Automobile instrument panel segment code screen color display device, production method and display method

A technology for automobile instrument panel and color display, which is applied to instruments, vehicle parts, transportation and packaging, etc., can solve the problems of dark display and the inability to achieve color gradient effect on segment code screen, so as to reduce manufacturing cost and achieve better color display effect. , the effect of good print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

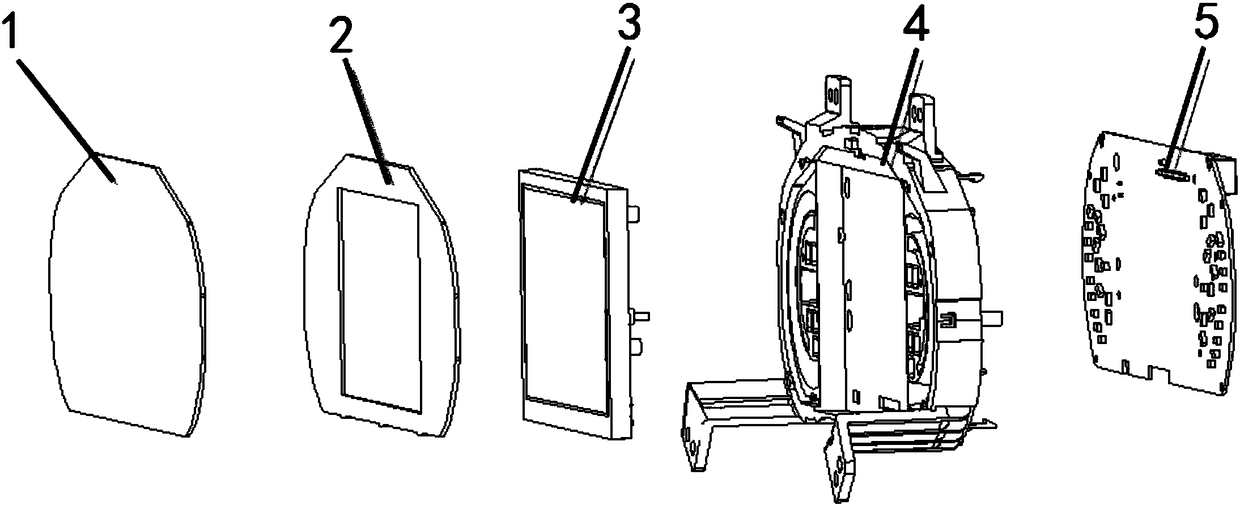

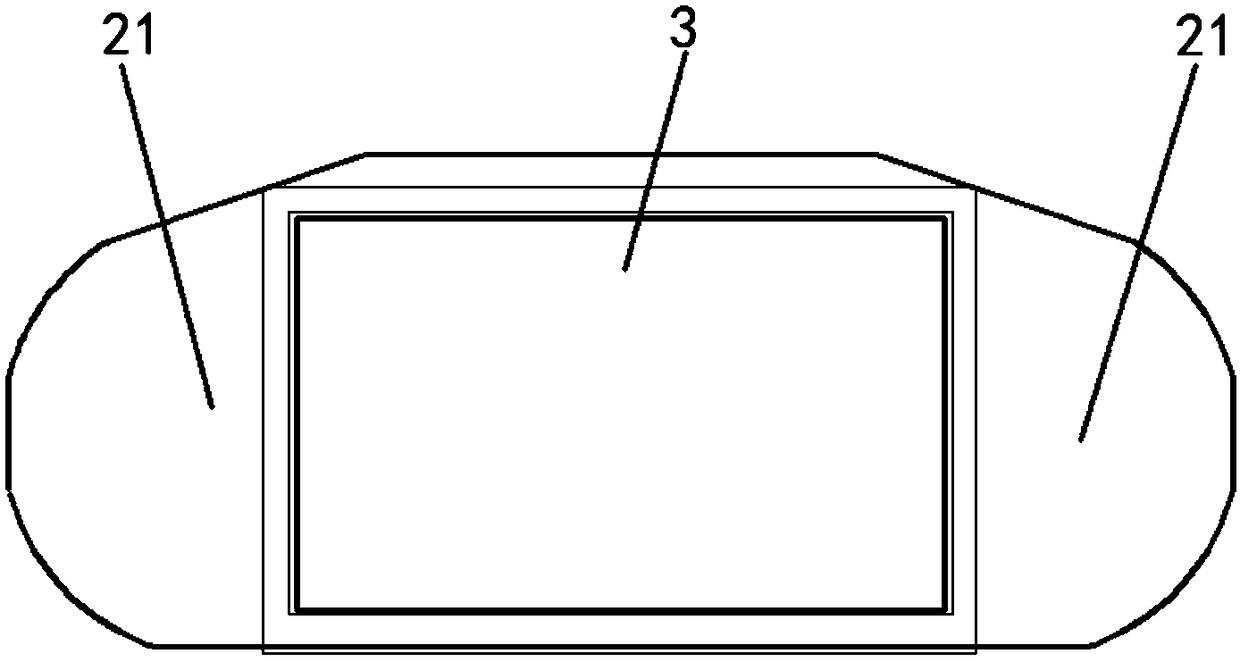

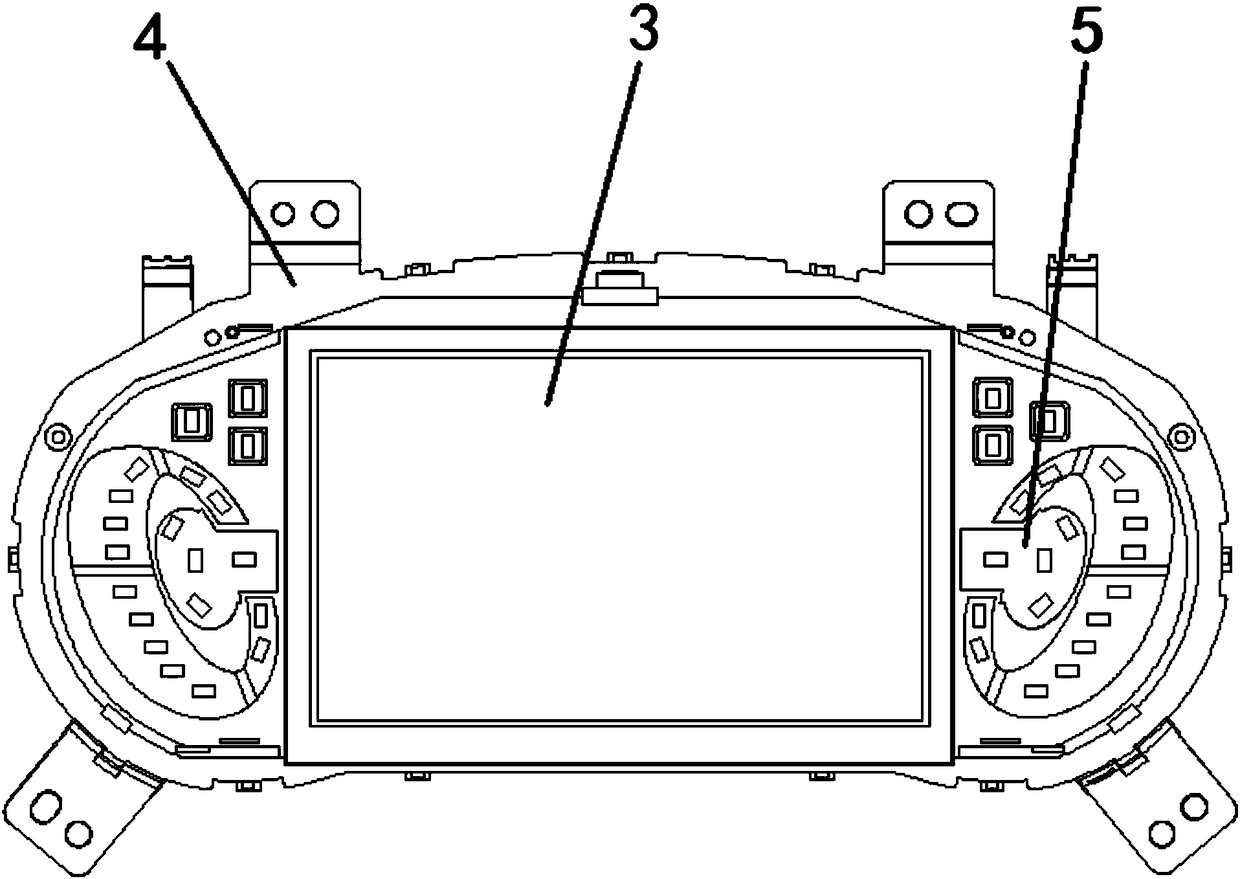

[0027] Specific implementation mode one: combine figure 1 To describe this embodiment,

[0028] The segment code screen color display device of the automobile instrument panel includes: segment code screen 1, UV printed color film 2, color liquid crystal screen 3, light guide bracket 4, instrument PCB board 5; color liquid crystal screen 3 can be an LCD liquid crystal screen (STN liquid crystal screen, TFT LCD screen), OLED LCD screen or LTPS LCD screen, etc.

[0029] The segment code screen 1 is set on the uppermost layer (the outermost layer), starting from the segment code screen, and from the upper layer to the lower layer, there are UV printed color film 2, color LCD screen 3, light guide bracket 4, and instrument PCB board 5, namely The bottom of the segment code screen 1 (the surface facing the color LCD screen) is closely attached to the UV printed color film 2, and the color LCD screen 3 is arranged under the color film 2. The area of the liquid crystal display are...

specific Embodiment approach 2

