Colorant, color filter, LCD device, composition and preparation

A technology of colorant and composition, applied in the field of color filters, can solve the problems of poor dispersion stability of colorant, lower developing performance of photosensitive resin composition, and limit the application field of colorant, etc.

Active Publication Date: 2008-12-17

BOE TECH GRP CO LTD

View PDF8 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The defect that prior art exists is, because the kind and usage amount of dispersant or dispersing resin have greater influence on the stability of the pigment dispersion system in colorant, cause the dispersion stability of colorant poor; As the amount increases, the developing performance of the photosensitive resin composition will decrease significantly

When the acrylic copolymer with an ammonia value greater than 0 and an acid value of 0 is added to an alkali-sol

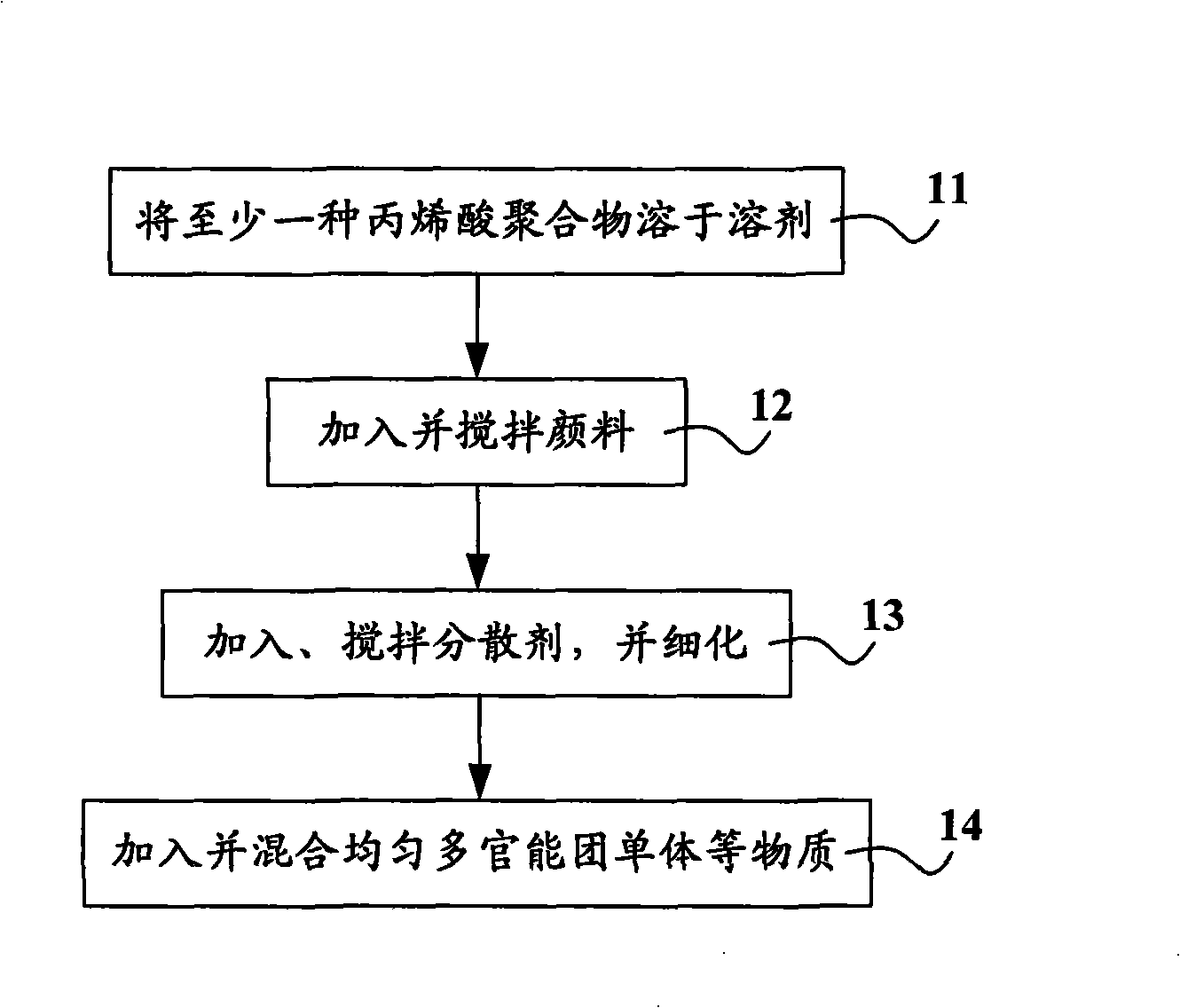

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Login to View More

Abstract

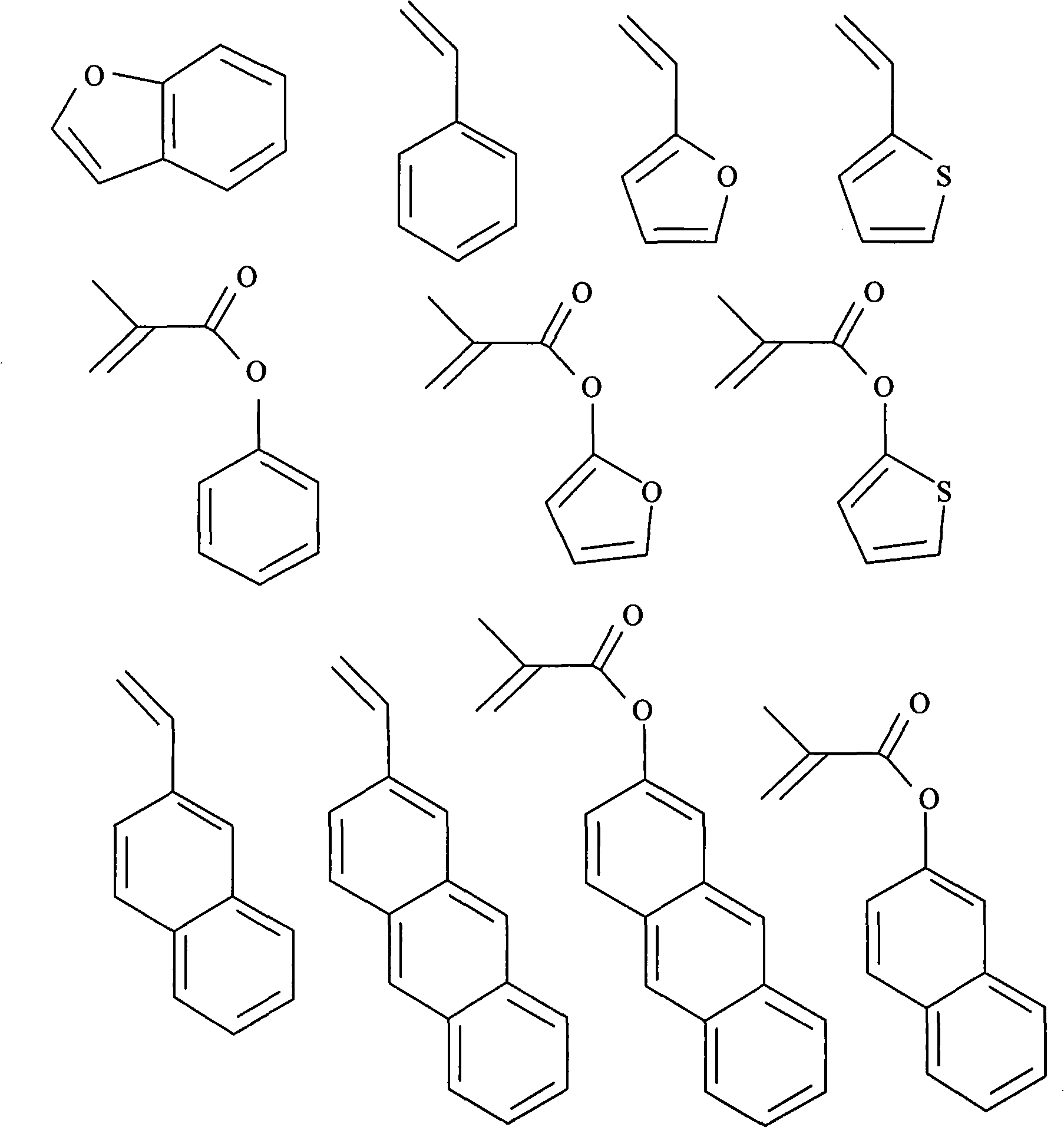

The invention relates to a colorant, a colored filter, a liquid crystal display (LCD), a composition and a preparation method thereof. The colorant covers pigment grains through acrylic polymer which comprises aromatic groups and has the acid value of more than 20mgKOH/g, thus not only improving the dispersing capacity of the pigment grains but also greatly enhancing the stability of the pigment grains. A photosensitive resin composition with the colorant ensures that the development performance is not affected basically, thereby meeting the requirements of high transmittance, high color