High-purity alumina fiber and preparation method thereof

A technology of alumina fiber and oxide, applied in the field of heat insulation of refractory materials, can solve the problem of low temperature of fiberboard, achieve high Young's modulus, improve mechanical properties, and improve thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 40g of anhydrous aluminum chloride, dissolve it in 500ml of water, pour the aluminum chloride solution and 38.0g of aluminum powder into a reaction kettle with heating and reflux, heat at 90-100°C for 2-2.5h, cool and filter to obtain polychloride Aluminum mother liquor (Al 2 o 3 The mass fraction of 14.8%). Then add 20ml of lactic acid as a colloidal stabilizer and spinning aid, vacuum concentrate at 65-70°C for 1.5-2 hours, and make a colloid with a viscosity of 20-35Pa.s.

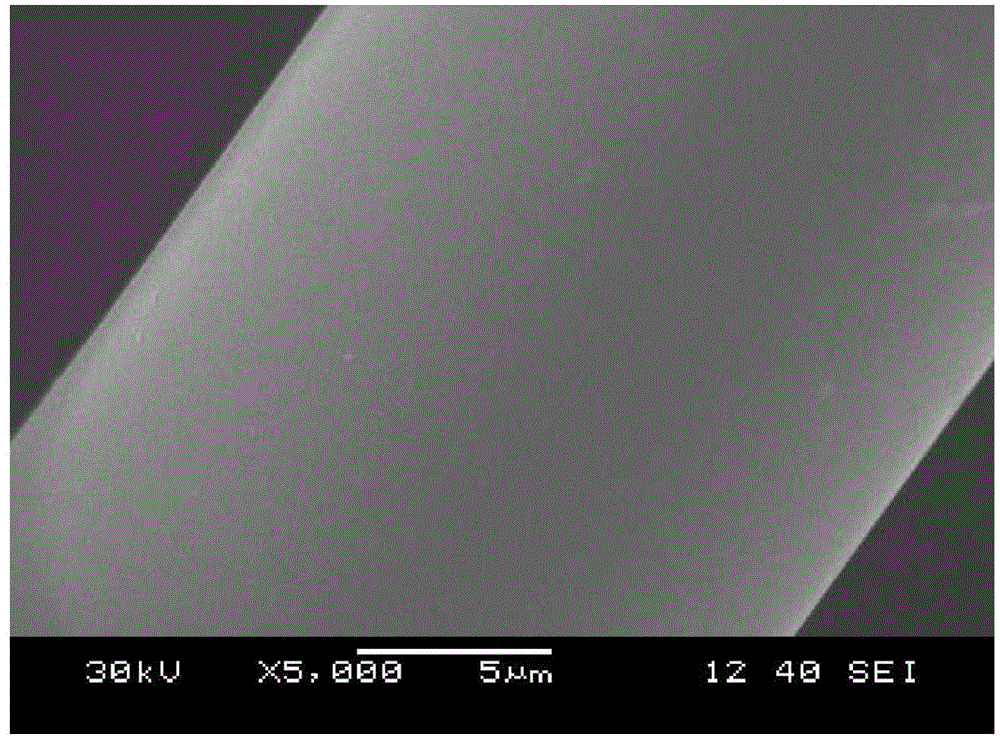

[0038] The self-made centrifugal spinning machine is used for centrifugal spinning, and the sol forms white and soft gel fibers under the centrifugal force and the secondary traction of hot air flow, and is collected by a drum to form a fiber cover. Such as figure 1 As shown, the diameter of the fiber is 15-20um, the length is 30-80cm, and the surface is smooth, and the cross-section of the fiber is circular. Among them, the diameter of the spinning head is 45mm, the height is 35mm, and 1...