[0034] The color film 2 in this embodiment includes a substrate and a color light-transmitting area and a black light-blocking area printed on the surface of the substrate, and the substrate is a white film made of pc (polycarbonate) material; that is, made of pc material The white film is used as the substrate, and the surface of the substrate is printed with a colored light-transmitting area and a black light-blocking area; the colored light-transmitting area is an area formed by printing a corresponding shape and color at a corresponding position according to the UI design. The black light-blocking area is the area that is printed into the corresponding shape and formed in black. After testing, it has been proved that UV printing on pc material has good stability, can adapt to the working conditions of automobile instruments, and can serve for a long time without fading or color cast, thus ensuring the display effect and service life of automobile instrument panels. .

[0...

specific Embodiment approach 3

[0036] The thickness of the color film 2 in this embodiment is 0.125mm-0.175mm. If the color film is too thick, it will affect the light transmittance of the light source below, which will cause the display of the segment code screen to be dark; if the color film is too thin, it will cause excessive light transmittance, which will cause the color display under the segment code screen or the color film of the color film to appear in the visual effect. The color of the light-transmitting area becomes lighter, which reduces the contrast and affects the display effect; and the color film is too thin, the color film is too soft, and it is difficult to fit closely under the segment code screen, and even creases are generated, which cannot be completely fitted with the segment code screen. It may cause light leakage and reduce the yield.

[0037] Other structures and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com