purity and high contrast ratio of the colored filter. With the picture formed by the photosensitive resin composition with comparatively high dispersing stability and development performances, the coloredfilter greatly improves the transmittance, color purity and contrast ratio. The LCD remarkably improves the display effect of colored pictures through the colored filter with high transmittance, highcolor purity and high contrast ratio.

Description

technical field [0001] The invention relates to a color filter, in particular to a colorant capable of improving the color display effect of a liquid crystal display device, a color filter, a liquid crystal display device, a photosensitive resin composition and a preparation method thereof. Background technique [0002] The color filter is the key to realize the color display of liquid crystal display (LCD), and its production methods include dyeing method, pigment dispersion method, printing method, electroplating method, inkjet method and so on. Due to the advantages of the pigment dispersion method in terms of color characteristics and quality, the pigment dispersion method is currently used to make color filters. The color filter is prepared by the pigment dispersion method, and the purpose of patterning is mainly achieved through a series of operations such as coating a photoresist on the substrate, exposure, and development, so as to obtain a color filter. [0003] Wh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09B67/00G03F7/004G03F7/028G02B5/23G02F1/1335

CPCC09B67/0069C09B67/009G02B5/201G02B5/223G03F7/0007G03F7/033

Inventor 张卓何璇李琳杨久霞赵吉生

Owner BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com