Embodiment 2

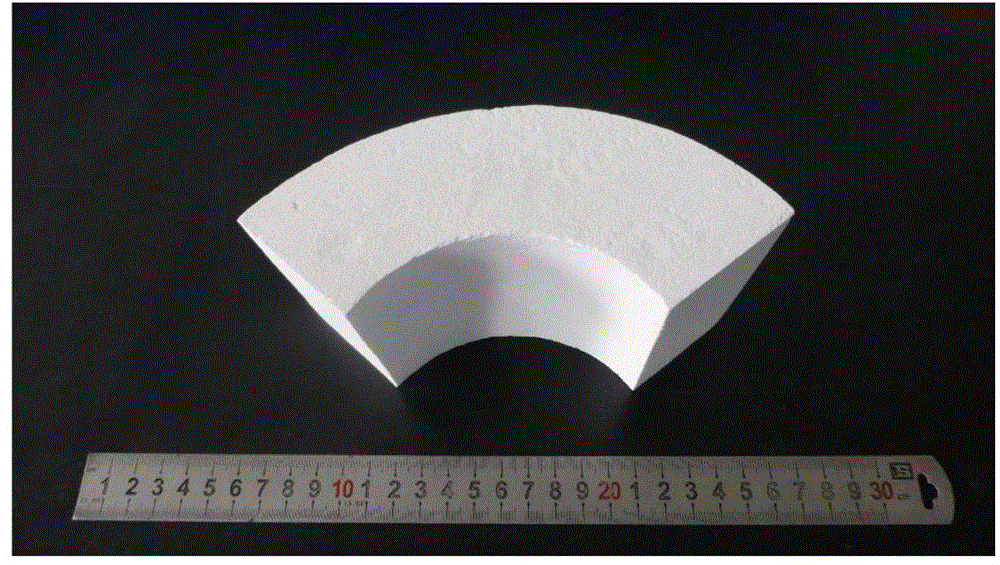

[0041] Take 350g of alumina fibers obtained in Example 1, add 600g of polyaluminum chloride solution, 10g of polyacrylamide, and 40g of spinel micropowder, fully stir and make pulp, and shorten the stirring time as much as possible. A wet billet is produced in a corresponding mold by manual pressing, and dried at 90°C for 50 hours to remove moisture and internal binder gel to obtain a dry billet.

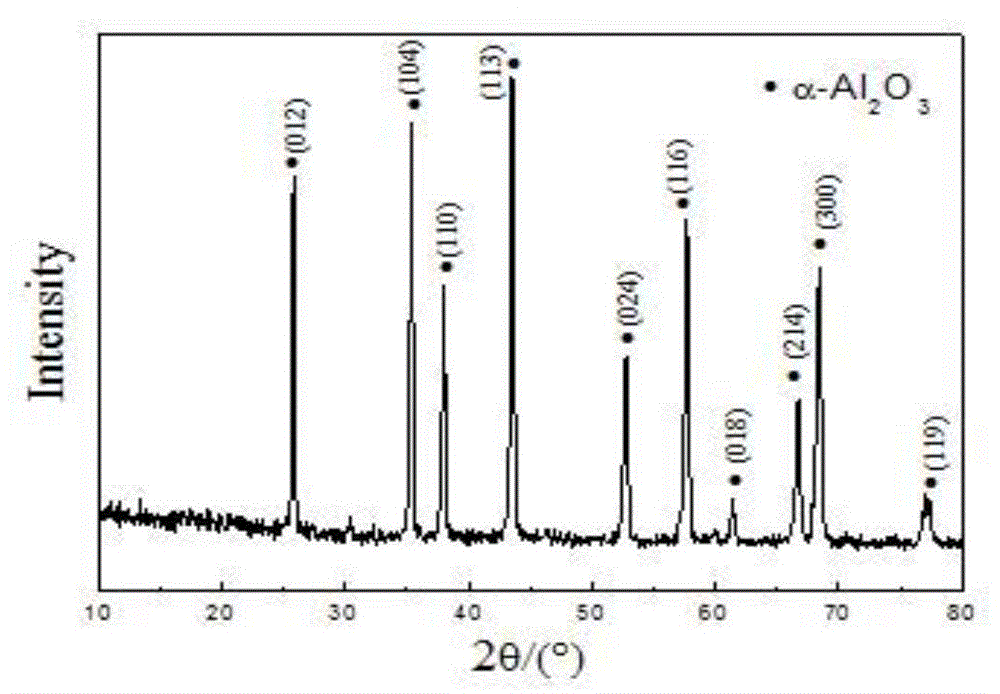

[0042] The dry compact was sintered at 1600°C for 2 hours, and the main crystal phase was α-Al 2 o 3 fiberboard blanks. Cut according to the required size, and after surface treatment, the final alumina fiber board is obtained. The density of the product is 0.54 / cm 3 ; Refractoriness is 1600~1700℃; Reburning permanent line change: 1400℃×2h≤0.3%; Cold compressive strength: ≥2.4Mpa; Thermal conductivity 1000℃: <0.24W / (m·K).

Embodiment 3

[0044] Take 40g of anhydrous aluminum chloride, dissolve it in 500ml of water, put the aluminum chloride solution and 35.6g of aluminum powder in a certain ratio (n(Al):(Cl)=1.8) into a trident flask with heating and reflux, at 90°C Heating for 2 to 3 hours, cooling and filtering to obtain polyaluminum chloride solution (Al 2 o 3 The mass fraction of 14.2%).

[0045] Get the polyaluminum chloride solution prepared above, according to Al 2 o 3 Be the chemical composition of 98:1 with MgO mass ratio, measure the basic magnesium carbonate of 2.0g (chemical formula 4Mg(OH) 2 · MgCO 3 ) was dissolved in 10 g of glacial acetic acid to form a transparent solution. After mixing, 30 ml of glacial acetic acid was added as spinning aid and stabilizer. After vacuum concentration at 67°C for 2 hours, a colloid with a viscosity of 30P.s was obtained. Spin on a self-made centrifugal spinning machine to obtain gel fibers with a length of 30-50 cm and a diameter of 15-20 um. Wherein, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com