Manufacturing method of high-efficiency light conversion color display pixel film

A technology for displaying pixels and color display, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, diodes, etc., can solve the problem of low utilization rate of light, and achieve the effect of improving utilization rate, expanding the display color gamut, and displaying better colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

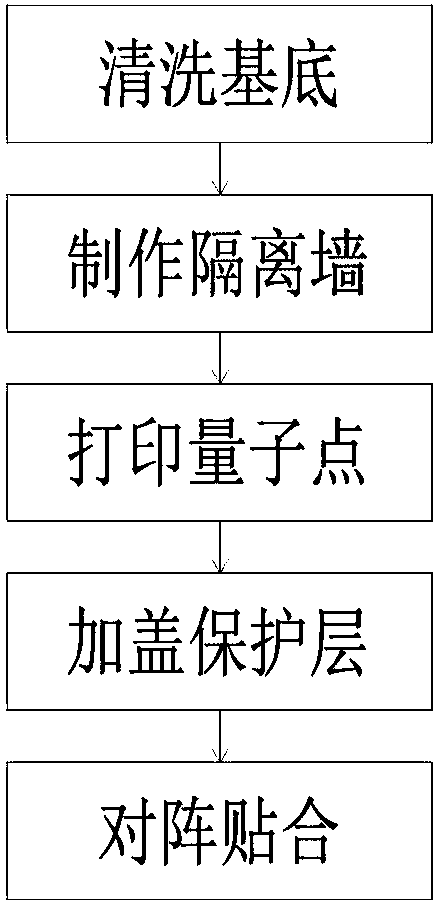

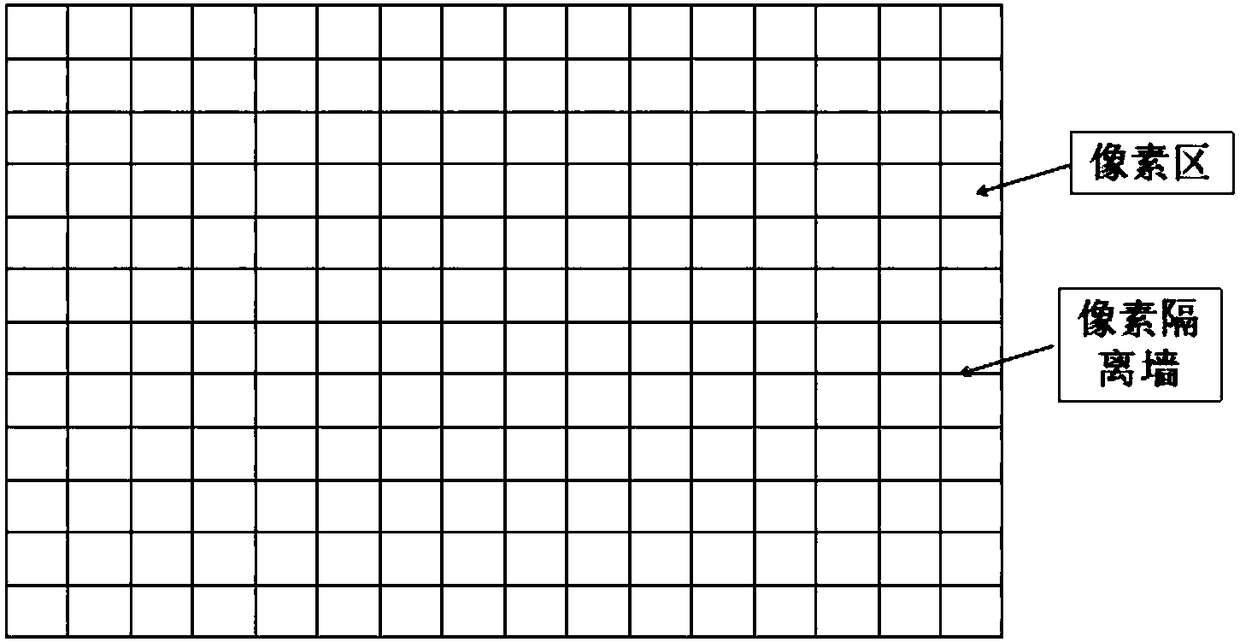

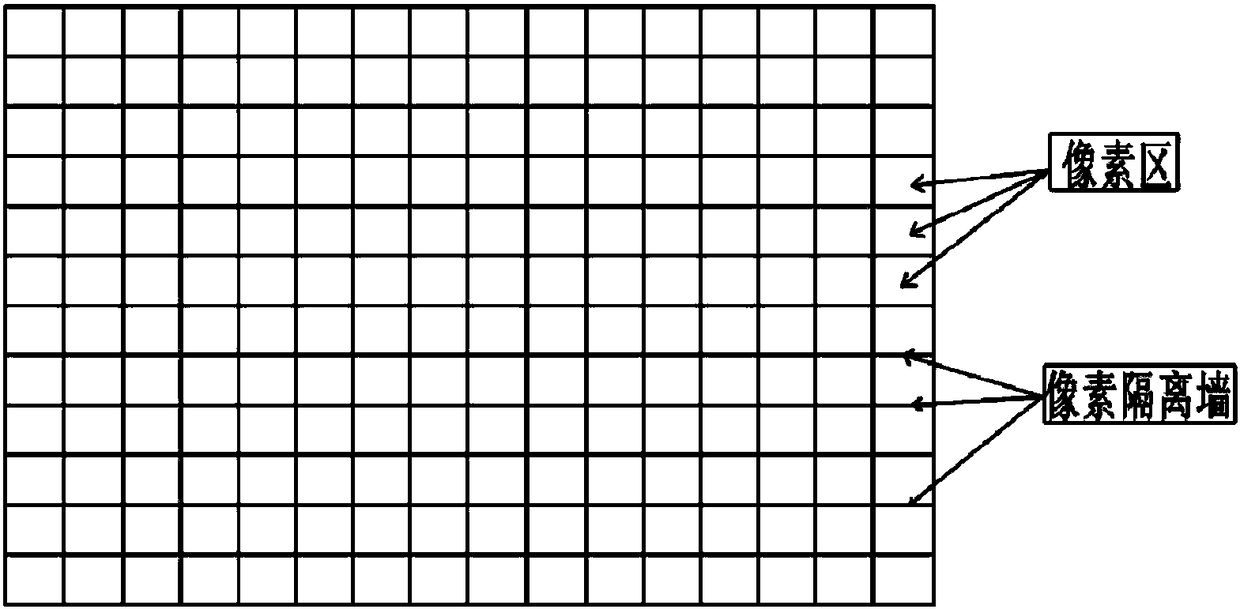

Method used

Image

Examples

Embodiment 2

[0094] Embodiment two: if Figure 4 As shown, blue OLED is used, red and green pixels use red quantum dot film and green quantum dot film respectively instead of traditional red and green filter films, and blue pixels use the light emission of blue OLED itself or traditional blue filter, that is ( Red QD+Green QD+Blue OLED or blue traditional filter).

[0095] The color OLED display adopts the production of blue OLED plus the corresponding (red, green) color quantum dot pixel color-changing film, and the blue pixel area uses the blue OLED itself to emit light, and the blue quantum dot film can also be used to improve the display color effect; (red, green) Green) The method of quantum dot pixel is the same as method 1. Take the blue OLED, the blue pixel uses the blue OLED itself to emit light as an example: image 3

Embodiment 3

[0096] Embodiment 3: adopt (green+blue) OLED to emit light, its red pixel uses red quantum dot film, blue, green pixel uses traditional blue, green filter; color film+traditional blue filter+green filter.

Embodiment 4

[0097] Embodiment 4: Use (green + blue) OLED to emit light, its red and green pixels use red and green quantum dot films, and blue pixels use traditional blue filters; that is: use blue and green OLEDs, use red and green QD color filter+traditional blue-green light film, where the wavelength of OLED green light can be smaller than that of QD green light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com