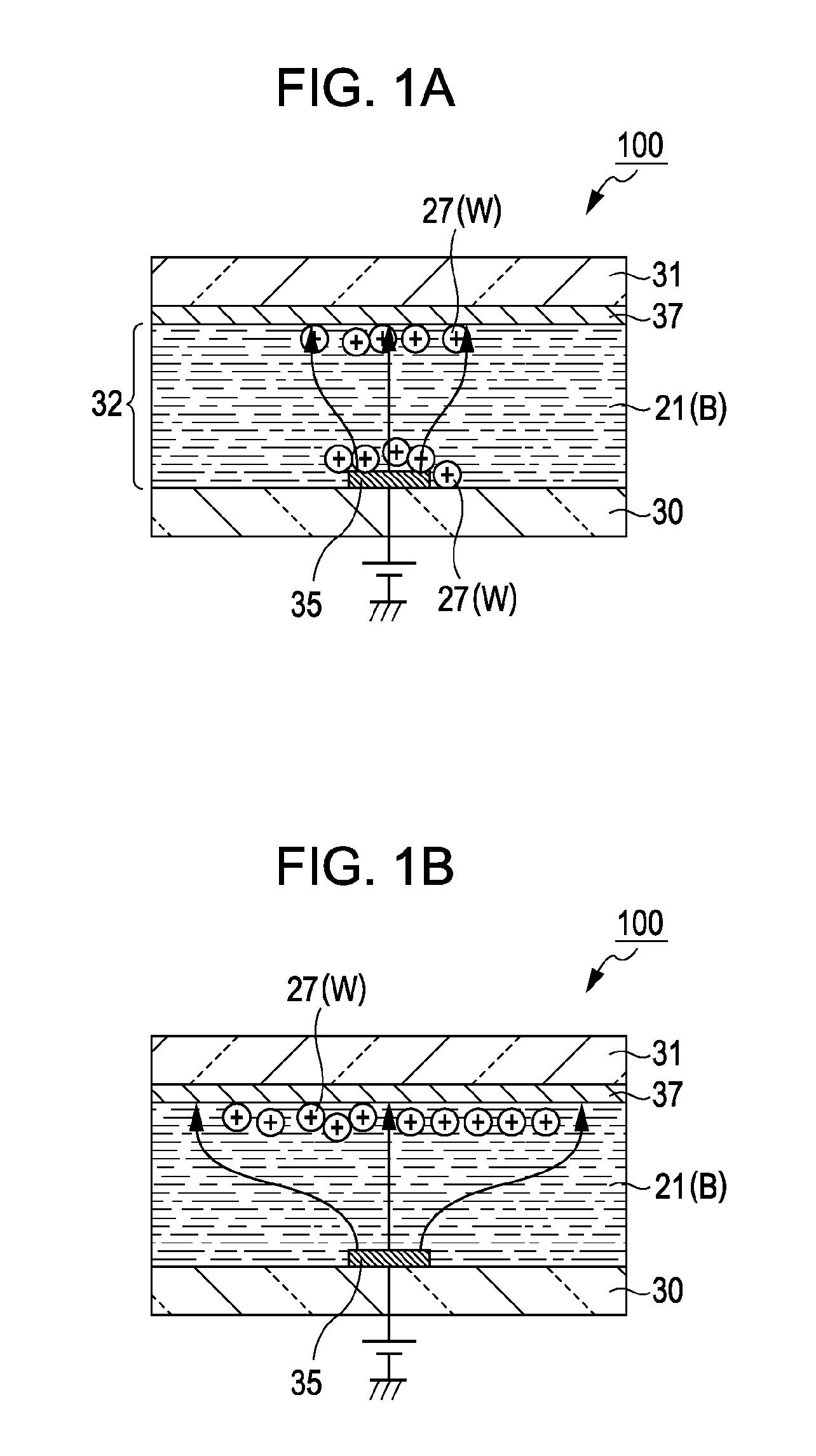

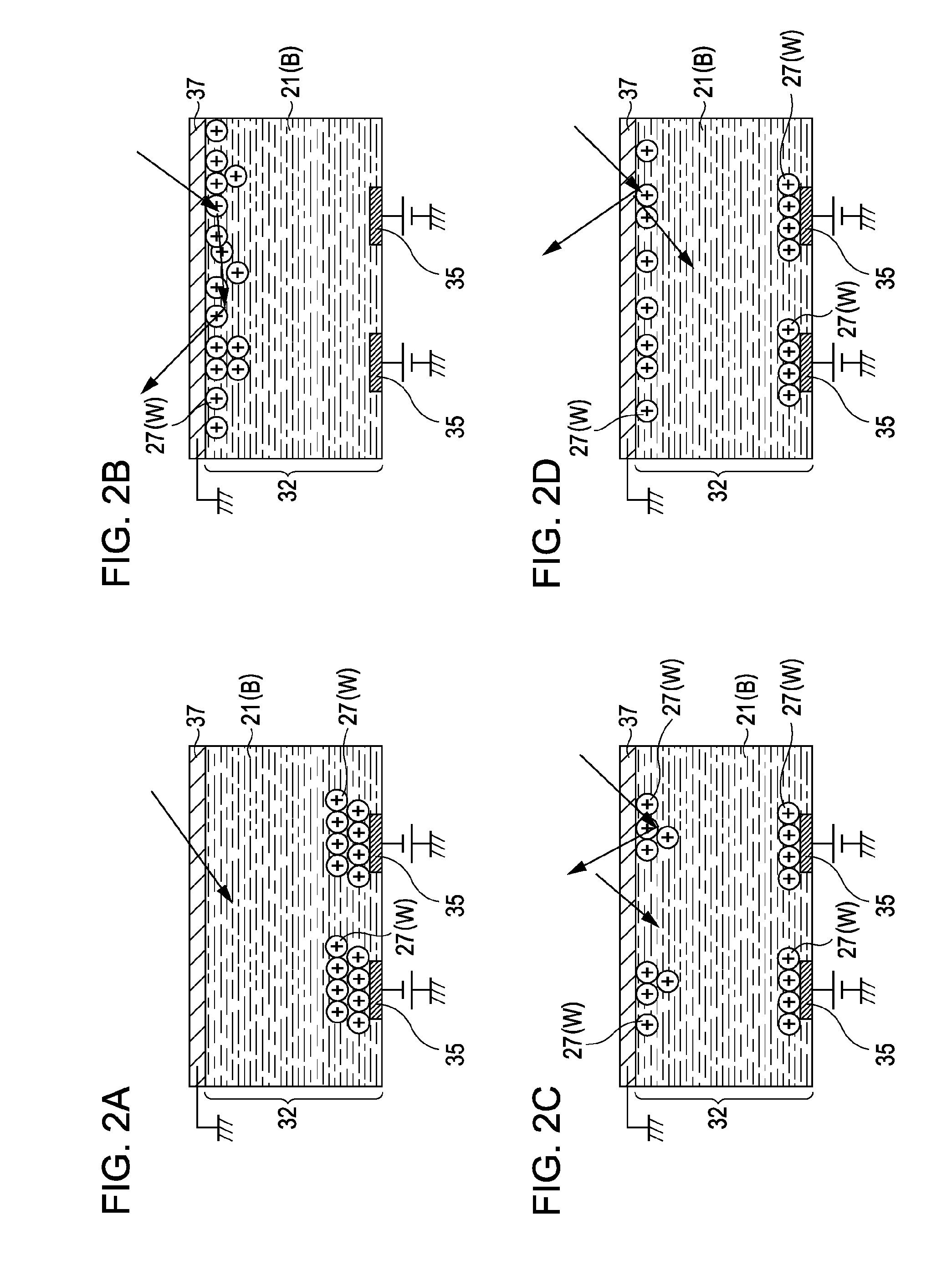

The invention relates to an electrophoretic color display panel, the display panel comprising at least one pixel (10, 12), the at least one pixel (10, 12) comprising a layer cavity (18ab) containing a suspension with a first set of charged particles (24a) having a first optical property and a second set of charged particles (24b) having a second optical property, and a pair of control electrodes (20a, 20b) arranged adjacent to the layer cavity (18ab), such that charged particles (24a, 24b) are essentially in-plane displaceable in an in-plane direction within the layer cavity (18ab) upon application of a control voltage over the electrode pair, wherein the in-plane distribution of charged particles (24a, 24b) having first and second optical properties in the layer cavity (18ab) depends on at least one of a differing control property additional to any polarity difference of the charged particles (24a, 24b) for each set of charged particles, or at least one additional electrode arranged adjacent to the layer cavity, wherein the electrode pair (20a, 20b) and the at least one additional control electrode are arranged essentially outside of a viewing area (26) of the at least one pixel (10, 12), such that a composite optical property of at least a portion of the at least one pixel (10, 12) is controllable. According to the invention, the control electrodes will be arranged at essentially the outer ends, or arranged in-plane, at a peripheral, of a prolonged layer cavity, such that the particles move in an in-plane direction within the layer cavity when the control voltage is applied. This facilitates the handling of the pixel since the layer cavity can be reached from essentially the outside of the pixel. Another advantage is that since only a minor part of the pixel area has to be covered with an electrode material the total transmission and thus the brightness of the pixel can be optimized.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

