Touch display device and manufacturing method thereof

A technology of a touch display device and a manufacturing method, which is applied to instruments, electrical digital data processing, and input/output processes of data processing, etc., and can solve problems such as short circuit and affecting the touch performance and display effect of a touch display device 10, To achieve the effect of reducing the resistance value, improving the touch performance and display effect, and the best touch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

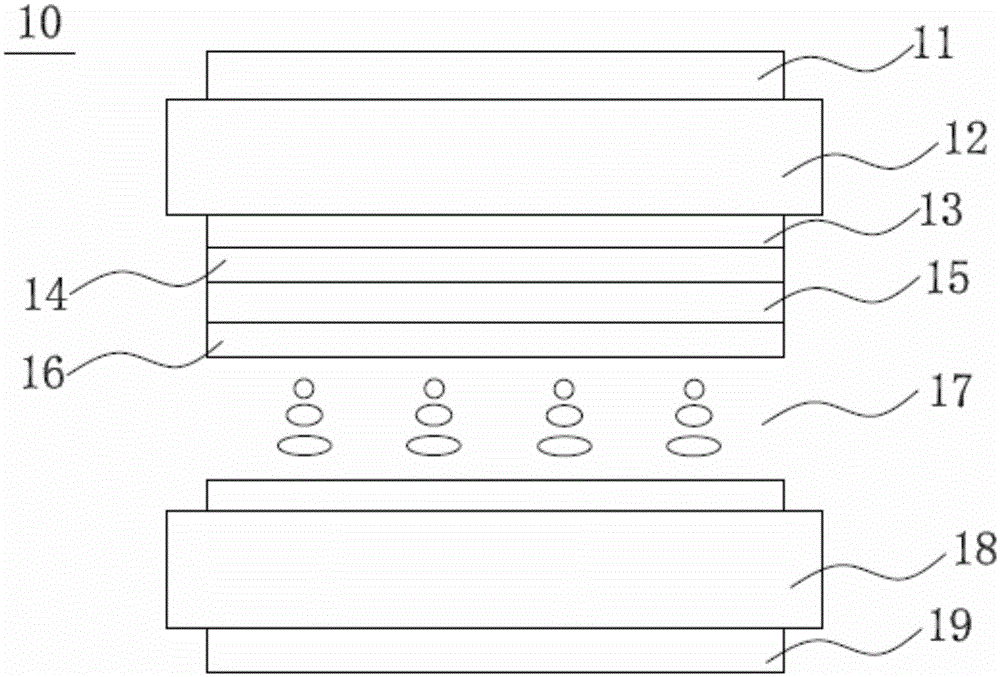

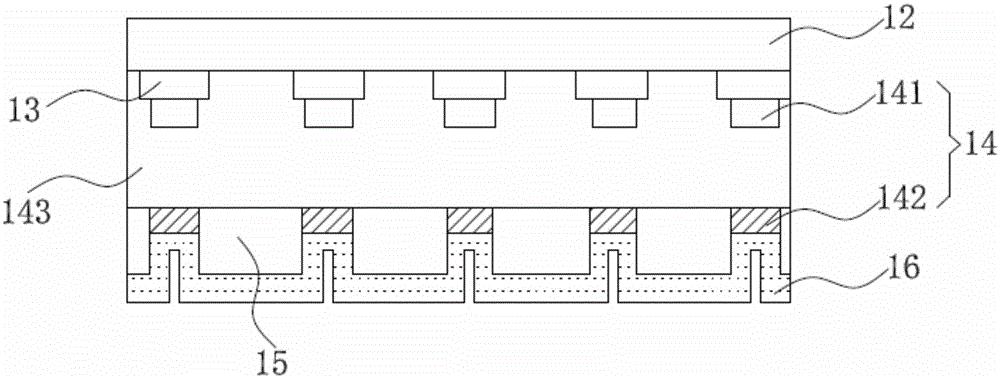

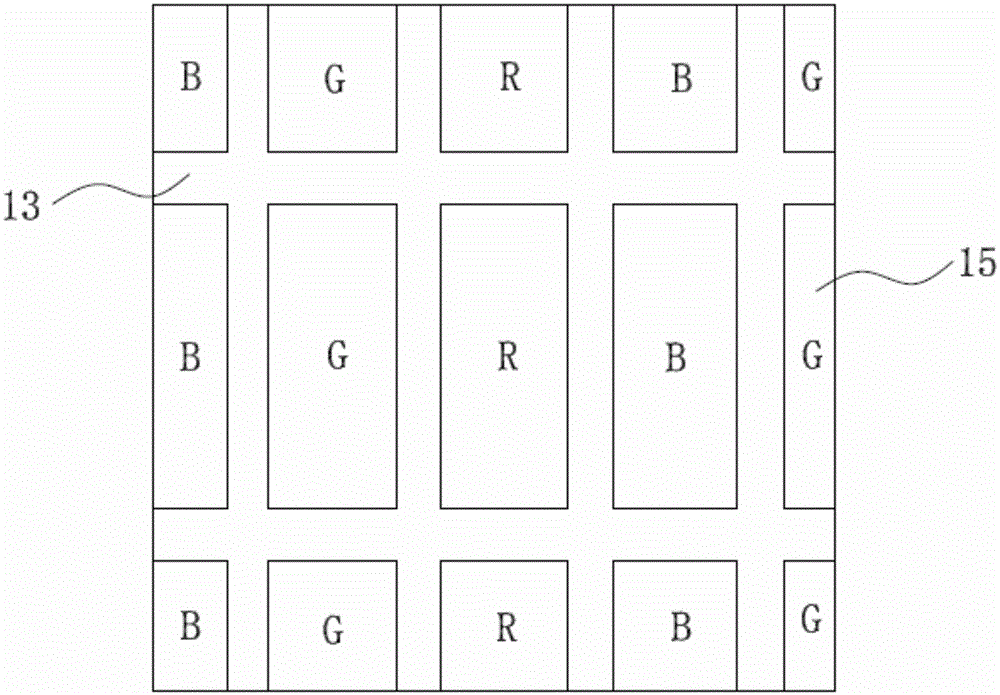

[0027] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0028] Please refer to image 3 , Figure 4A ~ Figure 4F and Figure 5A ~ Figure 5F , image 3 It is a schematic flow chart of the manufacturing method of the touch display device of the present invention, Figure 4A ~ Figure 4F It is a partial top view of each step of the manufacturing method of the touch display device in the present invention; Figure 5A ~ Figure 5F for Figure 4A ~ Figure 4F A cross-sectional view along the line AA'.

[0029] The manufacturing method of the touch display device of the present invention is described in detail below, mainly introducing the black matrix layer 1300, the first metal layer 1410, the insulating layer 1430, the second metal layer 1420, the filter film layer 1500 and the common electrode on the upper glass substrate 1200. For the manufacturing method of the layer 1600 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com