Method for preparing carbon nano tube modified bipolar membrane with anion groups

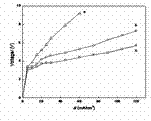

A carbon nanotube modification, anionic group technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor dispersion and application limitations, and achieve good compatibility and low cell voltage. , the effect of high water dissociation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

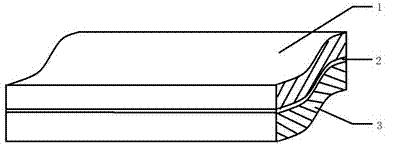

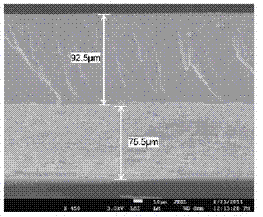

[0030] Preparation of PVA-CMC-CNTs-COOH / CS Bipolar Membrane with Carboxylated Carbon Nanotubes Modified Anodic Membrane Layer

[0031] The carbon nanotubes used in this example are directly ordered carboxylated carbon nanotubes.

[0032] 1. Preparation of carboxyl carbon nanotube modified cation exchange membrane

[0033] Accurately weigh 100 grams of CMC, dissolve it in distilled water, and prepare a CMC aqueous solution with a mass fraction of 10%. Another PVA was taken, heated and stirred with distilled water to dissolve, added to the above-prepared CMC aqueous solution, stirred evenly, degassed under reduced pressure to obtain a viscous film liquid, the mass fraction ratio of PVA and CMC in the step was 1:1. Accurately weigh 0.1 g of carboxyl carbon nanotubes, add them to 80 mL of ethanol, oscillate with ultrasonic waves to disperse evenly, add them to the PVA-CMC aqueous solution prepared above, stir evenly, degas under reduced pressure, and obtain viscous film liquid. ...

Embodiment 2

[0042] Preparation of PVA with cation exchange membrane layer modified by sulfonic acid carbon nanotubes - SA-CNTs-SO 3 H / CS bipolar membrane

[0043] The carbon nanotubes used in this example are directly ordered products, the model is XFM01 multi-walled carbon nanotubes (long), OD: <8 nm, Length: 10-30 μm. Before use, it needs to be pretreated to make it into a sulfonic carbon nanotube.

[0044] 1. Preparation of cation exchange membrane modified by sulfonic acid carbon nanotubes

[0045] Accurately weigh 80 grams of SA, dissolve it in distilled water, and prepare an 8% SA aqueous solution with a mass fraction. Separately take PVA (the mass fraction ratio of PVA to CMC is 1:1), heat and stir with distilled water to dissolve, add it to the SA aqueous solution prepared above, stir evenly, degas under reduced pressure, and obtain a viscous film liquid.

[0046] Add XFM01 multi-walled carbon nanotubes (CNTs) to the aqueous solution, and after ultrasonic dispersion for 1 hour...

Embodiment 3

[0052] Preparation of PVA with Hydroxyl Carbon Nanotubes Modified Cathodic Layer - CMC-CNTs-OH / CS bipolar film

[0053] The carbon nanotubes used in this example are directly ordered hydroxyl carbon nanotubes with hydroxyl groups.

[0054] 1. Preparation of hydroxyl carbon nanotube modified cation exchange membrane

[0055] Accurately weigh 100 grams of CMC, dissolve it in distilled water, and prepare a CMC aqueous solution with a mass fraction of 10%. Take another PVA (the mass fraction ratio of PVA to CMC is 0.6:1), heat and stir with distilled water to dissolve, add it to the CMC aqueous solution prepared above, stir evenly, degas under reduced pressure, and obtain a viscous film liquid. Accurately weigh 0.2 g of hydroxyl carbon nanotubes, add them to 100 mL of ethanol, oscillate with ultrasonic waves to disperse evenly, add them to the PVA-CMC solution prepared above, stir evenly, degas under reduced pressure, and obtain viscous film liquid. The viscous film solution w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com