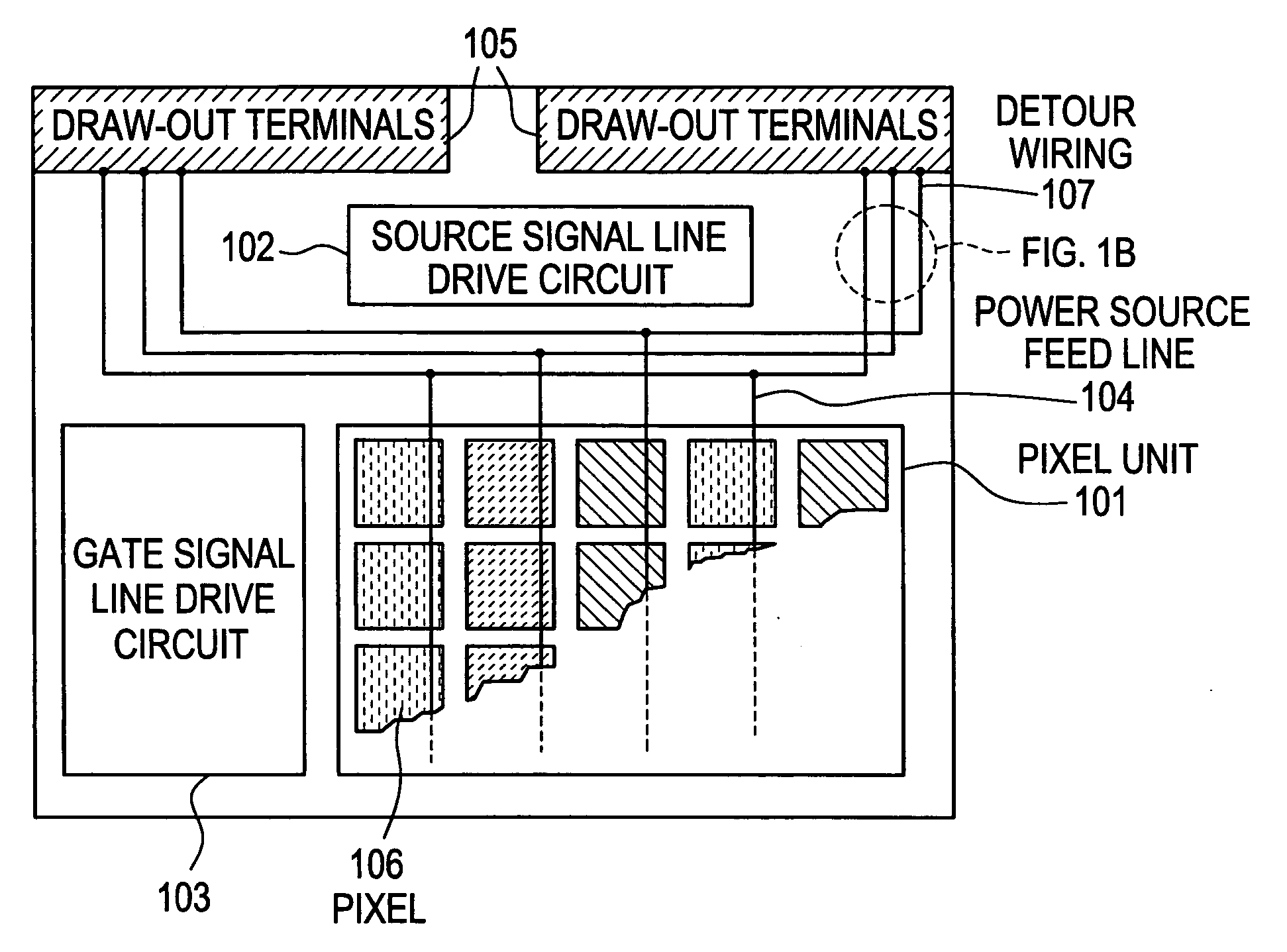

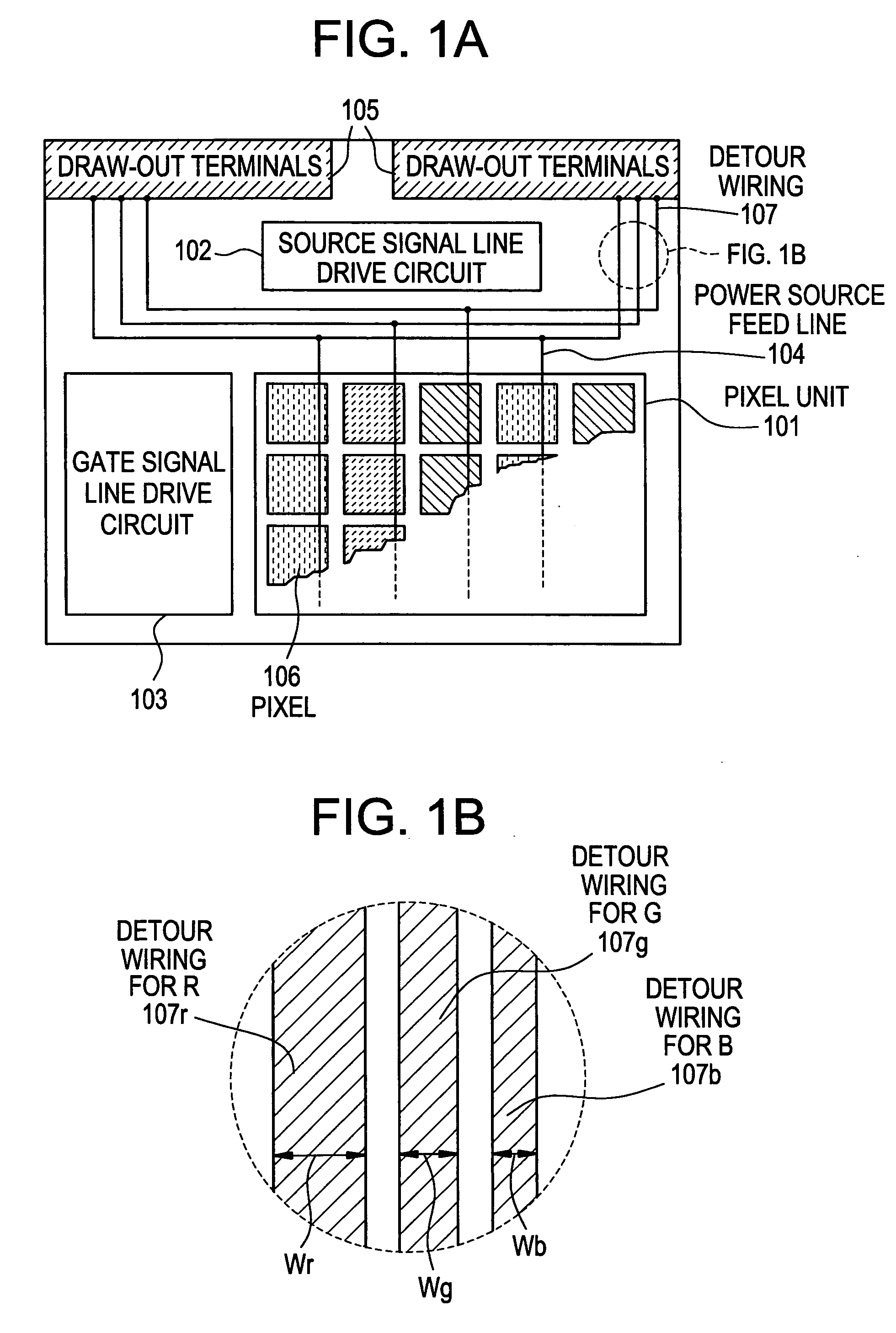

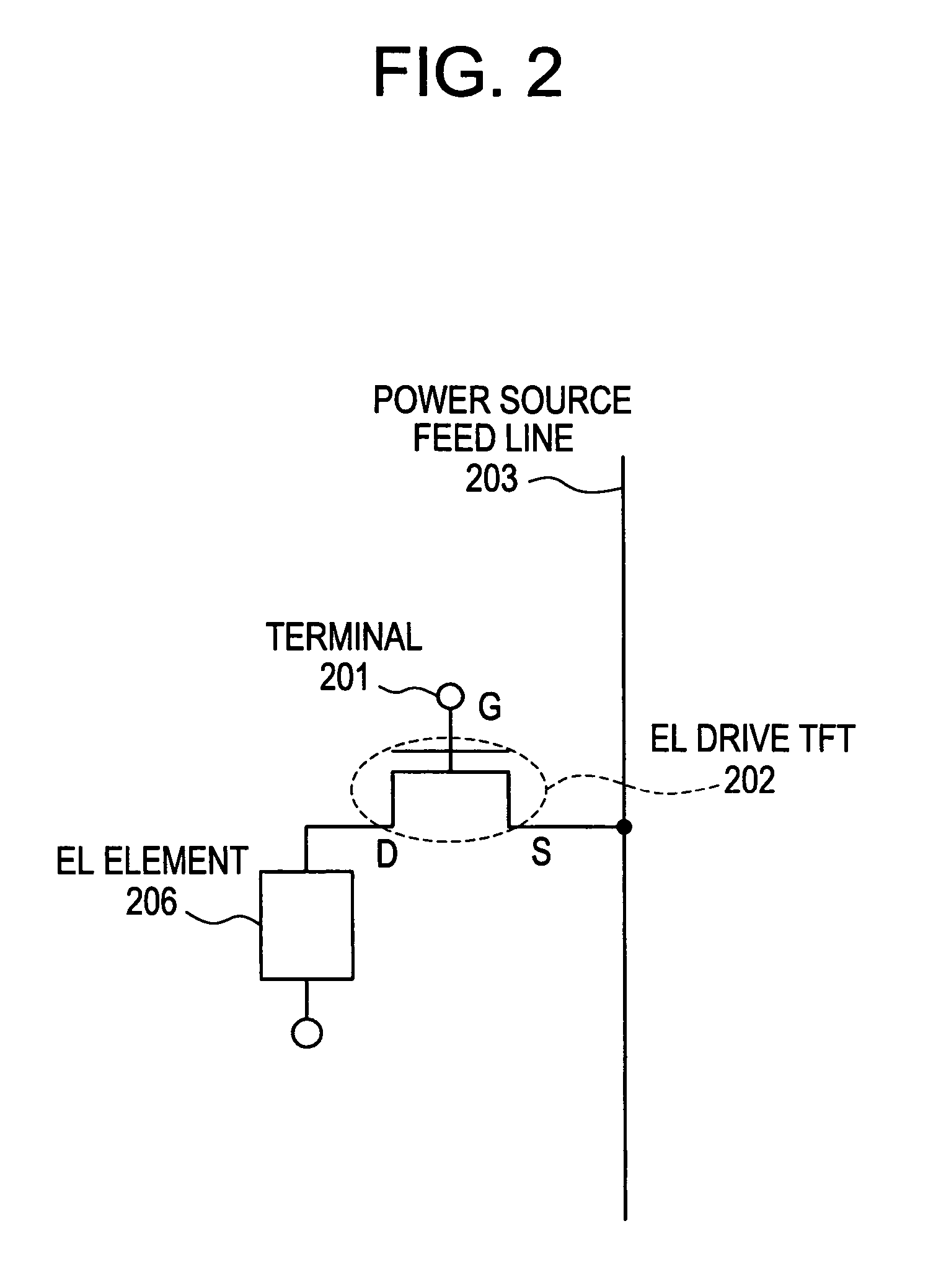

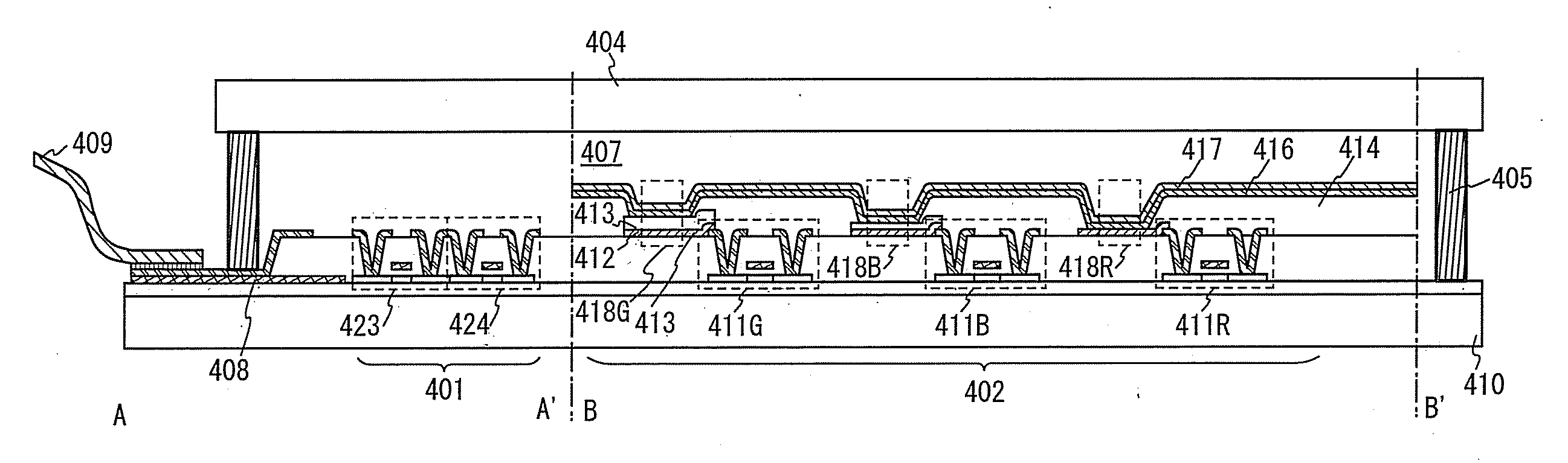

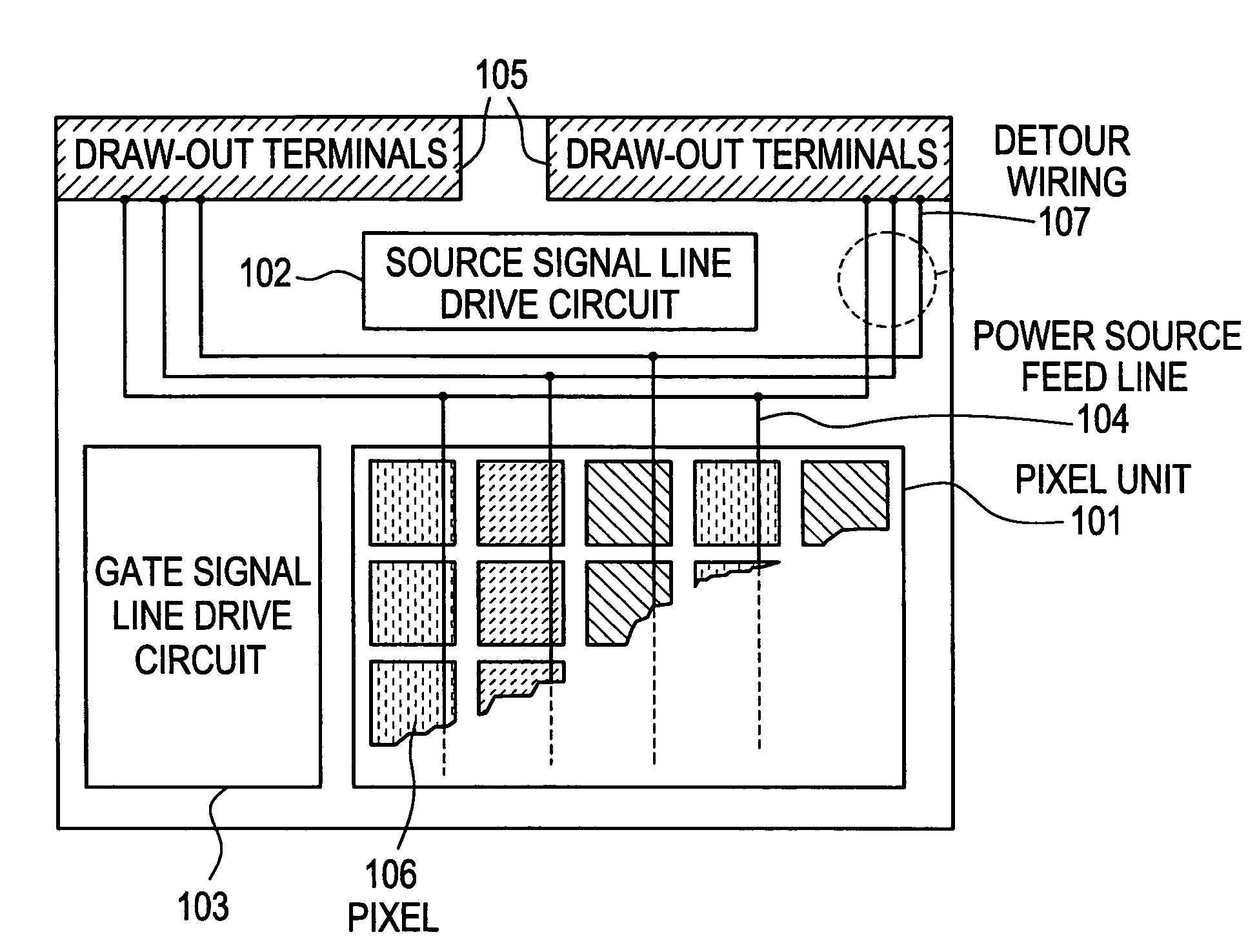

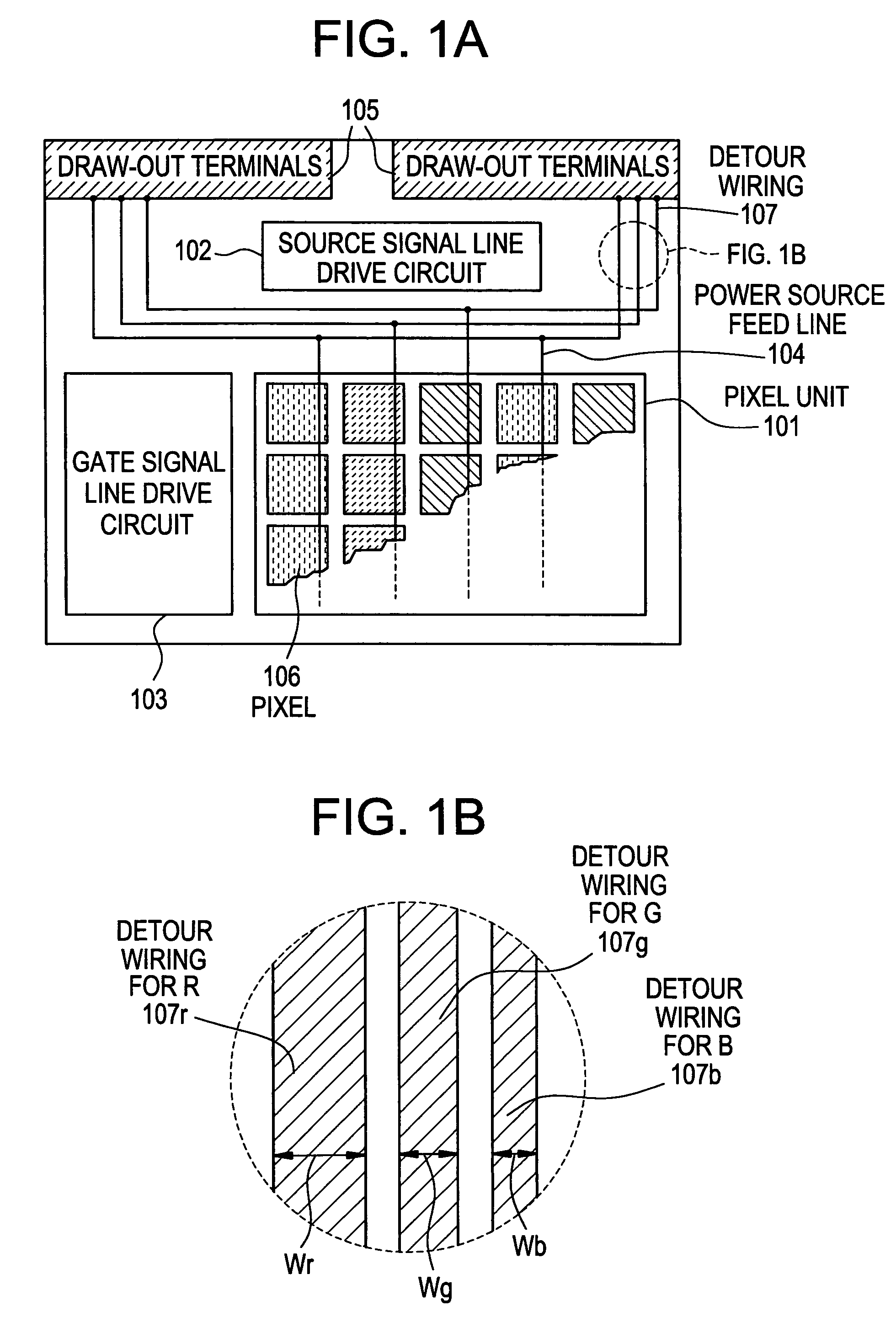

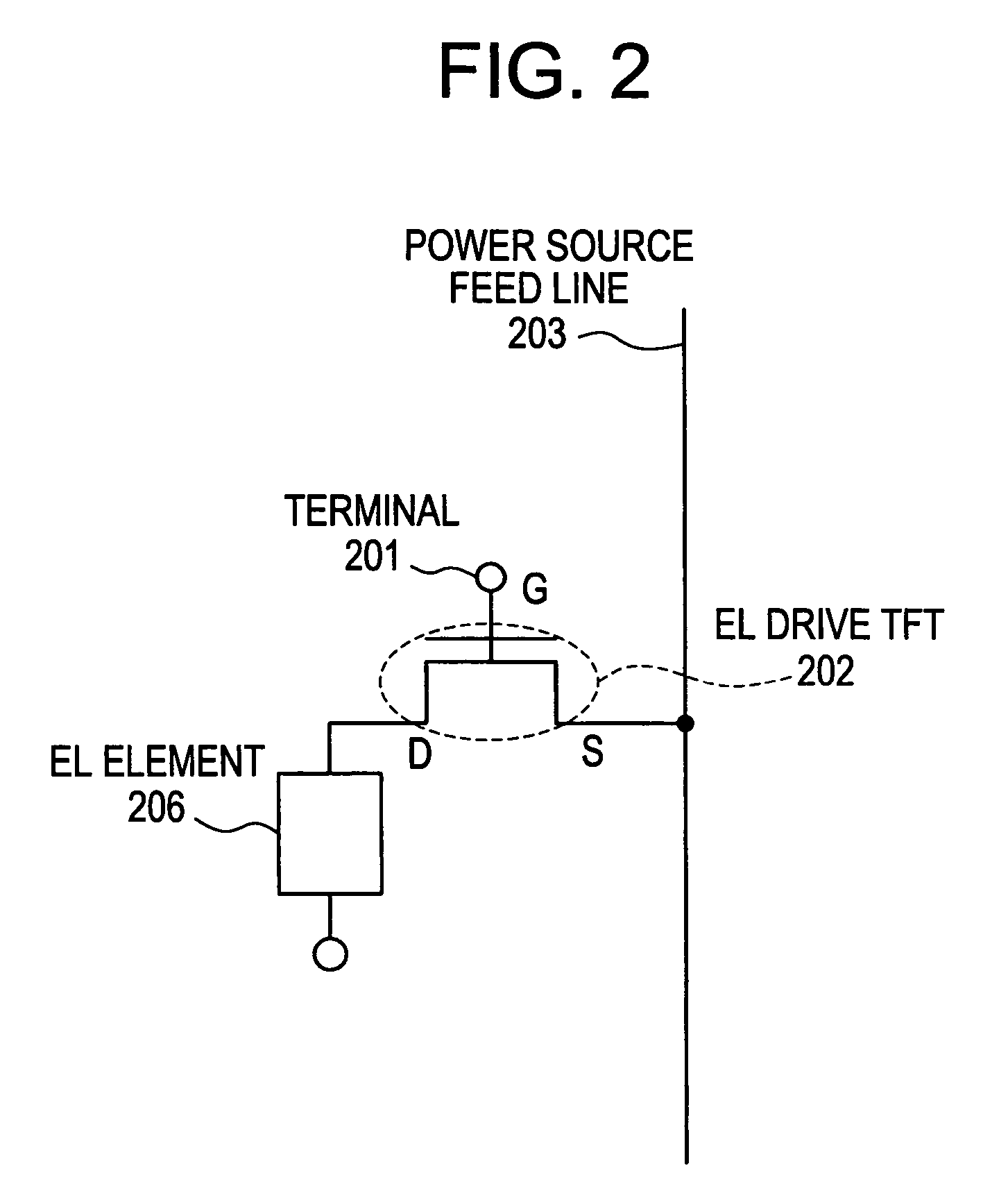

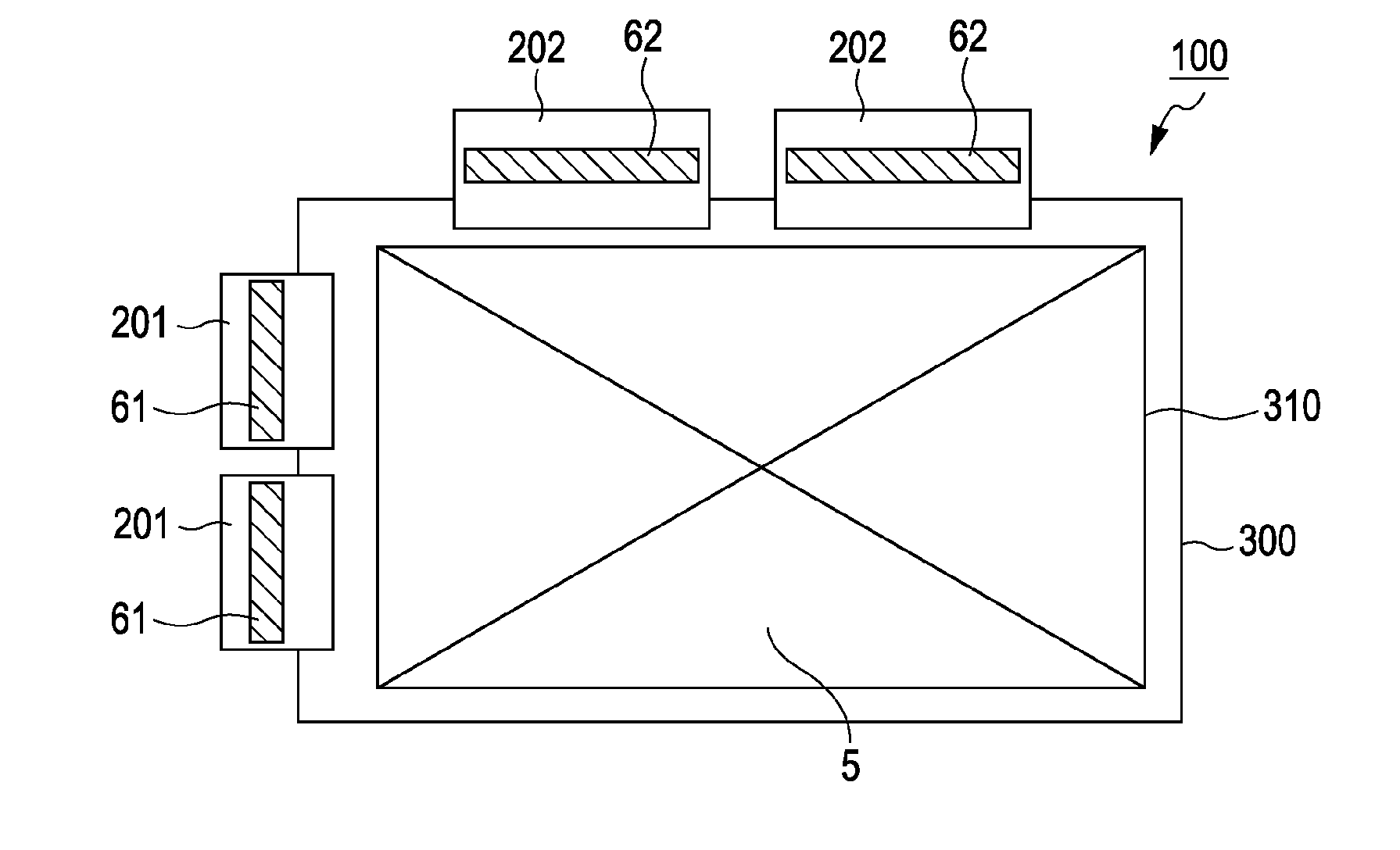

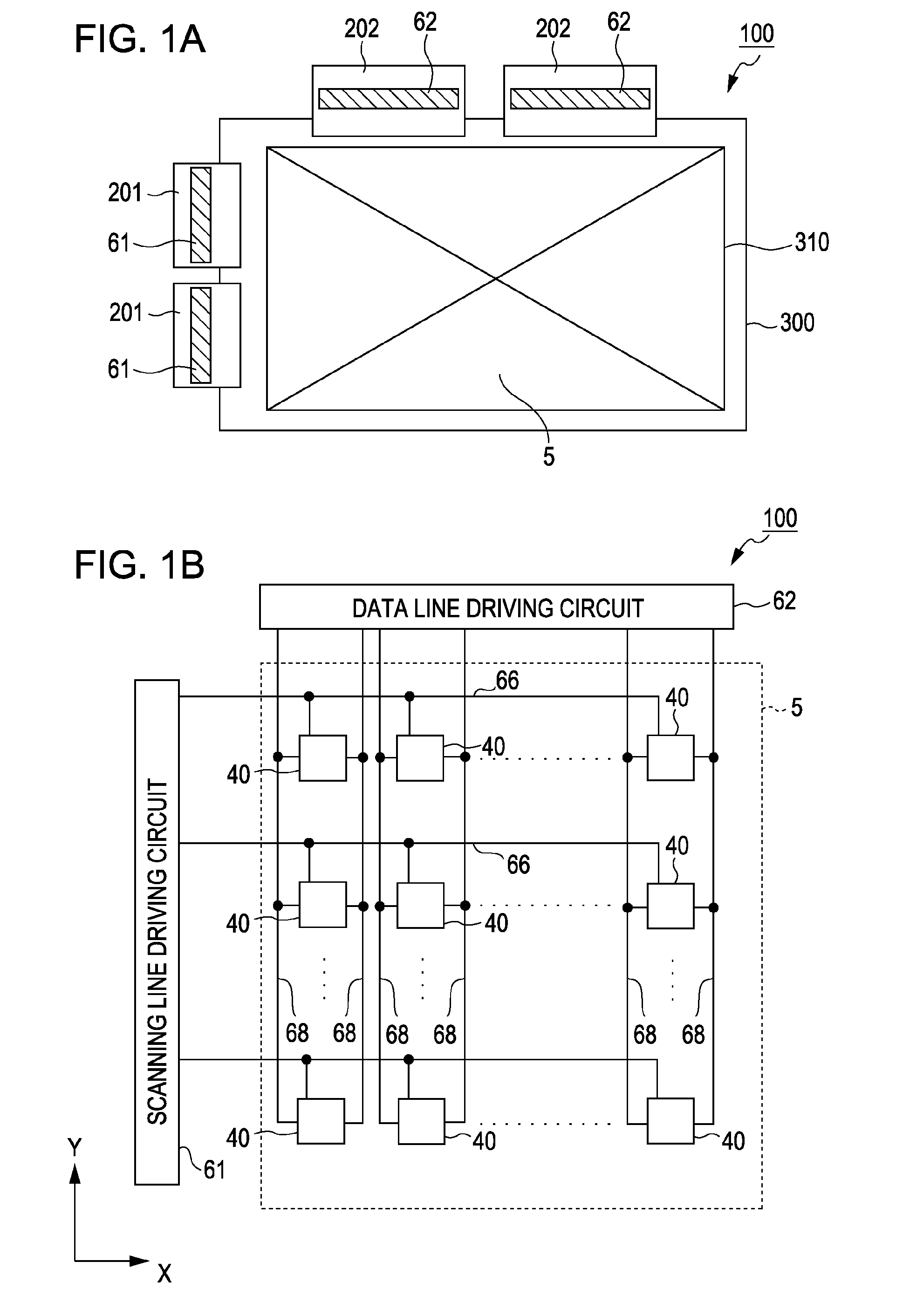

Display device and electronic device

InactiveUS20050093802A1Improve color displayIncrease widthElectroluminescent light sourcesSolid-state devicesDisplay deviceEngineering

A display device capable of displaying a picture of vivid colors maintaining a good balance of colors and a good balance of light-emitting brightnesses of the EL elements. The widths of the detour wirings supplying current to the power source feed lines are increased for those EL elements into which a current of a large density flows. This constitution decreases the wiring resistances of the detour wirings, decreases the potential drop through the detour wirings, and suppresses the amount of electric power consumed by the detour wirings.

Owner:SEMICON ENERGY LAB CO LTD

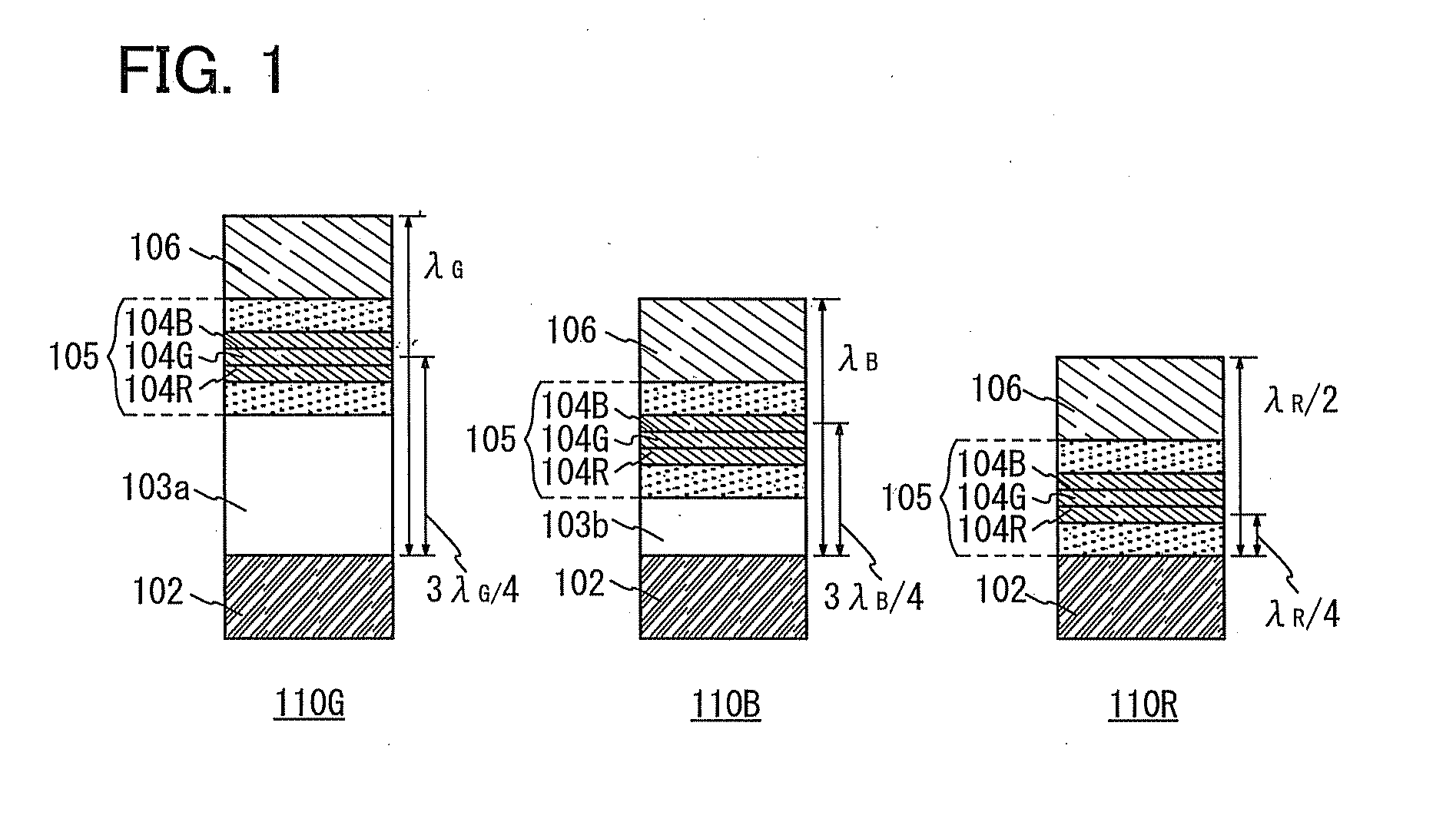

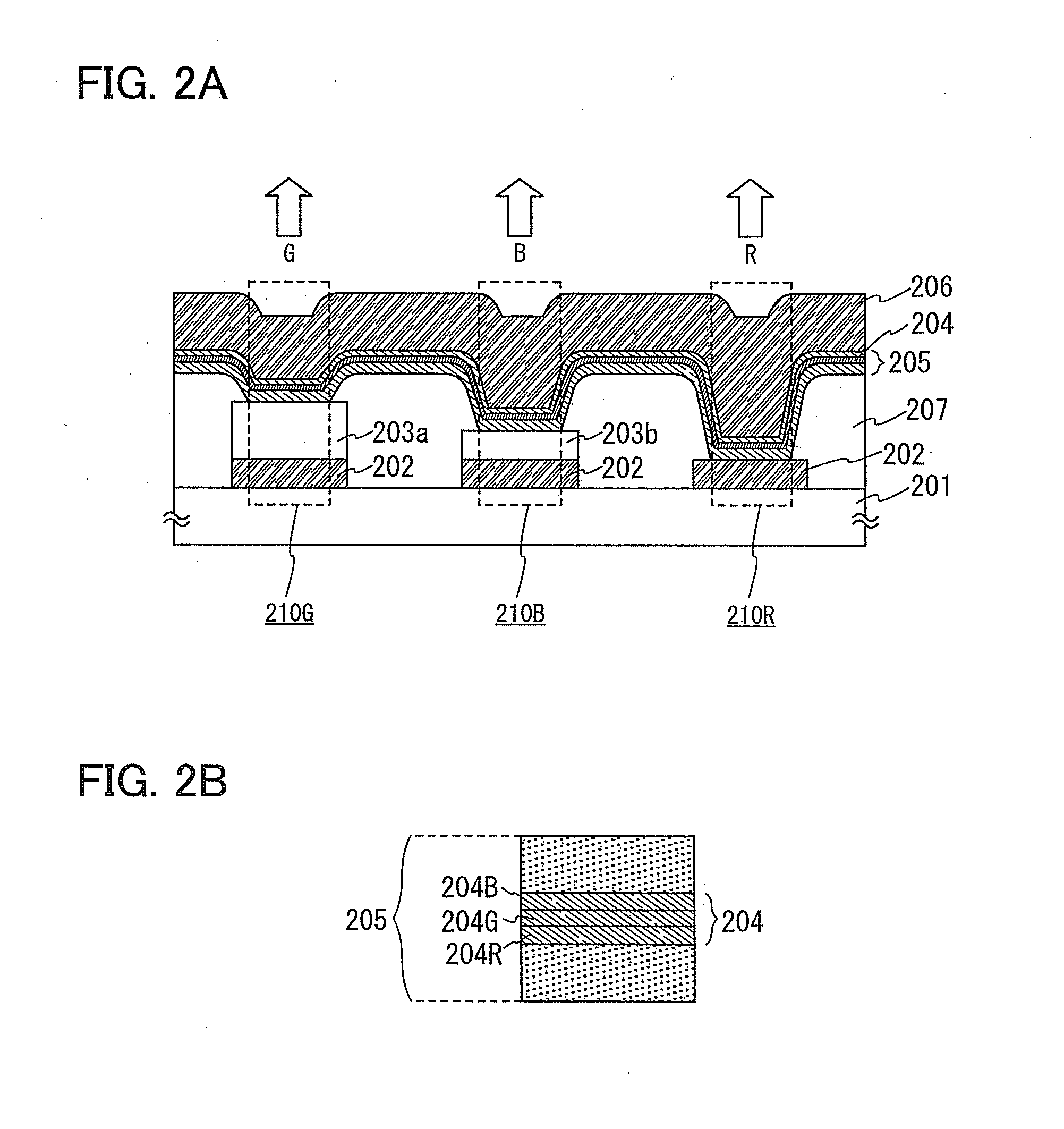

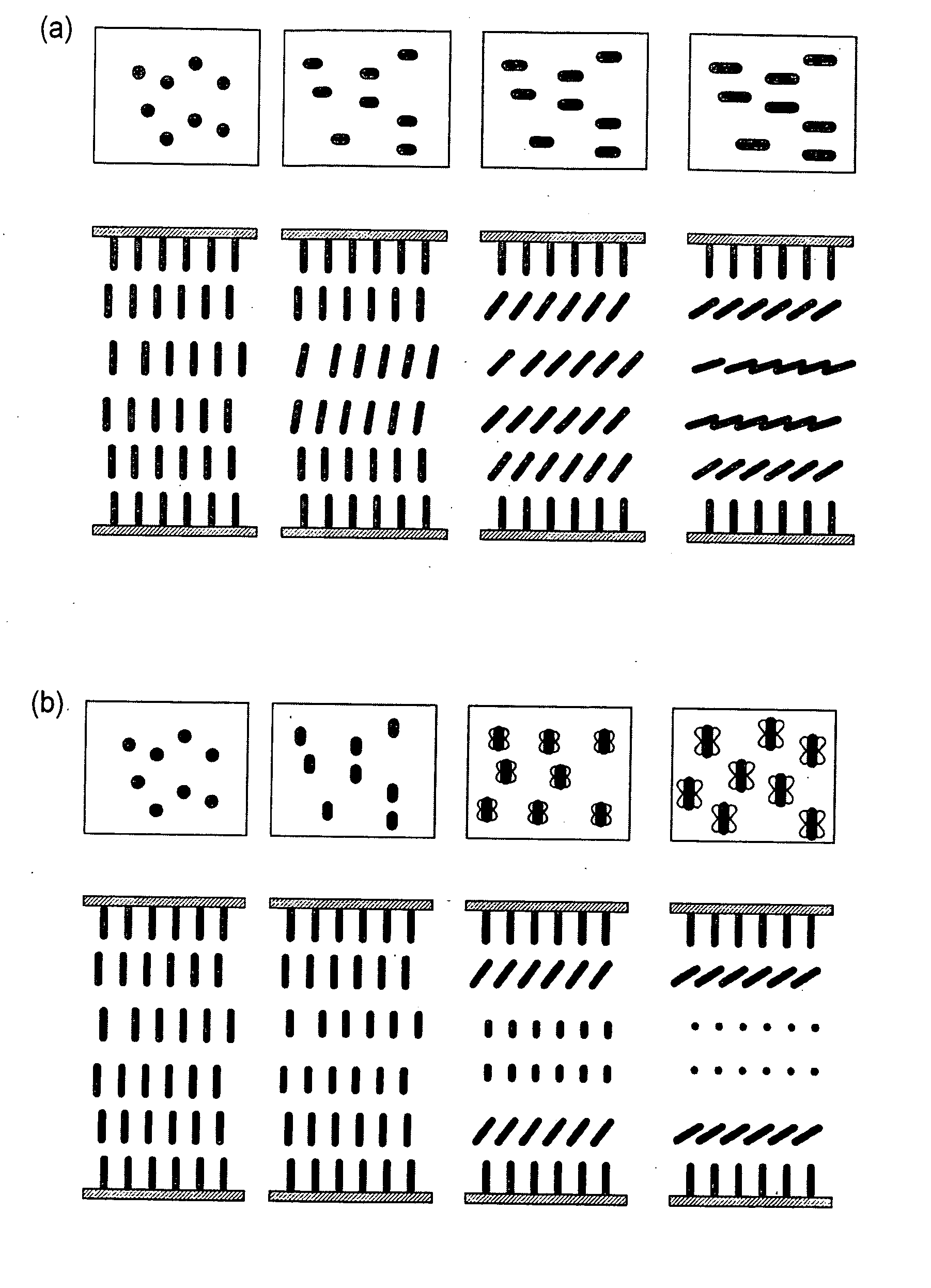

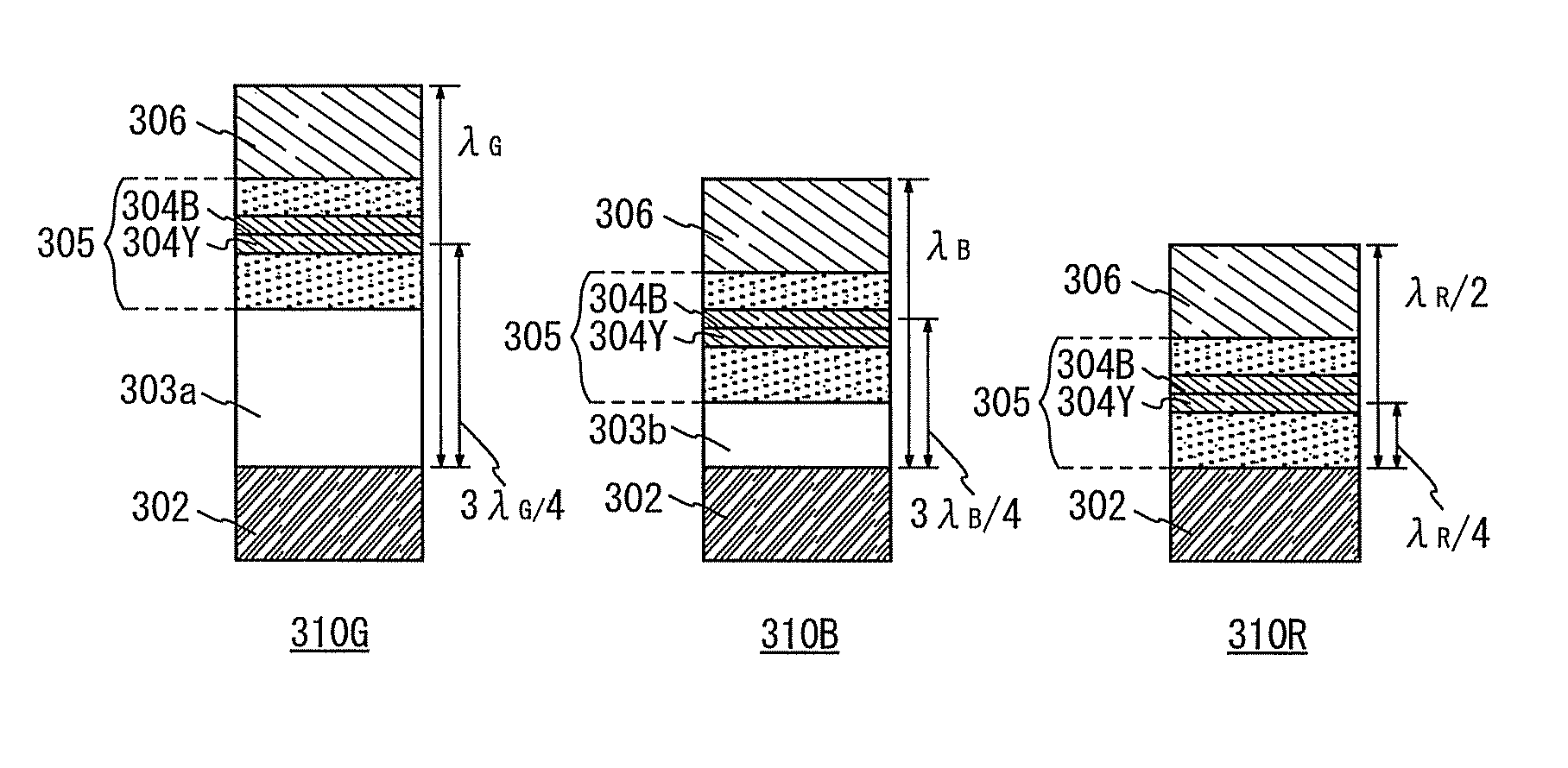

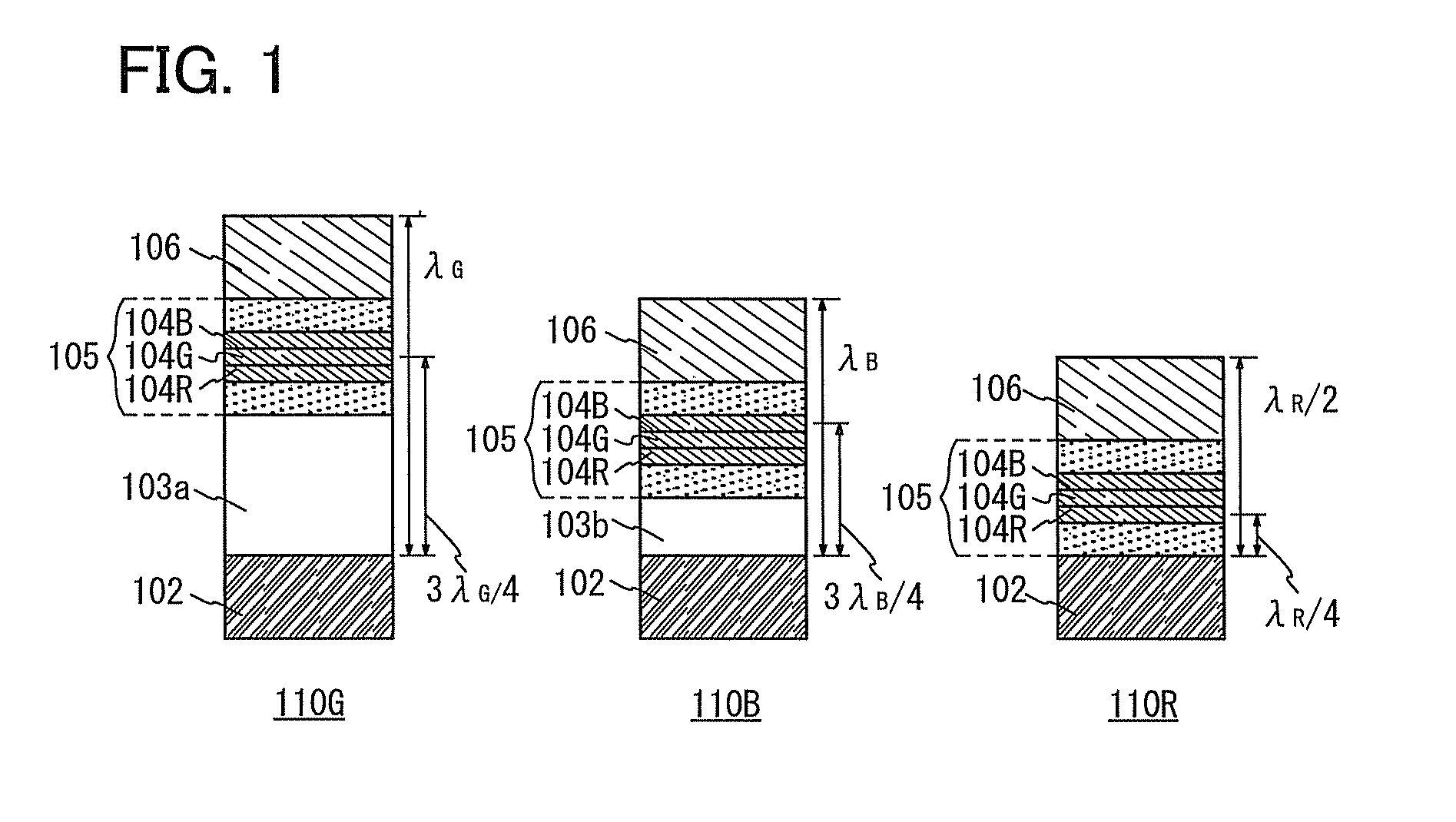

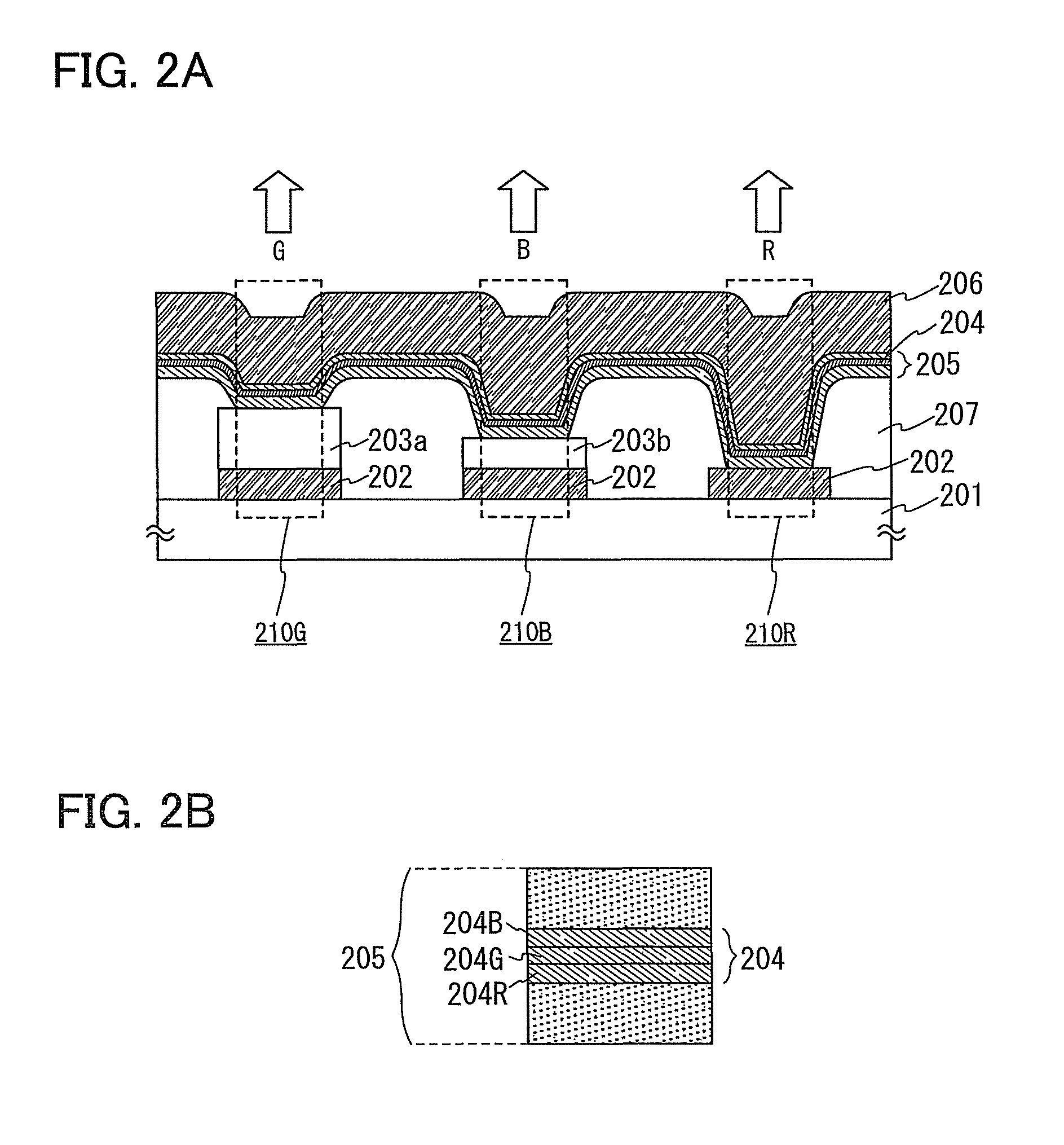

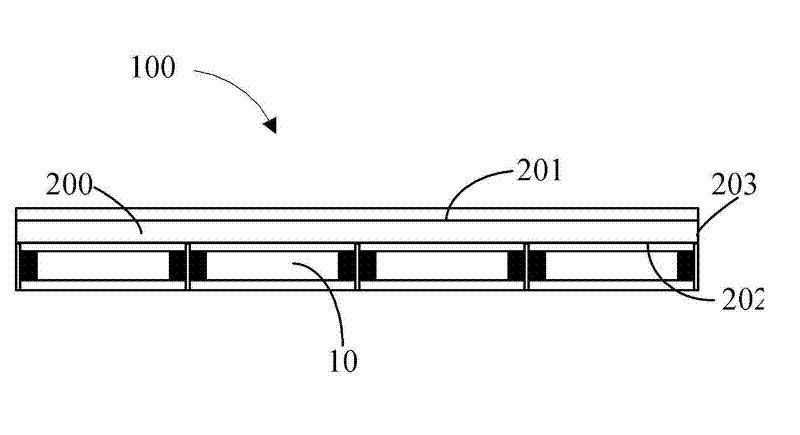

Light-Emitting Device, Electronic Appliance, and Lighting Device

ActiveUS20120256208A1Reduce power consumptionHigh definitionSolid-state devicesSemiconductor devices for light sourcesLength waveOptical path length

A light-emitting device and a lighting device each of which includes a plurality of light-emitting elements exhibiting light with different wavelengths are provided. The light-emitting device and the lighting device each have an element structure in which each of the light-emitting elements emits only light with a desired wavelength, and thus the light-emitting elements have favorable color purity. In the light-emitting element emitting light (λR) with the longest wavelength of the light with different wavelengths, the optical path length from a reflective electrode to a light-emitting layer (a light-emitting region) included in an EL layer is set to λR / 4 and the optical path length from the reflective electrode to a semi-transmissive and semi-reflective electrode is set to λR / 2.

