High-performance dynamic cross-linked polymer based on vinyl hydrazide bond and preparation method

A dynamic cross-linking and vinyl acyl technology, applied in the field of polymer materials, can solve the problems of complex and difficult application of self-healing material preparation process, difficulty in mass production, and difficulty in obtaining synthetic raw materials, etc., to achieve reduced mechanical properties and excellent mechanical properties. Properties, Effect of High Young's Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

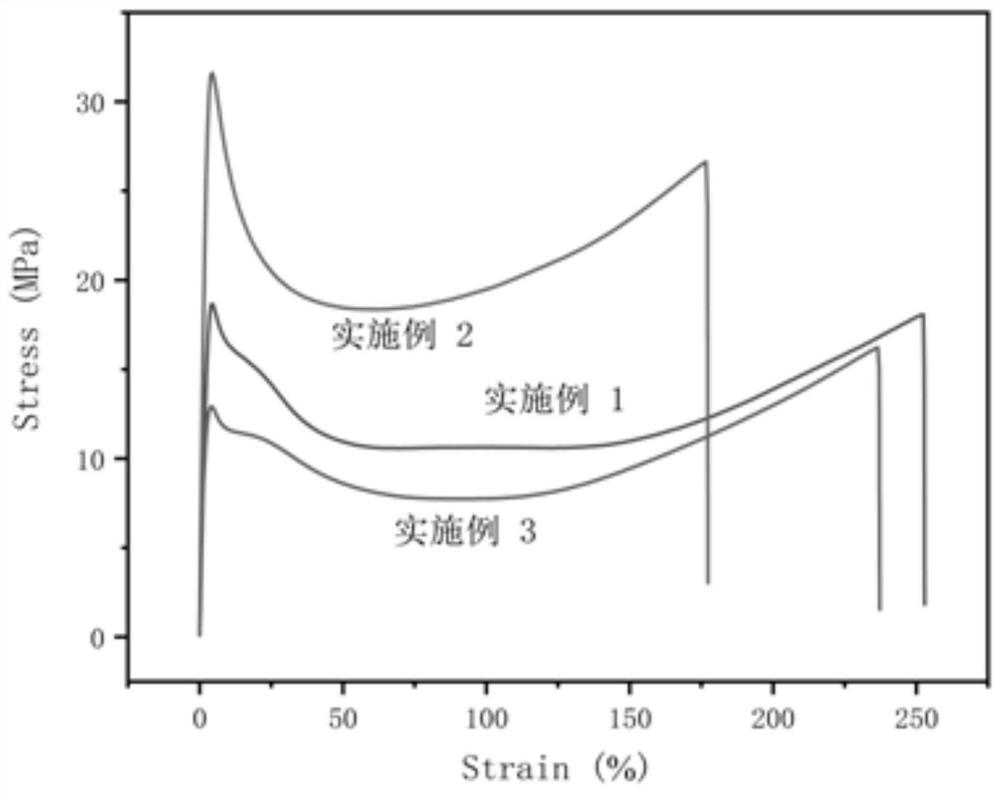

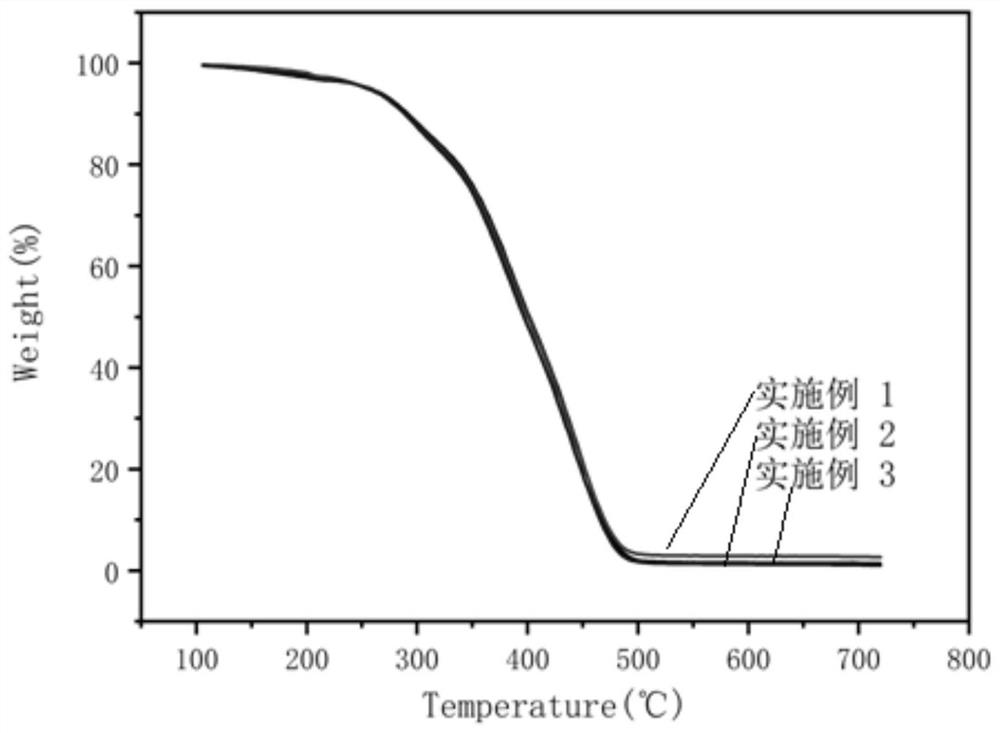

Embodiment 1

[0032] Preparation of high-performance reversible dynamic linear polymers containing vinylhydrazide linkages. Dissolve 4.18g of acetoacetate-esterified PTMEG-250 (PT250-AA) in 20ml of DMF solvent, stir well, then add 1.9419g of isophthalic hydrazide (IPDH), react in an oil bath at 60°C for 2h After the reaction is complete, the solution is light yellow, vacuum-dried in an oven at 60°C for 24 hours, and dried in an oven at 70°C for 48 hours. After removing the solvent, a cross-linked polymer material containing vinyl hydrazide bonds can be obtained.

[0033]

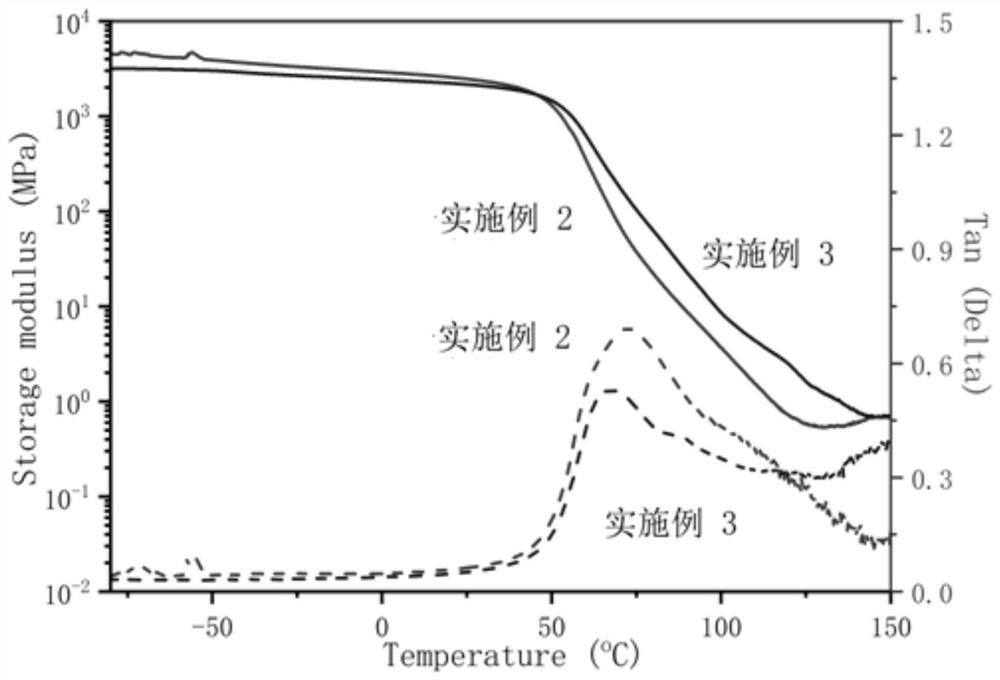

Embodiment 2

