Method for producing zircon oxide blank

A technology of zirconia blanks and zirconia, which is applied in the field of preparation of zirconia blanks, which can solve the problems of zirconia blanks, such as laborious, long processing time, unsatisfactory and long duration of dental restorations, etc., and achieve high translucency and good optical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Example 1 - Suspension with 76% by weight zirconia

[0088] 3.15 g of a dispersant containing citric acid or citrate (Dolapix CE64 from Zschimmer & Schwarz) and 1.5 g of tetramethylammonium hydroxide were successively dissolved in 194.4 g of distilled water. The pH of the solution is 10-10.5.

[0089] This solution was placed in the tank of a MicroCer agitated bead mill (from Netzsch) whose grinding chamber and rotor were made of zirconia. The grinding chamber was filled with 60 ml of zirconia grinding beads (from Tosoh) with a diameter of 0.2-0.3 mm. The solution was continuously pumped through the milling chamber using a peristaltic pump (tubing inner diameter 8 mm) at a rotor speed of 1500 rpm. Then, under stirring and continuously, 630 g was added with 3 mol% Y 2 o 3 Partially stabilized zirconia powder (TZ-PX-245 from TOSOH Corporation, primary particle size: 40 nm) was added to the solution in the storage tank. Once the addition of the zirconia powder is ...

Embodiment 2

[0102] Example 2 - Suspension with 83% by weight zirconia

[0103]To prepare a suspension with 83% by weight zirconia and process it to form a test piece (A) and a block (B) for "chairside" applications, Example 1 was repeated with the change that 164.5 g of distilled water was added , 4.05 g of a dispersant containing citric acid or citrate (Dolapix CE64 from Zschimmer & Schwarz) and a solution of 1.5 g of tetramethylammonium hydroxide, and 810 g of Y with 5 mol % 2 o 3 Partially stabilized zirconia powder (TZ-PX-430 from TOSOH Corporation, primary particle size: 90 nm) and pre-sintered at 900° C. for 2 h with the same heating rate of 0.250 K / min.

[0104] The viscosity η of suspension is 7.0mPas (at 1000s -1 shear rate and temperature of 25°C).

[0105] Each test piece obtained according to (A) has the following properties:

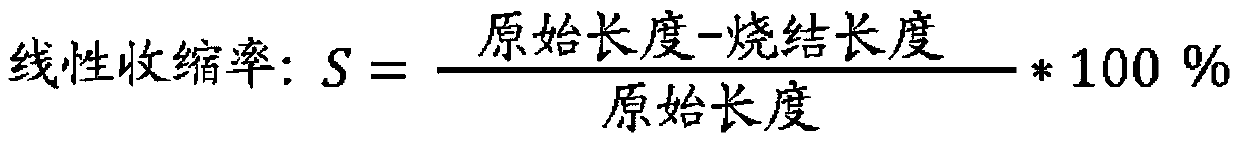

[0106] - Linear shrinkage: 14.43% (test piece: length = 25mm ± 1mm, width = 5mm ± 0.5mm and height = 4mm ± 0.5mm)

[0107] - Density: 3.791g / c...

Embodiment 3

[0111] Example 3 - Suspension with 80% by weight zirconia

[0112] To prepare a suspension with 80% by weight of zirconia and process it to form test piece (A), Example 1 was repeated with the change that 179.5 g of distilled water, 3.6 g of dispersant containing citric acid or citrate were added (Dolapix CE64 from Zschimmer & Schwarz) and 1.5 g of tetramethylammonium hydroxide solution, and the addition of 720 g with 4.25 mol% Y 2 o 3 Partially stabilized zirconia powder (TZ-PX-551 from TOSOH Corporation, primary particle size: 90 nm).

[0113] The viscosity η of suspension is 14.6mPas (at 500s -1 shear rate and temperature of 25°C).

[0114] The test pieces obtained according to (A) have the following properties:

[0115] - Linear shrinkage: 14.59%

[0116] - Density: 3.780g / cm 3 .

[0117] The test pieces obtained according to (A) were pre-sintered at 1000° C. for 2 h. The heating rate is 0.250K / min. The test pieces were then cooled to room temperature within 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com