Owner:SEMICON ENERGY LAB CO LTD

Display device and electronic device

InactiveUS7639248B2Improve color displayIncrease widthElectroluminescent light sourcesSolid-state devicesDisplay deviceLightness

A display device capable of displaying a picture of vivid colors maintaining a good balance of colors and a good balance of light-emitting brightnesses of the EL elements. The widths of the detour wirings supplying current to the power source feed lines are increased for those EL elements into which a current of a large density flows. This constitution decreases the wiring resistances of the detour wirings, decreases the potential drop through the detour wirings, and suppresses the amount of electric power consumed by the detour wirings.

Owner:SEMICON ENERGY LAB CO LTD

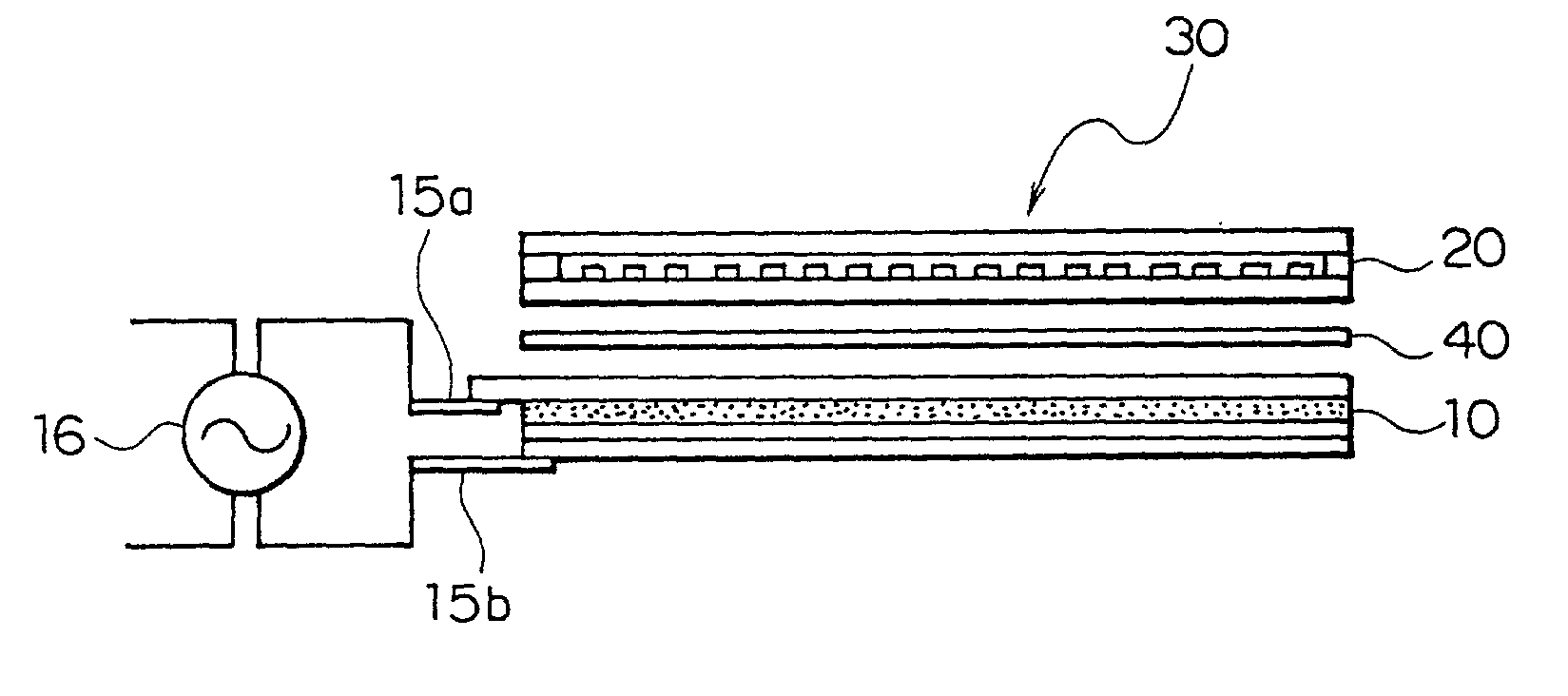

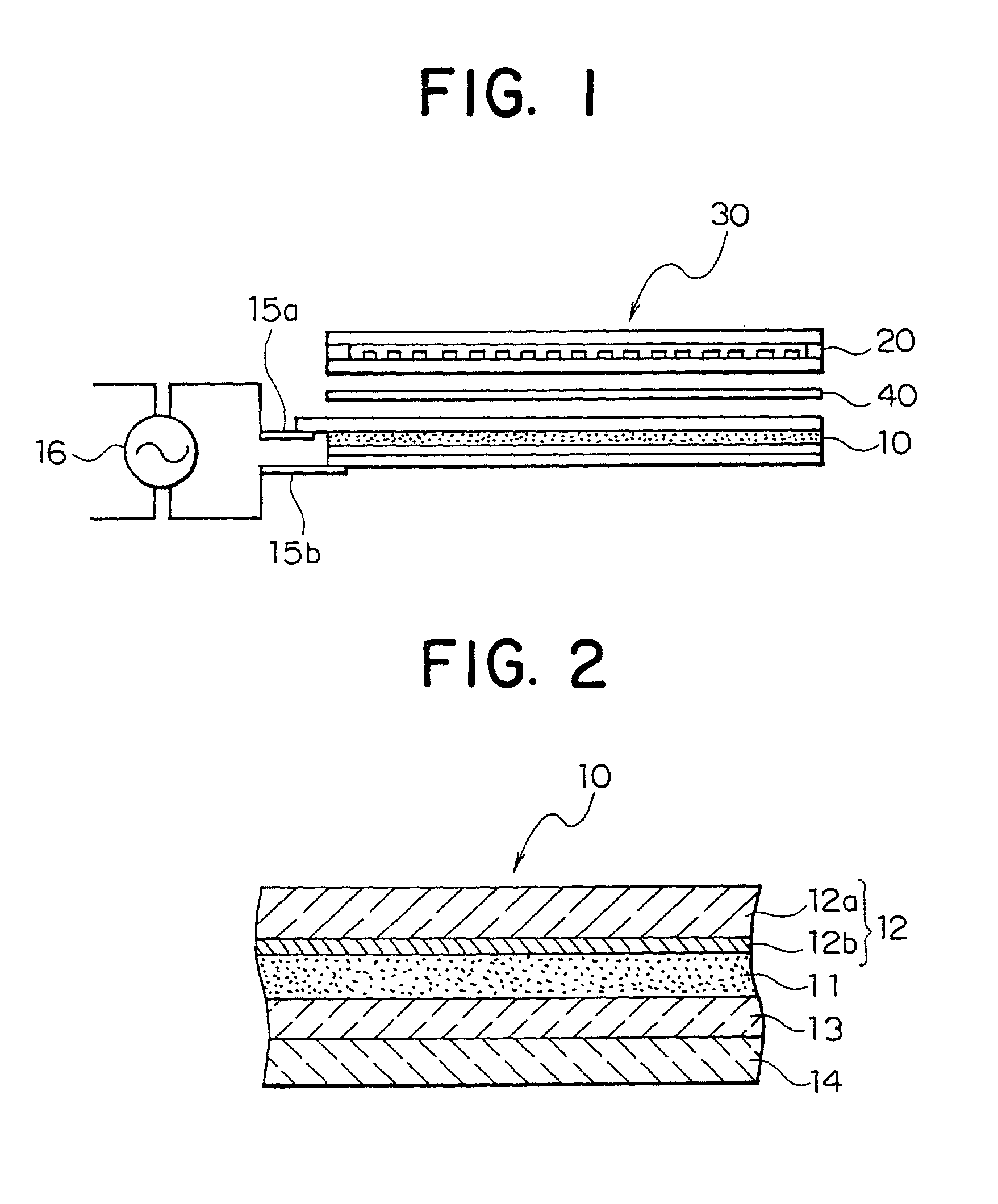

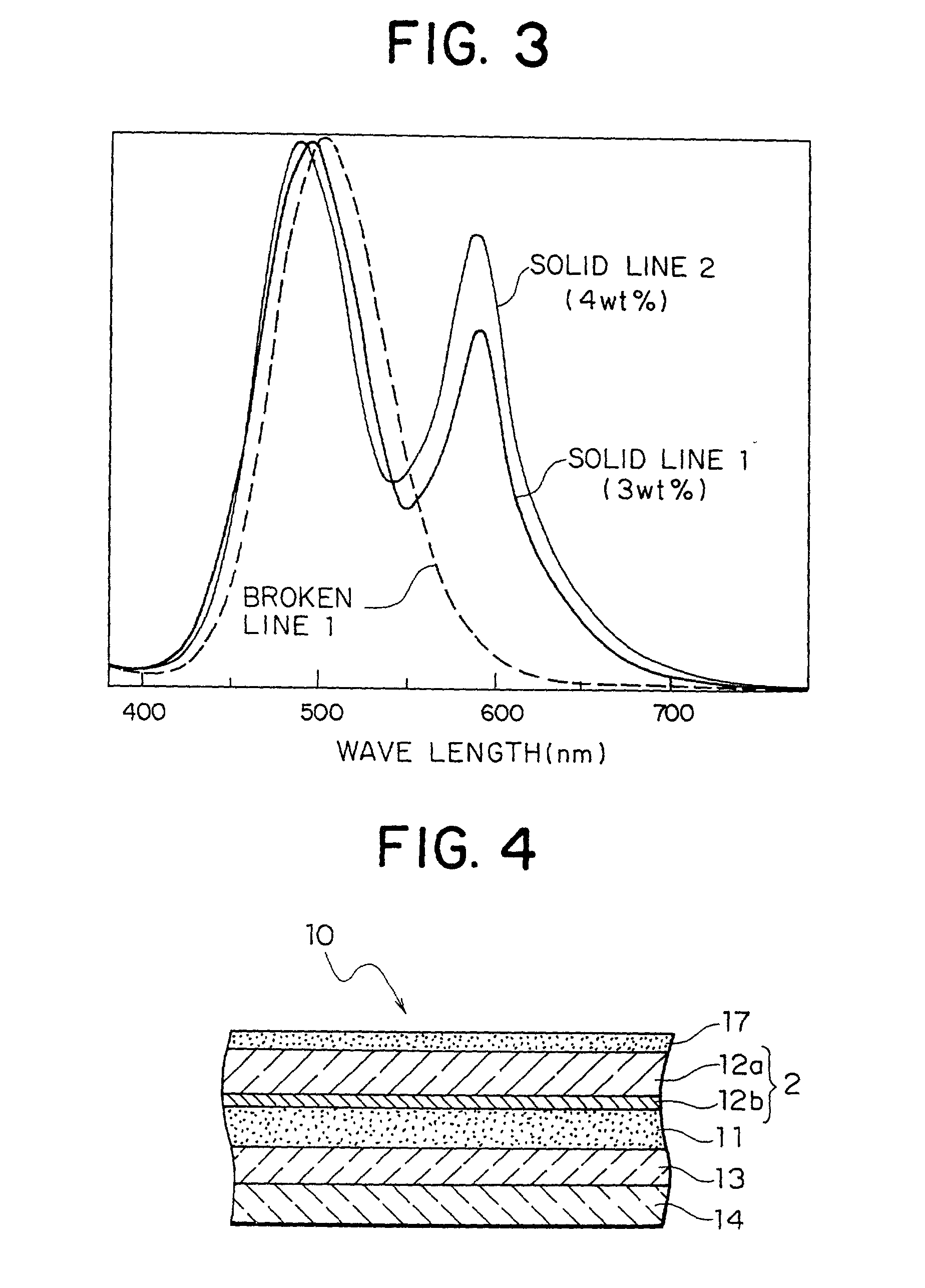

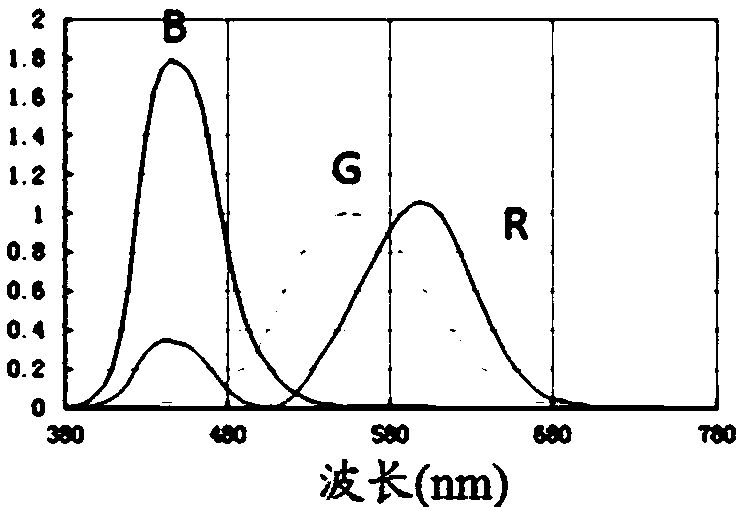

Backlight for color liquid crystal, color liquid crystal display device, and EL element for backlight of color liquid crystal device

InactiveUS20020003594A1Improve color displaySatisfactory characteristicDischarge tube luminescnet screensStatic indicating devicesDielectricElectricity

A backlight for color liquid crystal comprises a light-emitting layer having EL phosphor particles dispersed in a matrix of dielectrics, a transparent electrode layer disposed along a main surface on an emitting side of a light-emitting layer, and a reflective insulating layer and a rear electrode layer stacked in turn along a main surface on a non-emitting side of a light-emitting layer. An EL element, under the operational conditions of a voltage of 100 Vrms and a frequency of 400 Hz, emits white light of which brightness is 80 cd / m2 or more, and has characteristics of consumption power of 30 W / m2 or less. By the use of such EL element as a backlight, a color liquid crystal display device that is low in consumption power, excellent in display performance and suitable for a display portion of a portable information terminal can be provided.

Owner:KK TOSHIBA

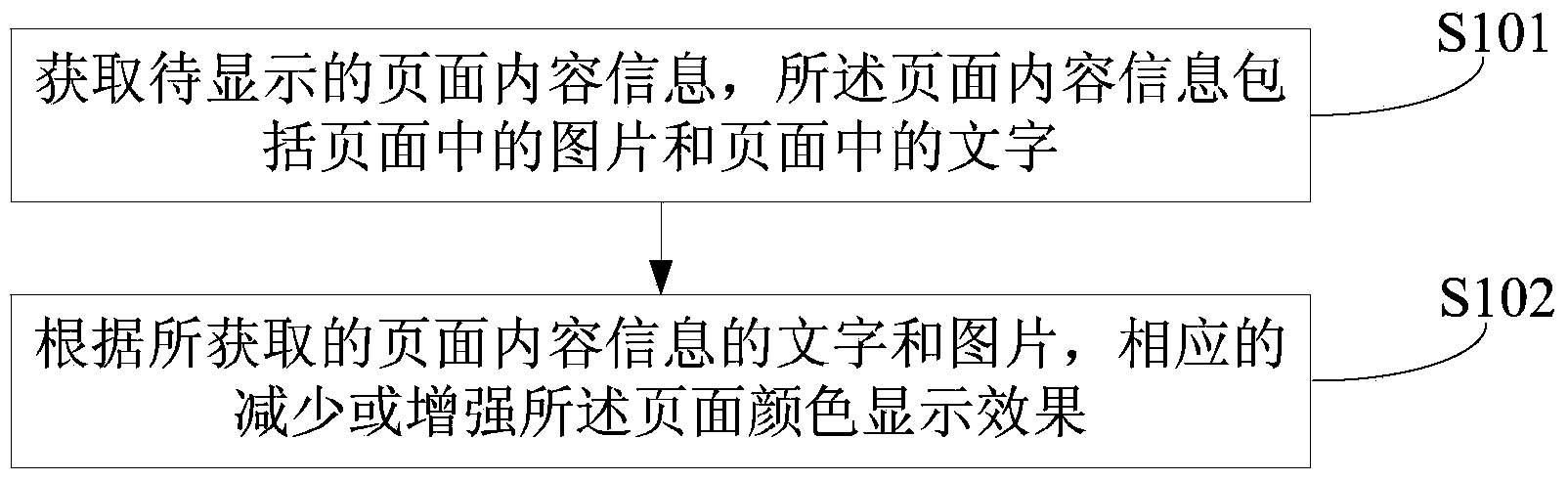

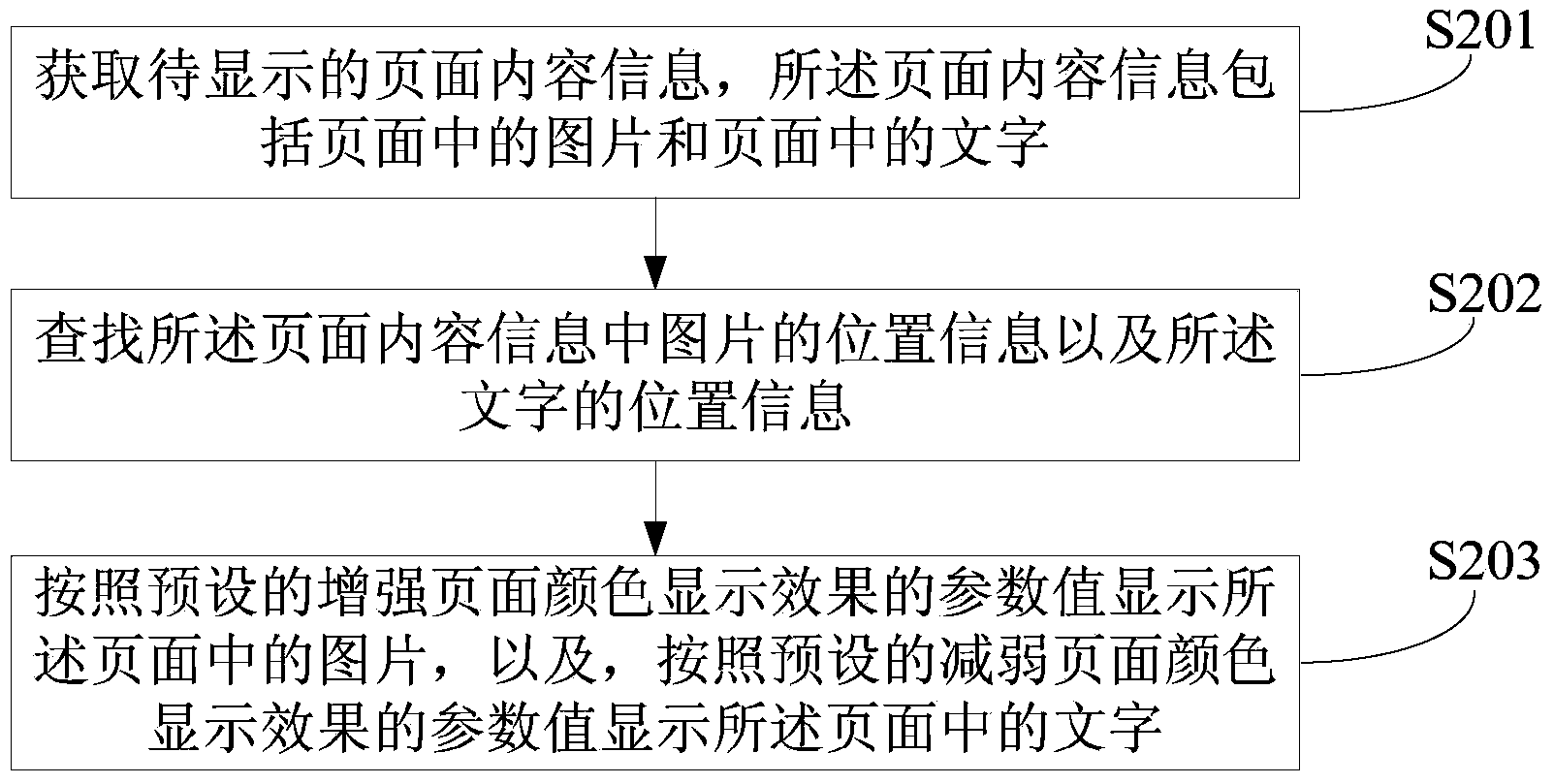

Page displaying method, device and terminal

ActiveCN104331524AFade color effectEnhance page color display effectSpecial data processing applicationsComputer graphics (images)Computer terminal

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Color liquid crystal display device

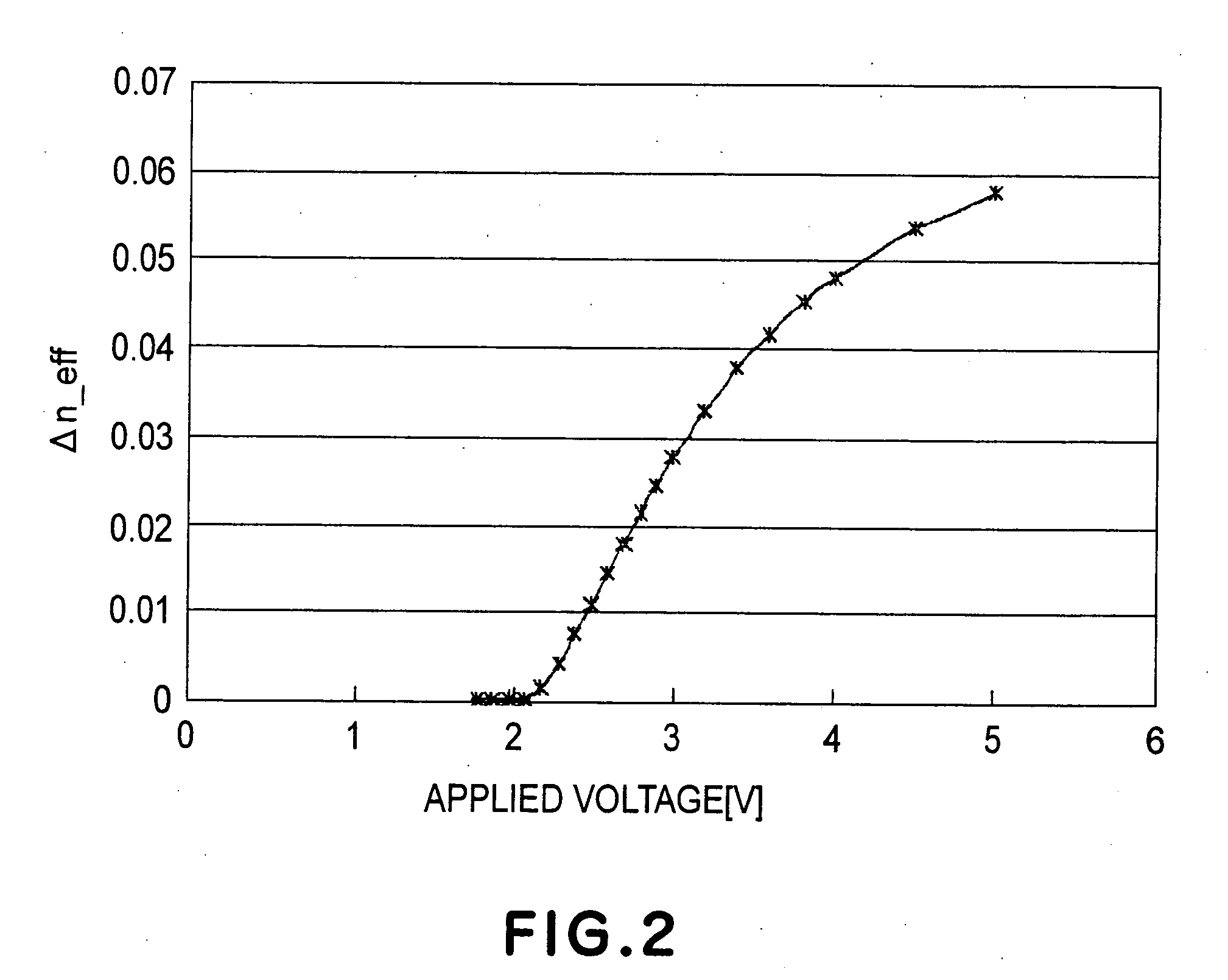

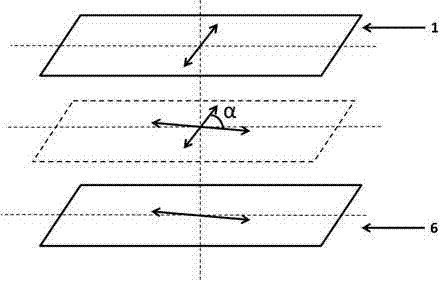

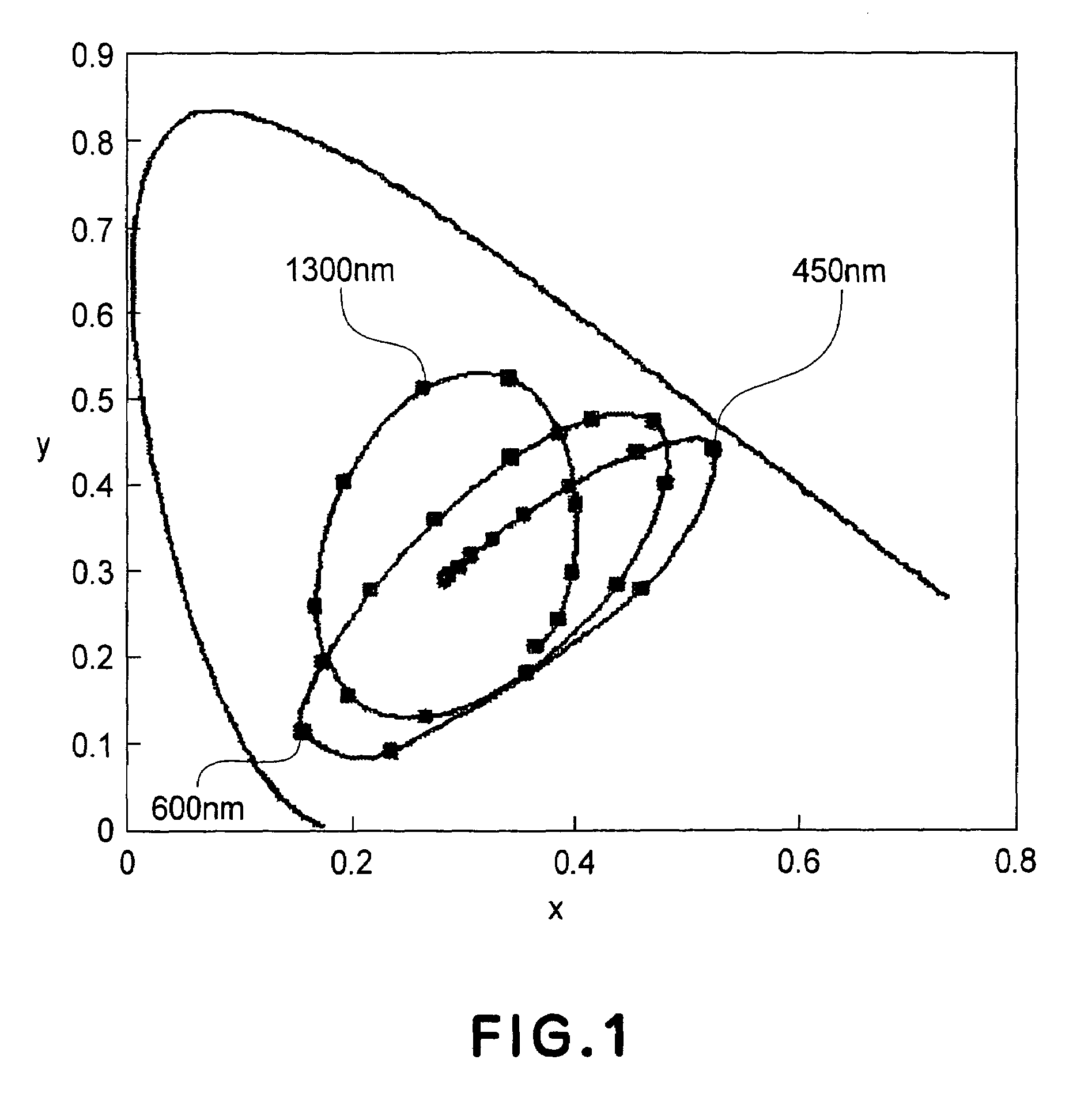

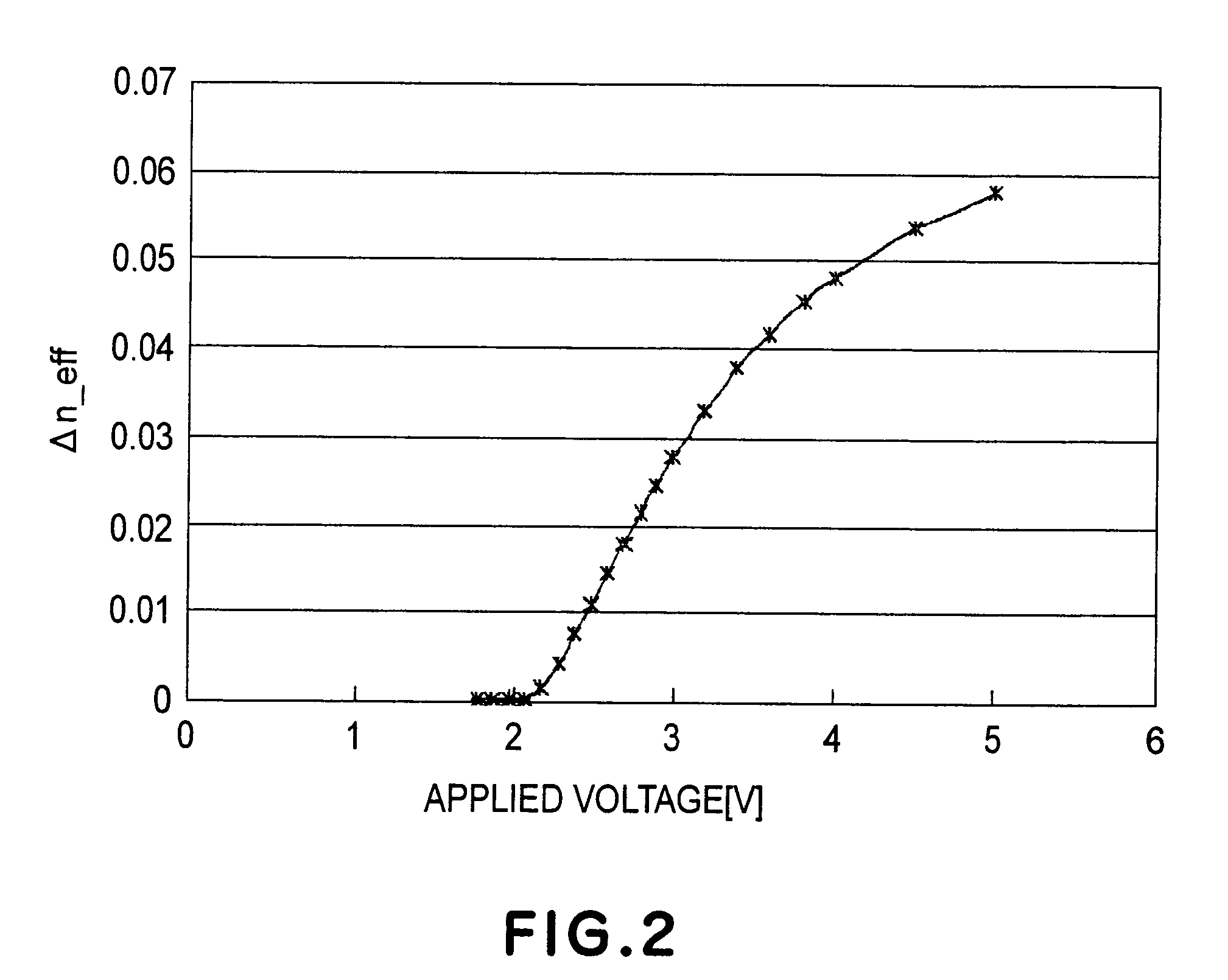

InactiveUS20050248714A1Improve color displayInhibition of temperature dependenceLiquid crystal compositionsNon-linear opticsLiquid-crystal displayEngineering

A color liquid crystal display device includes a pair of oppositely disposed substrates each of which is provided with an electrode and has been subjected to homeotropic alignment treatment, and chiral nematic liquid crystal disposed between the pair of oppositely disposed substrates. The chiral nematic liquid crystal is capable of causing birefringence leading to a change in brightness and a change in hue depending on a voltage applied between the electrodes. The liquid crystal is twistedly aligned under electric field application to change a twisted angle, so that a fluctuation in birefringence with temperature is compensated.

