Hua celadon and preparation method thereof

A technology of china celadon and a production method, which is applied in the field of daily-use ceramics, can solve the problems of single color and luster of white porcelain, poor ornamental, and weak color change of celadon, and achieves smooth and bright glaze surface, no glare surface, and difficult process control. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

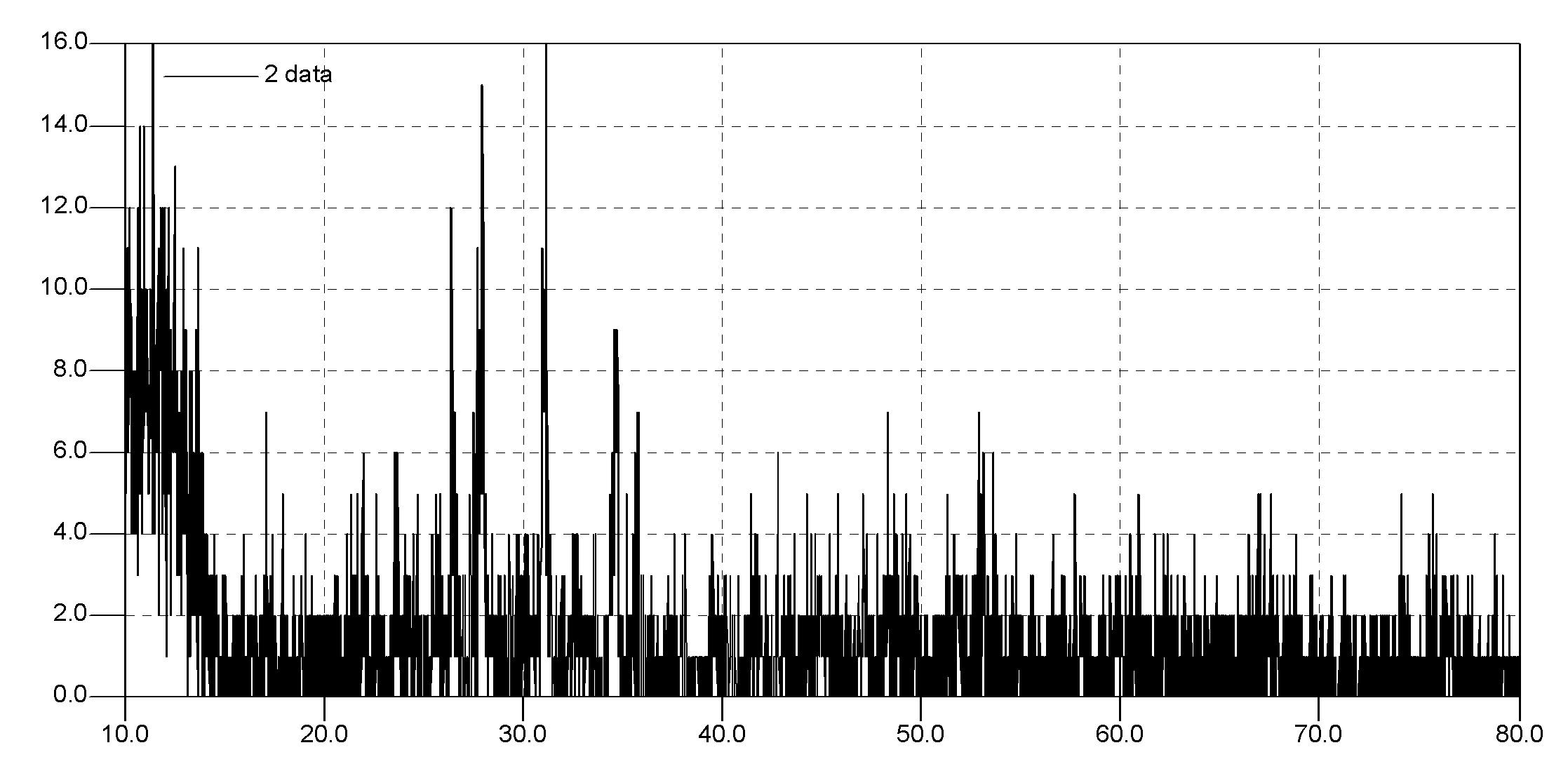

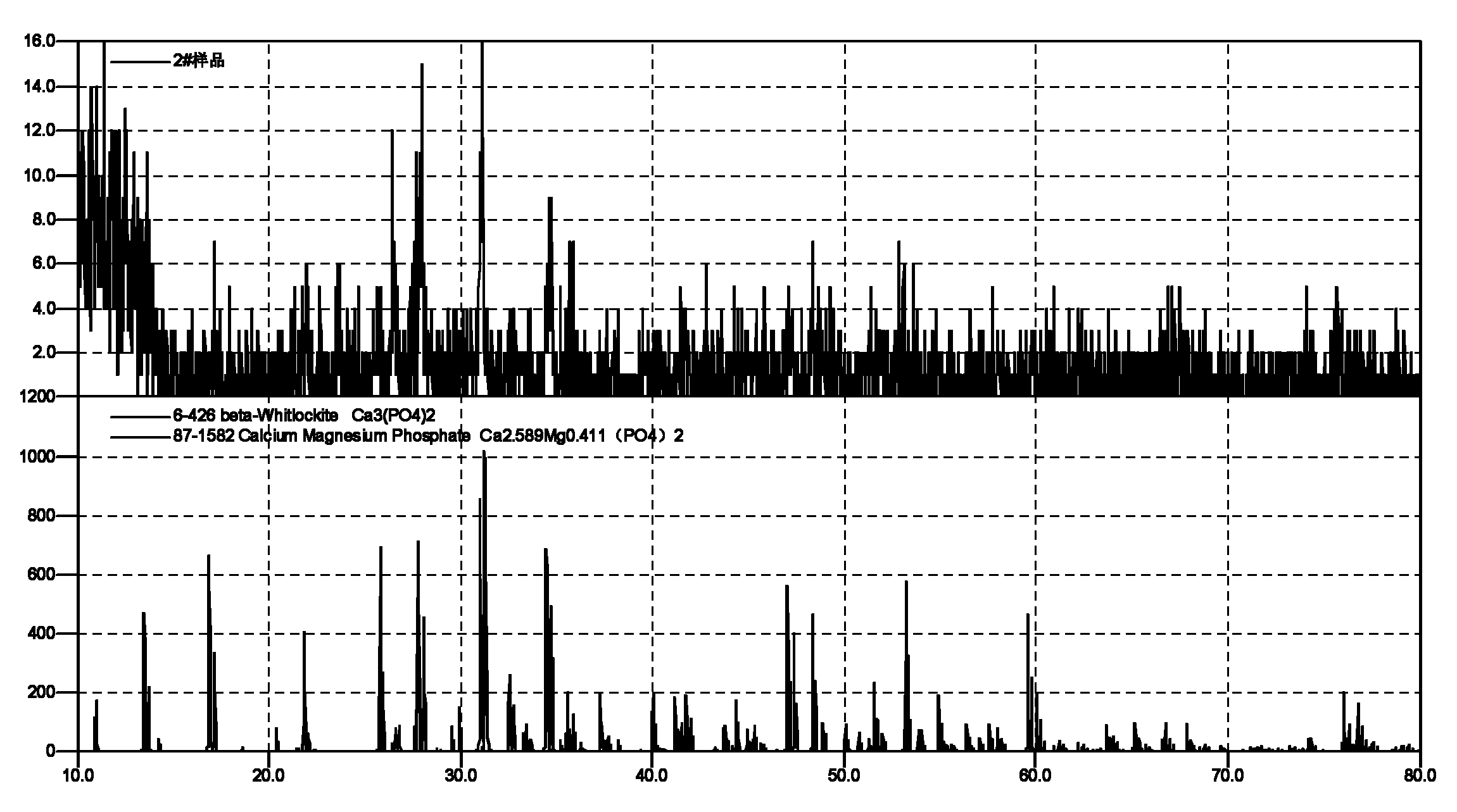

Image

Examples

Embodiment 1

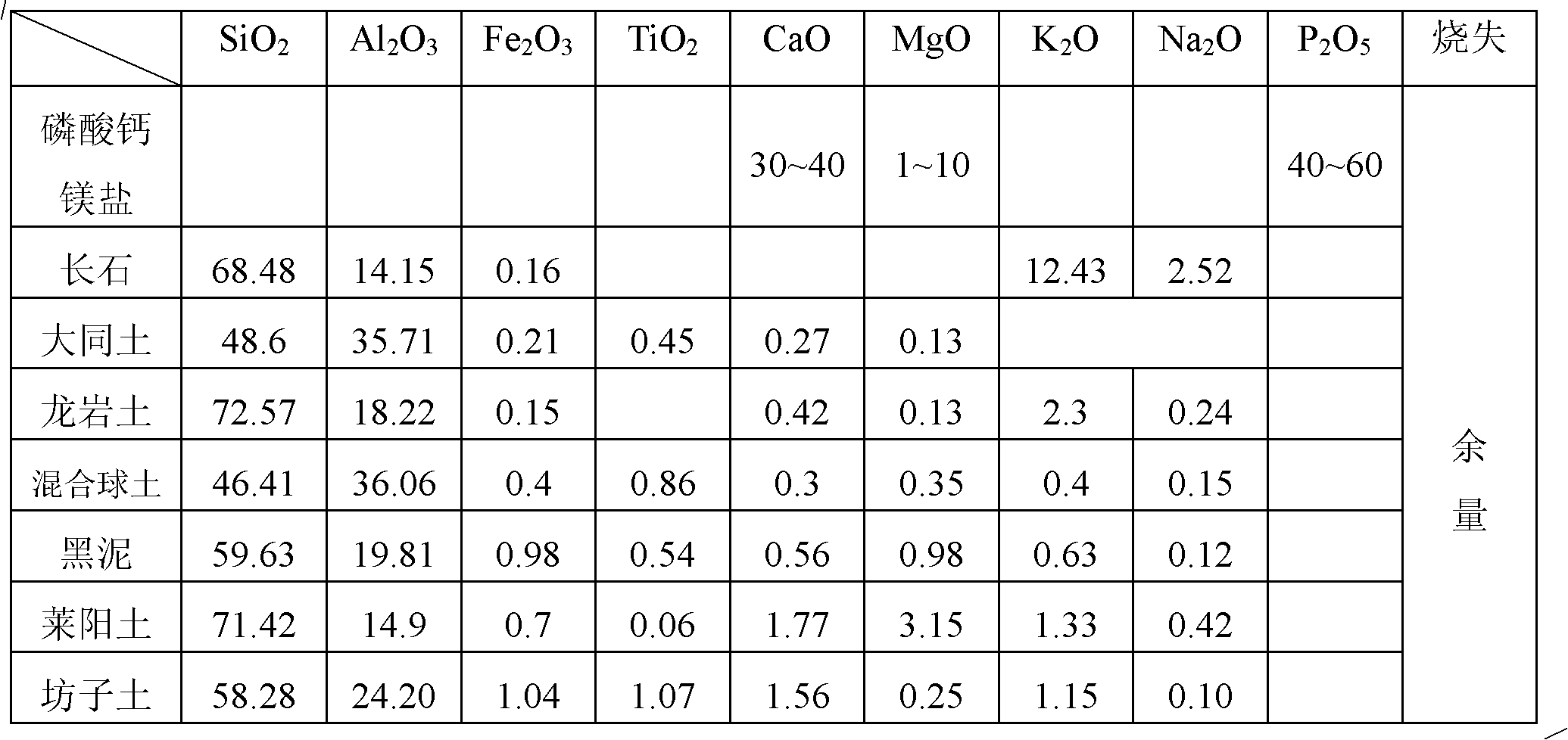

[0032] Preparation of calcium magnesium phosphate salt:

[0033] Ca(OH) 2 , MgCO 3 by weight Ca 2+ :Mg 2+ = 7: 3 ratio mixing, adding to the reaction device at the same time, adding water to dilute, stirring for 20-30min, making solution A for later use;