[0035] Preparation of polyether-type high-performance reversible dynamic cross-linked polymers containing vinyl hydrazide linkages. Dissolve 4.18g of acetoacetified PTMEG-250 (PT250-AA) and 2.5759g of cross-linking agent triacetoacetoxymethylpropane (TMPAA) in 20ml of DMF solvent, stir well, then add 3.8838g of m-benzene Diformyl hydrazide (IPDH), reacted in an oil bath at 60°C for 2h, the solution was light yellow after the reaction was complete, vacuum dried in a 60°C oven for 24h, and vacuum dried in a 70°C oven for 48h, and the solvent containing Cross-linked polymer material of vinyl hydrazide linkages.

Embodiment 3

[0037] Preparation of high-performance reversibly dynamically crosslinked polymers containing vinylhydrazide linkages. Dissolve 1.5253g 1,4-bis(hydroxymethyl)cyclohexane diacetoacetate (CDM-AA) and 0.3145g crosslinker triacetoacetoxymethylpropane (TMPAA) in 10ml DMF solvent, stir well Finally, add 1.1853g of isophthalic hydrazide (IPDH) and react in an oil bath at 60°C for 2 hours. After the reaction is complete, the solution turns light yellow. Vacuum dry in an oven at 60°C for 24 hours, and dry in an oven at 70°C for 48 hours. , after removing the solvent, the cross-linked polymer material containing vinyl hydrazide bonds can be obtained.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com