Owner:CANON KK

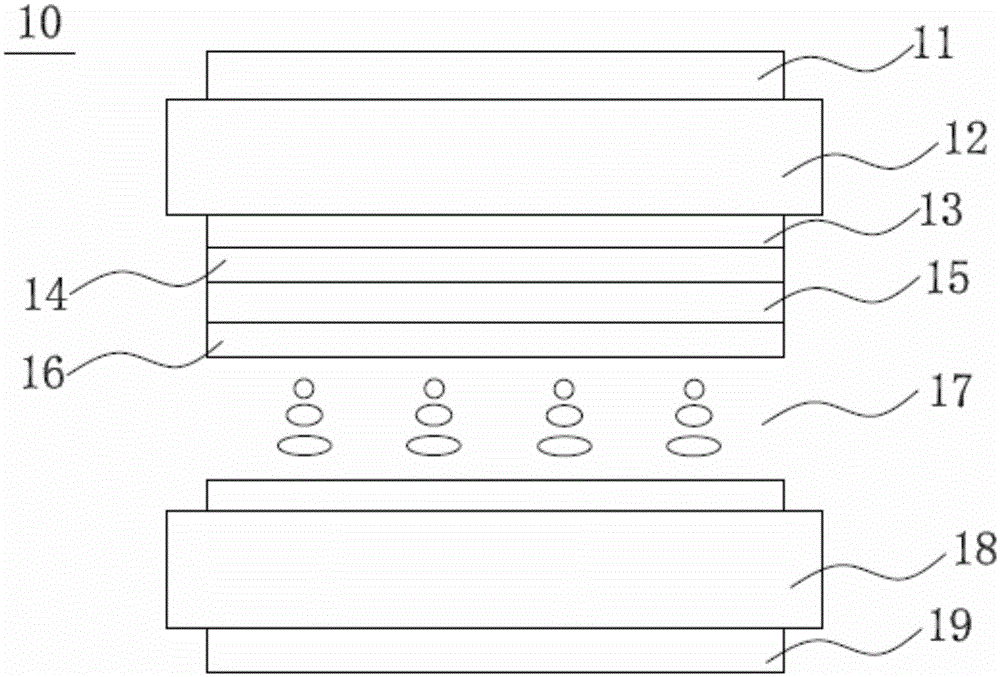

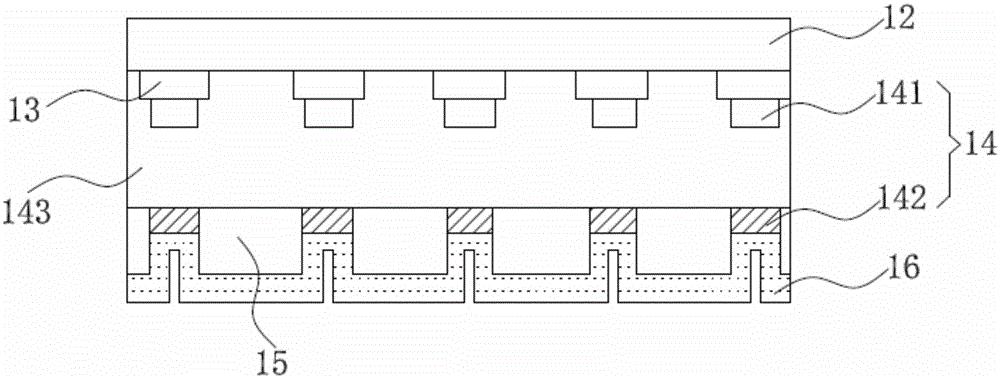

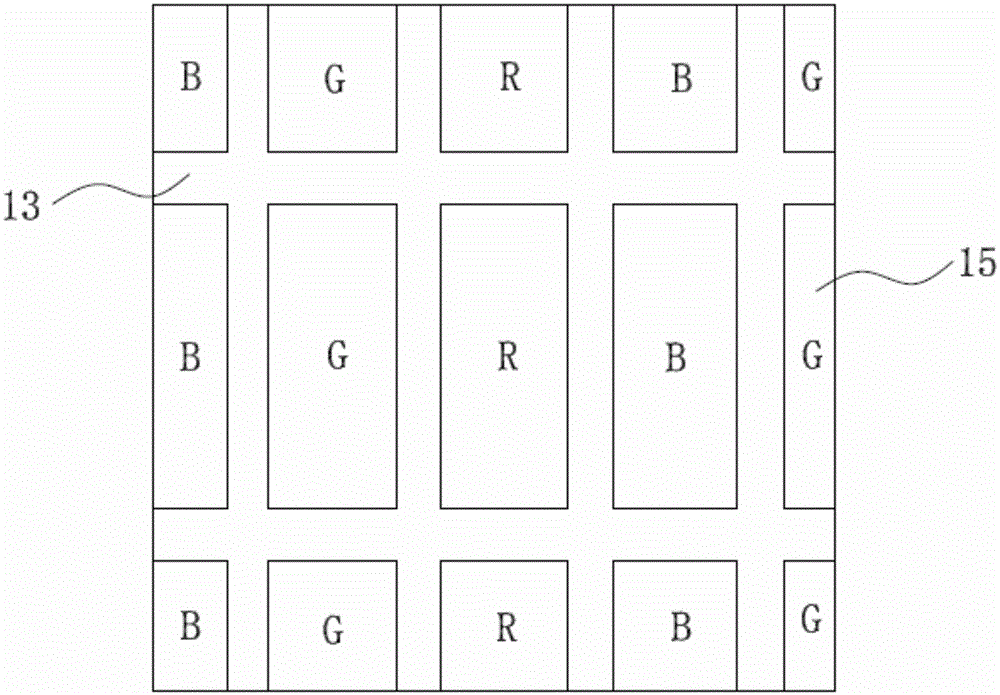

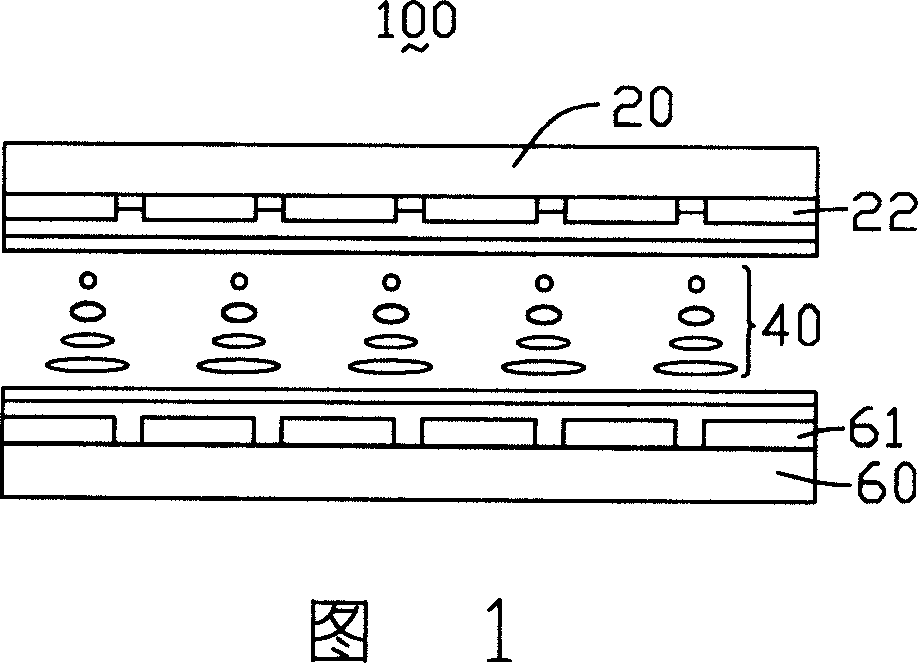

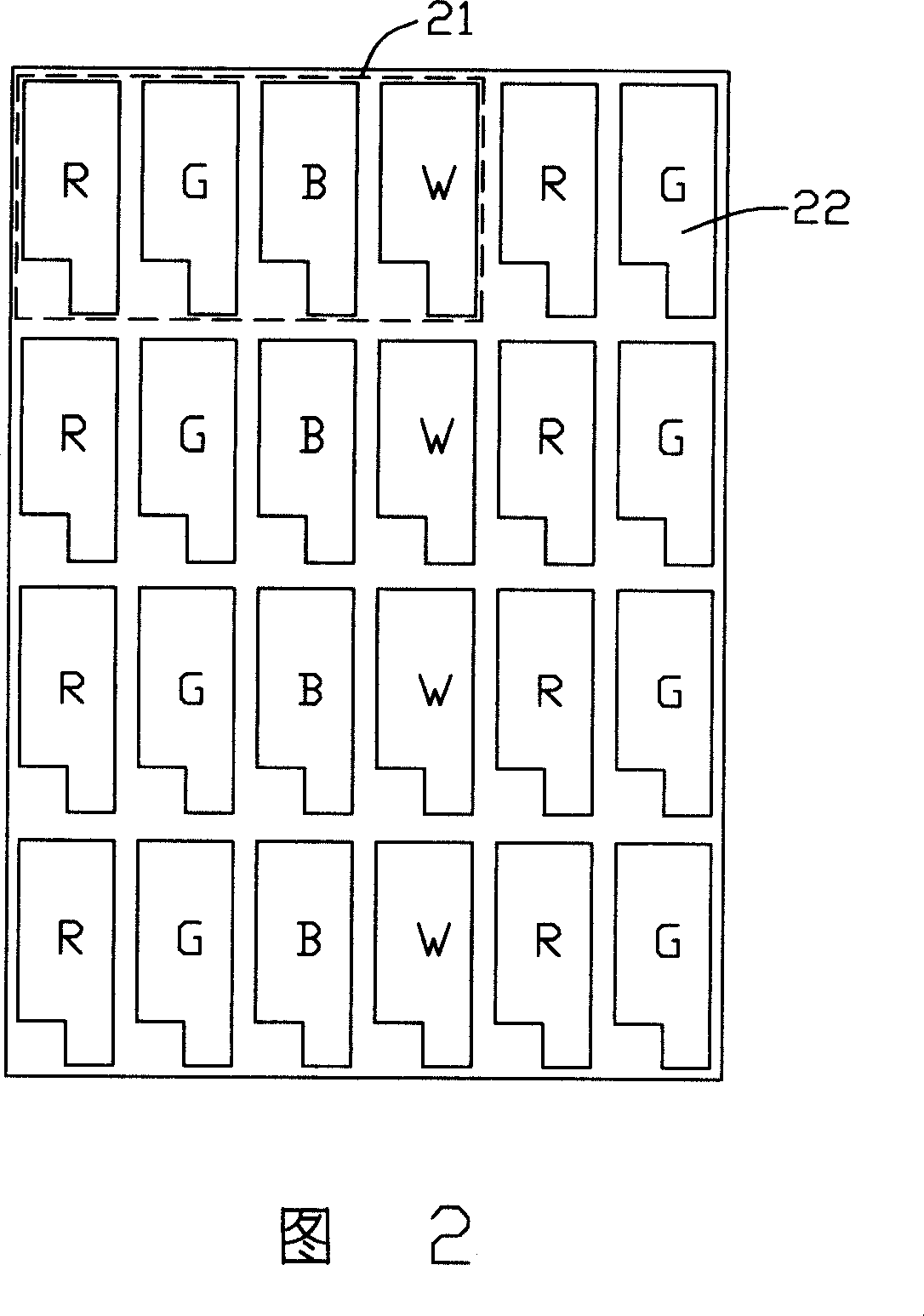

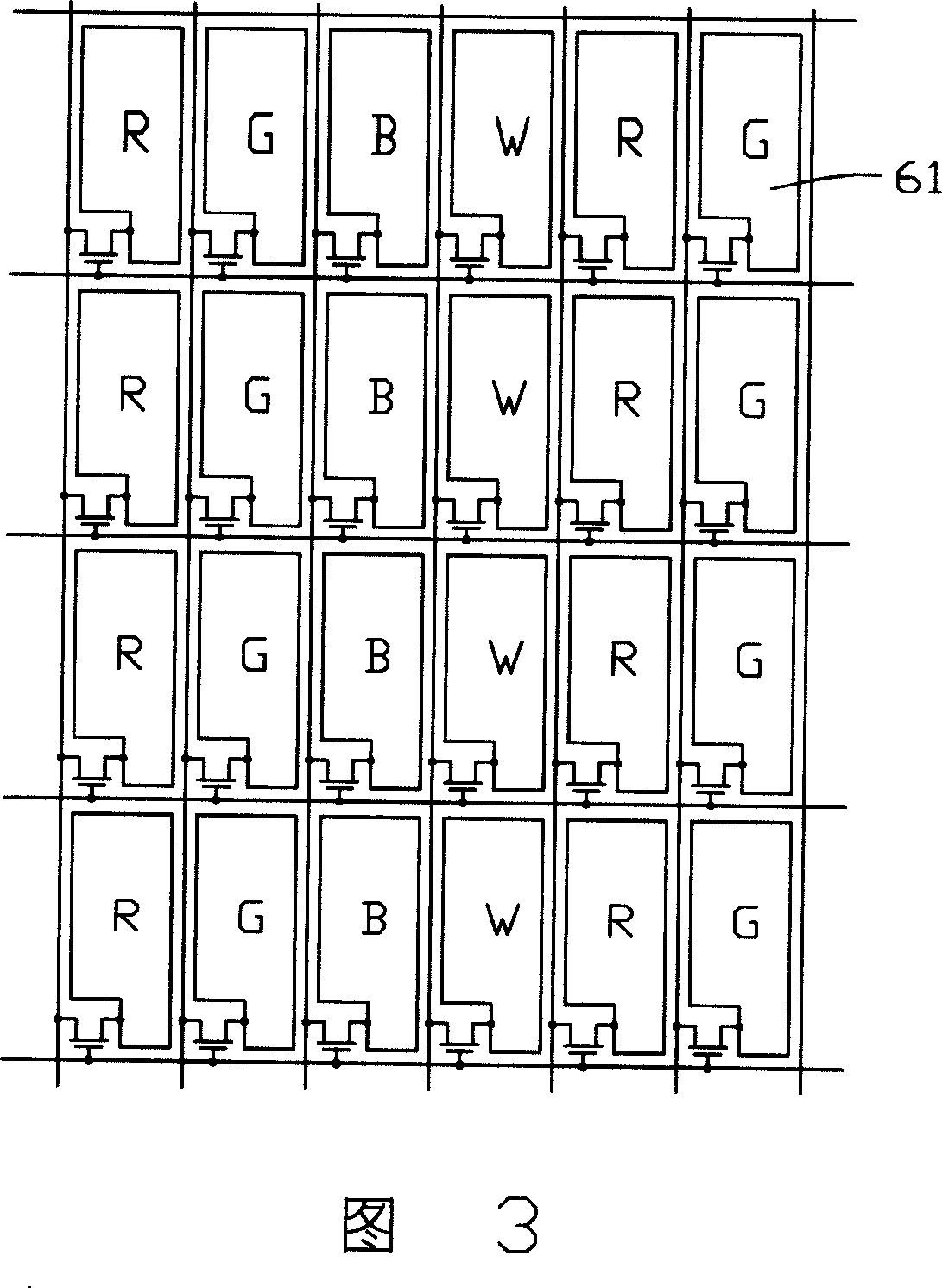

Color film substrate, liquid crystal display panel and liquid crystal display device

ActiveCN103926737AImprove color displayIncrease widthNon-linear opticsLiquid-crystal displayBlue filter

The invention discloses a color film substrate, a liquid crystal display panel and a liquid crystal display device. The color film substrate comprises a red filter layer, a green filter layer, a blue filter layer, a first shade layer isolating the red and green filter layers, a second shade layer isolating the green and blue filter layers, and a third shade layer isolating the blue and red filter layers. The third shade layer is wider than the first and second shade layers. According to the embodiments, the shade layer between the blue and red filter layers is widened, color shift of the liquid crystal display panel is significantly decreased, and display effect of the liquid crystal display panel is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

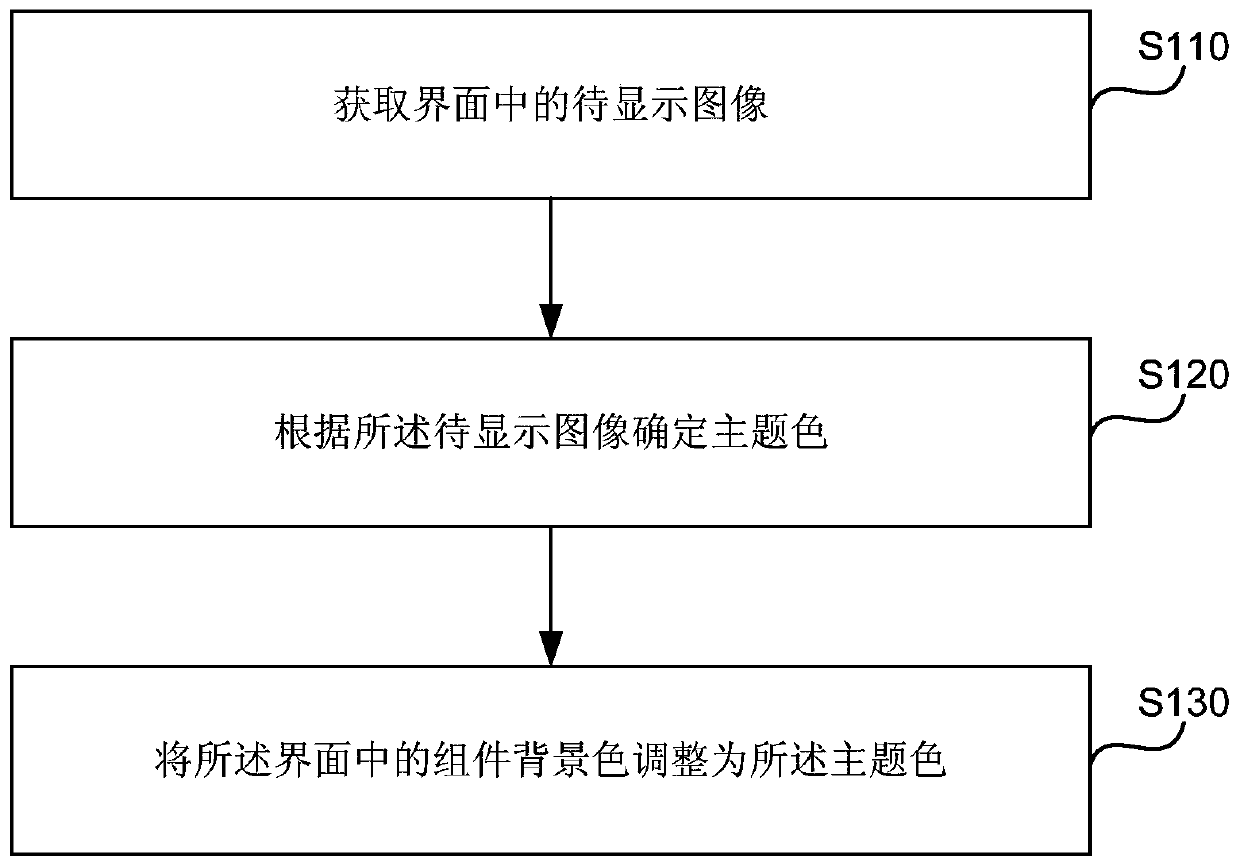

Color adjustment method and device for interface assembly, equipment and medium

ActiveCN109783178AImprove color displayGood colorExecution for user interfacesComputer graphics (images)Color changes

The embodiment of the invention discloses a color adjustment method and device for an interface component, equipment and a medium. The method comprises the steps of obtaining a to-be-displayed image in an interface; determining a theme color according to the to-be-displayed image; and adjusting the background color of the component in the interface to the theme color. According to the technical scheme, the background color of the component in the interface can be changed along with the color change of the image to be displayed, the colors of various components in the interface are effectivelyimproved, and the color display effect of the interface is better.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Light-emitting device comprising light-emitting elements having different optical path lengths

ActiveUS9287332B2Reduce power consumptionHigh definitionSolid-state devicesSemiconductor/solid-state device manufacturingOptical path lengthLight emitting device

A light-emitting device and a lighting device each of which includes a plurality of light-emitting elements exhibiting light with different wavelengths are provided. The light-emitting device and the lighting device each have an element structure in which each of the light-emitting elements emits only light with a desired wavelength, and thus the light-emitting elements have favorable color purity. In the light-emitting element emitting light (λR) with the longest wavelength of the light with different wavelengths, the optical path length from a reflective electrode to a light-emitting layer (a light-emitting region) included in an EL layer is set to λR / 4 and the optical path length from the reflective electrode to a semi-transmissive and semi-reflective electrode is set to λR / 2.

Owner:SEMICON ENERGY LAB CO LTD

Reflective display device with light compensation module

InactiveCN102402095AImprove color displayPoint-like light sourceLighting device detailsLight guideDisplay device

The invention discloses a reflective display device with a light compensation module. The reflective display device comprises a light guide plate, at least one light source module, a photo sensor unit, a processing unit and a storage unit, wherein the light source module at least comprises a red light source, a green light source and a blue light source; the storage unit stores a preset intensity proportion parameters of three basic color light, namely red light, green light and blue light, of standard white light; the photo sensor unit detects the intensity of the three basic color light, namely the red light, the green light and the blue light, and converts the intensity into corresponding electric signals which are then output to the processing unit; and the processing unit determines the intensity proportions of the three basic color light according to the electric signals, compares the intensity proportions with the preset intensity proportion parameter, and starts the luminous light source of the corresponding color in the light source module when the intensity of any light in the three basic color light in ambient light is lower than the preset intensity proportion parameter. The light, emitted by the light source module, of the corresponding color, compensates the intensity proportion of the three basic color light, namely the red light, the green light and the blue light, in the ambient light, so the color display effect of the reflective display device is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