[0034] Weigh phosphoric acid according to the molar ratio of Ca+Mg / P=115-1.35, pour it into a stainless steel container, and dilute it to a solution B below 40% for later use;

[0035] Slowly titrate solution B into solution A to make it react evenly. The specific reaction formula is:

[0036] MgCO 3 +Ca(OH) 2 +H 3 PO 4 -→ Ca 2 Mg(PO 4 ) 2 +H 2 O+CO 2

[0037] MgCO 3 +Ca(OH) 2 +H 3 PO 4 -→CaMg(HPO 4 ) 2 +H 2 O+CO 2

[0038] After the reaction, the pH of the solution is 4.5 to 7.0, and it is allowed to stand for 3 to 10 hours to obtain MgCa 2 (PO 4 ) 2 and CaMg(HPO 4 ) 2 The solution C of solution C is press-filtered and dried to obtain a filter cake with a water content of less than 10%;

[0039]...

Embodiment 2

[0046] The batching weight percentage of this embodiment Chinese celadon is composed of: calcium magnesium phosphate 43%, feldspar 8%, Datong soil 22%, Longyan 15%, black mud 4%, Fangzi soil 1%, mixed ball soil 2% and Laiyang soil 5%. Firing method is with embodiment 1. The concrete chemical composition weight percent of gained product is as shown in table 2.

[0047] Among them, the calcium magnesium phosphate salt is Ca(OH) 2 , MgCO 3 by weight Ca 2+ :Mg 2+ = Prepared by mixing in a ratio of 6:4. The preparation method is the same as in Example 1.

Embodiment 3

[0049] The batching weight percent of this embodiment Chinese celadon is composed of: calcium magnesium phosphate 46%, feldspar 11%, Datong soil 15%, Longyan 16%, black mud 3%, mixed ball soil 5%, Fangzi soil 2% and Laiyang soil 2%. Firing method is with embodiment 1. The concrete chemical composition weight percent of gained product is as shown in table 2.

[0050] Among them, the calcium magnesium phosphate salt is Ca(OH) 2 , MgCO 3 by weight Ca 2+ :Mg 2+ = Prepared by mixing in a ratio of 8:2. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com