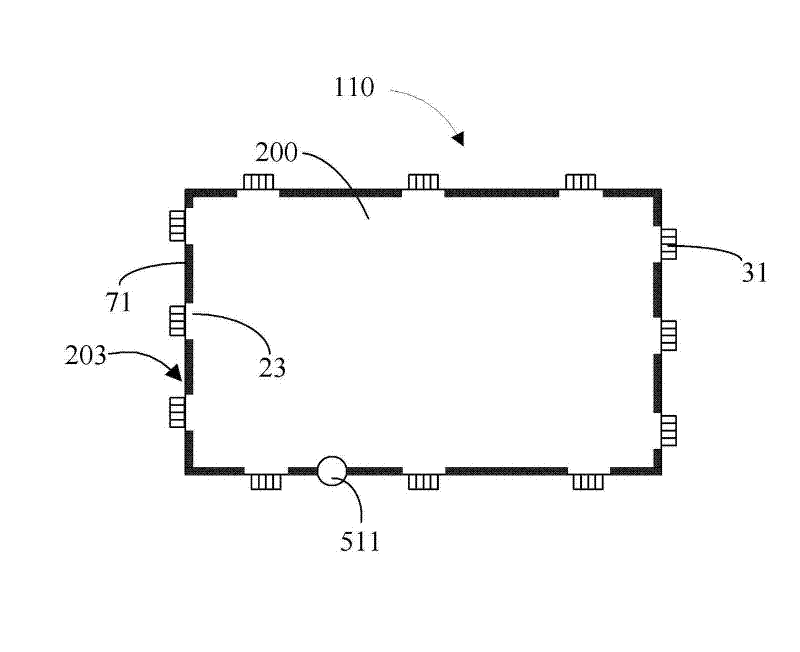

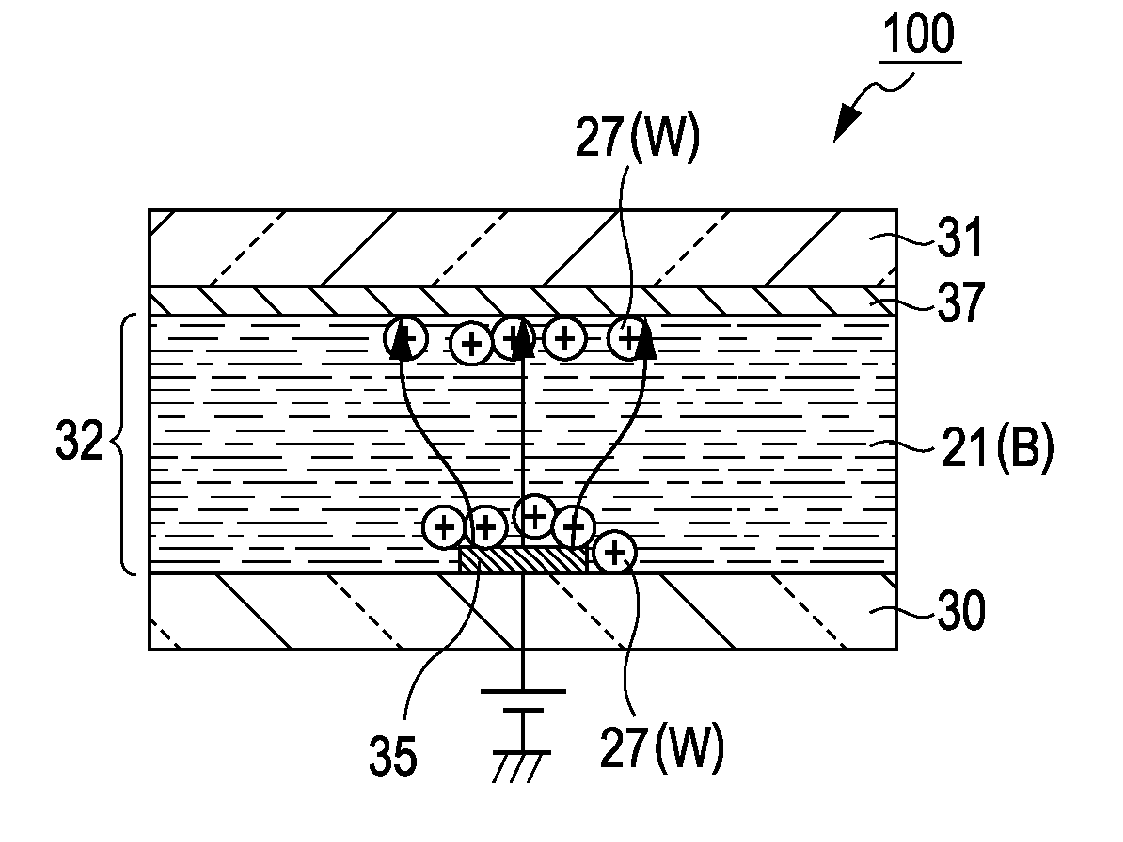

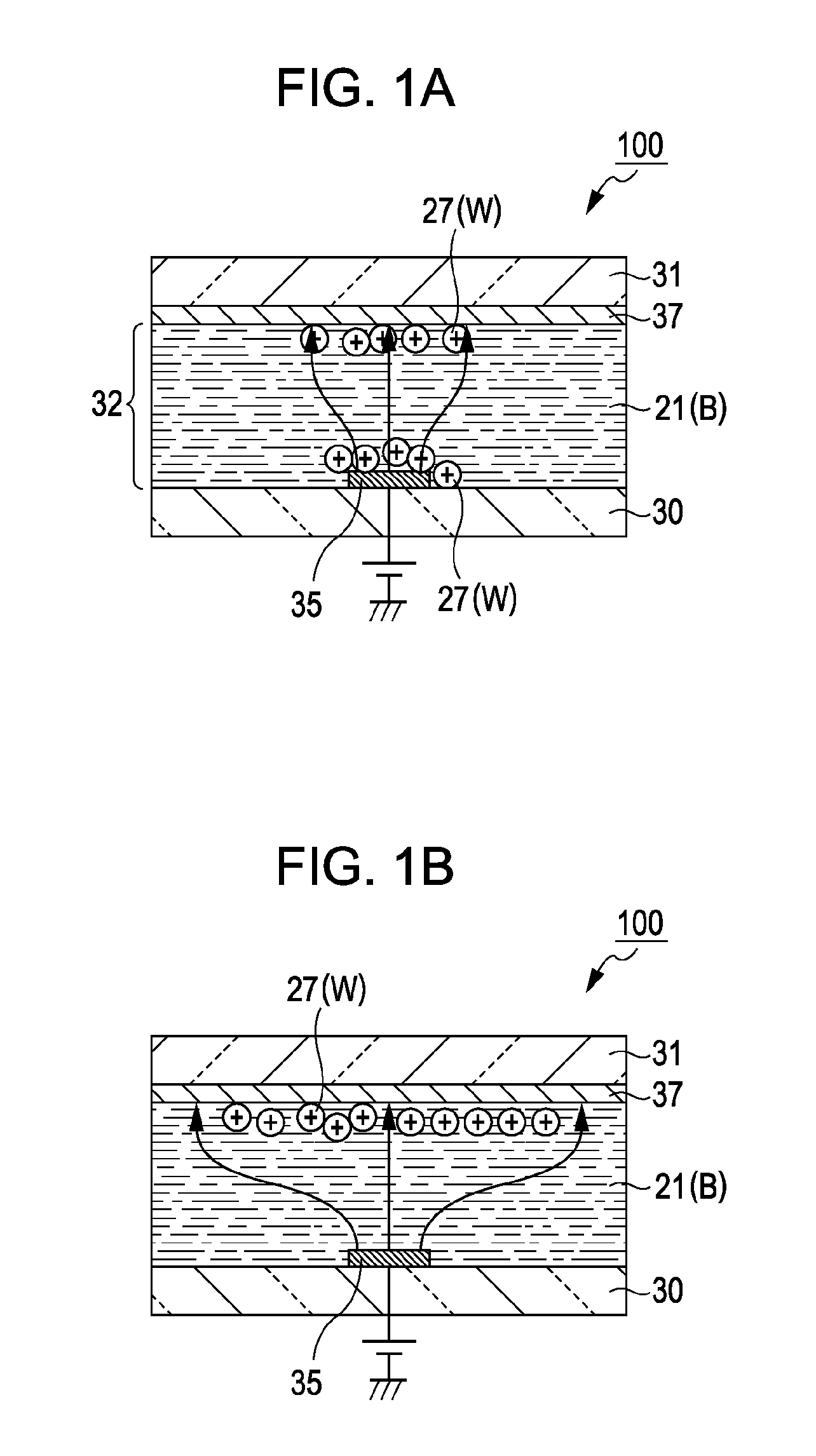

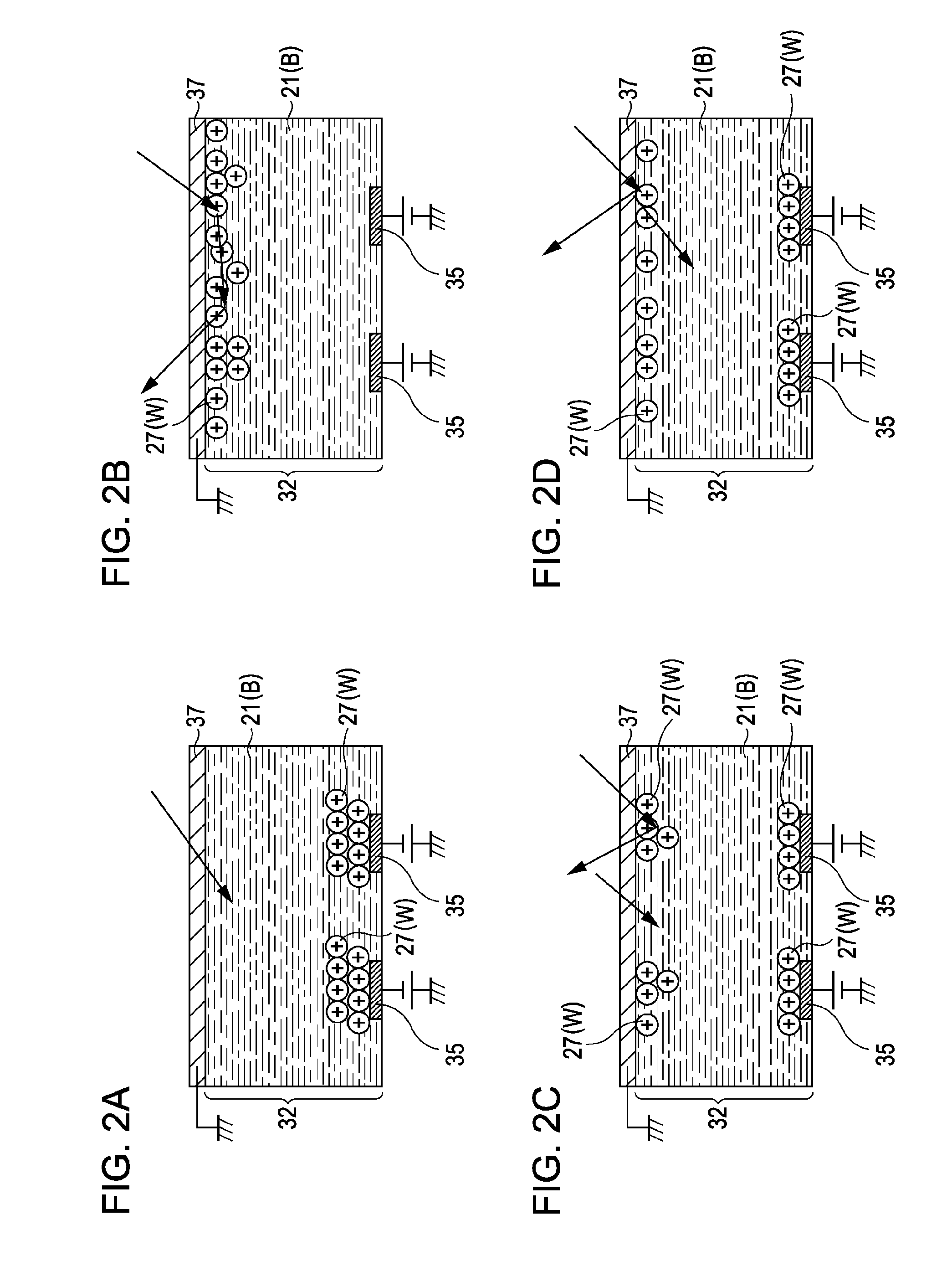

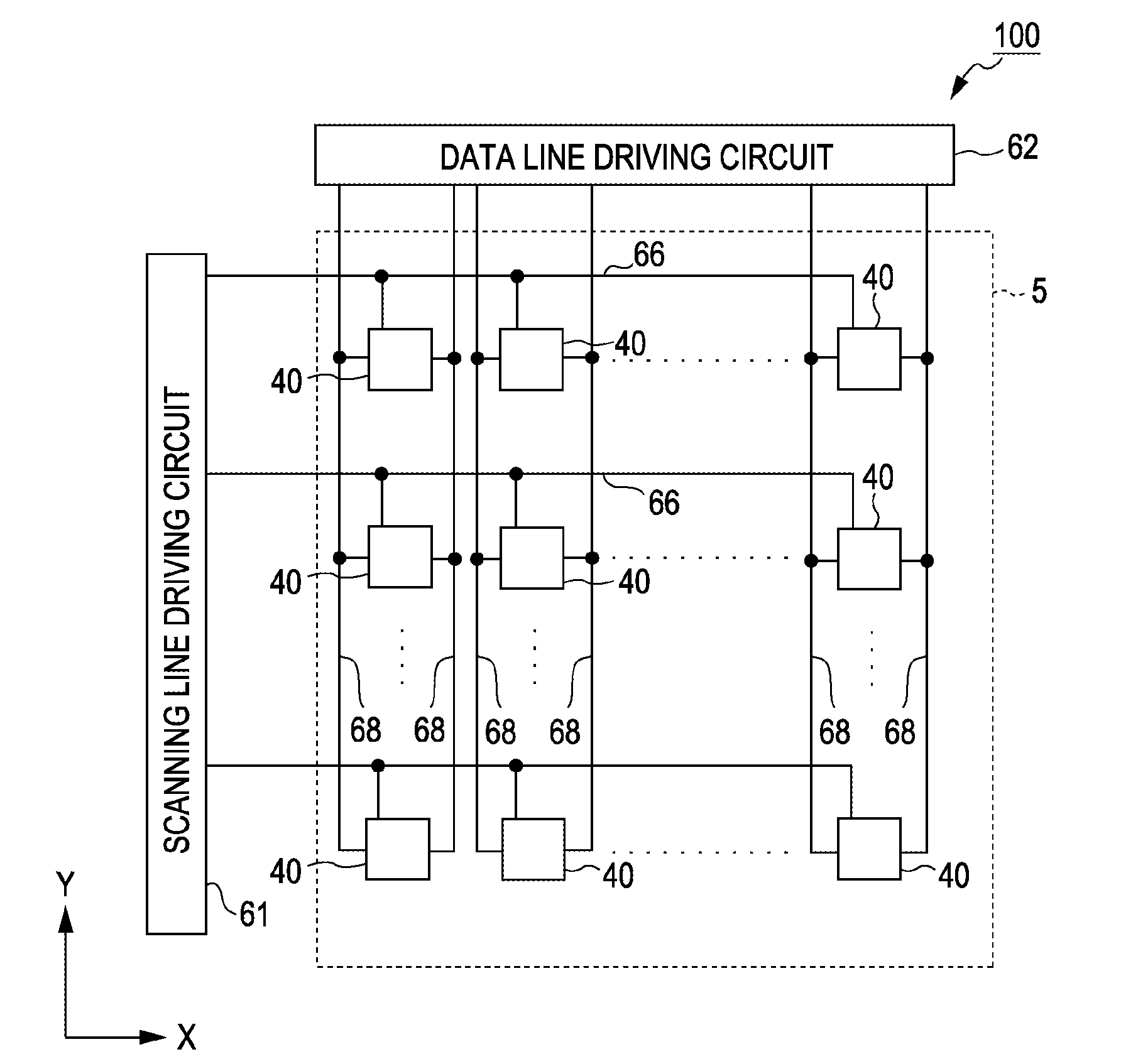

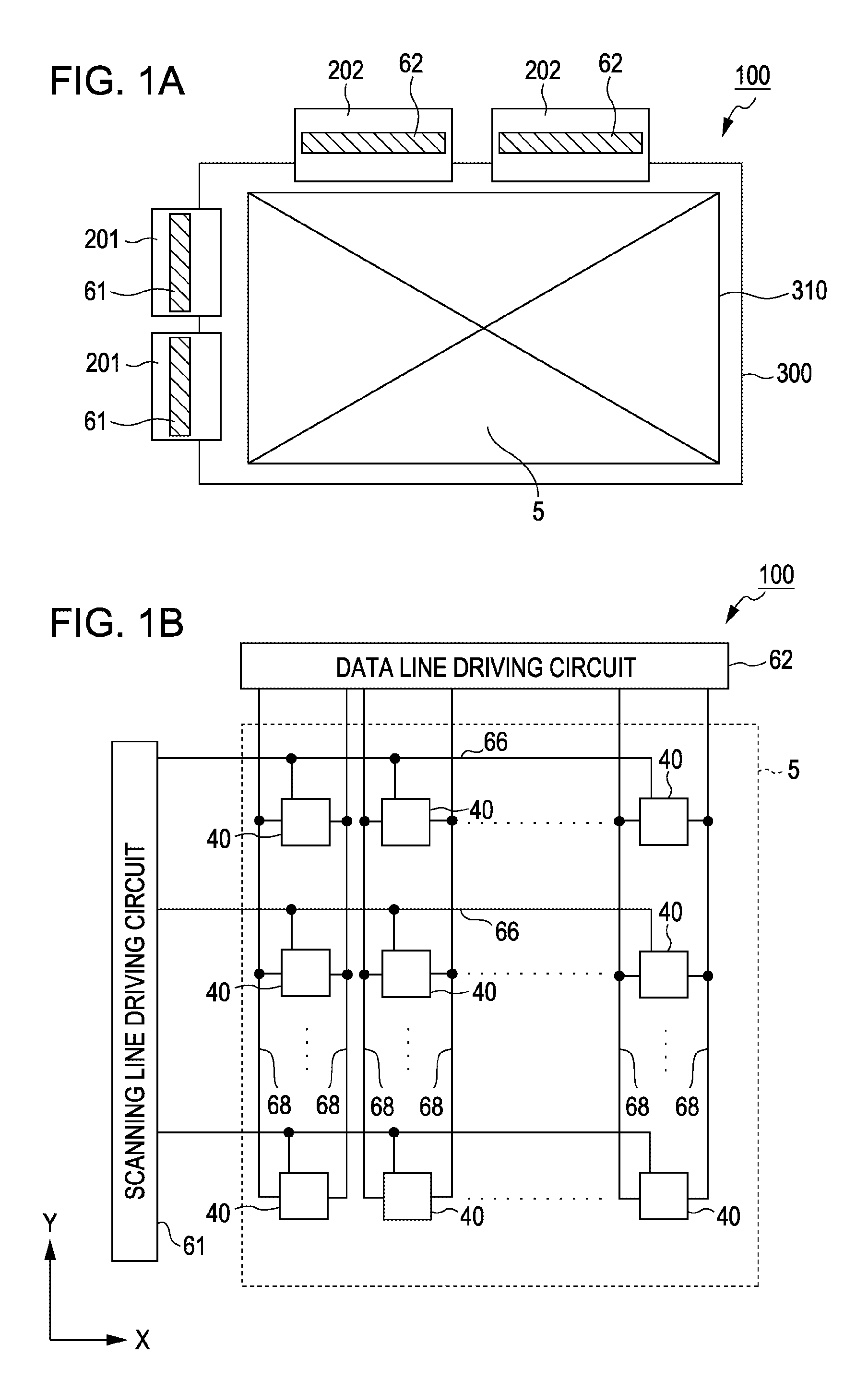

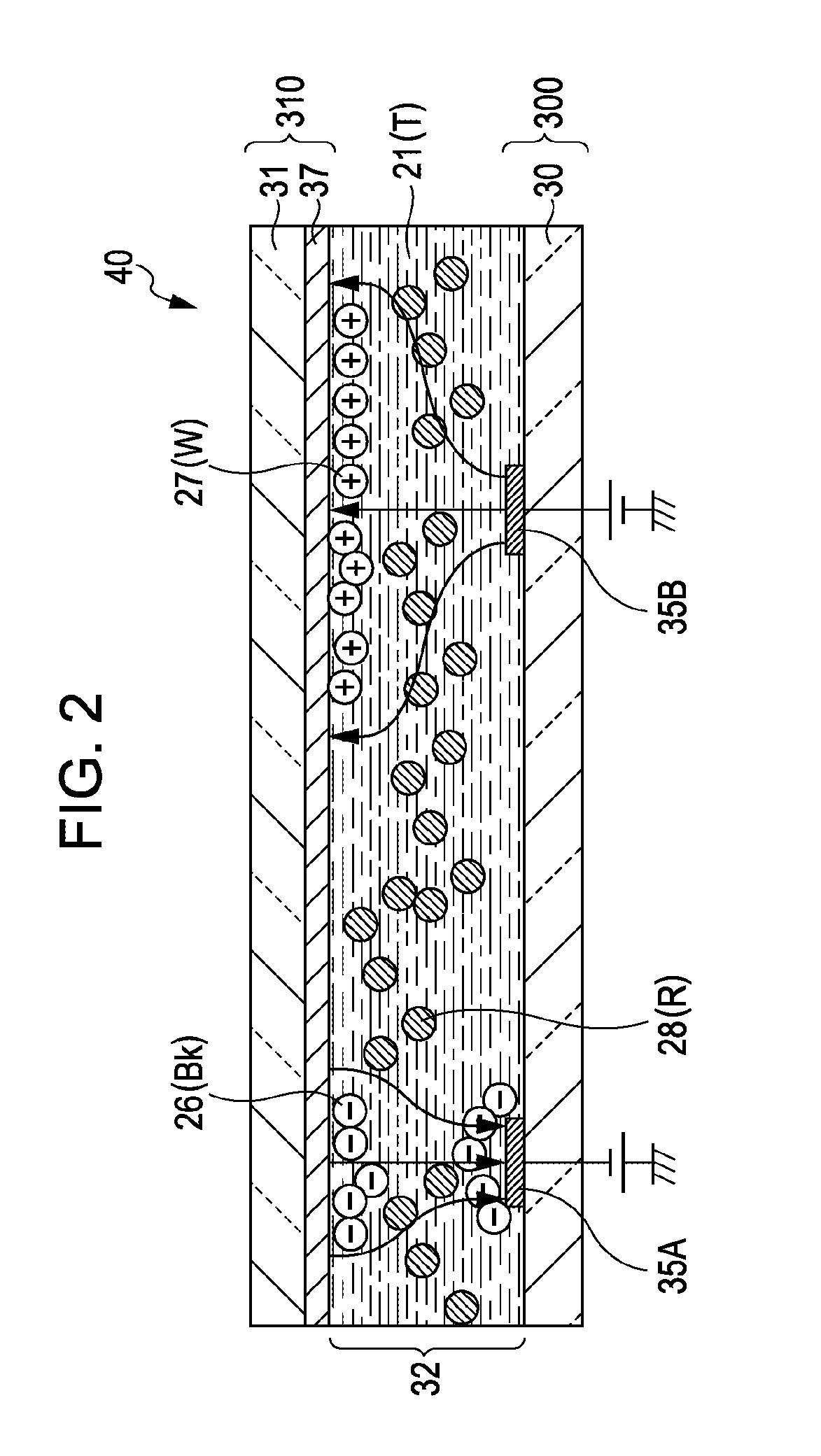

Electrophoretic display device and electronic apparatus

InactiveUS20110248909A1Improve color displayStatic indicating devicesNon-linear opticsElectrophoresisDisplay device

Provided is an electrophoretic display device including: a first substrate; a second substrate; an electrophoretic layer which is arranged between the first substrate and the second substrate and has at least a dispersion medium and particles mixed in the dispersion medium; a plurality of first electrodes which is formed in an island shape on the electrophoretic layer side of the first substrate and is provided for each pixel; and a second electrode which is formed on the electrophoretic layer side of the second substrate with an area wider than that of the first pixel electrode. Gradation is controlled using an area of the particles which are visually recognized when the electrophoretic layer is viewed from the second electrode side.

Owner:SEIKO EPSON CORP

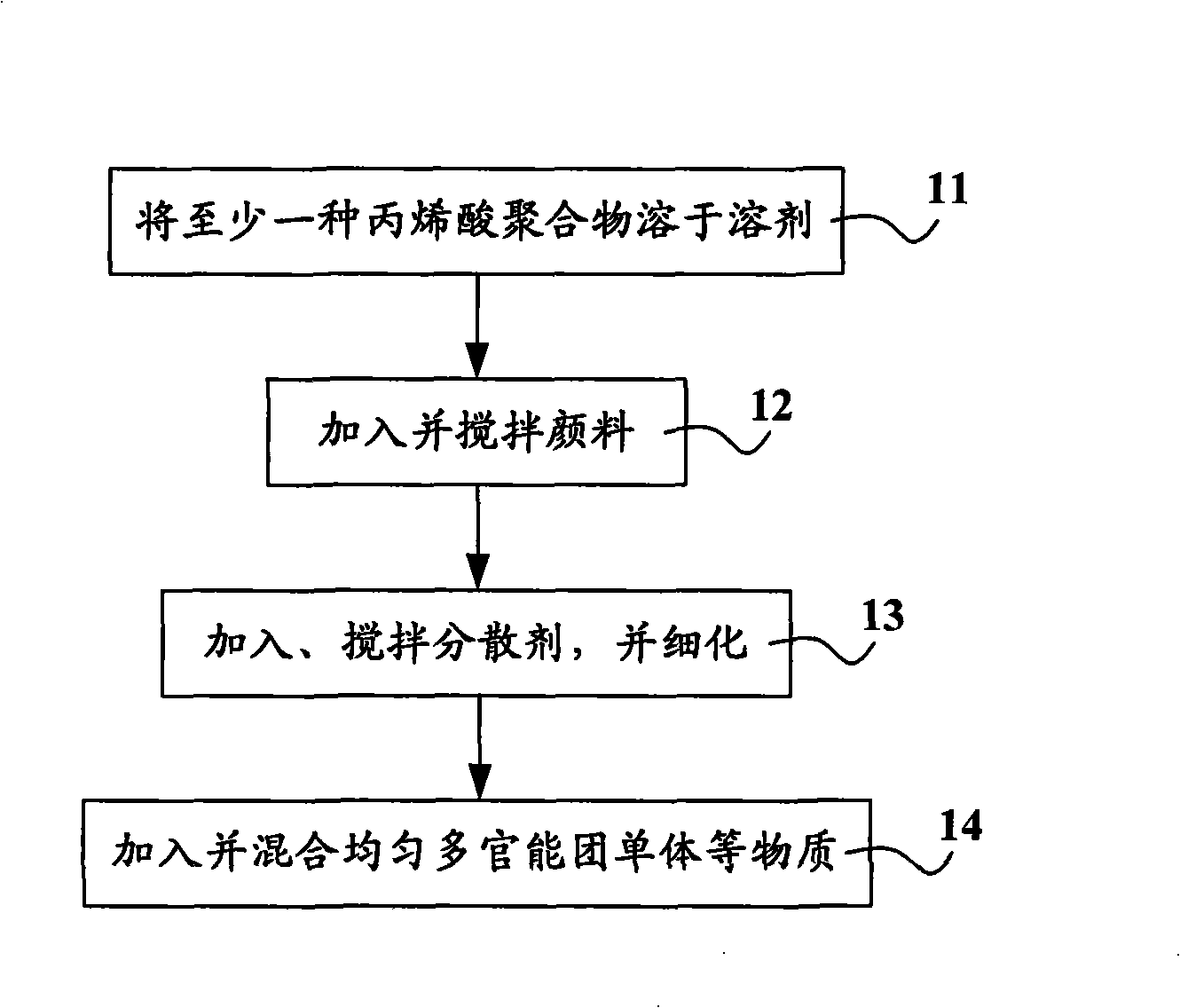

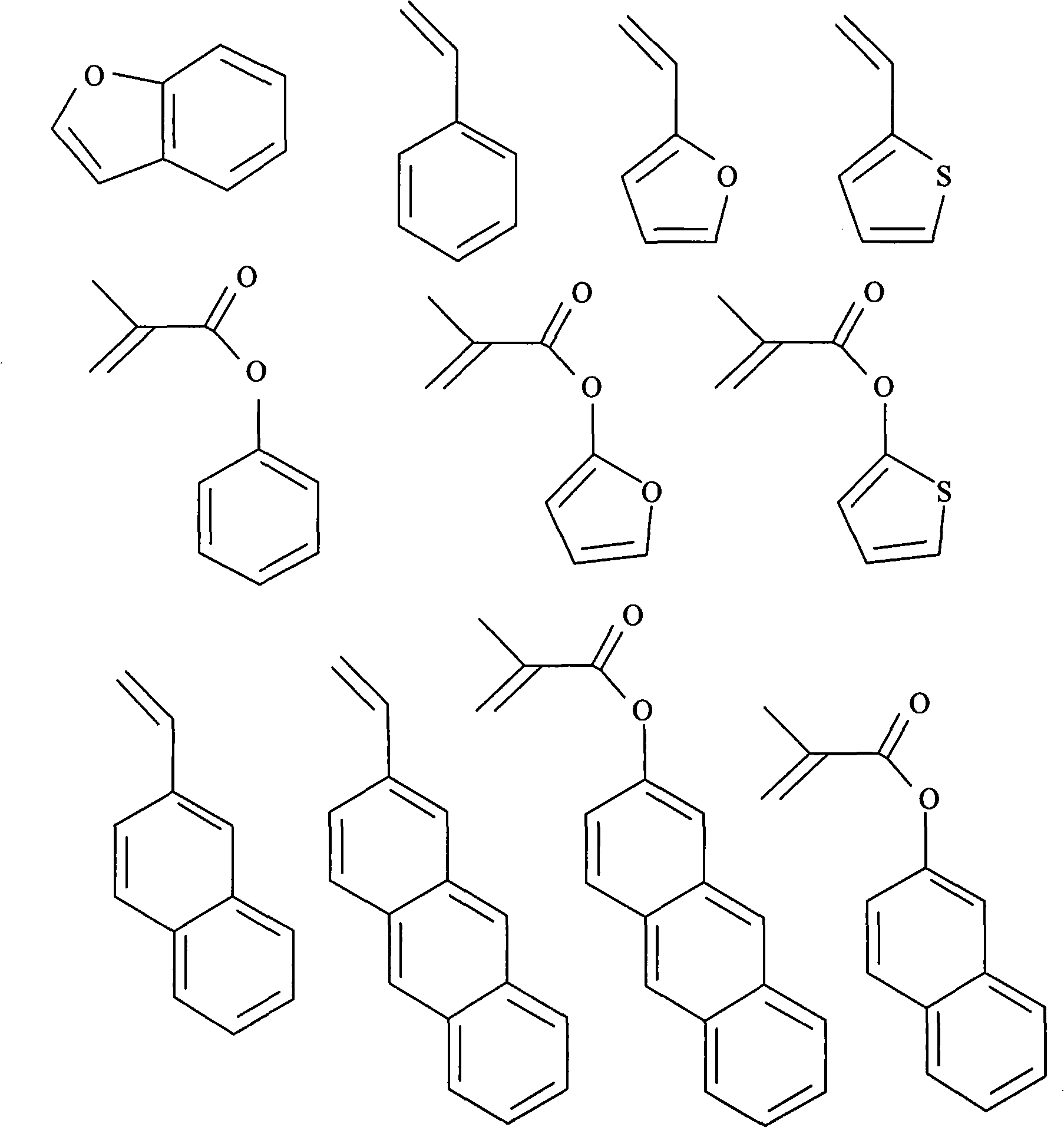

Colorant, color filter, LCD device, composition and preparation

ActiveCN101323708AImprove transmittanceHigh color purityOrganic dyesPhotosensitive materials for photomechanical apparatusAcrylic polymerPhotochemistry

Owner:BOE TECH GRP CO LTD

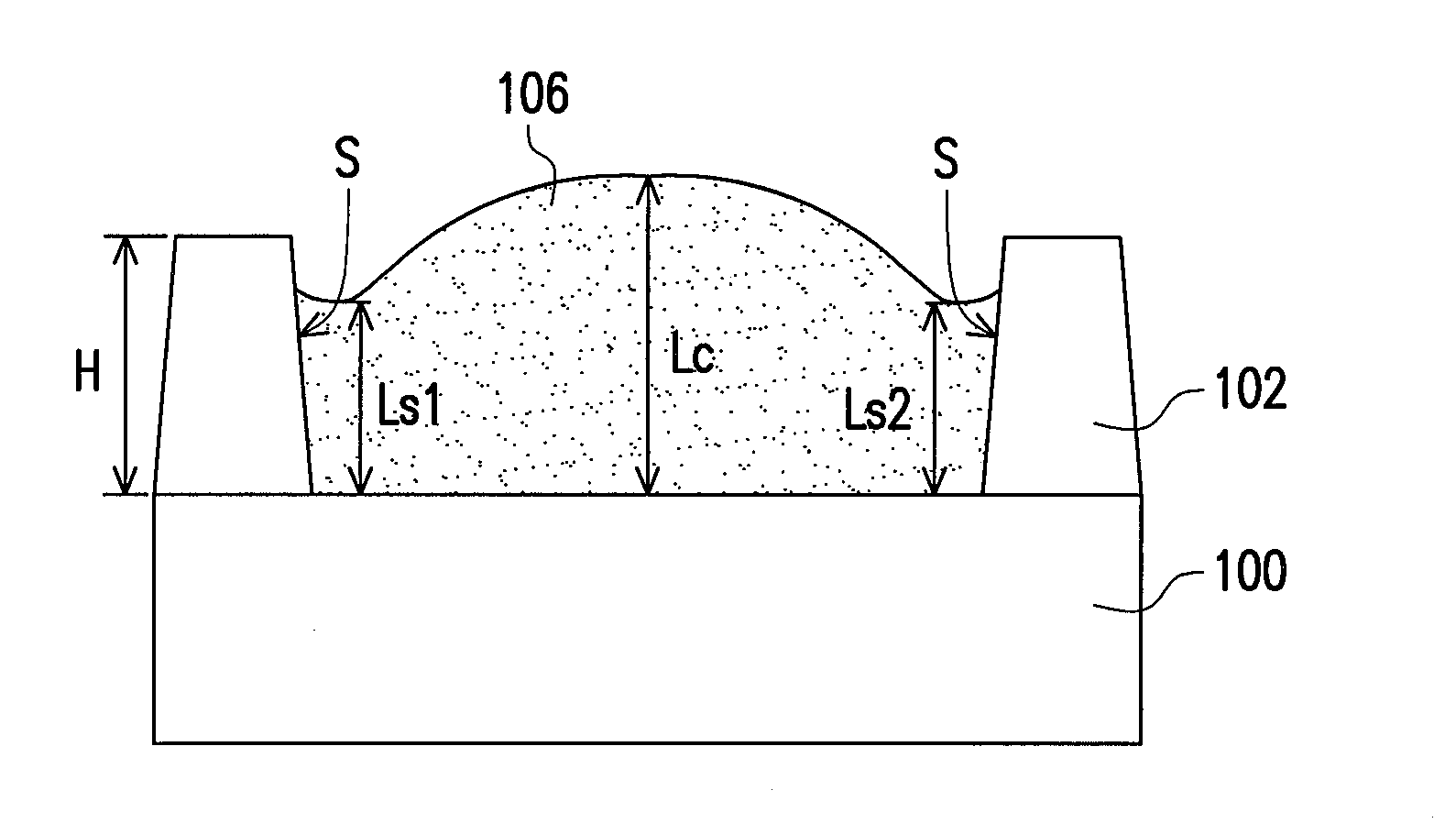

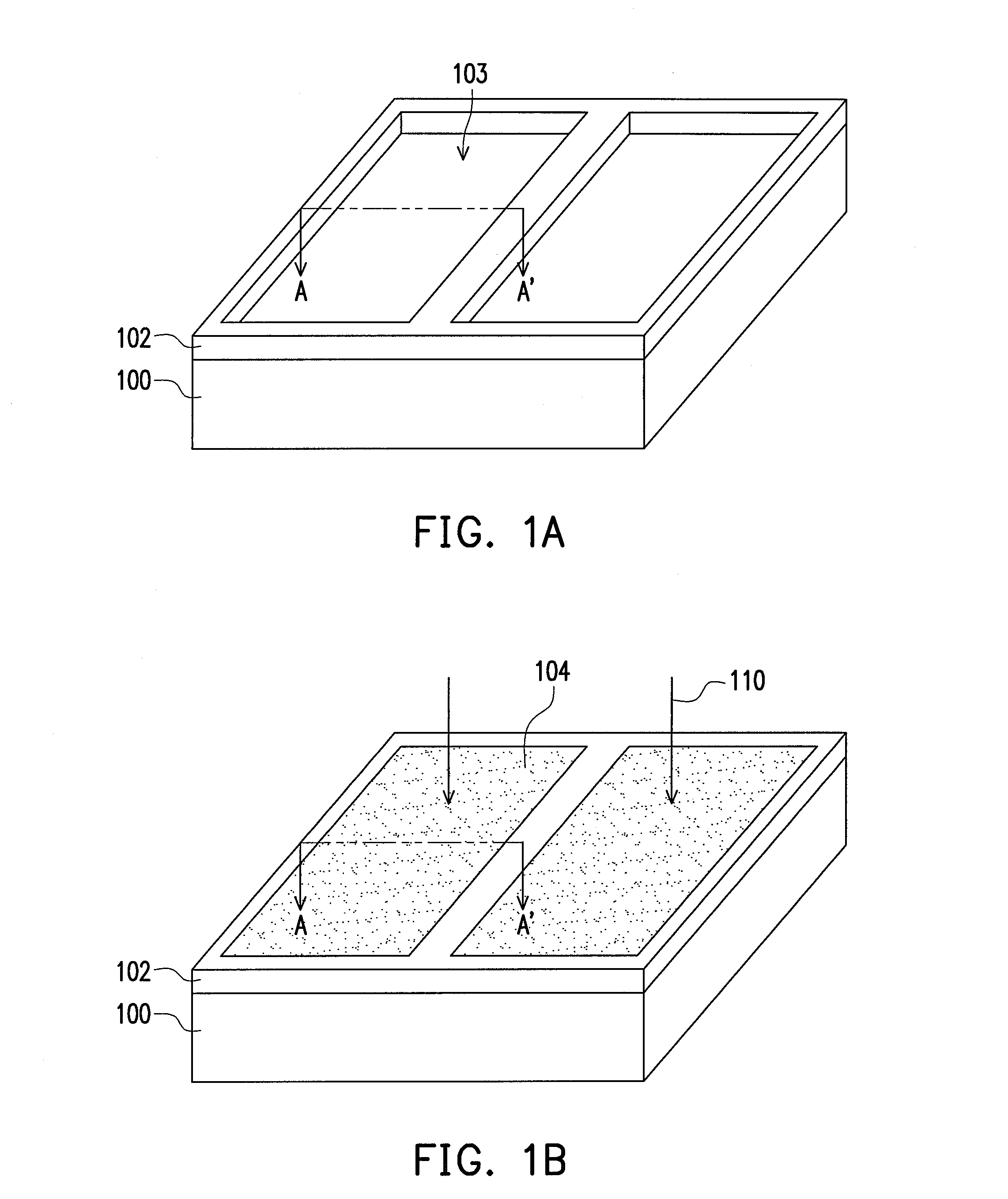

Color filter array and manufacturing method thereof

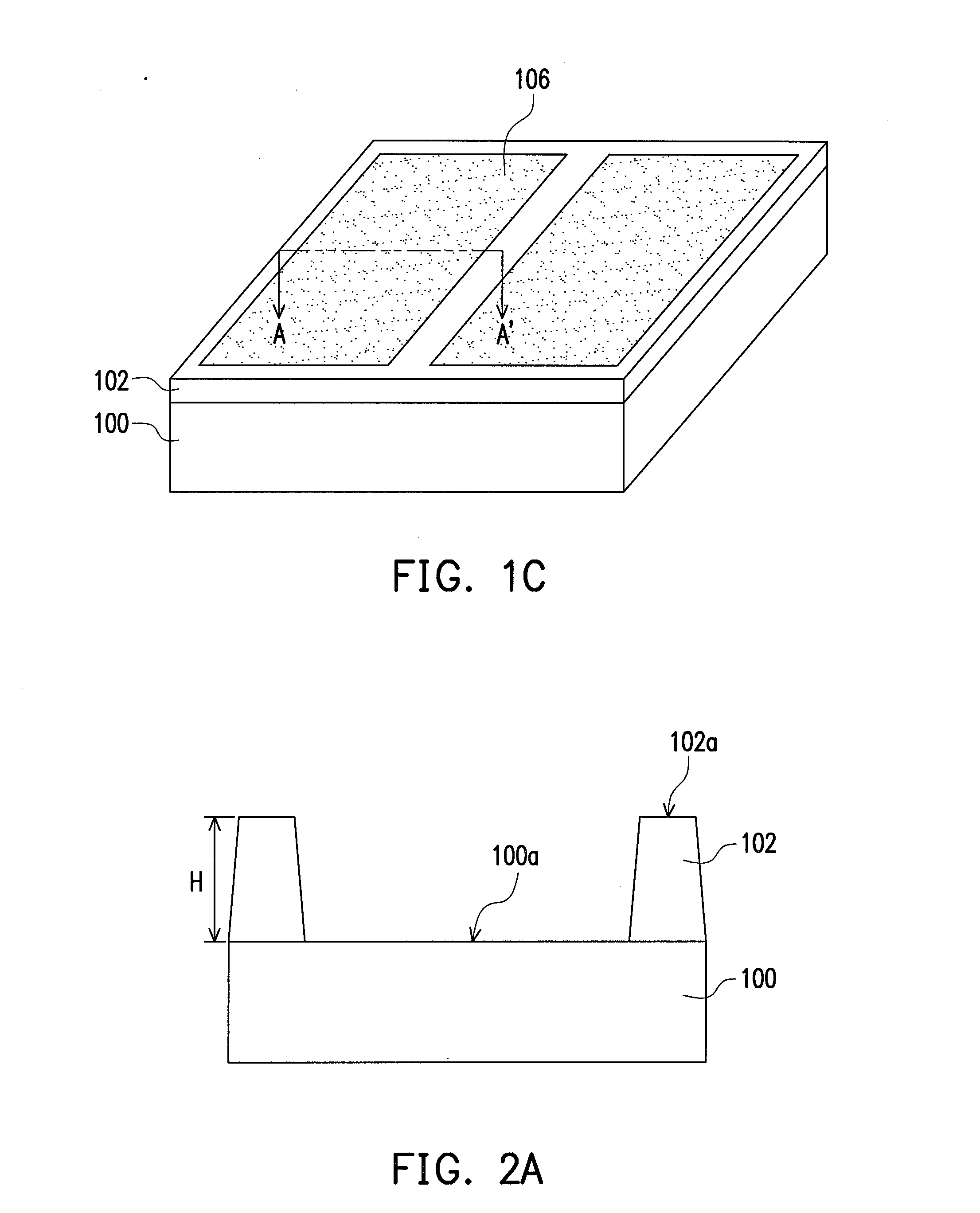

ActiveUS20130038958A1Lessening difference in film thicknessImprove the display effectInking apparatusPretreated surfacesEngineeringColor filter array

A color filter array includes a substrate, a light shielding layer, and color filter patterns. The light shielding layer is on the substrate and has openings exposing a surface of the substrate. Besides, the light shielding layer has a height H. The color filter patterns are located in the openings of the light shielding layer. Each color filter pattern has the maximum film thickness Lc and the minimum film thickness Ls, and the difference between the maximum film thickness Lc and the minimum film thickness Ls is ΔL. The maximum film thickness Lc of each color filter pattern satisfies (m×H)<Lc<(n×H), wherein m comprises about 0.83, n comprises about 0.91, the height H of the light shielding layer satisfies a<H<b, wherein a comprises about 1.6 um and b comprises 2.22 um, and the difference ΔL is less than about 0.39 um.

Owner:AU OPTRONICS CORP

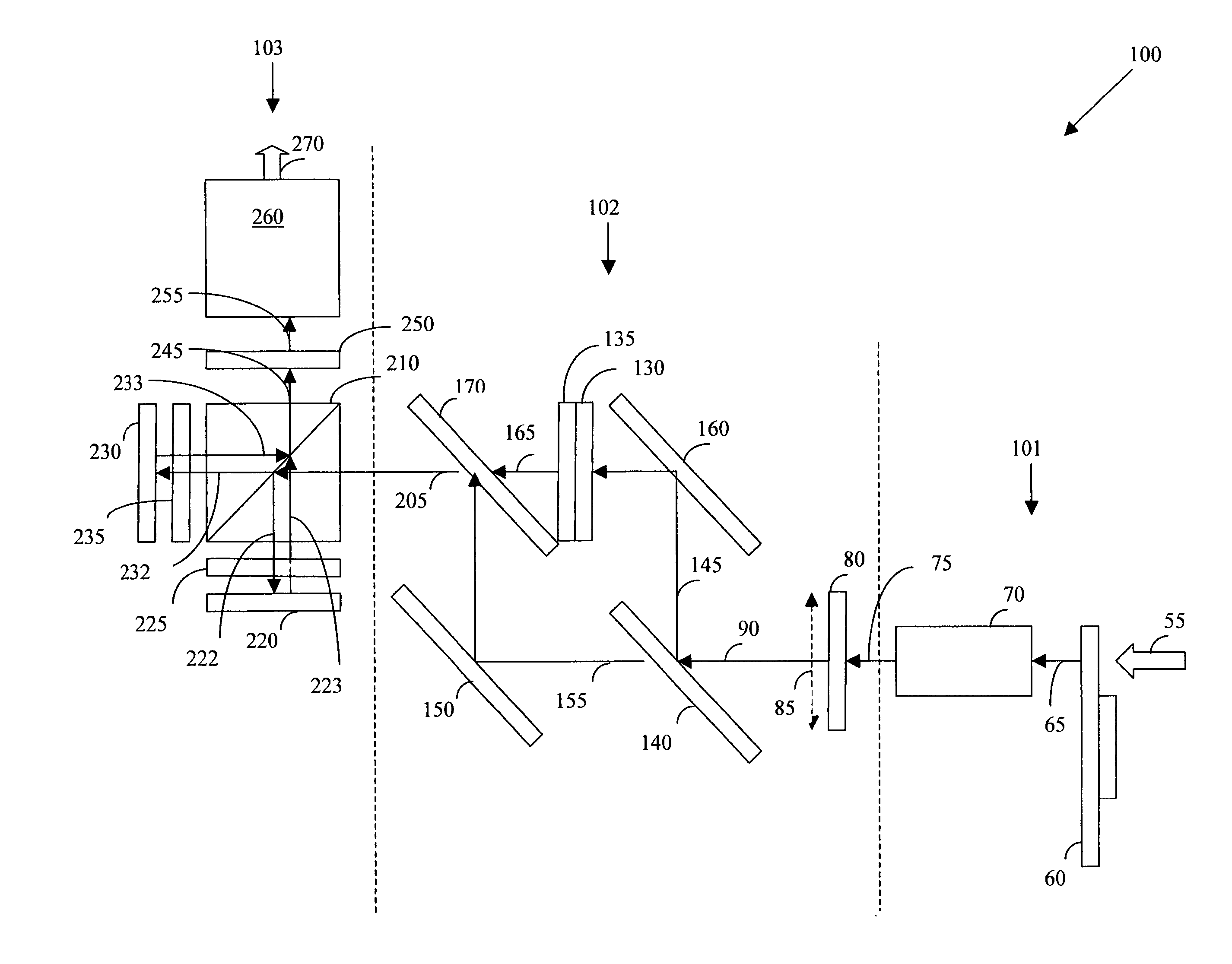

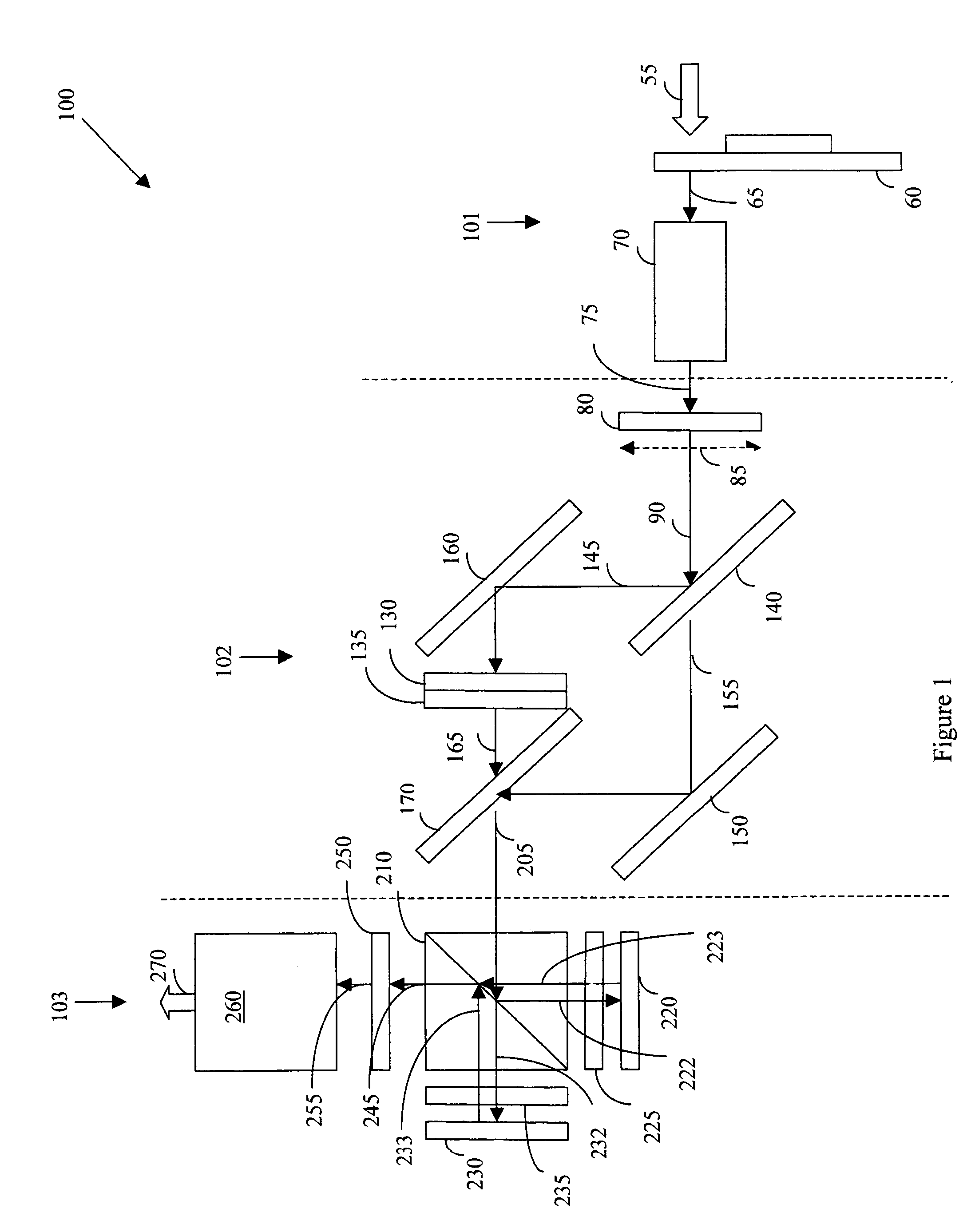

Two panel optical engine for projection applications

InactiveUS7008064B2High quality color display effectLow costProjectorsOptical elementsComplex adaptive systemBill of materials

Optical engines using a reduced number of components offer advantages over more complex optical systems. Three panel optical engines have offered the advantage of relatively high throughput but at the cost of complexity and increased components on the bill of materials. Conventional two-panel engines have required the use of complex retarder structures to achieve the dual polarizations state for the three primary colors. The present invention achieves this goal while using simpler optical retarders.

Owner:JASPER DISPLAY

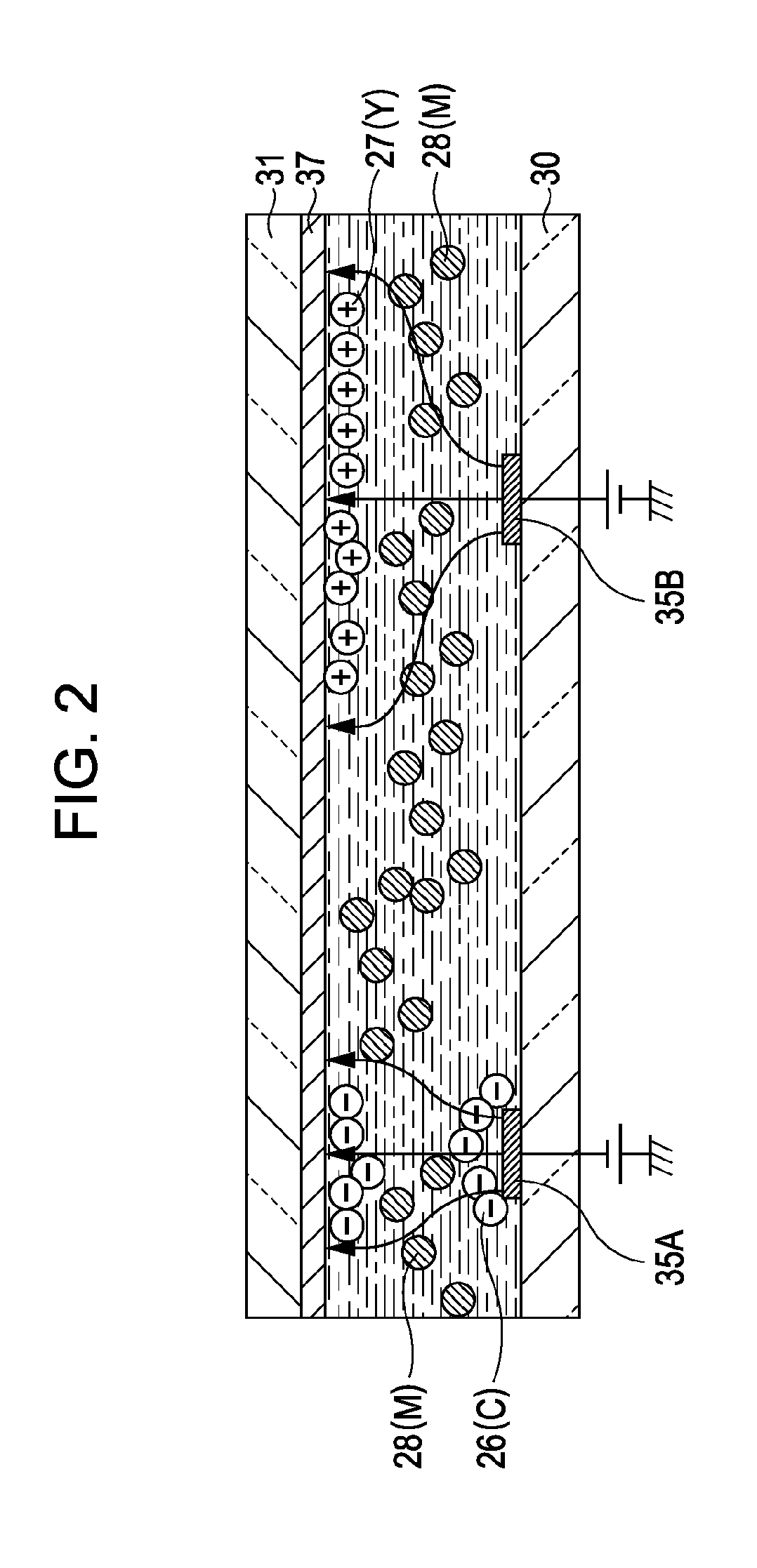

Electrophoretic display device, driving method of the same, and electronic apparatus

ActiveUS20110249043A1Improve color displayCathode-ray tube indicatorsNon-linear opticsOptoelectronicsDisplay device

An electrophoretic display device is provided with a first substrate, a second substrate, an electrophoretic layer which is arranged between the first substrate and the second substrate and has at least a dispersion medium and particles mixed in the dispersion medium, a first electrode which is formed in an island shape on the electrophoretic layer side of the first substrate for each pixel, and a second electrode which is formed on the electrophoretic layer side of the second substrate with an area wider than the first electrode, where gradation is controlled using an area of the particles which are visually recognized when the electrophoretic layer is viewed from the second electrode side.

Owner:E INK CORPORATION

Electrophoretic display device, driving method therefor, and electronic apparatus

InactiveUS20110285756A1Smooth movementImprove color displayCathode-ray tube indicatorsNon-linear opticsElectrophoresisDisplay device

An electrophoretic display device includes a first substrate and a second substrate, an electrophoretic layer disposed between the first substrate and the second substrate and containing at least a dispersion medium and positively or negatively charged particles mixed in the dispersion medium, first electrodes formed in island shapes and driven independently in respective pixels on a side of the electrophoretic layer of the first substrate, a second electrode formed on a side of the electrophoretic layer of the second substrate and having a larger area than the first electrodes, transistors connected to the first electrodes, and a first control electrode disposed in at least part of an area where the first electrodes are absent above a drain electrode of a first transistor of the transistors. A potential for repelling the particles is applied to the first control electrode.

Owner:SEIKO EPSON CORP

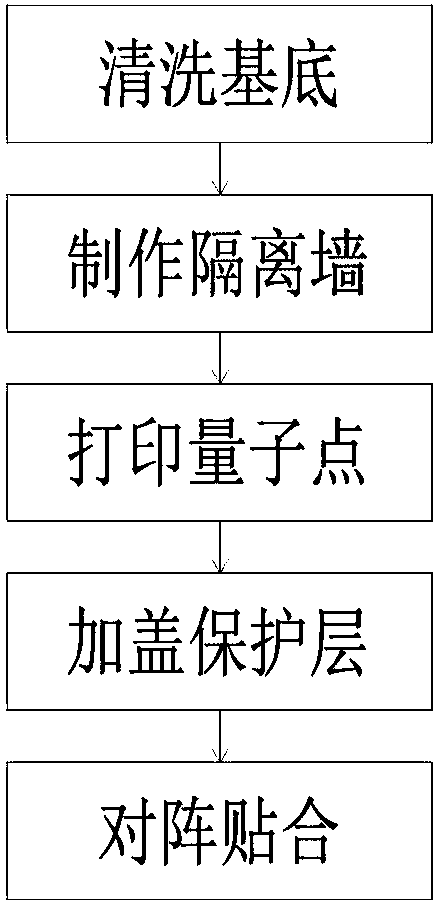

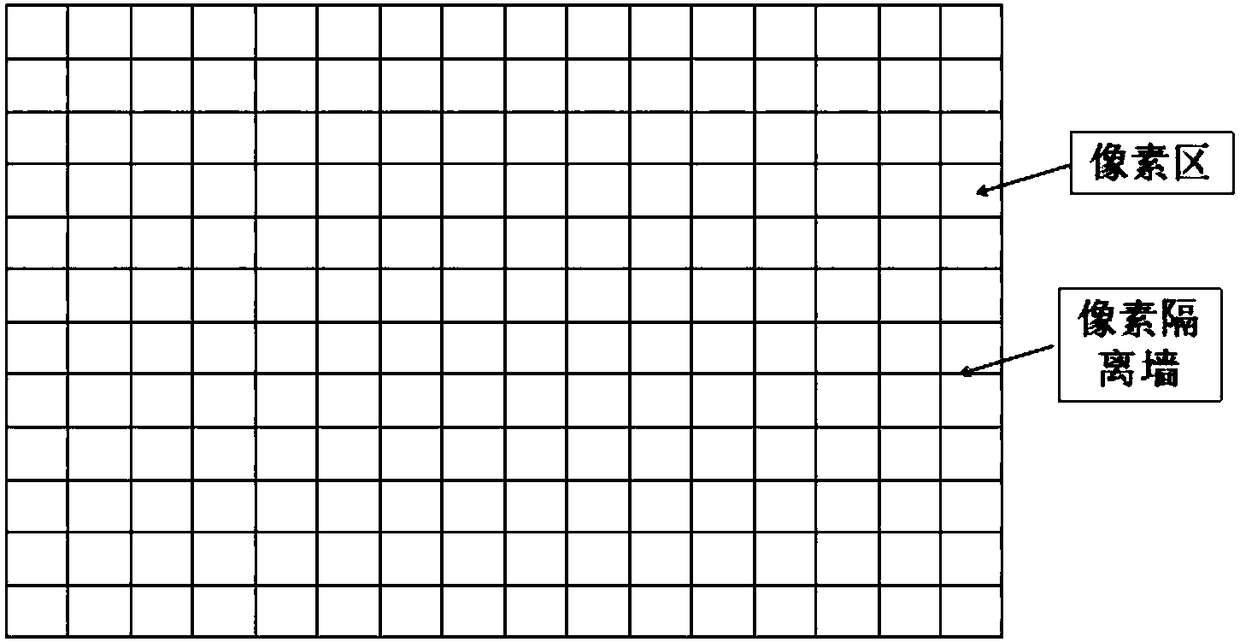

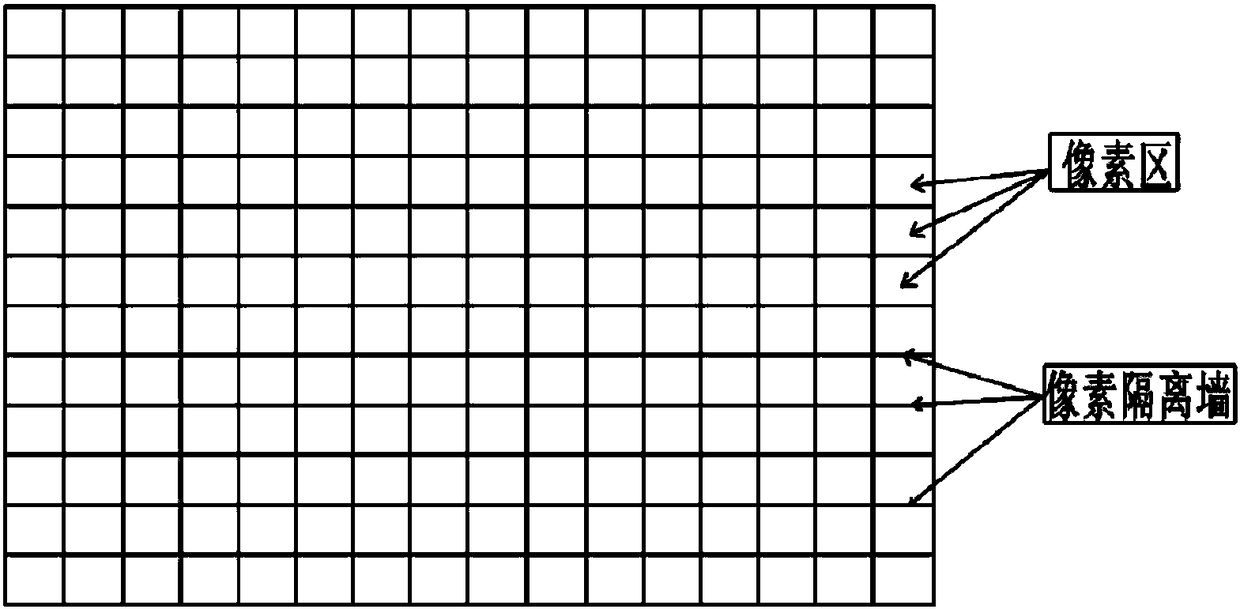

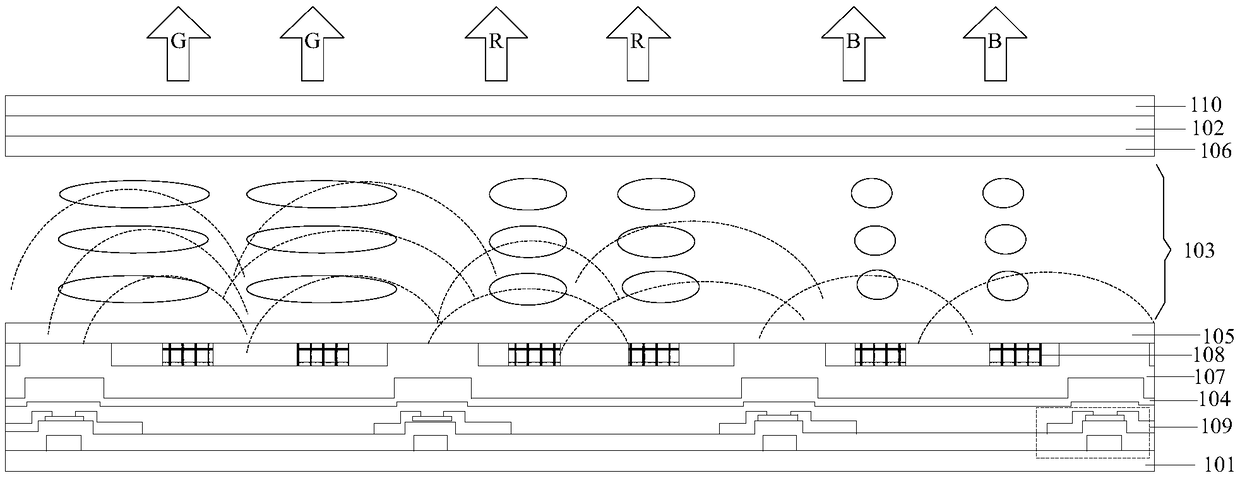

Manufacturing method of high-efficiency light conversion color display pixel film

InactiveCN108321170AIncrease profitImprove display color gamutSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotQuantum

The invention relates to the technical field of display, and particularly relates to a manufacturing method of a high-efficiency light conversion color display film. The manufacturing method comprisesthe following steps that A) a substrate is provided and the substrate is cleaned; B) a pixel isolation wall is manufactured on the cleaned substrate; C) the quantum dot material of the correspondingcolor is printed in the designed pixel area; D) a transparent protection layer is additionally arranged on the prepared quantum dots; and E) the quantum dot plate is aligned and fit with the corresponding OLED display pixels so as to form a color display device. The beneficial effects of the manufacturing method are that the following advantages can be obtained by application of the manufacturingmethod of the high-efficiency light conversion color display pixel film: 1) the light utilization rate can be enhanced for multiple times; 2) the display color area is extended so that the display color is enabled to be better; and 3) the monochrome display device can be colorized.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

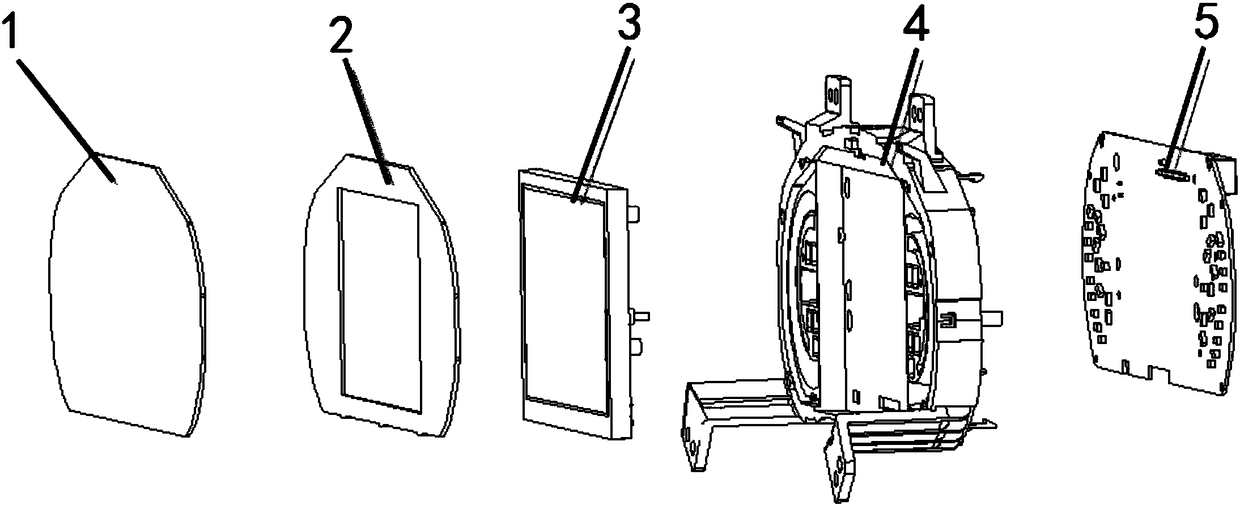

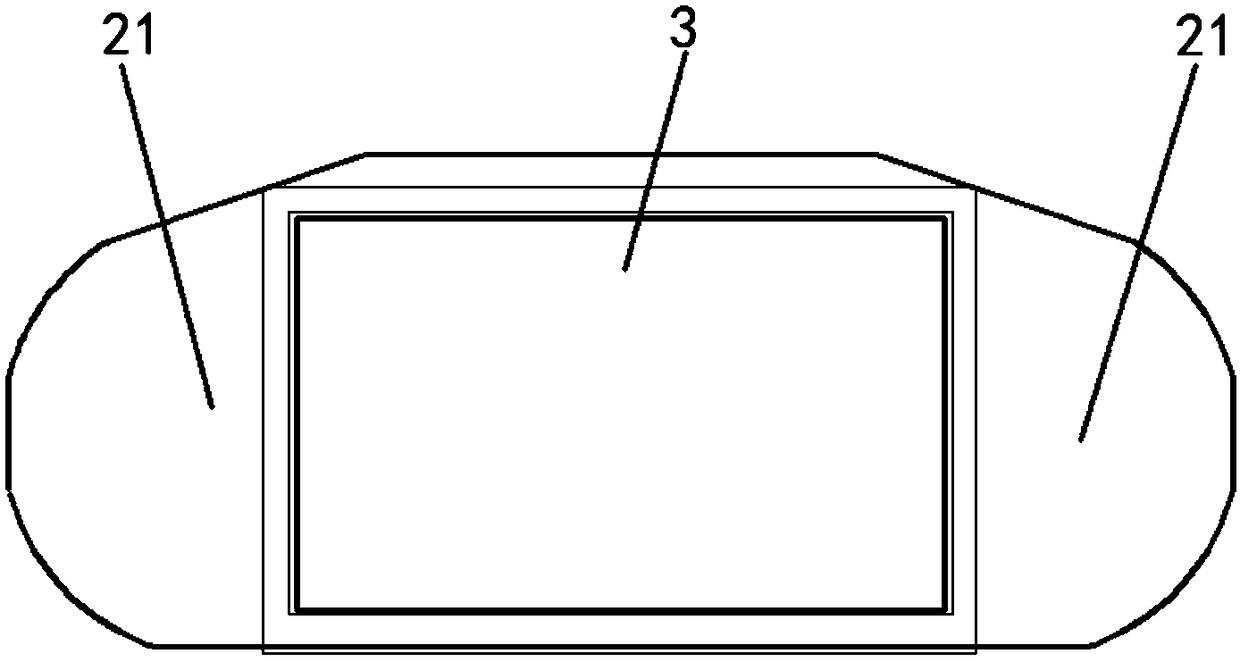

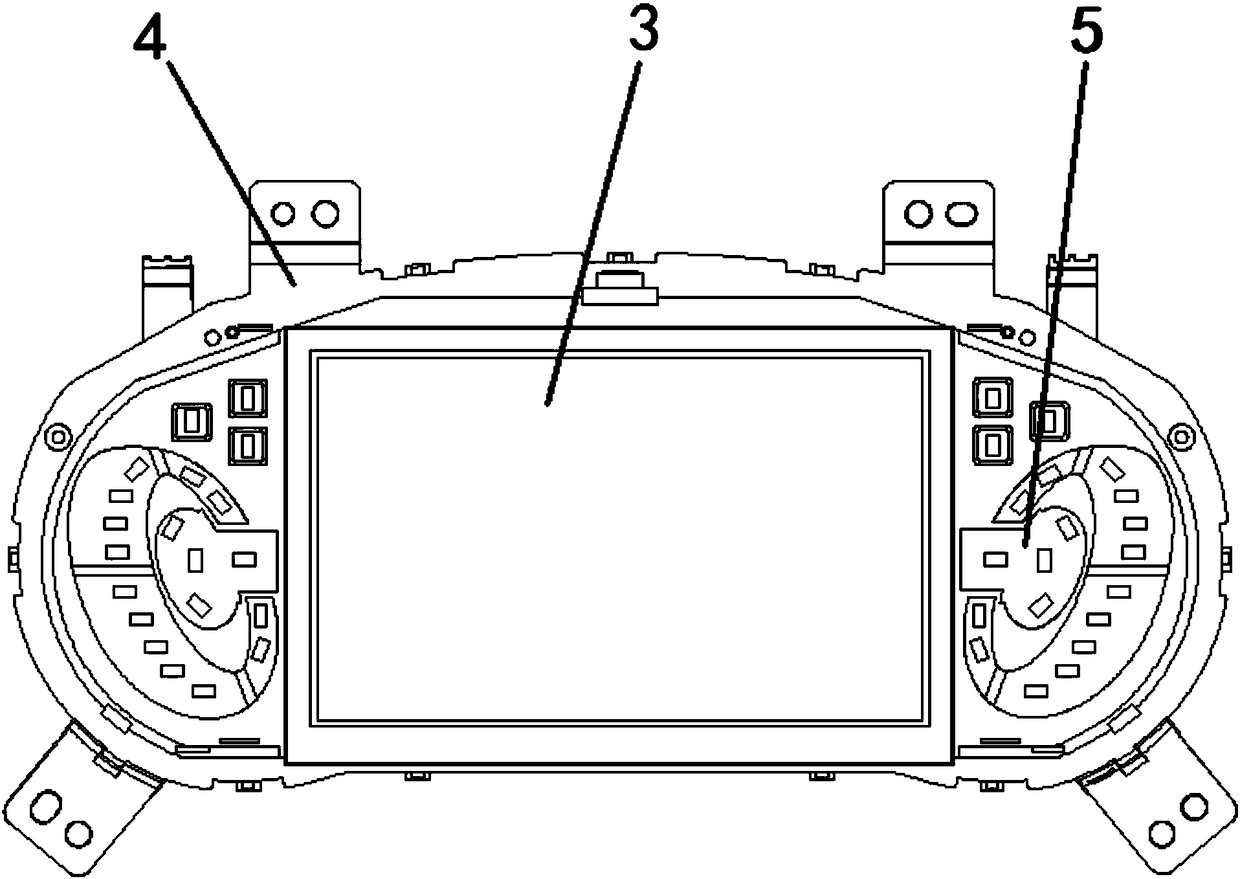

Automobile instrument panel segment code screen color display device, production method and display method

PendingCN108528217AImprove brightness and contrastImprove the display effectVehicle componentsNon-linear opticsLiquid-crystal displayLiquid crystal

The invention provides an automobile instrument panel segment code screen color display device, production method and display method, and relates to the field of automobile instrument panel liquid crystal screens. In order to solve the problem that an existing segment screen display cannot realize a color gradation effect and the display is darker. A segment code screen of the device is arranged on the uppermost layer, a color film printed by UV is stuck below the segment code screen, and a color liquid crystal screen is arranged below the color film; the center of the color film printed by the UV is provided with a liquid crystal screen display port, the liquid crystal screen display port and a liquid crystal display area of a color liquid crystal screen have same sizes and correspondinglocations; the color film around the liquid crystal screen display port is provided with a color light transmission area, and areas except the color light transmission area are black light blocking areas; a liquid crystal screen assembly is arranged on a light guiding bracket, an instrument PCB board is arranged under the light guiding bracket; an LED light source is arranged on the instrument PCBboard, a light guiding hole is formed in the light guiding bracket, and the positions of the LED light source, light guiding hole corresponds to color light transmission area of the color film. The automobile instrument panel segment code screen color display device, production method and display method are suitable for the production of automobile instrument panels.

Owner:黑龙江连特科技有限公司 +1

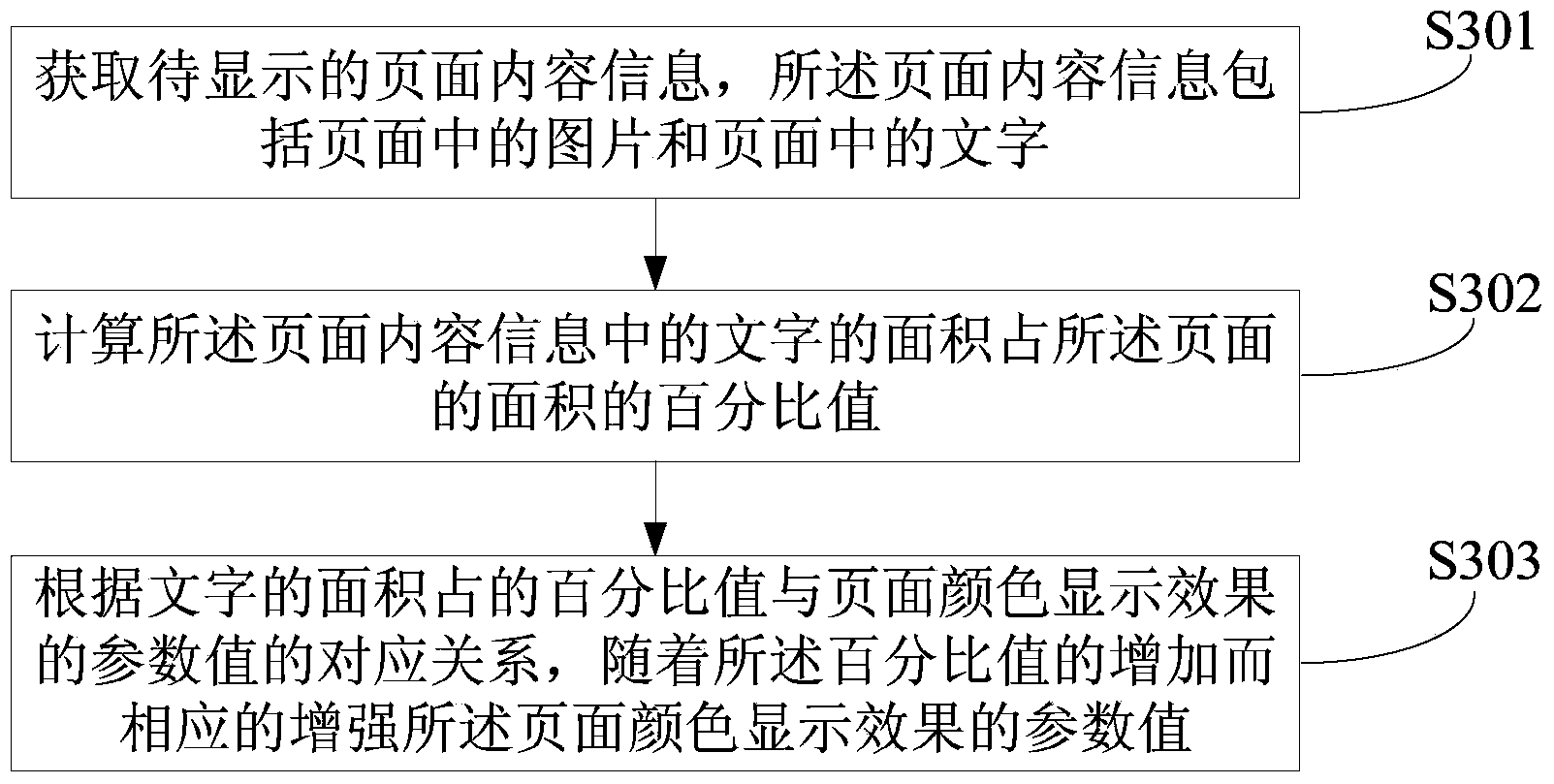

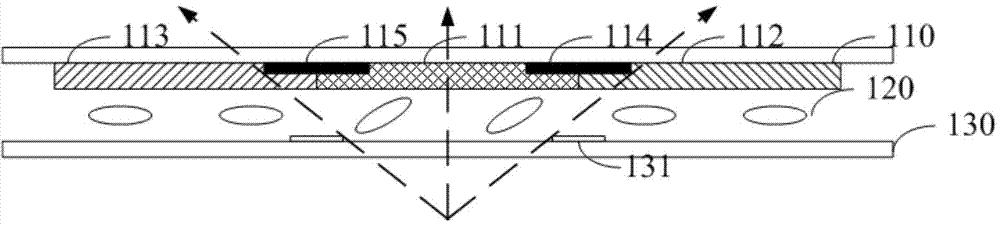

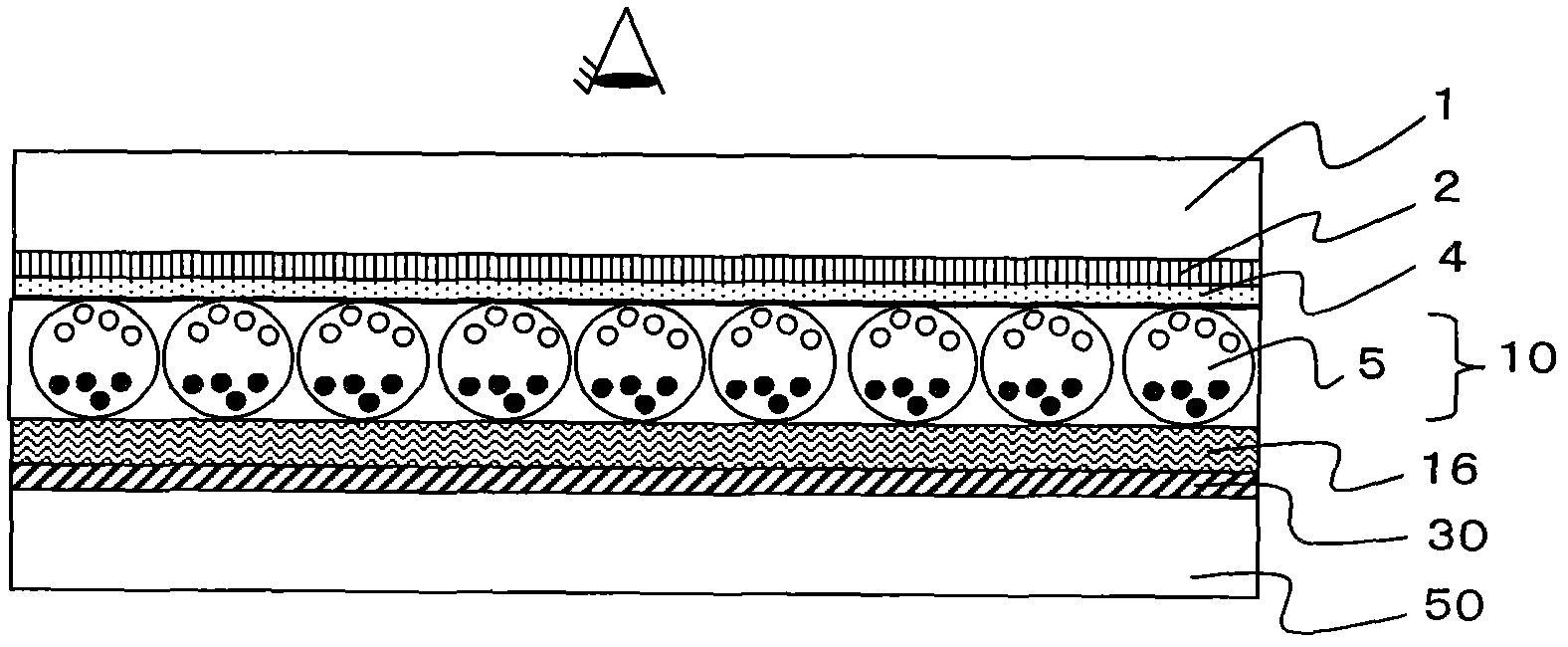

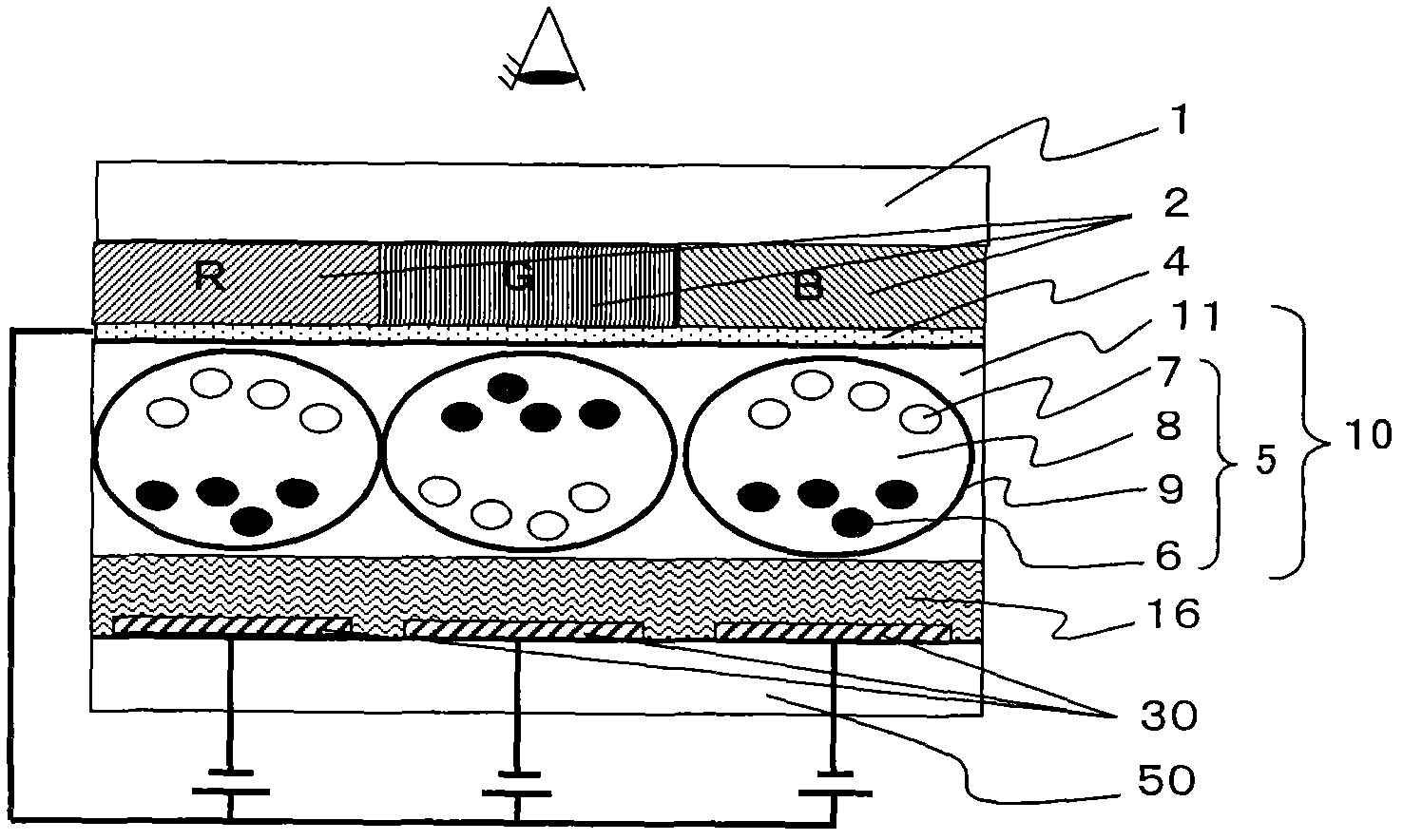

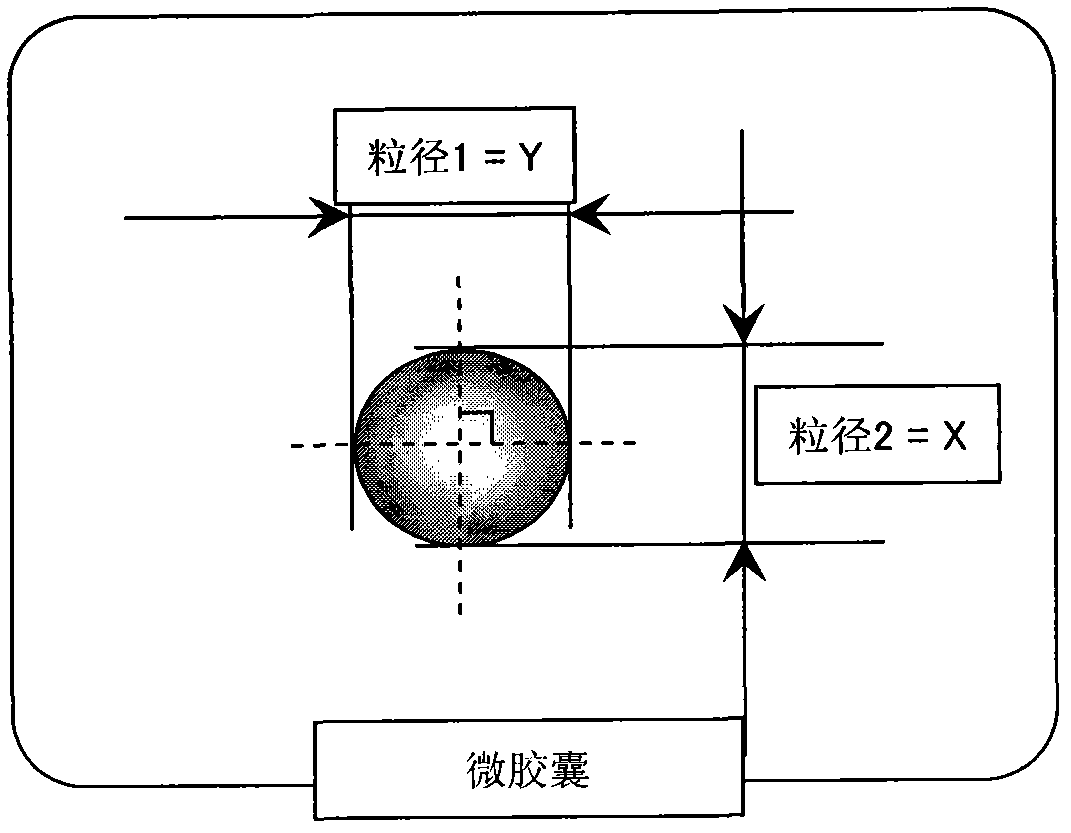

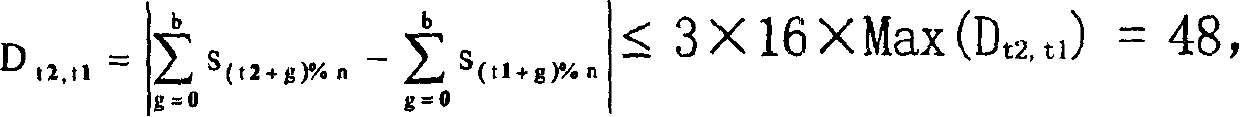

Color-electrophoresis type display media panel

InactiveCN102681280AGood qualityImproved image qualityNon-linear opticsParticle-size distributionElectrophoresis

The invention relates to a color-electrophoresis type display media panel which can ensure excellent display luminance and excellent display quality heterogeneity and can improve the narrow viewing angle. The color-electrophoresis type display media panel comprises a transparent substrate, a color filter layer, a transparent electrode layer, a microcapsule layer, an adhesive laye and a back electrode plate which are overlapped in sequence; the microcapsule layer is directly overlapped on the transparent electrode layer; the average particle diameters in arbitrary direction are defined as X and the average particle diameters in the orthogonal direction are defined as Y in the state of observing the particle diameters of the microcapsule in the microcapsule layer from the observation side; the distribution of the microcapsules with the average particle diameters X is as follows: more than 80% of the microcapsules have the average particle diameters of above X1 (X-20mum) and below X2 (X+20mum), less than 20% of the microcapsules have the average particle diameters of below X1 (X-20mum), and less than 5% of the microcapsules have the average particle diameters of above X2 (X+20mum), wherein the X is 35-45mum; and the distribution of the microcapsules with the average particle diameters of Y is the same as that of the microcapsules with average particle diameters of X.

Owner:TOPPAN PRINTING CO LTD

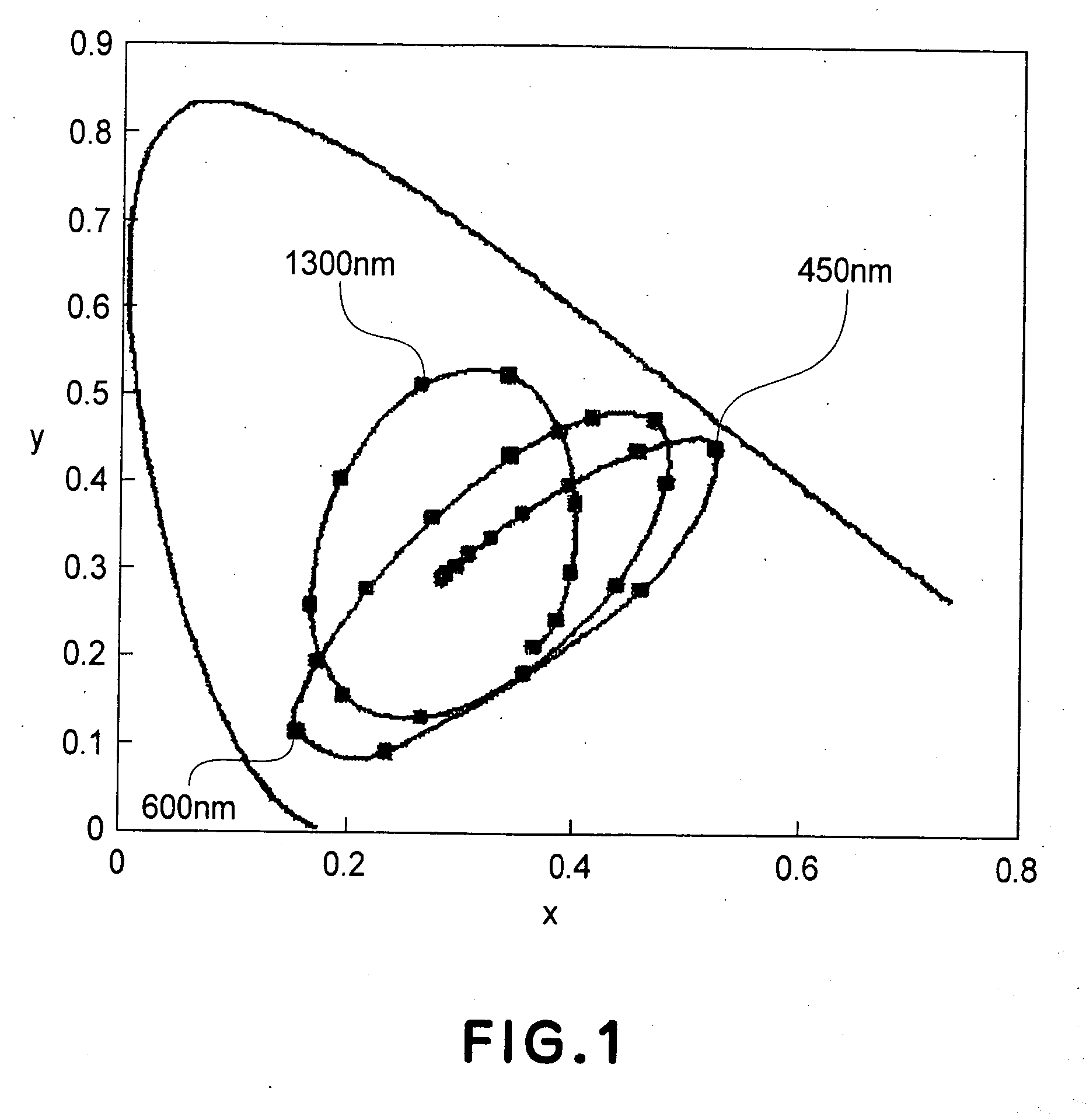

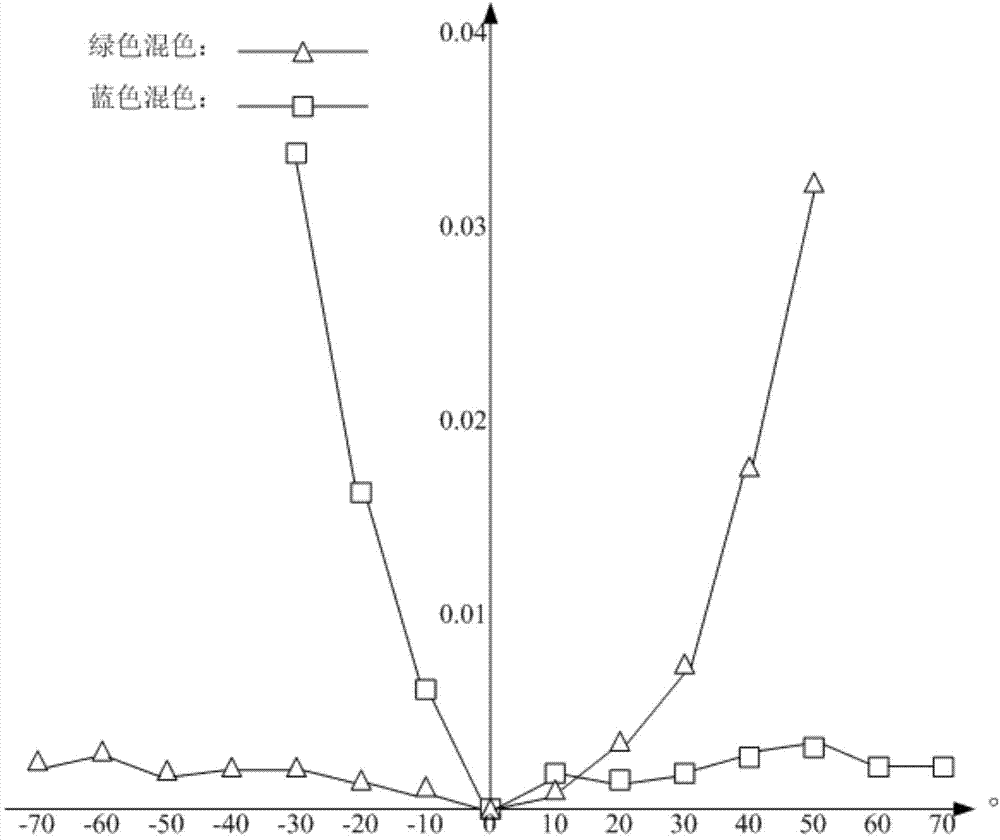

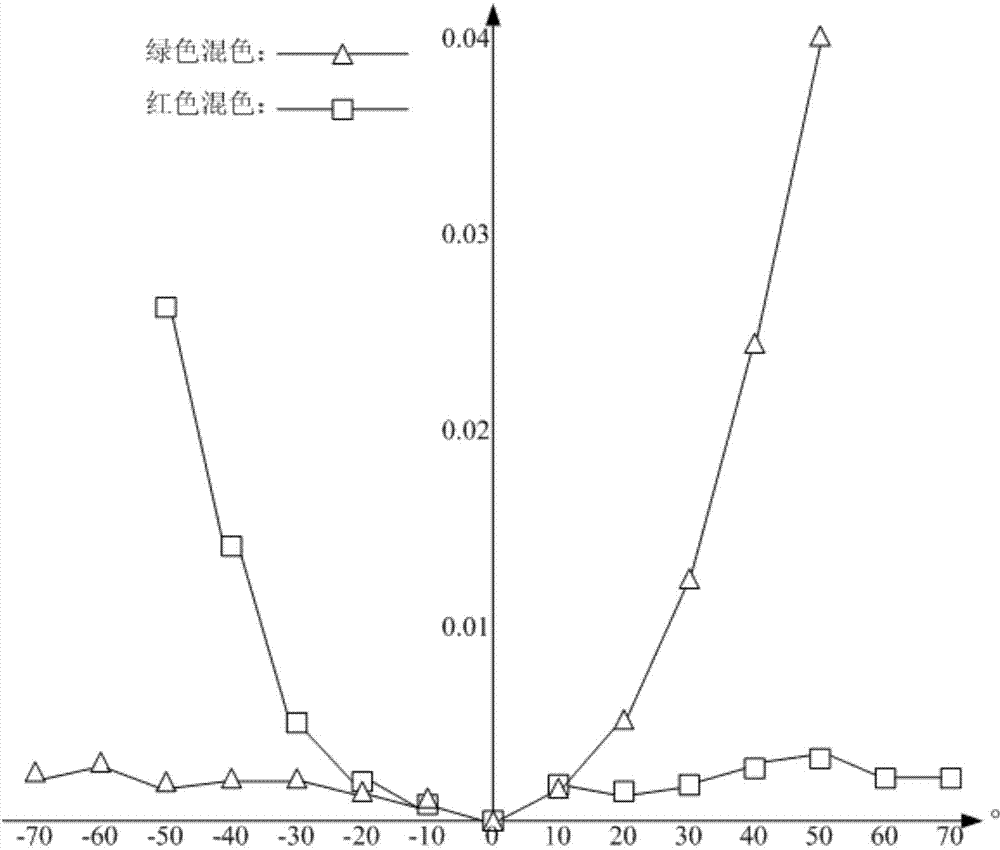

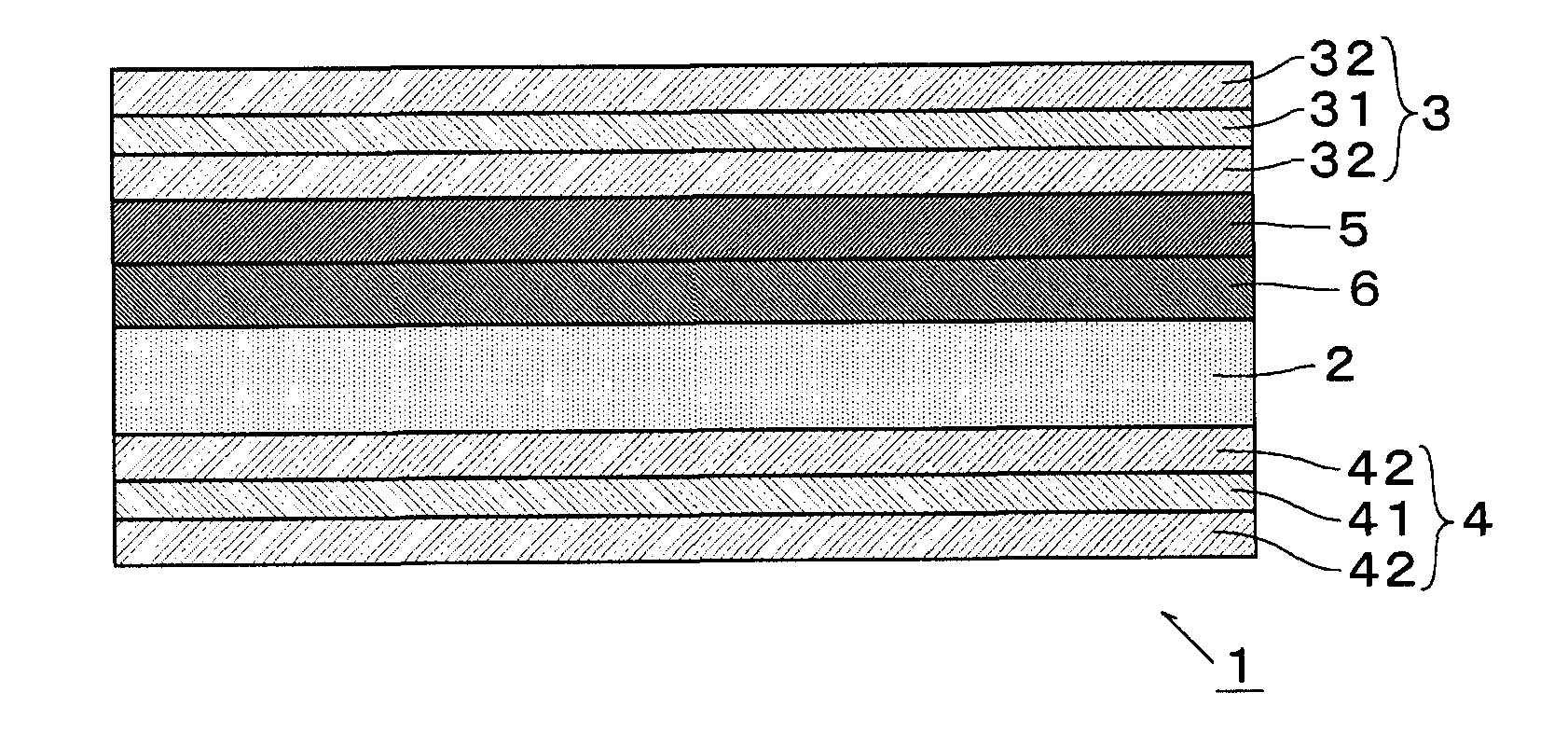

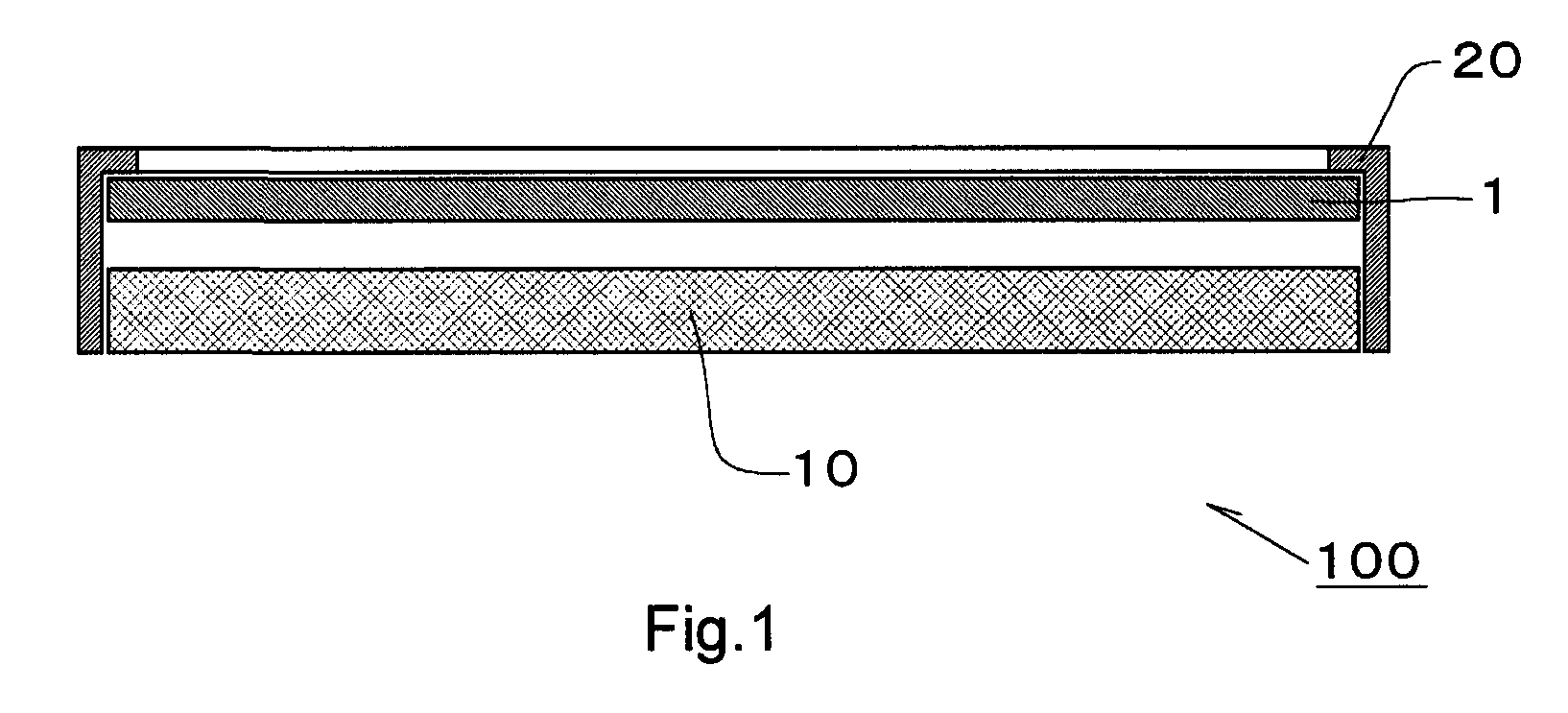

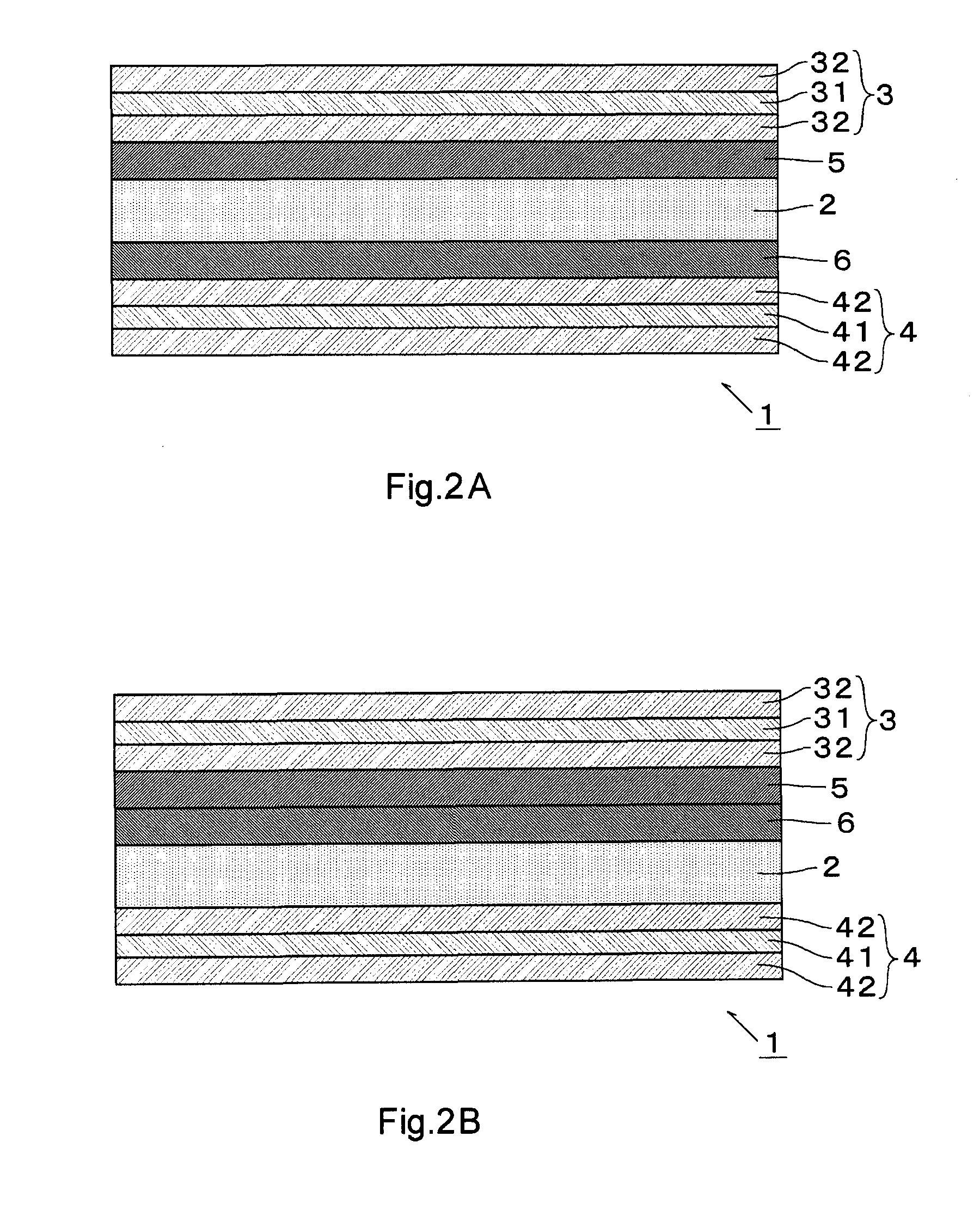

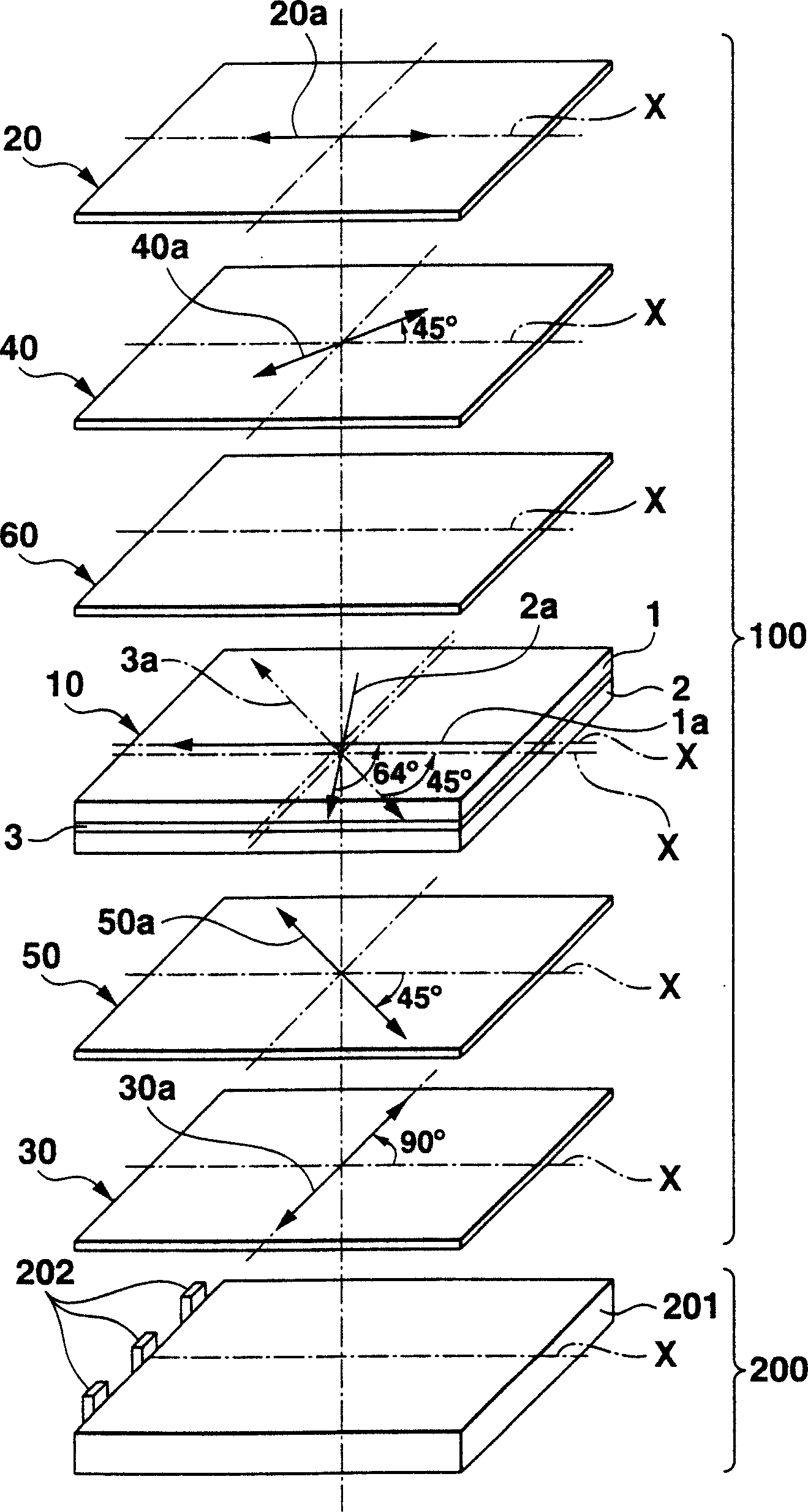

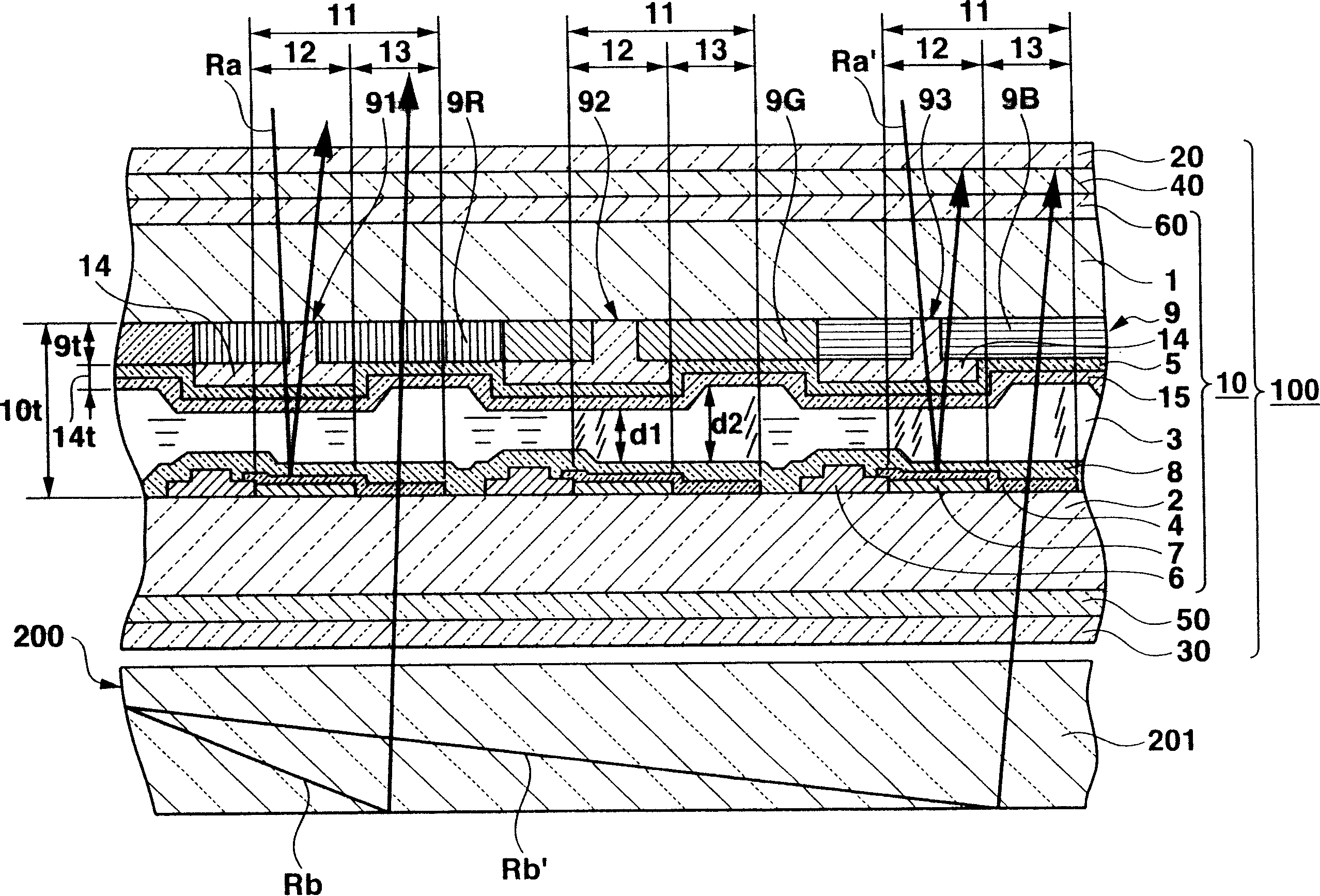

Liquid crystal panel and liquid crystal display

ActiveUS20100020279A1Inhibit coloringColor shiftNon-linear opticsOptical elementsColor shiftAzimuth direction

The liquid crystal panel 1 of the present invention comprises a liquid crystal cell 2, a first polarizer 31 disposed on one surface side of the liquid crystal cell 2, a second polarizer 41 disposed on the other surface side of the liquid crystal cell 2, and first optical compensation layer 5 and second optical compensation layer 6 disposed between the first polarizer 31 and second polarizer 41, and the liquid crystal cell 2 satisfies a relationship of 0.8<Re[450] / Re[550]<1, the first optical compensation layer 5 satisfies relationships of the Nz coefficient is from 0.8 to 1.4 and 0.8<Re[450] / Re[550]<1, and the second optical compensation layer 6 satisfies relationships of nx=ny>nz and 0.98<Re[450] / Re[550]<1.04.The liquid crystal panel of the present invention is hardly generated color shift when the panel is viewed from all azimuth angle directions and polar angle directions, so that the liquid crystal panel is excellent in color display characteristics.

Owner:NITTO DENKO CORP

Semi-transmission reflection type colour liquid crysta display

ActiveCN1534354AHigh saturationIncrease light intensityOptical filtersPolarising elementsLayer thicknessHigh luminance

A color filter constituted by red, green, and blue color filter elements is formed on an internal surface of a front transparent substrate. A reflective film is provided on a part corresponding to approximately a half of a pixel area on an internal surface of a back transparent substrate. The half of the pixel area on which the reflective film is provided is a reflective portion, and approximately the other half is a transmissive portion. An inter-substrate gap and a thickness of the color filter in the transmissive portion are set such that transmissive display achieving high luminance and high contrast can be realized. A thickness of the color filter and the thickness of a liquid crystal layer in the reflective portion are set to optimal values so that reflective display achieving high contrast can be realized, by adjusting a thickness of a liquid crystal layer thickness adjusting layer.

Owner:ORTUS TECH

Touch display device and manufacturing method thereof

InactiveCN106484157AImprove touch performanceImprove the display effectInput/output processes for data processingTouch SensesDisplay device

A touch display device and a manufacturing method thereof are provided. The touch display device has a touch sensing area and a virtual touch area, and comprises a first and a second metal layer, filter layers, and common electrode layers. The first metal layer is arranged below an upper glass substrate, and the first metal layer includes a first touch line that is located in the touch sensing area; the second metal layer is arranged below the first metal layer, and includes a second touch line and a second virtual line, wherein the second touch line is located in the touch sensing area, the second virtual line is located in the virtual touch area, and the second touch line and the first touch line form a touch sensing element; the filter layer located in the touch sensing area covers the second touch line, and the filter layer located in the virtual touch area does not cover the second virtual line; and the common electrode layer located in the touch sensing area is not in contact with the second touch line, and the common electrode layer located in the virtual touch area is in direct contact with the second virtual line to reduce the resistance of the common electrode layer. The present invention also discloses a manufacturing method for the touch display device.

Owner:AU OPTRONICS CORP

Liquid crystal display device

InactiveCN1928654AImprove color displayLarge color mixing areaNon-linear opticsLiquid-crystal displayEngineering

Owner:INNOCOM TECH SHENZHEN +1

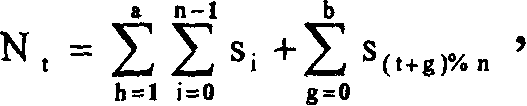

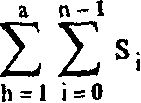

Method for processing space expansion FRC

InactiveCN1822089AAverage brightness unchangedImprove color displayCathode-ray tube indicatorsCritical path methodMaximum difference

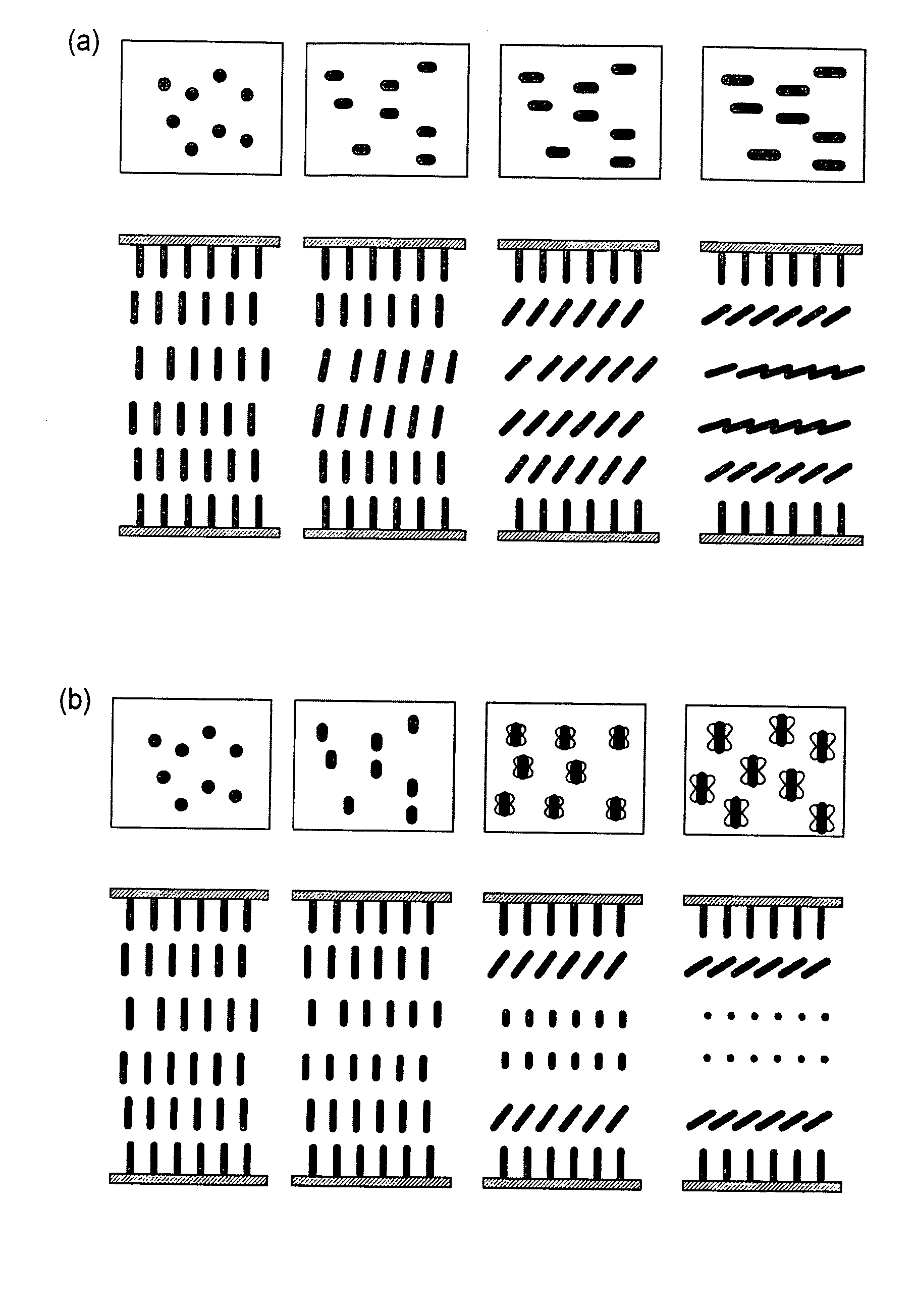

This invention discloses a method for processing special expanded FRC including: a step of realizing non-linear time mixed color by limitlessly repeating different time mixed color sub-sequences, a step of space-expanding pixels in a same color component stage having the following technical results: 1, fine color display performance, the maximum difference of the open pixels of two adjacent frames is smaller than the typical FRC and the group FRC and the mean brightness of the picture keeps the same, 2, the expanded area of FRC does not influence the entire LCD controller.

Owner:ZHEJIANG UNIV

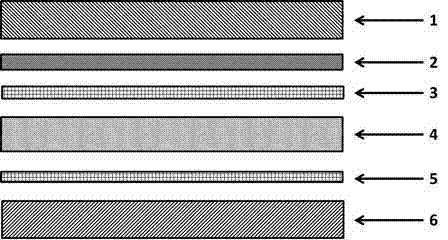

Transparent liquid crystal display panel and transparent display device

InactiveCN103676306AReduce the difficulty of productionGuaranteed YieldNon-linear opticsIdentification meansLiquid-crystal displayImage resolution

The invention discloses a transparent liquid crystal display panel and a transparent display device. Firstly, the invention provides the transparent liquid crystal display panel which comprises a first optical deflection piece, a liquid crystal layer and a second optical deflection piece, and is characterized in that the transparent liquid crystal panel further comprises a color filter layer, the color filter layer is composed of arrays of color filtering pixel regions, and each color filtering pixel region is composed of a red sub-pixel region, a green sub-pixel region and a blue sub-pixel region; sub-pixel regions in the same color are non-adjacent in arrangement. Secondly, the invention provides the transparent display device which comprises a box body, a light source and an inner decorating plate, and at least one side of the box body adopts the transparent liquid crystal display panel. The transparent liquid crystal display panel and the transparent display device employing the transparent liquid crystal display panel achieve transparent display in large size, wide colour range, high contrast ratio, high transparency, and high resolution ratio of true color imaging.

Owner:青岛斯博锐意电子技术有限公司

Reflective liquid crystal display panel, production method of reflective liquid crystal display panel and display device

ActiveCN109031797ALarge proportion of qualityRealize color displayNon-linear opticsAbsorption ratioDisplay device

The invention discloses a reflective liquid crystal display panel, a production method of the reflective liquid crystal display panel and a display device. In an unpowered case, a first alignment layer and a second alignment layer enable liquid crystal molecules to be completely and transversely arranged to form one direction, the liquid crystal molecules can drive chiral molecules to turn to onedirection, and at the moment, light on all wave bands is not absorbed, totally reflected by a reflection layer and displayed in a white state; and when pixel electrodes are applied with different voltages, transverse electric fields formed by the pixel electrodes and common electrodes, in which the liquid crystal molecules at different positions are positioned, are different in size, the liquid crystal molecules at different positions are promoted to have different transverse rotation angles so as to drive the chiral molecules to rotate by different angles, the chiral molecules rotating by different angles are different in absorption ratio for light on different wave bands, which is incident into ambient light inside the panel, and the reflection layer reflects the light on different wavebands out of the display panel to implement color display. Additionally, according to the invention, a color resistance layer does not need to be arranged, and thus, transmissivity is impoved, brightness and a contrast ratio are improved, and a color display effect is excellent.

Owner:BOE TECH GRP CO LTD +1

Electrophoretic display device, driving method of the same, and electronic apparatus

ActiveUS8698734B2Improve color displayCathode-ray tube indicatorsNon-linear opticsElectrophoresisDisplay device

An electrophoretic display device is provided with a first substrate, a second substrate, an electrophoretic layer which is arranged between the first substrate and the second substrate and has at least a dispersion medium and particles mixed in the dispersion medium, a first electrode which is formed in an island shape on the electrophoretic layer side of the first substrate for each pixel, and a second electrode which is formed on the electrophoretic layer side of the second substrate with an area wider than the first electrode, where gradation is controlled using an area of the particles which are visually recognized when the electrophoretic layer is viewed from the second electrode side.

Owner:E INK CORPORATION

Color liquid crystal display device

InactiveUS7599040B2Improve color displayInhibition of temperature dependenceLiquid crystal compositionsNon-linear opticsLiquid-crystal displayEngineering

A color liquid crystal display device includes a pair of oppositely disposed substrates each of which is provided with an electrode and has been subjected to homeotropic alignment treatment, and chiral nematic liquid crystal disposed between the pair of oppositely disposed substrates. The chiral nematic liquid crystal is capable of causing birefringence leading to a change in brightness and a change in hue depending on a voltage applied between the electrodes. The liquid crystal is twistedly aligned under electric field application to change a twisted angle, so that a fluctuation in birefringence with temperature is compensated.

Owner:CANON KK

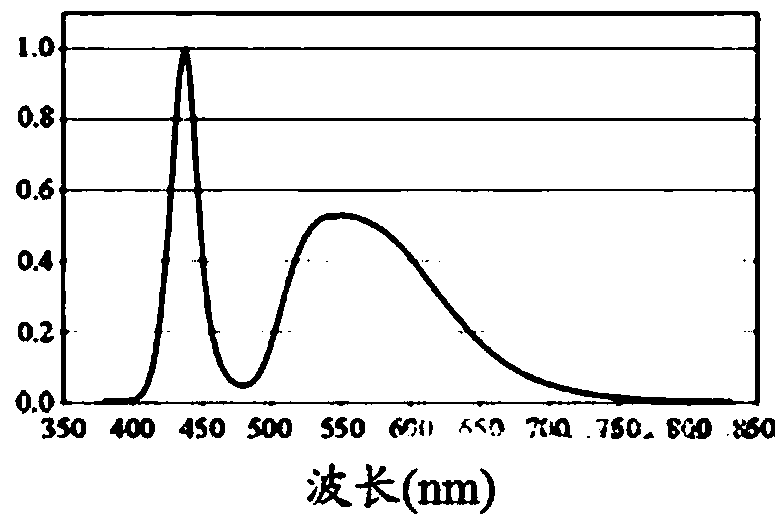

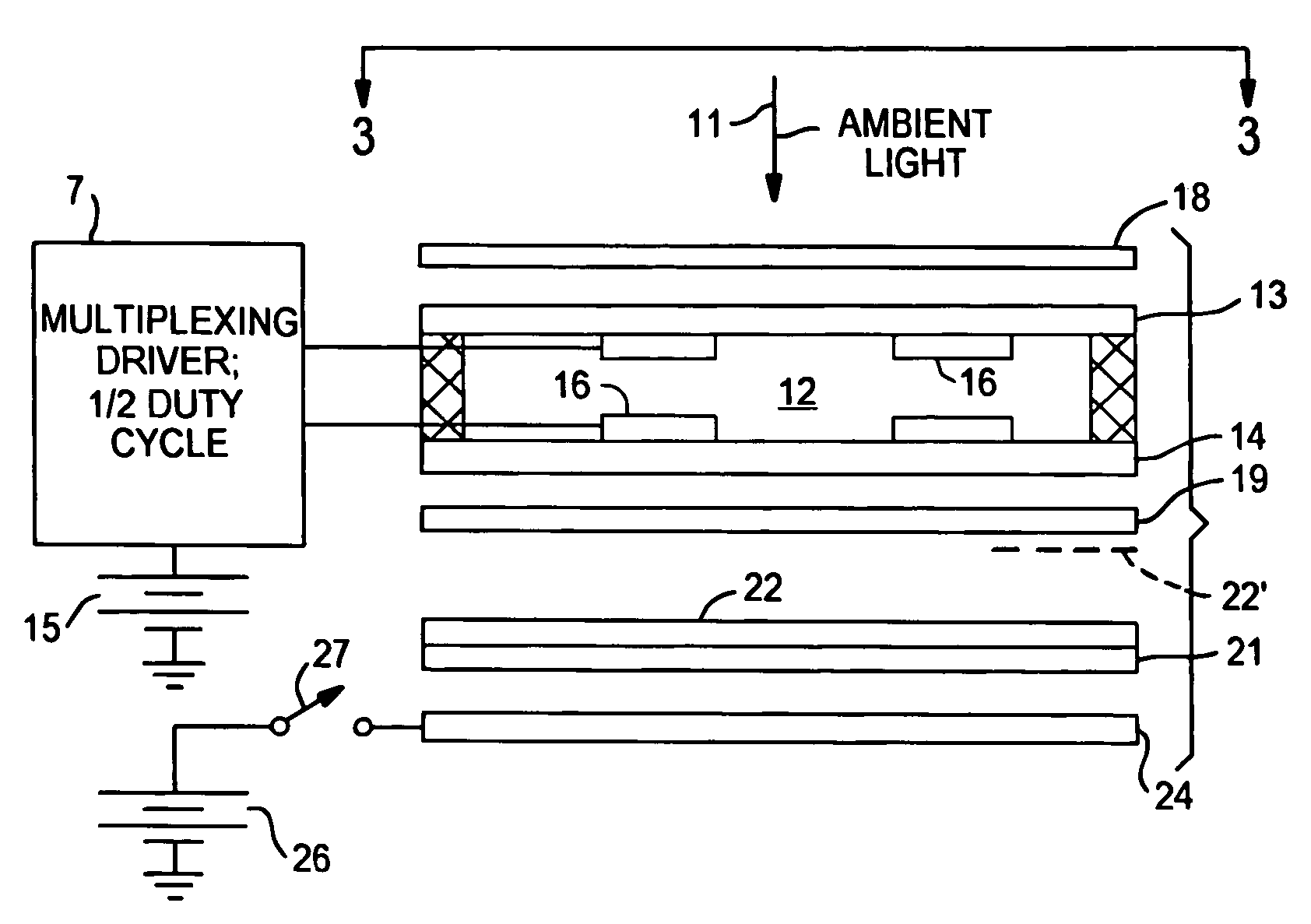

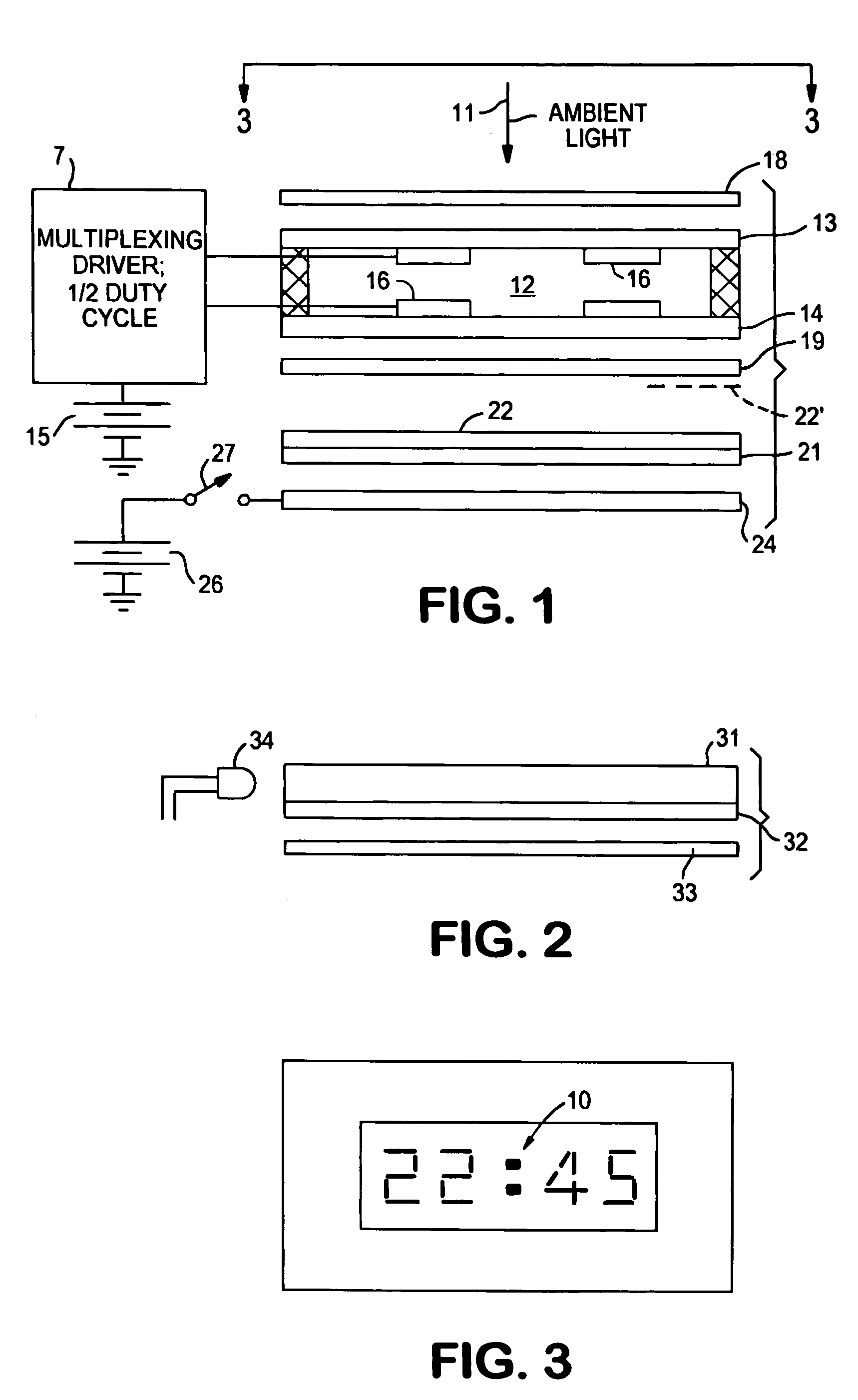

Liquid crystal display with fluorescent material

InactiveUS7123317B2Improve color displaySharp contrastSpectral modifiersNon-linear opticsLiquid-crystal displayElectrical battery

A liquid crystal display device such as a clock which is battery operated has enhanced color for its pixels under ambient light by the use of a fluorescent layer on the reflective backing of the display.

Owner:MONERAY INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com